Understanding 5-Axis CNC Machining

If you’ve wondered what sets 5-axis CNC machining apart, here’s a simple breakdown. 5-axis CNC machining refers to a process where a cutting tool moves across five different axes simultaneously. This multi-directional movement lets us create complex shapes and detailed parts with high precision.

What is 5-Axis CNC Machining and How It Works

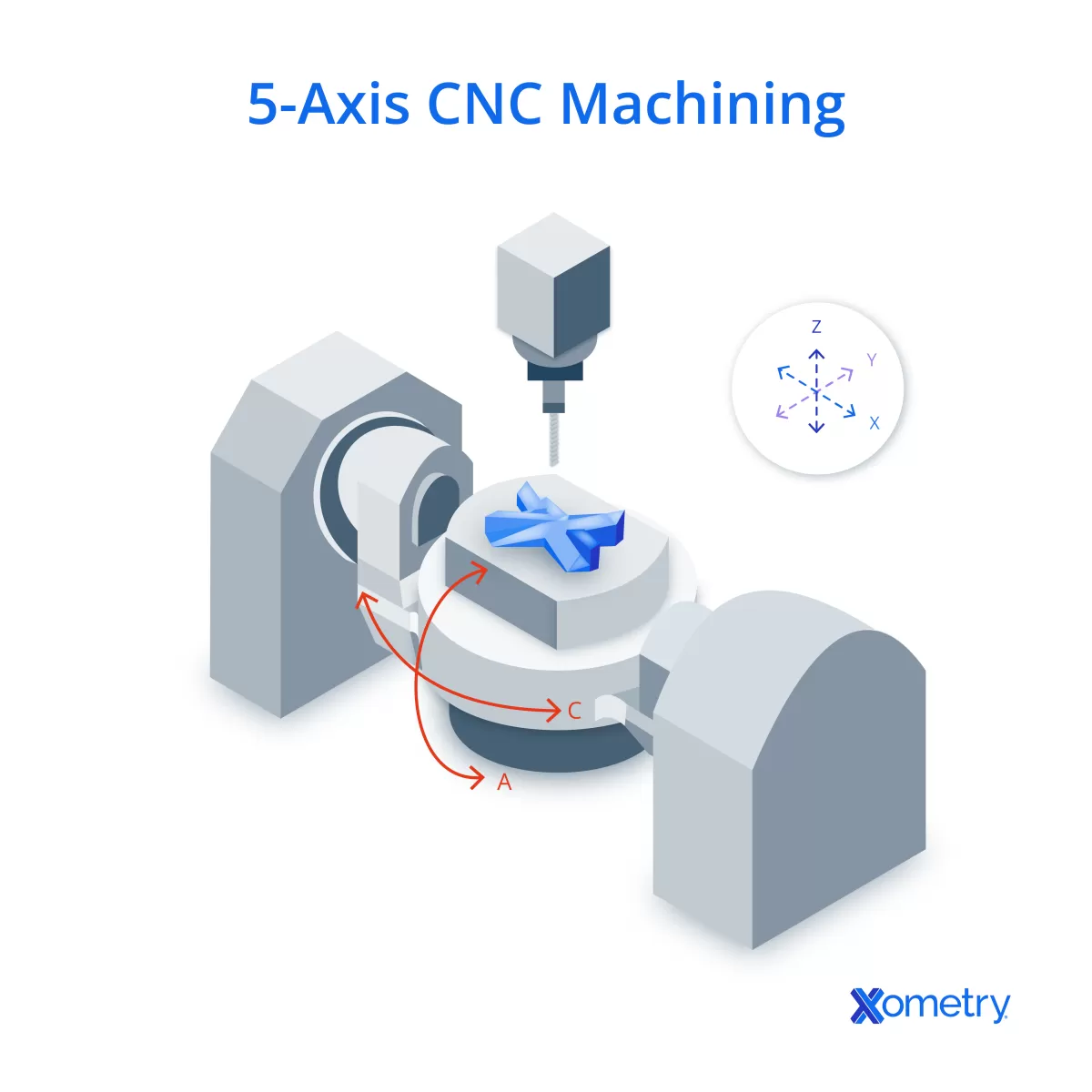

Unlike traditional 3-axis machines that move in X, Y, and Z directions, a 5-axis CNC machine adds rotational movements on two additional axes. This allows the tool or the part to tilt and rotate, giving access to more angles without repositioning the workpiece. The result? Faster, more accurate machining of intricate designs and complex geometry.

Key Components of a 5-Axis CNC Machine

- Rotary Axes: These allow the machine head or table to rotate on two additional axes, typically labeled A and B or A and C.

- Spindle: The part that holds and spins the cutting tool.

- Control System: The computer interface programs and operates the multi-axis movement.

- Worktable: Holds the raw material securely throughout the cutting process.

- Tool Magazine: Holds multiple tools and switches them automatically during jobs.

Types of 5-Axis Machining

- Simultaneous 5-Axis Machining: The most common and advanced method, where all five axes move at once for continuous complex cuts.

- Positional 5-Axis Machining: The machine orients the part in different positions, but only three axes move for cutting at a time.

5-axis capabilities excel in crafting parts that require tight CNC machining tolerances and precise, smooth finishes. It’s key to precision CNC machining for complex parts in aerospace, medical, and automotive industries.

For a deeper dive into precision and advanced machining capabilities, you can explore our precision machining services.

Ready to tackle your most challenging projects? Learn how our CNC machining services can bring your ideas to life with 5-axis technology.

Benefits of 5-Axis CNC Machining

5-axis CNC machining offers several clear advantages that make it a top choice for precision CNC machining.

Enhanced Precision and Accuracy

With the ability to move the tool along five different axes, this process allows for complex geometry machining with tight CNC machining tolerances. This means parts come out more precise, reducing errors and the need for rework.

Reduced Setup Time and Costs

Because the machine can approach the workpiece from multiple angles without repositioning, setup times drop significantly. This leads to faster production cycles and lower labor costs, which is great for keeping projects on budget.

Superior Surface Finishes

Multi-axis CNC milling creates smooth, high-quality surface finishes right off the machine. This cuts down on the need for extra finishing work and improves the overall look and durability of parts.

Versatility Across Materials

Whether you’re working with metals, plastics, or composites, 5-axis CNC machining is up to the task. Its flexibility supports a broad range of materials, making it ideal for custom CNC machining solutions across different industries.

Industries and Applications

5-axis CNC machining serves a wide range of industries thanks to its precision and ability to handle complex geometry machining. Here’s where it really shines:

Aerospace

In aerospace CNC machining, tight tolerances and flawless finishes are critical. 5-axis machines help produce lightweight, durable parts like turbine blades and structural components with high precision. This reduces waste and leads to safer, more efficient aircraft parts.

Medical

Medical CNC machining demands accuracy for devices like implants, surgical instruments, and prosthetics. The multi-axis CNC milling allows for intricate designs and smooth finishes, ensuring parts meet strict quality and safety standards.

Automotive

Automotive CNC machining benefits from 5-axis technology when working on engine components, molds, and custom parts. It speeds up production with fewer setups and maintains tight CNC machining tolerances vital for performance and durability.

Other Sectors

Beyond these, 5-axis CNC machining has applications in defense, electronics, and even art or prototyping. Its versatility lets manufacturers tackle high-precision jobs on metals, plastics, and composites, serving various custom CNC machining needs.

Why Choose HYCNC for 5-Axis CNC Machining

Choosing the right partner for 5-axis CNC machining makes all the difference. At HYCNC, we combine advanced technology with expert skills to deliver reliable, precise results every time.

State-of-the-Art Technology

We use the latest 5-axis CNC machines and software to handle complex geometry machining with high precision. Our equipment ensures tight CNC machining tolerances and consistent quality, no matter how detailed or challenging your project is.

Experienced Team

Our skilled machinists and engineers bring years of experience in aerospace CNC machining, medical CNC machining, automotive CNC machining, and more. They understand the unique demands of each industry and work closely with you to meet your exact specifications.

Fast Turnaround and Competitive Pricing

We know time and cost matter. Our streamlined processes and efficient multi-axis CNC milling capabilities help us deliver your parts quickly without compromising quality. Plus, we offer competitive pricing suited to your budget.

Custom Solutions

Every project is different. HYCNC offers custom CNC machining solutions tailored to your needs, whether it’s a one-off prototype or a large production run. We work with various materials and complex designs to bring your ideas to life.

With HYCNC, you get a trusted partner who focuses on precision, speed, and personalized service to help your business succeed.

How HYCNC Ensures Quality and Efficiency

At HYCNC, we focus on delivering top-notch 5-axis CNC machining services by combining advanced tooling, automation, and strict quality controls. Here’s how we make sure every project meets your expectations:

Advanced Tooling and Automation

- We use the latest multi-axis CNC milling machines equipped with smart automation to boost precision and speed.

- Our cutting-edge tools help handle complex geometry machining with high-precision machining tolerances.

- Automation reduces human error, keeping production consistent and on schedule.

Quality Assurance

- Every part undergoes rigorous inspection using state-of-the-art measuring equipment to ensure it meets exact specifications.

- We follow strict protocols and maintain ISO standards, so you get reliable, repeatable results with every job.

- Our experienced team constantly monitors the production process to catch and fix issues early.

Sustainability and Cost Efficiency

- We optimize material use and machine time to minimize waste without compromising quality.

- Efficient processes mean lower operational costs, which translates into competitive pricing for you.

- Our eco-friendly practices support sustainability goals while keeping turnaround times fast.

Choosing HYCNC means you get precision CNC machining with a strong focus on quality, efficiency, and responsible manufacturing.

Getting Started with HYCNC’s 5 Axis CNC Machining Services

Starting your project with HYCNC is simple and straightforward. Here’s how we make it easy for you:

Request a Quote

Just send us your design files or project specs, and we’ll provide a clear, competitive quote quickly. No surprises, just transparent pricing tailored to your needs.

Collaborate with HYCNC

Our team works closely with you throughout the process. From initial consultation to final delivery, we ensure your product meets the exact standards you expect with our precision CNC machining expertise.

Explore Our Case Studies

Want to see how we’ve helped other businesses? We have a variety of case studies showcasing successful 5 axis CNC machining projects across aerospace, medical, automotive, and more. It’s a great way to understand our capabilities and how we solve complex geometry machining challenges.

Contact Information

Ready to get started or have questions? Reach out to us directly by phone or email. Our local U.S. support team is here to assist you promptly with any inquiries about our custom CNC machining solutions and services.

HYCNC is your go-to partner for high-precision, multi-axis CNC milling that fits your timeline and budget. Let’s build something great together.

Frequently Asked Questions

What is 5-axis CNC machining?

5-axis CNC machining is a process that moves a cutting tool or part in five different directions, allowing for complex shapes and precise cuts in a single setup.

How does 5-axis CNC machining improve accuracy?

It reduces the need for multiple setups, which minimizes errors and ensures tight CNC machining tolerances for high-precision machining.

Which materials can be machined using 5-axis CNC?

Almost any material—metals, plastics, composites—can be machined. This versatility makes it ideal for aerospace, medical, and automotive CNC machining.

What industries benefit most from 5-axis CNC machining?

Aerospace, medical device manufacturing, automotive, and other advanced sectors that require complex geometry machining and precision CNC machining services.

Can HYCNC handle custom CNC machining solutions?

Yes. HYCNC offers tailored multi-axis CNC milling services to meet unique project requirements with fast turnaround and competitive pricing.

How do I get started with HYCNC’s 5-axis CNC machining services?

You can request a quote or contact us directly to discuss your project needs. Visit our CNC machining and precision machining pages for more info.

Have more questions? Reach out to us anytime—our team is ready to help your project succeed.