Key Principles of CNC Milling Part Design

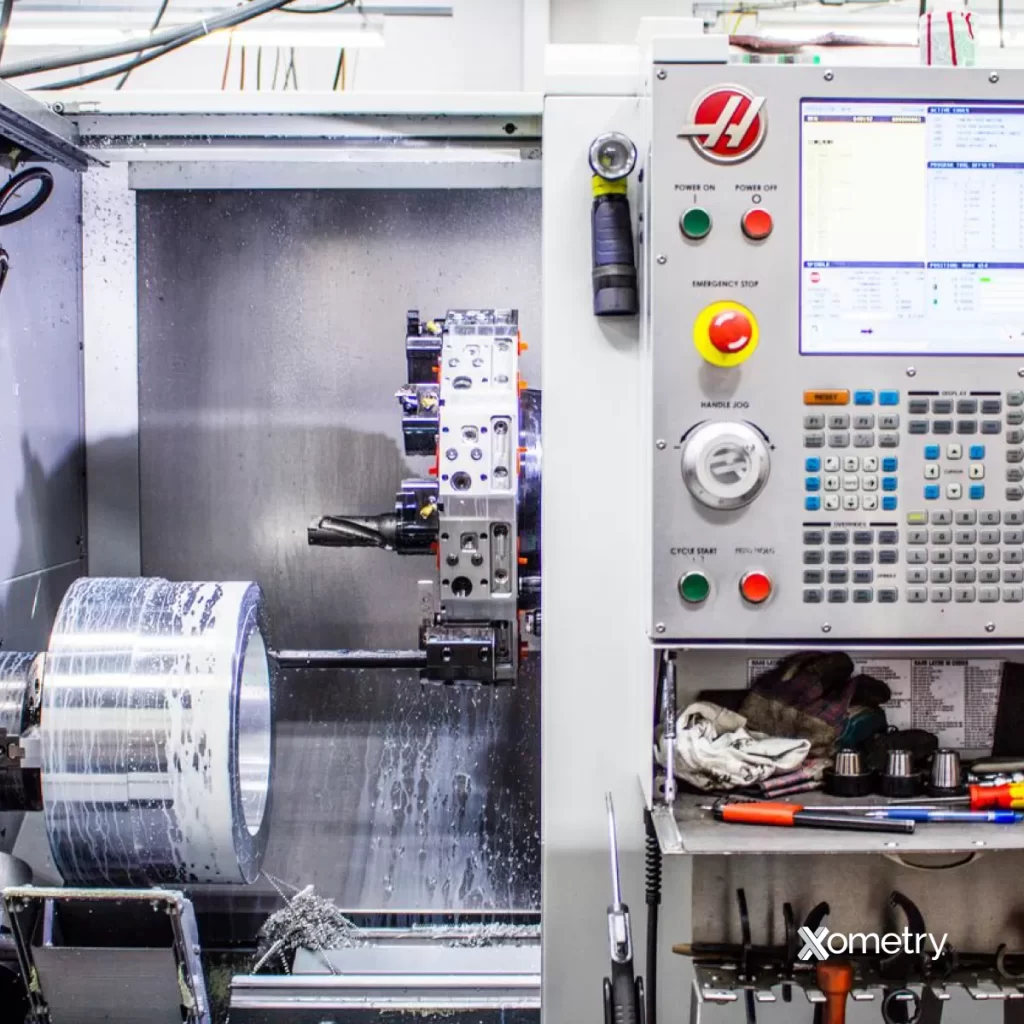

Understanding CNC Milling Basics

If you’re new to CNC milling, it’s important to grasp the fundamentals before jumping into design. CNC milling uses computer-controlled cutting tools to shape parts from various materials. It offers precision, repeatability, and the ability to produce complex geometries. However, the design must align with the machining process to avoid costly mistakes and delays.

Design for Manufacturability DFM

Design for Manufacturability (DFM) is all about making your part easy and cost-effective to produce without sacrificing quality. This means simplifying features, avoiding overly tight tolerances unless necessary, and ensuring tool access for smooth machining. Good DFM reduces cycle time, tooling wear, and scrap rates.

Material Selection for CNC Milling

Choosing the right material is a crucial step. Common CNC milling materials include aluminum, steel, stainless steel, brass, and plastics. Each material has different properties affecting machinability, strength, and finish quality. For example:

- Aluminum is easy to machine and ideal for lightweight parts

- Steel offers durability but may increase cycle time

- Plastics work well for prototypes but have lower strength

Selecting materials that fit your application while considering machinability helps optimize cost and performance.

Understanding these three pillars — the CNC milling process, manufacturability, and material choice — sets the stage for smarter part design that works well in real-world production.

Essential Design Guidelines for CNC Milling

Optimizing Geometries

When designing parts for CNC milling, keeping geometries simple and efficient is key. Avoid overly complex shapes that can slow down machining or increase costs. Focus on clear, straightforward designs that make the cutting path smooth and predictable. This means:

- Use gradual curves instead of sharp angles where possible.

- Keep features accessible to cutting tools.

- Design parts with uniform shapes to speed up production.

Optimizing geometries helps reduce machining time and improves part accuracy, aligning with solid CNC machining design guidelines.

Wall Thickness and Structural Integrity

Maintaining proper wall thickness is critical. Walls that are too thin risk bending or breaking during milling or in use, while unnecessarily thick walls waste material and increase cost. Here’s what to keep in mind:

- Follow recommended minimum thickness for your chosen material.

- Balance strength needs with weight reduction goals.

- Consider tooling limitations—machines often struggle with very thin or inconsistent walls.

This ensures your parts have the right structural integrity without driving up CNC machining cost.

Hole and Thread Design

Holes and threads are common but can be tricky in CNC milling. Proper design improves both functionality and machinability:

- Design holes with standard drill sizes to avoid custom tooling.

- Use appropriate thread depths and profiles according to machining capabilities.

- Always include allowances for post-processing finishes if threading is involved.

Correct hole and thread design make assembly easier and ensure parts fit perfectly, essential in precision CNC part design.

Fillets and Radii

Adding fillets and radii where sharp edges meet is not just aesthetic—it’s practical:

- Fillets reduce stress concentration, improving part durability.

- Rounded edges help cutting tools move smoothly, prolonging tool life.

- Standard radii should match tool sizes to avoid extra machining steps.

Including fillets in your design balances performance and manufacturability, a vital part of CNC milling part optimization. For more on design best practices, check out design optimization in CAD.

Surface Finishing Options for CNC Milled Parts

As-Machined Finishes

When your part comes straight off the CNC milling machine, it usually has an as-machined finish. This means the surface still shows the tool marks, slight ridges, or a matte texture depending on the material and cutting settings. For many applications, this finish is perfectly fine, especially if the part won’t be visible or require high cosmetic quality. As-machined finishes also help keep costs down since no extra work is involved.

Post-Processing Finishes

Sometimes, parts need an extra step to improve appearance, durability, or function. Common post-processing finishes include:

- Polishing or buffing: Smooths out rough surfaces and enhances shine

- Anodizing: Adds corrosion resistance and color to aluminum parts

- Powder coating or painting: Improves protection and aesthetics

- Deburring: Removes sharp edges and burrs to ensure safety and fit

- Surface grinding: Creates a very flat and smooth finish when tight tolerances are required

Balancing Finish Quality and Cost

Choosing the right finish is a balance between what your part needs and your budget. More advanced finishes add time and expense but can increase part life or appeal. For simple CNC parts used in prototypes or internal components, an as-machined finish often does the job. For commercial or visible parts, investing in the right post-processing can make a big difference without going overboard. Always discuss with your CNC provider to find the best finish that fits your function and cost goals.

Common Mistakes to Avoid in CNC Milling Part Design

When designing parts for CNC milling, avoiding certain pitfalls can save time, reduce costs, and improve overall quality. Here are some common mistakes to watch out for:

Overly Complex Geometries

Trying to pack too much detail into a part can lead to longer machining times and higher costs. Complex shapes might also require multiple setups or special tooling, increasing the chance of errors. Keep designs as simple as possible while meeting your functional needs.

Ignoring Tool Access

If the milling tool can’t reach certain areas, those features may be impossible to machine or require expensive custom tools. Always design with clear tool paths in mind and consider tool size, shape, and reachability to avoid machining issues.

Neglecting Material Properties

Different materials react differently during CNC milling. Hard materials might wear tools faster, while soft ones may deform easily. Failing to consider the material’s machinability can lead to poor surface finishes, tolerance problems, or even part failure. Choose materials wisely and design to match their strengths.

Avoiding these common mistakes helps ensure smoother CNC machining processes and better final parts. For more on optimizing your designs to fit manufacturing, check out our design optimization tips.

How HYCNC Enhances Your CNC Milling Part Design

Expert Consultation and DFM Analysis

At HYCNC, we start by helping you optimize your design for manufacturability (DFM). Our experts review your parts early on to spot potential issues that could raise costs or slow production. This consultation saves time and money by addressing challenges before they become problems. Whether you’re working on tight tolerances or complex features, our team guides you to create CNC machining designs that are efficient and reliable. You can also learn more about design for manufacturability and assembly in sheet metal fabrication on our DFM guide.

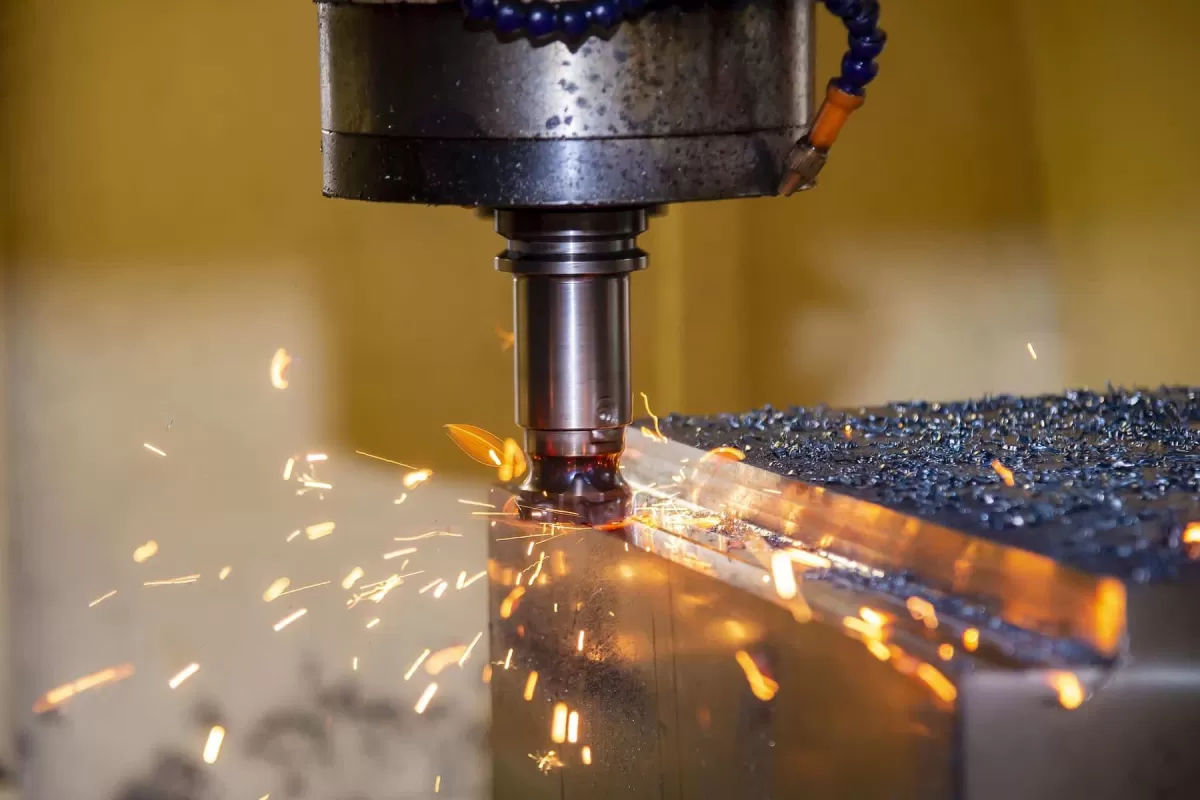

Advanced CNC Milling Capabilities

HYCNC offers state-of-the-art machining centers capable of handling intricate part geometries with precision. We work with a wide range of materials and can manage tight CNC milling tolerances thanks to our precise equipment and skilled operators. This means your parts come out exactly as designed, down to the smallest detail. Our advanced technology also supports the production of complex features like multi-axis milling, fine threads, and sharp radii, so your design isn’t limited by manufacturing constraints.

Rapid Prototyping and Production

We understand how critical timing is. That’s why HYCNC offers quick-turn prototyping to test and refine your CNC milling part designs fast. Once your prototype is approved, we move smoothly into full production without missing a beat. This streamlined process helps you get your parts on time and within budget, whether you need small runs or larger batch manufacturing.

Case Study Successful Part Design with HYCNC

A client needed a precision aluminum part with tight tolerances and complex geometries for the aerospace sector. Our team conducted a thorough DFM analysis, suggested material adjustments, and optimized the wall thickness for durability and cost savings. Using our advanced milling machines, the part was prototyped in days, then moved into full production seamlessly. The result: a reliable, high-quality part delivered on schedule, demonstrating how HYCNC’s expertise transforms designs into successful finished products.

Tools and Software for CNC Milling Part Design

Choosing the right tools and software is key to smooth CNC milling part design. CAD CAM software is the backbone here, helping you create precise 3D models and convert them into milling instructions. Popular options like Fusion 360, SolidWorks, and Mastercam let you design parts with the right tolerances and optimize them for CNC machining.

Simulating and testing your designs before production saves time and avoids costly errors. Most CAD CAM programs offer built-in simulation tools that show how the milling tool moves, checks for collisions, and predicts surface finish quality. Running these checks lets you spot design issues early and adjust accordingly.

At HYCNC, we provide design support that goes beyond software. Our experts work with you to review your CAD files, suggest improvements for manufacturability, and ensure your designs meet both your needs and CNC machining capabilities. Whether it’s fine-tuning wall thickness, hole placement, or surface features, HYCNC helps turn your ideas into precision CNC milled parts efficiently.

By combining advanced CAD CAM tools, thorough simulation, and HYCNC’s expert design support, you can achieve high-quality CNC milling results on time and within budget.

FAQs

What is CNC milling part design?

CNC milling part design is the process of creating parts optimized for CNC machining. It involves shaping the part to be easily and efficiently produced by milling machines, considering factors like geometry, material, and tolerances.

Why is design for manufacturability (DFM) important in CNC milling?

DFM helps reduce production costs and time by ensuring parts are designed for easy machining. This means avoiding overly complex shapes, ensuring proper tool access, and choosing suitable materials.

How do I choose the right material for CNC milling?

Consider strength, machinability, and cost. Metals like aluminum and steel are common, but plastics are also an option depending on the part’s use. Make sure the material matches your part’s durability and finish needs.

What are common CNC milling tolerances?

Tolerance varies by material and machine capability but typically ranges from ±0.002 to ±0.005 inches. The tighter the tolerance, the higher the cost, so balance precision needs with budget.

How can I optimize my part for CNC milling?

Keep geometries simple

Use standard hole sizes and thread types

Maintain uniform wall thickness

Include fillets to reduce stress concentrations

What surface finishes can I expect from CNC milling?

You can get as-machined finishes or request post-processing like anodizing or polishing. The finish quality affects both aesthetic and function, so specify this early in the design phase.

Can HYCNC help with my CNC part design?

Yes, HYCNC offers expert consultation and DFM analysis to optimize your design. They also provide rapid prototyping and advanced milling capabilities to bring your parts from idea to reality quickly.

For more on designing your parts effectively, check out Design for Manufacturing and Assembly for Easier Sheet Metal Fabrication and Design Optimization in CAD.