What Is CNC Machining A Comprehensive Guide by HYCNC

Are you wondering what CNC machining really is and why it matters in manufacturing today? At HYCNC, we believe understanding this technology is key to making smarter choices for your projects.

CNC machining stands for Computer Numerical Control machining. It’s a subtractive manufacturing process where we use computer-guided machines to remove material from a solid block—metal, plastic, or composite—to create precise custom parts. This method is essential for today’s modern manufacturing because it delivers unmatched accuracy, repeatability, and speed.

Why should you consider HYCNC for your CNC machining needs? We’re a leader in precision CNC machining services with advanced technology and decades of experience. From multi-axis milling to turning and drilling, we handle complex geometries and tight tolerances that many shops can’t. Our goal with this guide is to introduce you to the CNC machining world and highlight how HYCNC’s expertise helps your business get the best quality parts, faster turnaround, and excellent value.

Whether you’re prototyping a new product or producing large volumes, CNC machining at HYCNC offers you a reliable, cost-effective solution tailored to your needs. Let’s dive deeper to show you how it all works.

How CNC Machining Works

CNC machining starts with a CAD design, where the part is created digitally. This design is then turned into a toolpath using CAM software, which tells the machine exactly how to cut the material. Once programmed, the CNC machine—whether it’s a mill, lathe, or router—follows these instructions to shape the part precisely.

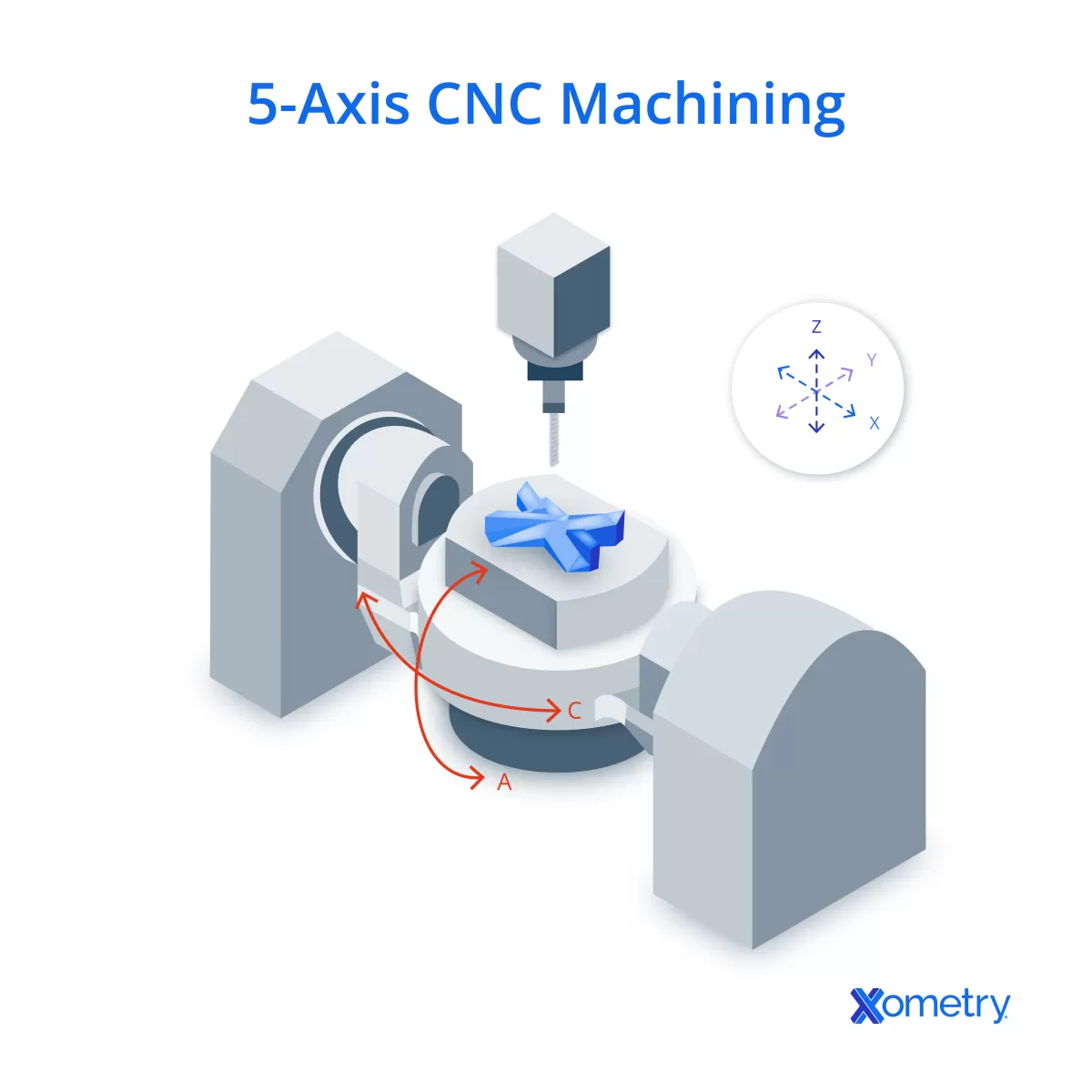

Key components in CNC machining include the machine itself, cutting tools, and the control software that runs everything. At HYCNC, we use advanced multi-axis CNC machines that allow movement along several directions for complex shapes. Our software integration ensures smooth operation from design to finished product.

We also specialize in pseudo-5-axis machining. This approach offers near 5-axis precision but at a lower cost, perfect for parts requiring tight tolerances without breaking the budget. Overall, our process combines top-tier equipment with skilled programming to deliver precision, efficiency, and quality.

Types of CNC Machining Processes

CNC machining covers several common processes like milling, turning, drilling, and grinding. Milling involves cutting material with rotating tools to create shapes, while turning spins the workpiece to shape it, typically on lathes. Drilling makes precise holes, and grinding smooths surfaces for tight finishes.

At HYCNC, we offer specialized machining too. This includes 3-axis, 5-axis, and pseudo-5-axis machining. The 3-axis handles parts with simpler geometry, while 5-axis machines provide full flexibility for complex shapes and tight angles. Our pseudo-5-axis machining delivers high precision at a lower cost, ideal for many production needs.

We’re equipped to handle complex geometries and thin-walled parts, which are often tough to machine. This ability makes HYCNC a go-to for demanding sectors like aerospace, automotive, medical, and electronics. Whether you need custom CNC parts or intricate components, we have the tools and expertise to deliver quality you can trust.

Benefits of CNC Machining with HYCNC

When you choose CNC machining with HYCNC, you get precision and accuracy that meet the toughest tolerances. Our advanced CNC milling and turning processes ensure your parts come out exactly as designed, every time.

We handle projects of all sizes—from quick prototypes to large-scale production runs. Whether you need a handful of parts or thousands, HYCNC scales with your needs smoothly and efficiently.

Material choice? No problem. We work with a wide range of materials including metals, plastics, and composites. This flexibility lets you pick the best material for your application without worrying about manufacturing limits.

On top of that, we pride ourselves on fast turnaround times without cutting corners on quality. Our strict quality control and SPC (Statistical Process Control) keep each batch reliable. Plus, our competitive pricing helps you stay on budget without sacrificing performance.

In short, HYCNC offers precision, speed, versatility, and value—all key benefits that help your project succeed.

Design Tips for CNC Machining Success

Getting your design right from the start can save time and money in CNC machining. Here are some best practices to help you succeed:

- Use clear CAD designs and technical drawings. Make sure your files are clean and easy to read.

- Define datums carefully. This helps ensure parts line up just right during machining.

- Avoid hard-to-reach features. Complex internal corners or tiny holes can slow production and increase costs.

- Simplify complex shapes. The fewer intricate details, the smoother the CNC machining process.

- Optimize your toolpaths. Efficient paths reduce machine time and tool wear.

At HYCNC, we provide design-for-manufacturing guidance to help engineers and designers create parts that are easier and more cost-effective to machine. Whether you’re working on prototypes or production runs, our advice focuses on making your designs practical for CNC milling, turning, and other processes.

Keep these actionable tips in mind to get the most precision and value from your CNC machining project.

Why Choose HYCNC for CNC Machining Services

At HYCNC, we bring years of experience and industry certifications that back our precision CNC machining services. Our team knows what it takes to deliver custom CNC parts that meet the highest standards, especially for demanding fields like aerospace and medical industries.

Quality is not just a goal for us—it’s a commitment. We use Statistical Process Control (SPC) and vibration monitoring to keep every part within tight tolerances. This ensures consistent accuracy and long-term reliability for your components.

Our customers trust us because we consistently deliver on time and within budget. From complex aerospace parts to delicate medical components, HYCNC’s precision machining stands up to the challenge.

Ready to get started? Contact HYCNC today for a quote or consultation and see how we can help bring your CNC machining project to life with quality and speed you can count on.

The Future of CNC Machining

CNC machining is evolving fast, with new tech reshaping how parts get made. At the forefront are trends like AI and machine learning, which help predict tool wear before it causes downtime. This keeps production smooth and saves costs. Automation is another big shift, letting machines run longer with less human intervention and higher consistency.

At HYCNC, we’re investing heavily in these cutting-edge technologies. Our use of smart software and advanced sensors means better precision and faster turnaround for our customers. Plus, we’re adopting more energy-efficient machines and processes to reduce waste and lower our environmental impact.

Sustainability is becoming key in manufacturing, and we’re committed to staying green while delivering top-quality CNC machining services. That means smarter machines, less energy, and parts made right the first time—every time.