What Are Accuracy and Precision in Manufacturing

In manufacturing, especially in CNC machining, understanding accuracy and precision is essential for producing high-quality parts. Although these terms are often used interchangeably, they have distinct meanings that affect how parts are made and inspected.

Defining Accuracy

Accuracy refers to how close a manufactured part’s dimensions are to the specified target or design value. For example, if you’re machining a shaft that should be exactly 50 mm in diameter, accuracy measures how close your finished shaft is to that 50 mm goal. High accuracy means your part matches the intended specifications with minimal deviation.

Defining Precision

Precision is about consistency and repeatability. It measures how close repeated measurements or produced parts are to each other, regardless of whether they meet the target value. Using the same example, if every shaft you produce measures 49.8 mm, 49.9 mm, and 49.7 mm consistently, your process is precise because the variation between parts is very small.

Key Differences at a Glance

| Aspect | Accuracy | Precision |

|---|---|---|

| Focus | Closeness to the true or target value | Consistency between repeated results |

| Measurement Example | Single part dimension vs design specification | Variability in multiple parts dimensions |

| Importance | Ensures parts fit and function as intended | Enables reliable repeat production |

Understanding these differences helps manufacturers balance manufacturing accuracy and CNC machining precision to meet tolerances exactly and ensure quality control in CNC processes. This foundation supports more advanced precision engineering and helps avoid costly mistakes down the line.

Why Precision and Accuracy Matter in CNC Machining

In CNC machining, both precision and accuracy play a major role in delivering high-quality parts. When your manufacturing accuracy is spot on, parts fit together perfectly, reducing waste and rework. Precision ensures that every piece is consistent, which is crucial for meeting tight CNC machining tolerances and maintaining repeatability in manufacturing.

Getting these two right also impacts safety and compliance. Many industries, especially aerospace and medical device manufacturing, have strict standards. Accurate and precise parts help avoid failures, keeping products safe and meeting regulatory guidelines without headaches.

On top of quality and safety, the bottom line matters. Accurate machining reduces material waste and machining time, boosting cost-efficiency. Precision engineering means fewer machine adjustments and less downtime, which saves money and speeds up delivery.

In short, precision and accuracy are key to producing reliable, safe products on time and within budget for the demanding U.S. market.

How HYCNC Ensures Precision and Accuracy

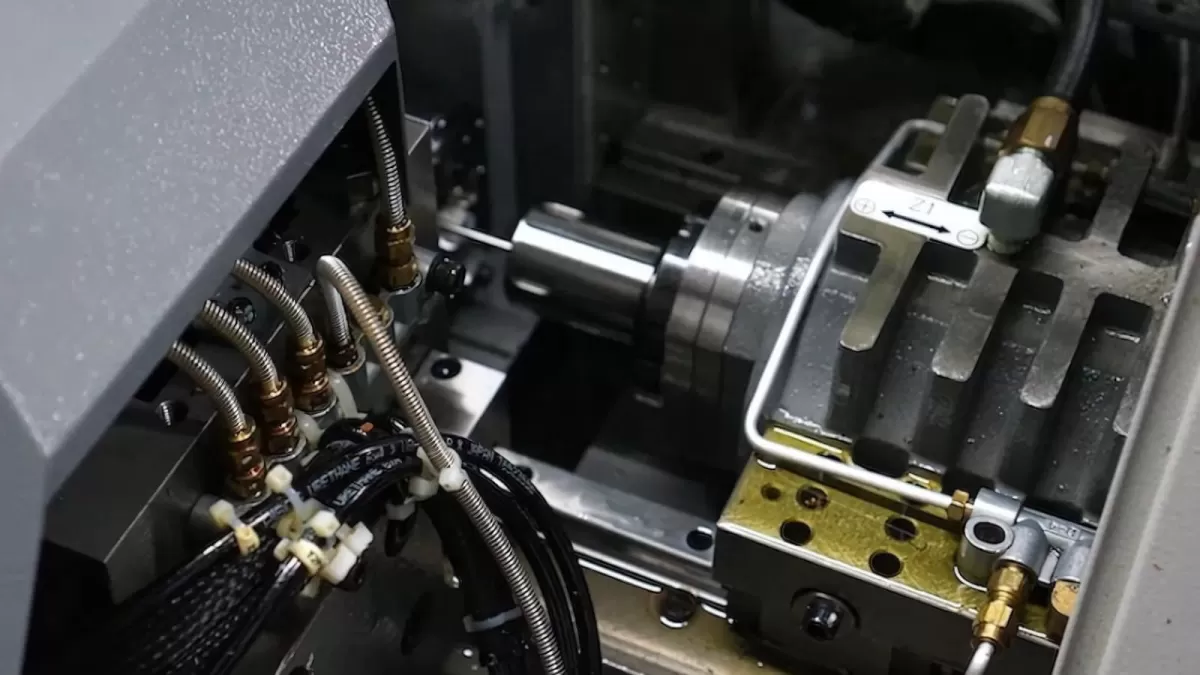

At HYCNC, we know precision and accuracy are non-negotiable in manufacturing. That’s why we use advanced CNC technology to hit tight tolerances consistently. Our machines are equipped with the latest controls to deliver reliable, repeatable results in every job.

We back that technology with strong quality control measures. From initial setup to final inspection, every part goes through rigorous checks to ensure it meets your specifications. This includes dimensional inspection, surface finish verification, and testing against engineering drawings.

Beyond machines and processes, our expert engineering team plays a crucial role. With years of experience in precision engineering and manufacturing accuracy, they troubleshoot, optimize, and fine-tune every project. Their hands-on involvement makes sure your parts aren’t just precise—they’re perfectly accurate.

Together, our technology, quality focus, and skilled team mean you get high precision manufacturing that fits your exact needs, helping your products perform flawlessly in the field. For more on how we manage quality in CNC, check out our precision machining services.

Practical Tips to Improve Precision and Accuracy in Manufacturing

Improving precision and accuracy in manufacturing isn’t just about fancy machines—it’s about smart practices. Here’s how you can get better results in your CNC machining precision and overall manufacturing accuracy:

Optimize Equipment Calibration

- Regularly calibrate CNC machines to keep tolerances tight

- Use precision tools to check alignment and settings

- Schedule maintenance to avoid drift and wear

Source High Quality Materials

- Choose materials with consistent properties to reduce variations

- Work with trusted suppliers to ensure raw material quality

- Keep track of batch differences to anticipate adjustments

Leverage Advanced Software

- Use CAD/CAM programs to plan for accurate machining paths

- Employ simulation tools to predict errors before production

- Take advantage of CNC machining tolerances settings for better control

Implement Robust Quality Assurance

- Set up inspection checkpoints throughout production

- Use measuring devices that offer high repeatability in manufacturing

- Train your team on precision engineering standards and quality control in CNC

Following these steps helps maintain consistent accuracy and precision, lowering costs and reducing errors in your manufacturing process.

Common Challenges and Solutions

In manufacturing, hitting both accuracy and precision isn’t always easy. Here are some common challenges you might face and how to handle them:

Achieving Accuracy Without Precision

You might produce parts that are close to the desired measurement (accurate), but if every part is slightly different from one another, you lack precision. This inconsistency can cause assembly problems or quality issues.

Solution: Focus on improving repeatability by maintaining tight CNC machining tolerances and regularly calibrating your equipment. Consistent processes and strict quality control in CNC help minimize variation between parts.

Achieving Precision Without Accuracy

On the flip side, you might make parts that are all almost identical (precise), but consistently off from the target specs (inaccurate). This means your whole batch is “wrong” even if consistent.

Solution: Adjust your CNC programming and tooling settings to correct the offset error. Make use of detailed engineering drawings and inspection reports to identify and fix the root cause. Accuracy improves when measurements align better with design intent.

Balancing Cost and Quality

High precision engineering and manufacturing accuracy often come with increased production costs. Finding a middle ground that meets quality standards without overspending is a common challenge.

Solution:

- Use tolerance analysis to set realistic specs that fit the application.

- Prioritize critical dimensions to save costs on less important features.

- Invest in advanced CNC technology and skilled operators to reduce rework and waste.

- Continuous process improvement ensures efficiency over time.

By understanding these challenges and applying practical solutions, you can strike the right balance of precision and accuracy — delivering quality parts that meet both design requirements and budget goals.

For deeper insights on improving machining processes, check out our post on precision machining services.

Real World Applications of Precision and Accuracy

In manufacturing, precision and accuracy aren’t just buzzwords—they’re crucial across major industries here in the U.S. Here’s how they matter in key sectors:

Aerospace Industry

In aerospace, even the smallest mistake can cause big problems. Precision engineering ensures parts fit and function exactly as designed. Accurate machining is vital to meet strict tolerances and safety standards, keeping flights safe and reliable.

Medical Device Manufacturing

Medical devices require extreme accuracy and precision. High precision manufacturing guarantees that instruments perform flawlessly, often inside the human body. This reduces risks and ensures regulatory compliance with FDA guidelines.

Automotive Sector

In automotive manufacturing, precision vs accuracy directly affects vehicle performance and safety. CNC machining precision helps produce engine parts and safety components with exact tolerances, improving efficiency and lowering the chance of failure on the road.

Across these industries, combining manufacturing accuracy with repeatability in CNC machining is key to delivering quality products that meet customer demands and regulatory requirements.

Why Choose HYCNC for Precision CNC Machining

When you need reliable CNC machining precision, HYCNC stands out as the go-to partner. We combine advanced CNC technology with a deep understanding of manufacturing accuracy to deliver parts that meet your exact specifications every time. Our expert engineering team takes pride in ensuring repeatability in manufacturing, so you get consistent results from batch to batch.

Here’s why HYCNC is the smart choice for precision engineering:

-

State-of-the-Art CNC Equipment

We use the latest machines capable of holding tight tolerances in manufacturing, ensuring each part is accurately machined with minimal variation.

-

Strict Quality Control Processes

Our quality control in CNC machining covers every stage—from initial setup to final inspection—so you can trust the accuracy of every component.

-

Experienced Engineers and Technicians

Our team knows how to balance precision and efficiency, optimizing machining processes to reduce waste and keep costs reasonable without sacrificing quality.

-

Customization and Flexibility

Whether your project demands ultra-high precision or complex geometries, HYCNC adapts to your needs with tailored solutions, enhancing product quality and reliability.

Choosing HYCNC means working with a partner committed to meeting the demands of today’s manufacturing standards. With our focus on precision and manufacturing accuracy, you can expect parts that fit perfectly and perform reliably.

For more about how we maintain strict tolerances and improve accuracy in machining, check out our Precision Machining Services. If you want to understand how accurate engineering drawings impact precision, visit our article on Engineering Drawings.

When precision and accuracy matter, we deliver.