What Is Laser Etching

Laser etching is a precise marking process that uses a laser beam to slightly alter the surface of a material. Unlike deeper engraving, laser etching creates a shallow mark by softening or melting the top layer, without cutting deeply into the material itself. This produces a subtle, smooth design that can be seen and felt but is less invasive.

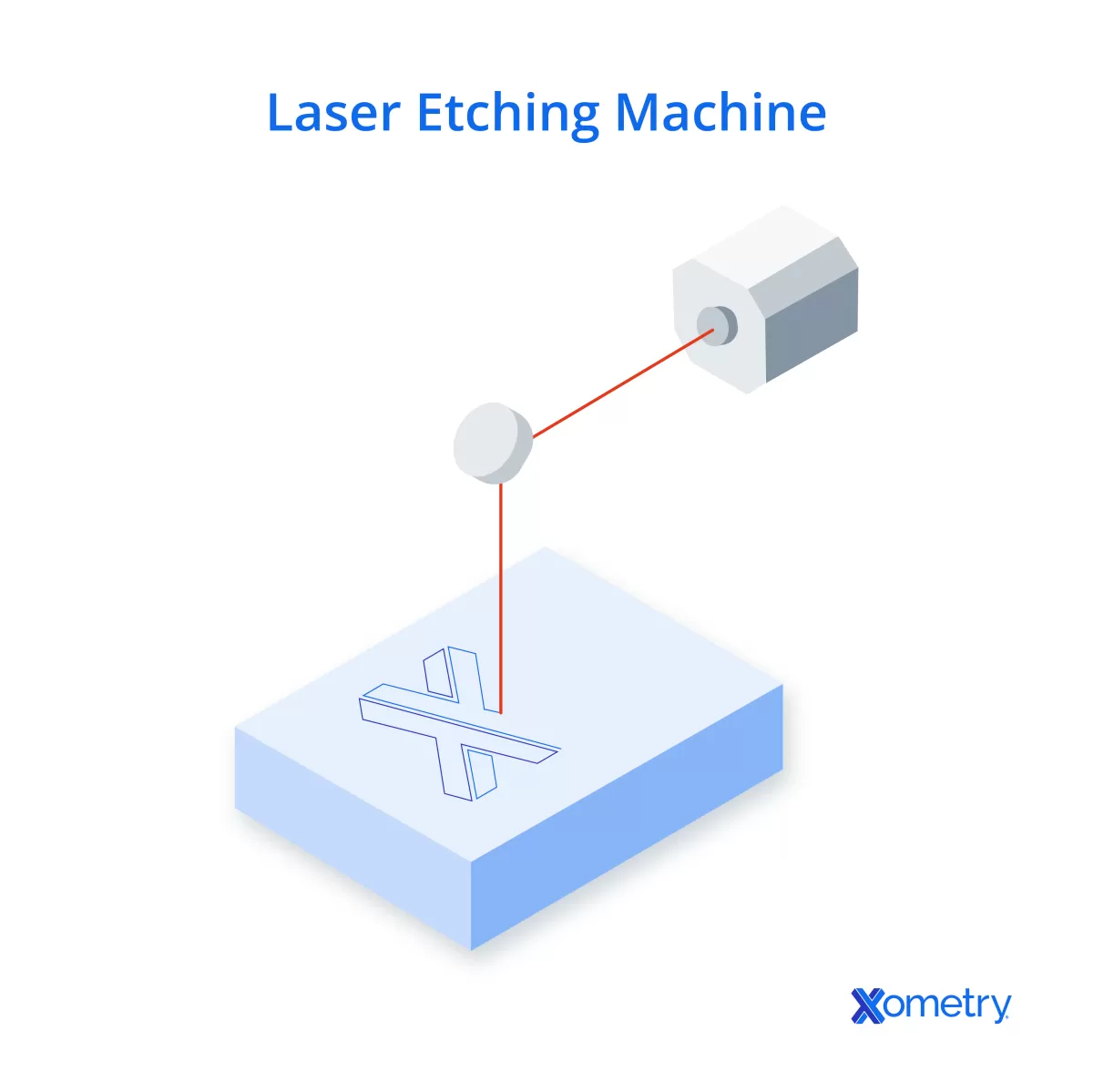

How Laser Etching Works

A focused laser beam is directed at the material’s surface, heating it enough to cause a controlled surface change. This process can involve slight melting, discoloration, or chemical changes depending on the material. It’s fast and accurate, making it ideal for detailed logos, serial numbers, or branding.

Key Features of Laser Etching

- Shallow surface mark, less than 0.001 inch depth

- Minimal material damage or deformation

- Fast processing speed for high-volume jobs

- Works well on metals, plastics, glass, and coated surfaces

- Precise and repeatable results using CNC laser services

Common Applications

Laser etching is popular for:

- Product serialization and part traceability

- Branding consumer goods like electronics and plastics

- Marking glassware and ceramics with logos or designs

- Creating barcodes or QR codes on industrial components

- Custom labels on jewelry, electronic enclosures, and more

Laser etching offers a durable, clean, and efficient way to add precise marks without compromising the material’s integrity, making it a top choice for many industrial and commercial uses.

What Is Laser Engraving

Laser engraving is a process that uses a focused laser beam to cut or carve into the surface of a material. Unlike laser etching, which only affects the top layer, laser engraving removes a portion of the material to create a deeper, more permanent mark. This method works by vaporizing or melting the material to form grooves or patterns.

Key features of laser engraving include:

- Deep and lasting marks that are highly resistant to wear and fading

- High precision and detail, making it ideal for intricate designs

- Ability to work on a wide range of materials like metal, wood, glass, leather, and plastic

Common applications include:

- Industrial laser applications such as part traceability with serial numbers and barcodes

- Jewelry engraving for personalized designs

- Creating detailed signs, awards, and plaques

- CNC laser engraving metal for tools and equipment branding

Laser engraving is a go-to choice when you need durable, high-quality marks that won’t wear off easily, making it perfect for products meant to last.

Key Differences Between Laser Etching and Laser Engraving

Understanding the difference between laser etching and laser engraving helps you pick the right method for your project. Here’s a quick rundown of how they compare:

Depth of Mark

- Laser Etching creates a shallow mark on the material’s surface, usually less than 0.001 inches deep.

- Laser Engraving cuts deeper into the material, sometimes up to 0.01 inches or more, making the mark more pronounced.

Durability

- Etching marks are less deep, so they’re usually less durable and more prone to fading over time, especially in heavy-use environments.

- Engraving results are more durable due to the deeper cut, offering better wear resistance and long-lasting visibility.

Speed and Cost

- Etching is generally faster because it requires less power and time, making it more budget-friendly for short runs or simple designs.

- Engraving takes longer and uses more laser power, so it tends to cost more, but it’s worth it when you need that extra depth and durability.

Material Compatibility

- Etching works well on plastics, coated metals, and glass where surface marking is enough.

- Engraving fits better for metals, wood, and harder materials where deep and clear marks are necessary for part traceability or branding.

Visual and Tactile Outcome

- Etched marks are smooth to the touch, often with a frosted or glossy appearance but barely noticeable to feel.

- Engraved marks can be felt easily due to the engraved depth, often providing a textured and more defined look.

Comparison Table

| Feature | Laser Etching | Laser Engraving |

|---|---|---|

| Depth | Shallow (surface-level) | Deep (cuts into material) |

| Durability | Moderate, less resistant | High, more resistant |

| Speed | Faster | Slower |

| Cost | Lower | Higher |

| Material | Plastics, coated metals, glass | Metals, wood, tougher materials |

| Look and Feel | Smooth, subtle | Raised/deep, textured |

Knowing these differences helps you choose between laser etching vs laser engraving with a clear understanding of what fits your needs.

Which Should You Choose Factors to Consider

When deciding between laser etching vs laser engraving, it really comes down to your specific needs. Here’s what to think about:

Project Requirements

- Depth and detail: If you need a shallow, quick mark, laser etching works great. For deeper, more durable marks, laser engraving is the way to go.

- Material type: Some materials respond better to etching (like plastics), while metals often require engraving for better clarity and permanence.

- Design complexity: Both methods handle fine details, but engraving might provide a stronger contrast for complex designs.

Industry-Specific Needs

- Traceability: For industries like automotive or aerospace, where part traceability is crucial, laser engraving’s deeper marks usually hold up better over time.

- Jewelry and gifts: Laser etching tends to be preferred here for delicate, neat markings on small, sensitive surfaces.

- Industrial applications: Heavy-duty or high-wear environments often favor engraving due to its durability.

Budget Considerations

- Cost differences: Etching generally costs less since it’s faster and uses less laser power. Engraving can take more time and energy, raising the price.

- Production volume: For large runs, cost savings with etching add up. For short runs or high-value items, engraving may justify the expense.

- Learn more about the financial side of laser options in The True Cost of Owning a Laser Cutter.

Environmental Conditions

- Wear and tear: Items exposed to harsh conditions (weather, friction) benefit from engraving’s deeper marks.

- Surface finish: If a clean, less intrusive mark is needed—say on polished or coated surfaces—etching is less likely to cause damage.

By balancing these factors, you can choose the laser marking method that fits your project perfectly, whether it’s for precision laser marking on metals or laser etching plastics.

How HYCNC Can Help

At HYCNC, we specialize in CNC laser etching and engraving services tailored to meet your exact needs. Whether you’re working with metal, plastics, or other materials, our advanced laser marking technology ensures precise, high-quality results every time.

We have extensive experience handling a wide range of materials—from laser engraving jewelry to laser etching plastics—making us a go-to choice for many industries. No matter the size or complexity of your project, we offer custom solutions designed to fit your requirements and budget.

Here’s why you should choose HYCNC:

- Wide material expertise: We work with metals, plastics, wood, and more.

- Precision and consistency: Our CNC laser services deliver clean, durable marks for part traceability and branding.

- Flexible solutions: From small runs to large-scale industrial laser applications, we can handle it all.

- Competitive pricing: We provide cost-effective options without compromising on quality.

- Local support: As a US-based provider, we understand your market and offer quick turnaround times.

Partnering with HYCNC means you get reliable, professional laser etching and engraving that helps your products stand out while meeting industry standards.

FAQs

What materials work best for laser etching or engraving

Both laser etching and engraving work well on a variety of materials. Laser etching is great for plastics, coated metals, glass, and some softer materials. Laser engraving handles harder surfaces like metals, wood, leather, and stone with ease. If you’re working with metal for jewelry or industrial parts, laser engraving offers more precision and durability.

How do laser etching and engraving compare in durability

Laser engraving cuts deeper, so it creates marks that last longer and resist wear better than etching. Etching is more surface-level, so it’s fine for decorative items or light-use parts but might fade faster over time or with heavy handling.

How does laser etching compare to chemical etching

Laser etching is faster, cleaner, and more precise than chemical etching. It doesn’t require messy chemicals and can be easily adjusted for different designs. Chemical etching is mainly used for mass production but lacks the flexibility and detail you get from laser techniques.

Can laser etching and engraving handle small and large projects

Yes, both work for small detail jobs like jewelry or part traceability and large-scale projects like signage or industrial marking. Laser engraving is ideal for fine details on small items, while etching can quickly mark bigger surfaces without much setup.

What about cost differences between laser etching and engraving

Laser etching usually costs less because it’s faster and uses less energy, making it great for simple or large runs. Engraving takes longer and uses more power, so it’s pricier but worthwhile if you need deeper, more durable marks. Your project needs often decide which fits your budget best.