What is CNC Automation

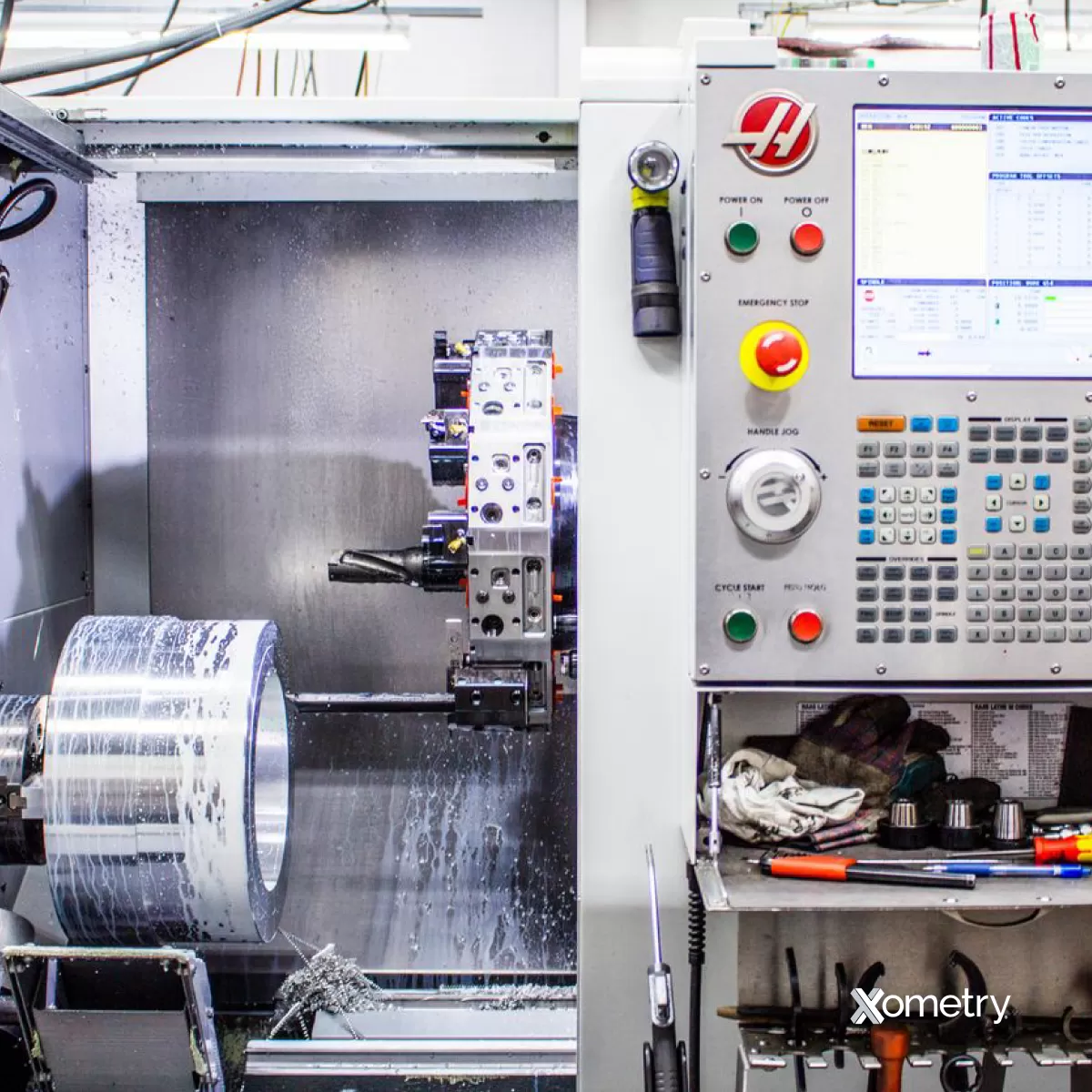

CNC automation combines computer numerical control (CNC) machines with automated systems like software and robotics to streamline manufacturing. At its core, CNC automation uses programmed commands to control machine tools—such as mills, lathes, and cutters—without constant manual intervention.

Key components include:

- CNC machines that perform precise cutting, drilling, or shaping

- Software systems like CAD/CAM that design and generate machine code

- Robotic systems that handle material loading, unloading, and part transfer

By integrating these parts, CNC automation improves speed, accuracy, and consistency in manufacturing. Automation reduces human error, increases production rates, and ensures every piece meets exact specifications—making it essential for modern precision manufacturing.

Benefits of CNC Automation for Manufacturers

CNC automation brings big advantages for manufacturers looking to boost efficiency and cut costs. Here’s how it helps:

-

Increased productivity and reduced labor costs: Automated CNC machines operate faster and longer than manual setups, cutting down on labor needs and speeding up production times.

-

Enhanced precision and quality control: Automation ensures consistent, precise machining, reducing errors and improving overall product quality.

-

Scalability for small and large production runs: Whether you need a few parts or thousands, CNC automation can quickly adjust to meet demand without compromising quality.

-

Reduced downtime and improved safety: Automated systems minimize human errors and reduce machine downtime with predictive maintenance, which also helps keep workers safer.

Studies show that automation can boost productivity by up to 14.5%, making it a valuable investment for manufacturers aiming to stay competitive and efficient.

Applications of CNC Automation in Industries

CNC automation plays a big role across many industries in the U.S., especially in aerospace, automotive, medical, and electronics. These fields demand high precision and consistent quality, which automated CNC machining delivers every time.

Common automated CNC processes include milling, turning, and cutting. These help speed up production while keeping tight tolerances, reducing errors that can happen with manual work.

At HYCNC, we understand each industry has unique needs. That’s why we offer tailored CNC automation solutions designed specifically for your sector. Whether it’s complex aerospace parts or delicate medical components, we provide the right technology and support to boost your manufacturing efficiency.

Why Choose HYCNC for CNC Automation

HYCNC stands out with its advanced CNC automation technology designed to meet the demands of today’s manufacturers. Our systems combine precision CNC machining with smart automation tools like robotic arms and intuitive CNC software, delivering seamless, reliable performance every time.

We offer customizable solutions tailored to a wide range of manufacturing needs—from small batch runs to full-scale production. Whether you’re in aerospace, automotive, medical, or electronics, HYCNC adapts automation to fit your unique process and goals.

Quality, reliability, and customer support are at the core of what we do. We prioritize minimizing downtime and maximizing your production efficiency with ongoing service and fast response times.

Take for example a recent client in the automotive industry who integrated our CNC automation solutions. They saw a 30% boost in production speed and a significant drop in errors, thanks to our tailored automation setup and hands-on support. This level of success is why many manufacturers trust HYCNC for their CNC automation needs.

Top CNC Automation Tools and Technologies

Today’s CNC automation relies on powerful tools that make manufacturing faster and smarter. Key players include CAD CAM software, which helps design and plan parts precisely before machining. These programs automate complex tool paths and reduce errors, making setups quicker and more efficient.

Robotic arms are another big part of the picture. They handle tasks like loading/unloading parts, tool changes, and finishing processes, cutting down manual labor and speeding up production lines.

On top of that, smart manufacturers are integrating AI and IoT technologies to create connected CNC machines. This means real-time monitoring, predictive maintenance, and data-driven optimizations that prevent downtime and boost consistency across runs.

At HYCNC, we leverage proprietary technologies and partner with leading automation innovators to deliver tailored solutions. Our setup combines the latest CNC automation software, robotic systems, and smart manufacturing tools designed for U.S. manufacturers aiming to stay competitive and efficient.

How to Implement CNC Automation with HYCNC

Implementing CNC automation with HYCNC is a straightforward process designed to fit your manufacturing needs. Here’s a simple step-by-step guide:

- Consultation: We start by understanding your current setup, production goals, and challenges. This helps us tailor automation solutions that fit your business.

- Assessment: Next, we analyze your existing CNC machines and workflow to identify opportunities for automation and efficiency gains.

- Planning and Proposal: Based on the assessment, we craft a detailed plan outlining the best tools, software, and robotic systems for your operation, along with timelines and cost estimates.

- Implementation: Our team handles the installation and integration of CNC automation equipment, ensuring minimal disruption to your production.

- Training: We provide hands-on training for your staff to smoothly transition to automated CNC processes.

- Ongoing Support: HYCNC offers continuous support and maintenance to keep your automated systems running optimally.

What to Consider Before Automating

- Cost: Initial investment varies depending on the level of automation, but HYCNC helps you project ROI through improved productivity and reduced labor costs.

- Return on Investment (ROI): Automation can boost output and quality, paying for itself over time.

- Training Needs: Skilled operators are key, so training is essential for maximizing automation benefits.

With HYCNC’s end-to-end support, from consultation to full implementation, you get reliable CNC automation solutions that grow with your manufacturing needs. This hands-on approach helps manufacturers across the U.S. stay competitive and efficient in today’s fast-paced market.

Future Trends in CNC Automation

The future of CNC automation looks exciting with AI-driven systems leading the way. Artificial intelligence helps machines learn from data, making processes smarter and more efficient. Predictive maintenance powered by AI means equipment can signal when it needs service before breaking down, reducing downtime and saving costs.

Industry 4.0 is transforming how CNC automation works by connecting machines through the Internet of Things (IoT). This means real-time data flows between machines, software, and operators, allowing better control and faster decision-making in manufacturing.

Sustainability is also becoming a big focus. CNC automation is helping companies use energy more efficiently and cut down on waste. Smarter machines and automated controls mean less material scrap and lower power consumption, which is good for both the environment and your bottom line.

Together, these trends are shaping CNC automation into a smarter, greener, and more reliable part of modern manufacturing in the US.

FAQs About CNC Automation

What is the cost of CNC automation

The cost varies depending on the size of the operation and the complexity of the system you need. Basic setups for small shops might start in the low tens of thousands, while larger, fully integrated CNC automation systems can go higher. At HYCNC, we work closely with you to find a solution that fits your budget and goals, ensuring you get good value without overspending.

How does automation improve CNC machining accuracy

Automation removes human error by relying on precise software and robotic systems. This means consistent tool paths, exact measurements, and fewer mistakes. The result is higher precision parts with tighter tolerances every single time, improving the overall quality of your manufacturing process.

What industries benefit most from CNC automation

CNC automation suits a range of industries, including aerospace, automotive, medical devices, and electronics manufacturing. Anywhere you need high precision, fast turnaround, and repeatable quality, automation brings major benefits—from milling and turning to cutting and drilling operations.

How can HYCNC help with automation integration

HYCNC provides tailored support throughout your CNC automation journey. We start with a consultation to understand your manufacturing needs, then help with system selection, installation, training, and ongoing support. Our goal is to make the switch to automated CNC machining smooth and efficient, maximizing your productivity and ROI.