Introduction to Plastic Injection Molding

What Is Plastic Injection Molding

If you’re wondering how complex and durable plastic parts are made fast and at scale, plastic injection molding is the answer. It’s a manufacturing process where melted thermoplastic material is injected into a specially designed mold to form precise parts. Once cooled, these parts are ejected, ready for use. This technique allows for highly detailed, consistent, and repeatable production, making it ideal for everything from simple housings to intricate automotive and medical components.

Why It Matters for Your Business

Plastic injection molding can transform your product development and manufacturing strategy. Whether you need custom plastic molding or high-volume plastic production, this process offers:

- Efficiency: Rapid creation of parts speeds up your time to market

- Cost savings: Scaling production reduces cost per unit without sacrificing quality

- Flexibility: Supports a wide range of designs and applications with precision injection molding

- Durability: Produces strong parts made to last, ensuring customer satisfaction

For businesses looking to innovate while controlling cost and quality, plastic injection molding is a game changer. With advancements like CNC mold manufacturing and thermoplastic molding, companies like HYCNC are at the forefront, delivering tailored solutions that meet today’s fast-paced market demands.

How Plastic Injection Molding Works

Plastic injection molding starts with melting thermoplastic material until it’s liquid. This melted plastic is then injected into a custom mold cavity with high pressure. Once cooled, the plastic hardens into the shape of the mold, producing a precise, repeatable part every time.

The Injection Molding Process

- Material Melting – Thermoplastic pellets are heated and melted in the injection unit.

- Injection – The molten plastic is injected into the mold cavity.

- Cooling – The plastic cools and solidifies inside the mold.

- Ejection – The finished part is ejected from the mold for collection.

This cycle repeats quickly, allowing high-volume plastic production with consistent quality.

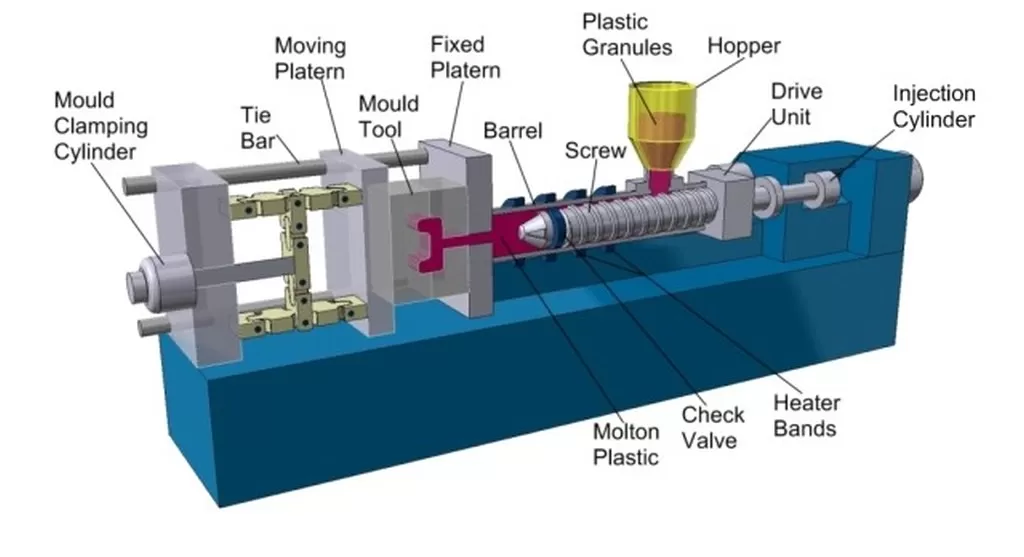

Key Components of the Process

- Mold – Made with CNC mold manufacturing for precision shaping.

- Injection Unit – Controls temperature and pressure for melting and injecting plastic.

- Clamping Unit – Holds the mold tightly during injection.

- Ejection System – Removes the finished part without damage.

HYCNC’s CNC Integration

At HYCNC, our expertise in CNC machining elevates the injection molding process. We use advanced CNC services to create custom molds with tight tolerances, improving part accuracy and reducing cycle times. This integration lets us handle both prototype molding and high-volume runs, ensuring durable and precise parts every time.

Benefits of Choosing HYCNC for Plastic Injection Molding

When you choose HYCNC for plastic injection molding, you’re getting more than just parts—you’re getting quality and reliability built into every piece. Here’s what sets us apart:

High-Quality Durable Parts

We use precision injection molding paired with advanced CNC mold manufacturing to create parts that last. Whether you need thermoplastic molding or overmolding services, our process ensures consistent strength and detail.

Custom Solutions for Diverse Industries

From prototype molding to high-volume plastic production, we tailor our services to fit industries like automotive, healthcare, and consumer goods. Our custom plastic molding adapts to your unique needs, making sure every product performs as expected.

Cost-Effective and Scalable

HYCNC’s expertise allows us to efficiently scale your production, keeping costs down without sacrificing quality. Whether you’re starting small with micro-injection molding or ramping up, we offer solutions that grow with your business.

Sustainability Focus

We understand the importance of sustainable plastic manufacturing. Our processes minimize waste and energy use, helping you meet eco-friendly goals while maintaining top-quality output.

For more on our capabilities, check out our injection mold tooling services and explore the range of plastics we work with.

Why Local Matters HYCNC Regional Advantage

At HYCNC, being local makes a real difference for your plastic injection molding needs. Our regional presence means faster turnaround times and smoother communication. When you work with us, you avoid the delays and confusion that can come from working with distant suppliers.

We understand the unique demands of businesses in the United States, especially those in our local markets. This local focus allows us to tailor our services so they align perfectly with your production schedules and quality standards.

Serving Local Markets Efficiently

- Quick response to inquiries and project updates

- Faster shipping and delivery options

- Better flexibility to handle urgent changes or special requests

Tailored Support for Local Businesses

- Personalized consultations based on regional industry needs

- Custom plastic molding and precision injection molding that fit your exact specs

- Support for small and medium businesses with scalable solutions

By choosing HYCNC, you get a partner who knows your market from the ground up. We’re not just a service provider; we’re part of your local business community, committed to your success with efficient, reliable plastic injection molding and CNC services.

Advanced Techniques in Plastic Injection Molding

At HYCNC, we don’t just follow standards—we push the boundaries with advanced techniques in plastic injection molding. We integrate innovative processes that improve precision, efficiency, and product quality to meet your specific needs.

Innovations HYCNC Employs

- CNC Mold Manufacturing: Our CNC machining services create highly accurate molds, ensuring each part fits perfectly.

- Gas-Assisted Molding: This method reduces material waste and improves part strength, ideal for complex designs.

- Micro-Injection Molding: We handle tiny, detailed components with precision, great for electronics or medical parts.

- Overmolding Services: Combining multiple materials, we add durability and functionality to your products.

Design for Manufacturability DFM

We work closely with you during the design phase to simplify production without sacrificing quality. Our DFM approach helps reduce costs and speeds up time-to-market by spotting potential production issues early on.

Automation and Technology

HYCNC leverages the latest automation tools to streamline plastic injection molding. Automated systems increase consistency, reduce errors, and support high-volume plastic production without compromising durability or detail.

By combining these advanced techniques with our strong CNC service background, HYCNC delivers custom plastic molding solutions that match your business goals while focusing on sustainability and cost-effectiveness.

How to Get Started with HYCNC

Getting started with HYCNC for plastic injection molding is simple and straightforward. Here’s how we work with you:

Consultation and Quote Process

- Reach out to us with your project details.

- We’ll review your requirements, including custom plastic molding or precision injection molding needs.

- Our team provides a clear, no-obligation quote tailored to your timeline and budget.

- We’re transparent about costs, so there are no surprises.

From Prototype to Production

- We support prototype molding to help you test and refine your designs.

- Once you approve the prototype, we move smoothly into high-volume plastic production.

- Our CNC mold manufacturing and thermoplastic molding capabilities ensure consistent quality.

- Whether you need overmolding services or micro-injection molding, we scale efficiently.

Contact HYCNC Today

Ready to improve your product with durable, precise parts? Contact HYCNC to start your plastic injection molding project. We offer professional, local support to businesses across the United States, focused on sustainable plastic manufacturing and custom solutions.

Let’s build your next project together.