What Are CNC Metal Cutting Tools Definition Types and Features

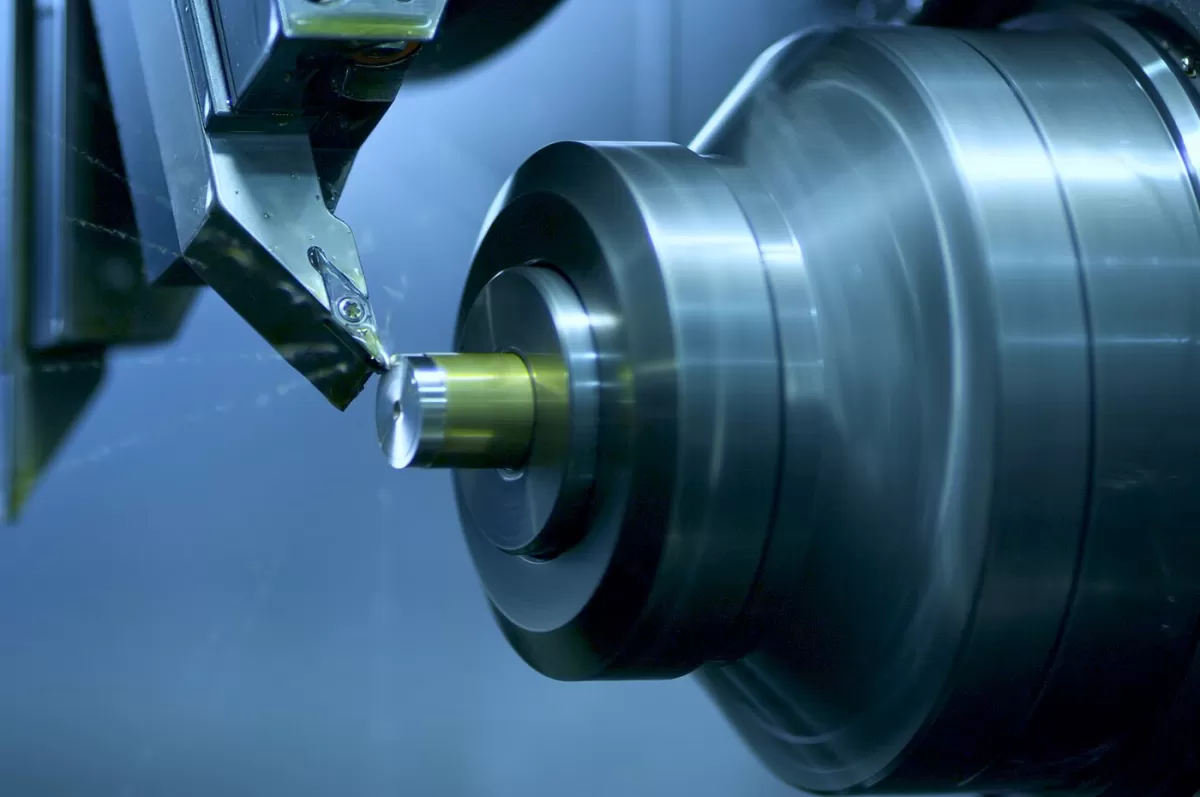

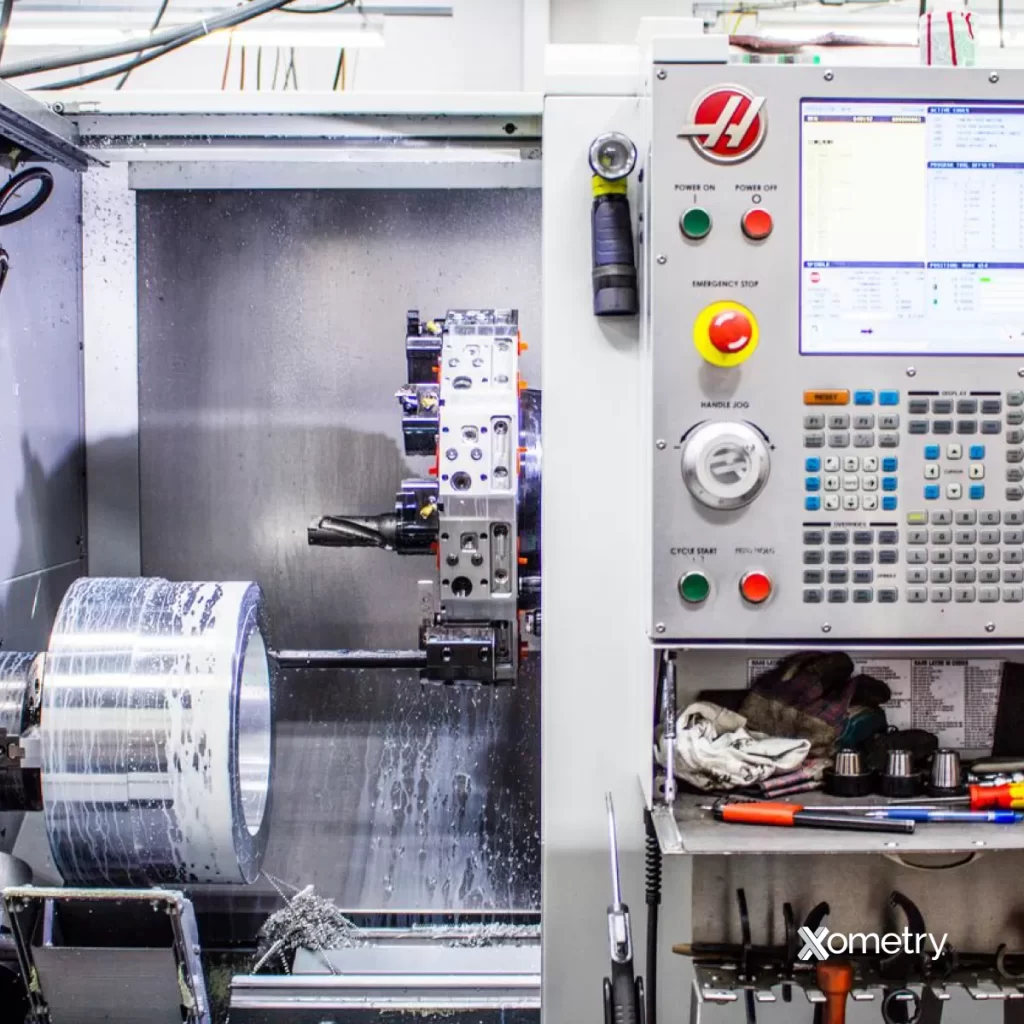

If you’re new to CNC machining, you might wonder, what exactly are CNC metal cutting tools? Simply put, these are precision tools designed to shape, cut, and finish metal parts using computer numerical control (CNC) machines. These tools work with high-speed machining processes to deliver consistent and accurate results.

Types of CNC Metal Cutting Tools

- End Mills for CNC: Versatile cutters used for milling applications like slotting and contouring.

- CNC Lathe Tools: Designed for turning operations, shaping cylindrical parts with precision.

- High-Speed Machining Tools: Engineered for fast cutting speeds while maintaining quality.

- CNC Milling Cutters: Various shapes and sizes used to machine different geometries.

- Industrial Cutting Tools: Heavy-duty tools for metal fabrication in tough environments.

Key Features

- Precision and Accuracy: Tools are made to exact specifications for tight tolerances.

- Durability: Built from high-grade materials like carbide or coated steel for longer life.

- Versatility: Suitable for a range of metals including steel, aluminum, and titanium.

- Compatibility: Designed to fit various CNC machines and applications.

- Efficiency: Optimized cutting edges reduce machining time and improve surface finish.

In short, CNC metal cutting tools are the heart of any CNC machining process, offering the precision and performance needed for modern manufacturing. Whether you’re working in aerospace, automotive, or electronics, picking the right tool impacts your final product quality and efficiency.

Key Applications of CNC Metal Cutting Tools

CNC metal cutting tools play a crucial role across many industries in the U.S., thanks to their precision and reliability. Here are some of the key areas where these tools make a big difference:

Automotive

From engine parts to chassis components, CNC machining tools help produce durable, high-precision metal parts that meet strict safety and performance standards. They speed up production while keeping quality high in this fast-moving market.

Aerospace

In aerospace, precision metal cutting is essential. CNC milling cutters and lathe tools create complex parts like turbine blades and structural components with tight tolerances, ensuring safety and efficiency in aircraft manufacturing.

Electronics

The electronics sector relies on metal fabrication tools to make tiny, intricate components. CNC tool suppliers provide end mills for CNC and high-speed machining tools that deliver sharp detail and clean finishes for circuit boards and housing.

Medical Devices

Medical equipment demands the highest level of accuracy. CNC metal cutting tools produce surgical instruments, implants, and diagnostic devices with exact specifications, helping improve patient outcomes.

Other Industries

Beyond these, CNC metal cutting tools support industries like construction, energy, and defense. Their versatility allows companies to tackle a wide range of metal fabrication tasks, from heavy-duty parts to delicate components.

Each of these sectors benefits from the dependability and precision that CNC machining tools bring, making them essential for modern manufacturing in the United States.

Benefits of Using HYCNCs CNC Metal Cutting Tools

When it comes to CNC metal cutting tools, HYCNC delivers serious advantages that fit the needs of U.S. manufacturers across industries. Here’s why using HYCNC’s tools pays off:

Precision and Accuracy

HYCNC’s CNC machining tools are built for tight tolerances. Whether you need precision metal cutting or intricate shapes, their CNC milling cutters and end mills for CNC consistently produce exact results, minimizing errors and waste.

Efficiency

Thanks to high-speed machining tools and advanced CNC lathe tools, HYCNC helps speed up production while maintaining quality. Faster setups and smooth operation mean you can meet deadlines without cutting corners.

Cost Effectiveness

Using durable, long-lasting metal fabrication tools from HYCNC reduces tool wear and downtime. This lowers overall maintenance and replacement costs, making them a smart investment for businesses focused on the bottom line.

Sustainability

HYCNC is committed to eco-friendly manufacturing. Their tools help optimize material use and energy efficiency, supporting sustainable practices that align with growing industry trends in the U.S.

Versatility

From automotive parts to medical devices, HYCNC’s industrial cutting tools cover a wide range of applications. They work with various metals and complex designs, making them a versatile choice for any CNC machining project.

Case Study

A Midwest automotive supplier switched to HYCNC’s high-speed machining tools and saw a 20% boost in production speed with a 15% drop in tool costs. This example highlights how HYCNC tools deliver real-world results by improving precision and saving money.

In short, choosing HYCNC’s CNC metal cutting tools means you get reliable, high-performance tools designed to enhance your manufacturing process from start to finish.

Choosing the Right CNC Metal Cutting Tools for Your Needs

Picking the right CNC metal cutting tools is key to getting the job done efficiently and accurately. Here’s what you should keep in mind:

Factors to Consider

- Material type: Different metals like aluminum, stainless steel, or titanium need specific cutters for the best results.

- Tool type: Milling cutters, end mills for CNC, or lathe tools each serve different purposes.

- Machine compatibility: Your CNC machine’s specs affect what tools will work best.

- Cutting speed and feed rates: Matching these with your tools avoids wear and improves finish quality.

- Tool coating: Coatings like TiN or TiAlN boost tool life and performance in high-speed machining.

Comparison of Tool Types

| Tool Type | Best For | Key Features |

|---|---|---|

| CNC Milling Cutters | Complex shapes, grooves | Versatile, good for metal stock |

| End Mills for CNC | Precision cuts, finishing | Sharp edges, wide sizes |

| CNC Lathe Tools | Turning and cylindrical parts | High durability, rigid design |

Why Choose HYCNC for Consultation

At HYCNC, you get experts who understand your local market needs across the US and can recommend tools tailored to your project. They help match your machine, material, and budget with ideal tools for precision metal cutting.

Tips for Optimizing Tool Performance

- Regular CNC tool maintenance keeps cutters sharp and reliable.

- Use stable workholding to reduce vibrations that wear tools down.

- Follow manufacturer guidelines on speed and feed for each tool.

- Monitor tool wear and replace before quality drops.

- Consider high-speed machining tools for faster turnaround without sacrificing quality.

Choosing the right CNC metal cutting tools isn’t just about buying the latest gear—it’s about matching the tool to your specific metal fabrication needs. HYCNC makes this simple by providing guidance and top-quality industrial cutting tools fit for your projects.

Industry Trends Shaping CNC Metal Cutting Tools

The world of CNC metal cutting tools is evolving fast, driven by some major trends shaping how we work and what we expect from our tools.

Automation and Industry 4.0

Automation is changing the game. With smart factories and Industry 4.0, CNC machining tools are becoming more connected and intelligent. This means better monitoring, faster adjustments, and less downtime. High-speed machining tools are now integrated with sensors and software that help optimize cutting processes automatically. For anyone in metal fabrication or precision metal cutting, this boost in efficiency is a big deal.

Electric Vehicle Boom

The rise of electric vehicles (EVs) is pushing CNC tool suppliers to innovate. EV manufacturing demands new kinds of metal parts that require specialized CNC milling cutters and CNC lathe tools capable of handling lightweight metals and composites. This trend is expanding the scope and complexity of CNC machining tools used across the automotive industry.

Sustainability

Sustainability is front and center. More businesses in the U.S. want CNC metal cutting tools that reduce waste, use eco-friendly materials, and improve energy efficiency. HYCNC is committed to offering tools and processes aligned with these goals, helping clients cut costs and waste while staying green.

Additive Manufacturing

Though often seen as separate, additive manufacturing is blending with traditional CNC machining. Hybrid approaches allow manufacturers to build complex parts that are then finished with precision CNC cutting. Tools designed for this hybrid workflow are becoming essential in aerospace, medical devices, and electronics industries.

HYCNC Technology

At HYCNC, we stay ahead by integrating these trends into our CNC service offerings. From high-speed machining tools synced with smart factory tech to sustainable metal cutting tools designed for new material demands, HYCNC ensures you get the latest innovations that meet the U.S. market’s evolving needs.

These trends are not just buzzwords—they’re reshaping what CNC metal cutting tools can do and how you get the most value from them.

Why Choose HYCNC for CNC Metal Cutting Tools

When it comes to CNC metal cutting tools, HYCNC stands out for several reasons that matter to U.S. manufacturers and fabricators. Here’s why HYCNC should be your go-to supplier.

Overview of Services

HYCNC offers a full range of CNC machining tools, including high-speed machining tools, CNC milling cutters, and CNC lathe tools. Whether you need precision metal cutting or custom metal fabrication tools, we deliver reliable solutions tailored to your project’s specs. Plus, our expertise extends to sheet metal fabrication and metal etching, providing versatile options for various manufacturing needs.

Global Reach

Although based in the U.S., HYCNC connects you with a worldwide network of CNC tool suppliers and manufacturing partners. This global reach helps us source the best materials and technology while keeping delivery times competitive for American customers. It means you get access to cutting-edge tools without the long wait.

Commitment to Quality

Quality isn’t just a buzzword at HYCNC—it’s the foundation of everything we do. Our CNC metal cutting tools undergo strict quality control to ensure durability, precision, and performance. We make sure every end mill for CNC and industrial cutting tool meets high standards before it reaches your workshop, helping you avoid downtime and costly rework.

Customer Testimonials

Many local manufacturers rely on HYCNC for their CNC machining tools and praise our consistent quality and excellent customer service. They highlight our responsiveness, technical support, and practical advice on CNC tool maintenance that keeps their operations smooth and efficient.

Call to Action

Ready to upgrade your metal cutting tools? Contact HYCNC today to find the right CNC metal cutting tools for your specific needs. Visit our website or reach out for a consultation—let’s help your business get the precision, efficiency, and reliability it deserves.

For more on related services, check out our sheet metal fabrication and metal etching offerings.