What is Laser Cut Steel

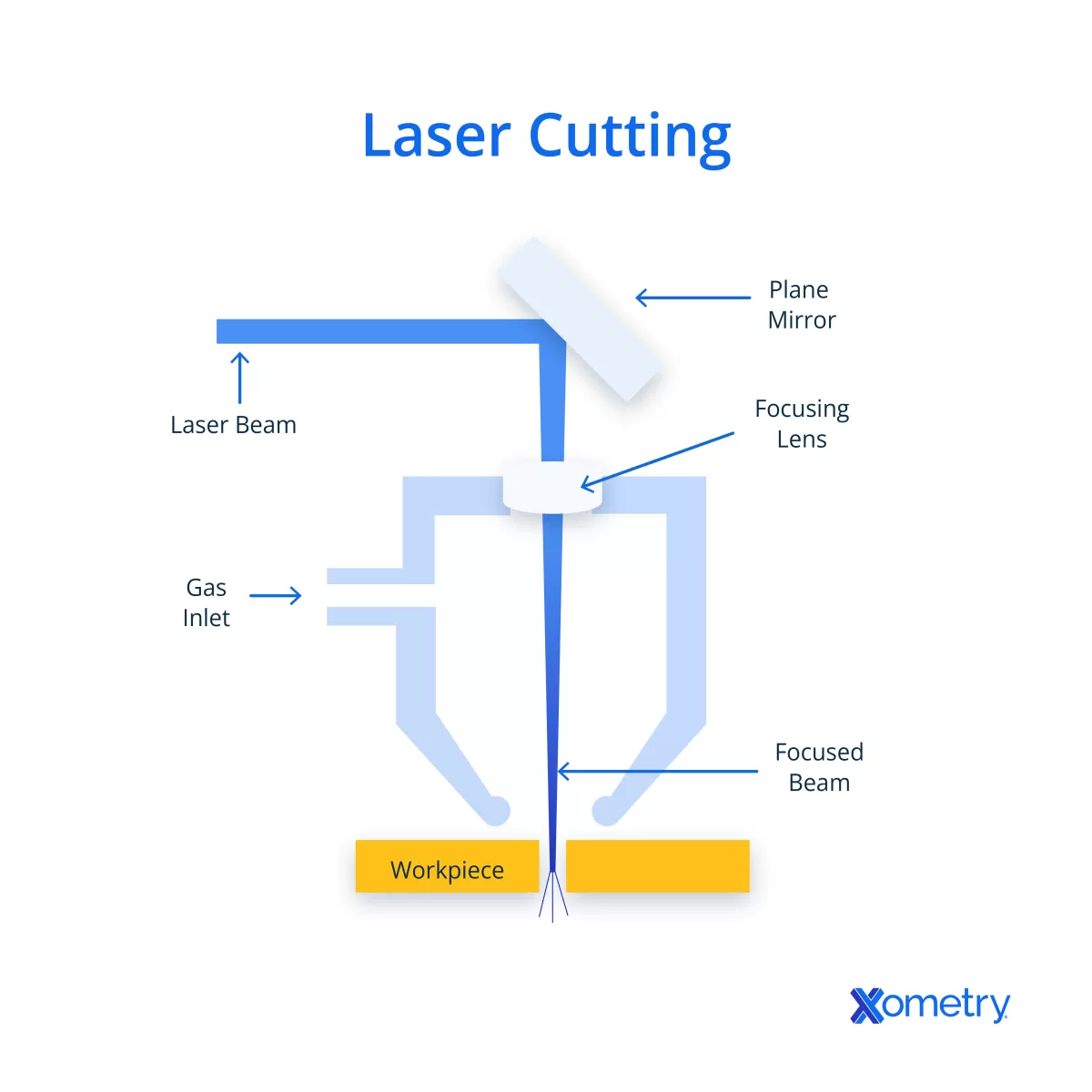

Laser cut steel is steel that has been precisely shaped using a high-powered laser beam. This cutting method uses CNC laser cutting technology to heat, melt, or vaporize steel along a defined path, achieving clean and accurate cuts with minimal material waste.

The process starts with creating a digital design, which guides the laser cutter to follow exact patterns. Two common types of lasers in steel cutting are fiber laser cutting and CO2 laser cutting. Fiber lasers are efficient for cutting stainless steel and other metals, while CO2 lasers excel with thicker steel plates.

Common steel types used in laser cutting include:

- Carbon Steel – versatile and cost-effective for structural parts

- Stainless Steel – corrosion-resistant and ideal for precision metal fabrication

- Tool Steel – used for high-strength applications requiring durability

Laser cutting steel offers advantages like narrow kerf width, reduced heat-affected zones, and smooth surface finishes, making it suitable for detailed custom steel parts across various industries.

HYCNC’s Laser Cutting Capabilities

At HYCNC, we specialize in precision laser cut steel using advanced fiber laser cutting and CO2 laser cutting technology. Our equipment handles a variety of steel types, including mild steel, stainless steel, and carbon steel, to meet diverse project needs. We focus on delivering tight tolerances to ensure every cut fits perfectly, typically maintaining precision within ±0.005 inches.

Our process minimizes the heat-affected zone, reducing distortion and preserving material strength. This means smoother edges and less post-processing work for you. We also control steel kerf width carefully, keeping cuts clean with minimal surface roughness.

To fit your project requirements, we offer a range of finishes from raw cuts to polished edges. Every piece undergoes strict quality assurance checks, including dimensional inspection and surface analysis, to guarantee consistency and reliability. Whether you need single custom steel parts or large production runs, HYCNC’s CNC laser cutting service is built to deliver high-quality results every time.

Explore our steel material options like mild steel hot rolled and cold rolled to find what fits your build.

Applications of Laser Cut Steel

Laser cut steel is used across many industries where precision and durability matter. Here’s a quick look at some top applications:

-

Industrial: From machinery parts to heavy equipment frames, laser cut steel ensures clean, accurate cuts that fit perfectly with minimal adjustments. This helps keep production running smoothly.

-

Aerospace and Marine: These industries demand strong, lightweight, and precisely shaped steel components. Laser cutting delivers the tight tolerances and smooth edges needed for safety-critical parts in planes and ships.

-

Custom Projects: Whether it’s architectural designs, art installations, or custom metalwork, laser cut steel lets you create intricate shapes and patterns with consistent quality. It’s perfect for one-off or small batch projects that need that extra edge.

Case Study

A regional construction company needed complex steel brackets for a new commercial building. Using CNC laser cutting, we produced parts that fit perfectly without extra machining. This cut their installation time by 30% and reduced material waste. Projects like this show how laser cut steel brings real value to customers across the US by combining precision and speed.

Benefits of Choosing HYCNC for Laser Cut Steel

When you choose HYCNC for laser cut steel, you’re getting more than just a cut piece of metal. Here’s what sets us apart:

Precision You Can Trust

Our CNC laser cutting technology ensures tight tolerances and clean edges with minimal heat-affected zones. Whether it’s stainless steel cutting or fiber laser cutting on thicker steel, every part meets your specs with high accuracy.

Scalability for Any Project

From small custom steel parts to large industrial orders, we can scale production without sacrificing quality. Our advanced CNC machining handles one-off prototypes and high-volume runs efficiently.

Customization to Fit Your Needs

We work closely with you to deliver exactly what you want. You can choose from various steel types, finishes, kerf widths, and more. Custom shapes, holes, or intricate designs are all possible with our industrial laser cutting.

Sustainability Matters

HYCNC focuses on reducing waste through precise cuts and optimized nesting. Our processes use energy-efficient fiber and CO2 laser cutting to minimize environmental impact while still delivering top-quality results.

Fast Turnaround Times

We know deadlines matter. Our streamlined workflow, from design submission to final production, means you get your laser cut steel parts quickly without compromising quality. We handle everything smoothly, so you don’t have to worry about delays.

Choosing HYCNC means you get reliable service, quality workmanship, and expert support every step of the way. If you want to learn more about the steel types we work with, check out our mild steel options.

How HYCNC Ensures Quality in Laser Cut Steel

At HYCNC, quality is at the heart of everything we do in laser cut steel. We focus on fine-tuning every step to deliver parts that meet tight tolerances and high standards.

Process Optimization

- We continuously refine our CNC laser cutting methods, including fiber laser cutting and CO2 laser cutting, to reduce the heat-affected zone and minimize steel kerf width.

- Our advanced software ensures precise cutting paths, improving surface roughness and accuracy for every batch.

Quality Checks

- Each steel part undergoes thorough inspection, including dimensional checks and visual reviews, to make sure it matches your specs.

- We measure variables like thickness, edge quality, and flatness to keep the finished product consistent and reliable.

Post Processing

- After cutting, we offer various finishing options like deburring and surface treatments to enhance durability and appearance.

- This ensures your custom steel parts are ready for assembly or further machining without compromising integrity.

Certifications

- HYCNC maintains industry certifications that back up our commitment to quality and safety standards.

- These certifications ensure you receive laser cut steel parts that comply with the toughest industrial requirements.

Together, these steps guarantee that every project—whether it’s stainless steel cutting for aerospace or industrial laser cutting for marine applications—is completed with precision and care. For more about the steel types we use, check out our materials like mild steel tube and hot rolled mild steel.

How to Get Started with HYCNC

Getting started with HYCNC for your laser cut steel needs is simple and straightforward. Here’s how we make the process easy from design to delivery:

Design Submission

Send us your design files in common formats like DXF, DWG, or STEP. If you’re unsure about your design or need help optimizing for CNC laser cutting, our team is ready to assist. We also work with custom steel parts and can guide you through design tweaks to improve efficiency and quality.

Quote Process

Once we have your design, we provide a detailed quote quickly. Our pricing is transparent, factoring in materials, steel type (like stainless steel or mild steel), thickness, and the complexity of the cut. We use advanced fiber laser cutting and CO2 laser cutting, ensuring competitive prices without sacrificing precision.

Production

After you approve the quote, we schedule your order for production. Our CNC laser cutting uses the latest technology to deliver consistent quality, keeping kerf width tight and minimizing the heat-affected zone for cleaner cuts. We also offer various finishes and post-processing options to get your parts exactly how you want.

Delivery

We understand the importance of timely delivery. Our efficient workflow means fast turnaround times, and we keep you updated at every step. Whether you need a small batch or large-scale industrial laser cutting, we have the scalability to meet your deadlines.

Ready to start? Visit our website or contact us today to upload your design and get your custom laser cut steel parts underway. For more info on the steel types we work with, check out our mild steel options.

FAQs About Laser Cut Steel

What Steel Types Can You Cut with Laser Cutting

We work with a range of steel types, including mild steel, stainless steel, and carbon steel. Each material responds differently to laser cutting, but our fiber laser cutting and CO2 laser cutting tech handle them all with precision.

What Is the Maximum Thickness for Laser Cut Steel

Our machines can cut steel up to about 1 inch thick, depending on the type of steel. Thicker materials might need other methods, but for most custom steel parts, this thickness covers local manufacturing needs well.

How Does Laser Cutting Compare to Other Methods

Laser cutting offers cleaner cuts, narrower steel kerf width, and less warping from a smaller heat-affected zone compared to traditional plasma or waterjet cutting. It’s great for tight tolerances and smooth surface finishes.

Are There Special Considerations When Cutting Reflective Metals

Reflective metals like stainless steel need special handling to avoid reflectivity issues that can affect cut quality. Our CNC laser cutting setup includes tech to optimize cutting parameters and maintain consistency.

What Are Typical Lead Times for Laser Cut Steel Jobs

Lead times depend on the complexity and size of your order, but we prioritize fast turnaround to keep projects on schedule. Small to medium batches usually ship within a week, helping your project stay on track.

If you have more questions about precision metal fabrication or how we handle your steel cutting needs, reach out—we’re here to help.