What is 5-Axis CNC Machining

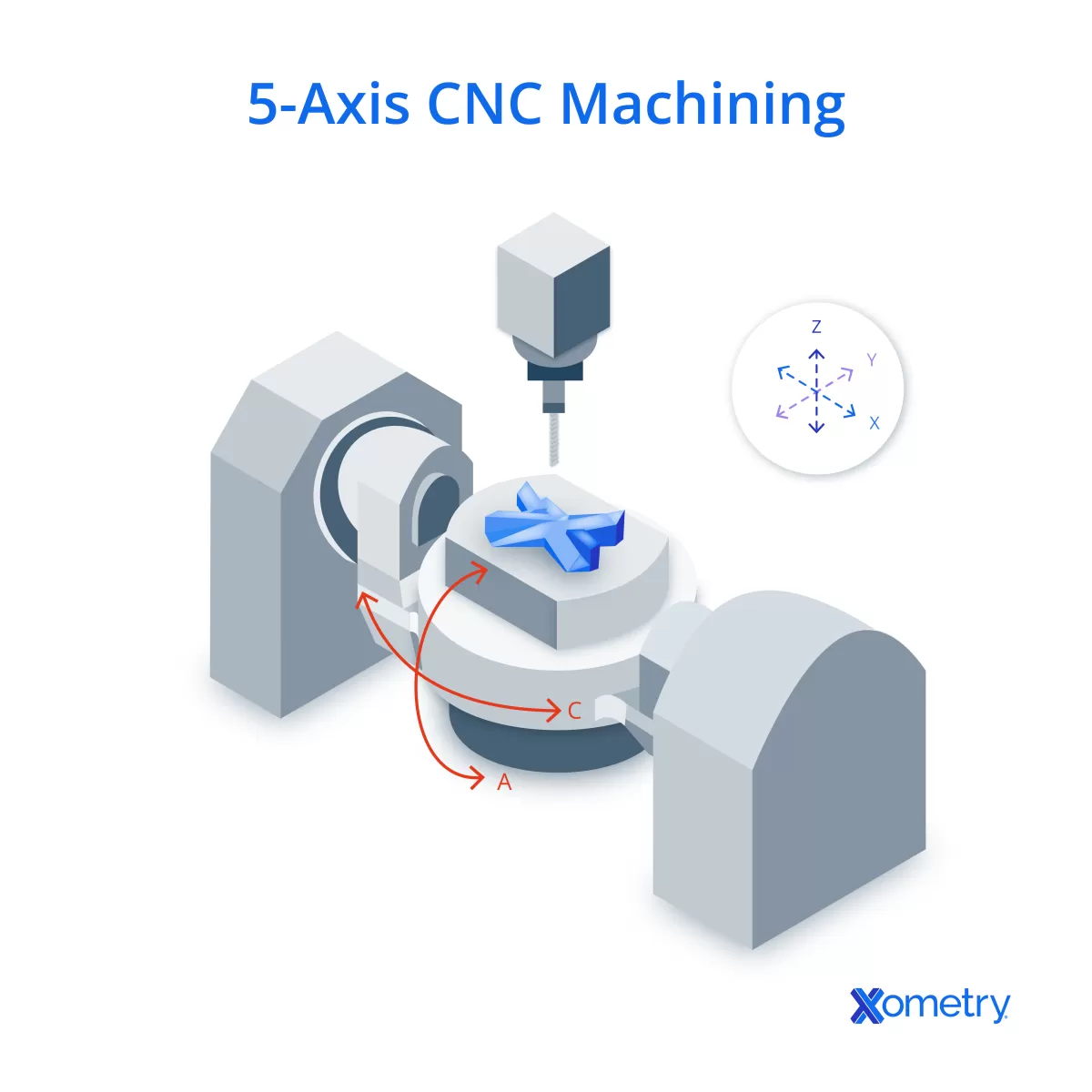

5-axis CNC machining is an advanced manufacturing process that moves a cutting tool or workpiece along five different axes simultaneously. Unlike traditional 3-axis CNC machines, which operate on the X, Y, and Z axes (left-right, forward-back, and up-down), 5-axis machines add two more rotational axes. This extra movement allows the tool to approach the part from nearly any direction, making it ideal for creating complex shapes and intricate details.

There are three main types of 5-axis CNC machining:

-

Continuous 5-Axis Machining: The tool moves in all five axes at the same time, enabling smooth and precise cuts on curved surfaces. This is perfect for complex organic shapes.

-

3+2 Machining (Positional 5-Axis): The tool is positioned using the two rotational axes, then performs cutting operations using the three linear axes. It is efficient for parts that need complex angles but not continuous multi-axis movement.

-

Mill-Turn Machines: These combine milling (cutting) and turning (rotating the part) in one setup, offering even greater flexibility for complex parts that require both types of machining.

Compared to 3-axis machining, 5-axis CNC provides the capability to handle more challenging geometries with fewer setups, reducing time and errors in complex part manufacturing.

How 5-Axis CNC Machines Work

5-axis CNC machines stand out because they can move both the tool and the workpiece in five different directions. Unlike traditional 3-axis machines that only move up and down, left and right, and front to back, 5-axis machines add two extra rotational movements. This means the cutting tool can approach the part from almost any angle.

This flexibility allows for more precise and complex cuts without constantly repositioning the material. The tool can tilt and rotate while the table holding the workpiece can also turn and pivot. Together, this multi-directional movement lets us reach tricky spots like deep cavities, undercuts, and curved surfaces with ease.

Overall, the greater freedom in movement reduces the need for multiple setups, lowers the chances of errors, and helps create high-precision complex parts faster than ever. This is why 5-axis CNC machining is a game-changer for industries demanding detailed and accurate components.

Why 5-Axis CNC Excels for Complex Parts

5-axis CNC stands out when it comes to making complex parts because it offers enhanced precision and accuracy through single setup machining. This means the part stays fixed in one position while the machine moves the tool around it on five different axes—cutting errors drop, and quality improves.

With fewer setups needed, production speeds up significantly. That cuts down on cycle time and labor costs, making your project more efficient and budget-friendly.

The surface finish is also better. Using shorter cutting tools reduces vibration during machining, resulting in smoother edges and finer details, which matter a lot in industries like aerospace and medical devices.

When it comes to design, 5-axis CNC handles complicated geometries with ease—think undercuts, deep cavities, and organic shapes that would be tough or impossible on a 3-axis machine.

Plus, it works well with a variety of materials, from metals like aluminum and titanium to plastics, providing flexibility whether you’re making durable parts or lightweight prototypes.

In short, 5-axis CNC machining brings precision, speed, and versatility together, making it the go-to choice for complex part manufacturing.

Key Industries Benefiting from 5-Axis CNC

5-axis CNC machining plays a huge role in industries where precision and complexity matter most. Here are the main fields that see major benefits:

- Aerospace: Manufacturing turbine blades, engine parts, and structural components that demand extremely tight tolerances and complex shapes.

- Automotive: Producing gearboxes, engine components, and custom high-performance parts that require intricate detailing and consistent quality.

- Medical: Crafting medical implants, surgical tools, and prosthetics that need smooth finishes and exact dimensions for patient safety.

- Energy: Handling parts for wind turbines and oil & gas equipment where durability and precision are critical for performance and safety.

At HYCNC, we specialize in servicing these key industries by combining advanced 5-axis CNC machines with skilled technicians. This ensures you get high-precision parts made efficiently, maintaining your project’s specifications and deadlines. Whether it’s aerospace engine components or complex medical implants, our expertise helps you tackle complex jobs with confidence.

Learn more about our 5-axis CNC machining services and how we support industries that demand the best.

Comparison of 5-Axis CNC to 3-Axis CNC for Complex Parts

When it comes to complex part manufacturing, 3-axis CNC machines have some clear limitations. They typically require multiple setups to reach all angles of a part, which increases the chance for errors and misalignment. This also leads to longer lead times and more labor costs because the part needs to be repositioned and recalibrated several times.

On the other hand, 5-axis CNC machining handles complex designs much better. It offers improved efficiency by allowing the tool to approach the part from different angles in a single setup. This reduces setup time, lowers error risks, and speeds up production. The result is higher precision and better surface finish, especially for intricate geometries like deep cavities, undercuts, and organic shapes.

Cost-wise, 5-axis CNC machines have a higher upfront investment compared to 3-axis machines. However, the long-term savings from faster cycle times, fewer setups, and reduced labor often outweigh the initial expenses. For businesses focused on precision CNC machining and high-volume production of complex parts, 5-axis machines deliver significant value.

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Number of Setups | Multiple required | Single or fewer setups |

| Precision | Moderate, prone to errors | High, consistent accuracy |

| Production Speed | Slower due to setups | Faster with continuous motion |

| Handling Complex Shapes | Limited | Excellent, versatile |

| Initial Cost | Lower | Higher |

| Long-Term Savings | Limited | Significant |

Choosing 5-axis CNC machining makes a real difference for US manufacturers looking to produce complex parts with speed, precision, and reliability.

How HYCNC Delivers Value with 5-Axis CNC Machining

At HYCNC, we combine state-of-the-art 5-axis CNC machines with a team of skilled technicians to deliver top-quality complex parts. Our advanced equipment ensures high precision, while our experts fine-tune every project for outstanding results. This means you get parts that meet tight tolerances with reliable consistency.

We understand the importance of fast turnaround times without sacrificing quality. That’s why we focus on efficient workflows and competitive pricing to keep your production on schedule and within budget. Whether you need aerospace turbine blades or custom medical implants, HYCNC is ready to tackle your toughest machining challenges.

For example, we recently completed a demanding aerospace component featuring intricate geometries and tight surface finish requirements—all accomplished in a single setup with minimal lead time. This project highlighted our ability to deliver complex parts that meet industry standards and customer expectations.

Ready to get started? Contact us for a free quote and easily upload your CAD files. Let HYCNC be your trusted partner for precision 5-axis CNC machining. Visit our 5-axis CNC machining service page to learn more.

Challenges and Considerations in 5-Axis CNC Machining

While 5-axis CNC machining offers great advantages, it does come with some challenges. First, the upfront costs for equipment and software are higher compared to traditional 3-axis machines. This can be a barrier for some shops or projects with budgets.

Second, operating 5-axis machines requires skilled and machinists who understand complex toolpaths and advanced programming. the right expertise, it’s easy to run into errors or machining.

At HYCNC, we tackle these challenges head. Our team of experienced technicians and programmers uses state-of-the-art software and equipment to ensure every job runs smoothly. We invest in ongoing training and advanced technologies so we can deliver precise, high-quality parts efficiently. This combination allows us to manage costs and complexity, giving you the benefits of 5-axis CNC machining without the typical hurdles.

FAQs about 5-Axis CNC Machining

What makes 5-axis CNC better than 3-axis

5-axis CNC machines move the tool and the part on five different axes, giving way more flexibility than 3-axis machines. This means they can handle complex shapes in a single setup, improving precision and cutting down production time. You get better surface finishes and less need for repositioning, which lowers errors and speeds things up.

Which industries benefit most from 5-axis CNC

Industries like aerospace, automotive, medical, and energy rely heavily on 5-axis CNC. They deal with complex parts like turbine blades, engine components, implants, and turbine equipment that need high precision and tight tolerances. 5-axis CNC makes these challenging jobs much easier and more reliable.

How does HYCNC ensure precision with 5-axis machining

At HYCNC, we combine advanced 5-axis machines with skilled operators and refined processes. Our tight quality control, real-time monitoring, and experience in programming complex jobs keep every part within spec. We handle everything from setup to finishing to make sure you get consistent, high-quality results.

What materials does HYCNC machine with 5-axis CNC

We work with a wide range of materials including various metals like aluminum, titanium, stainless steel, and specialty alloys, as well as engineering plastics. Our 5-axis machines and tooling are designed to handle tough materials used in aerospace, medical devices, and automotive parts.

How can I get a quote for 5-axis CNC projects at HYCNC

Getting a quote is simple. Just upload your CAD files on our website or contact our team directly. We’ll review your project specs and provide fast, competitive pricing tailored to your needs. Whether it’s a prototype or full production run, we’re ready to help.