What is Mild Steel HRPO

Are you wondering what makes Mild Steel HRPO stand out in the world of steel materials? Mild Steel HRPO, or Hot Rolled Pickled and Oiled steel, is a popular type of mild steel widely used in CNC machining and manufacturing.

HRPO Defined

HRPO steel undergoes a hot rolling process where the steel is heated above its recrystallization temperature and passed through rollers to achieve the desired shape and thickness. After hot rolling, the steel is pickled to remove surface scale and impurities through an acid bath. Finally, the steel is coated lightly with oil to protect it against corrosion during storage and transportation.

Benefits of Pickling and Oiling

Pickling produces a clean, smooth surface, improving weldability and paint adhesion.

Oiling provides temporary rust protection, extending the steel’s shelf life and maintaining quality before machining or fabrication.

HRPO Compared to Other Steel Types

Compared to cold-rolled steel, HRPO has a more textured surface but is generally more cost-effective and suitable for large-scale structural parts. Unlike stainless or alloy steels, HRPO offers easier machinability while still offering adequate corrosion resistance when properly maintained. This makes it ideal for a wide range of manufacturing applications, especially where budget and efficiency matter most.

For in-depth details on related steel types, you can explore our resources on mild steel tube and hot rolled mild steel.

If you need a reliable, versatile steel solution for CNC machining, Mild Steel HRPO is a smart choice combining durability, ease of processing, and cost-effectiveness.

Key Properties of Mild Steel HRPO

Mild steel HRPO (Hot Rolled Pickled and Oiled) is known for its balanced physical and chemical properties, making it a top choice for CNC machining steel projects. Here’s a quick look at what makes it stand out:

Physical Properties

- Tensile Strength: Typically around 370-470 MPa, offering good strength for structural parts

- Yield Strength: About 230 MPa, allowing for some flexibility under stress

- Ductility: Good, enabling easy shaping and forming without cracking

- Surface Finish: Smooth and clean due to the pickling and oiling process, which removes mill scale and prevents rust

- Dimensional Accuracy: Consistent thickness and flatness, ideal for precision work

Chemical Properties

- Mainly composed of iron with approximately 0.05% to 0.25% carbon

- Low levels of impurities such as sulfur and phosphorus to enhance machinability

- Contains small amounts of manganese to improve toughness and wear resistance

CNC Machining Advantages

- Easier to Cut: The smooth, scale-free surface reduces tool wear and improves cutting efficiency

- Consistent Quality: Maintains uniform hardness and thickness, leading to repeatable machining results

- Improved Finish: Produces cleaner edges and better dimensional control after CNC processes

Properties Table

| Property | Typical Value | Benefit for CNC Machining |

|---|---|---|

| Tensile Strength | 370-470 MPa | Strong enough for durable parts |

| Yield Strength | ~230 MPa | Flexible but sturdy |

| Carbon Content | 0.05% – 0.25% | Balanced hardness and machinability |

| Surface Finish | Pickled and oiled | Smooth, reduces tool wear |

| Thickness Tolerance | ±0.1 mm | Reliable precision |

These properties make mild steel HRPO a go-to option for precision CNC manufacturing where consistent quality and ease of machining are key.

Applications of Mild Steel HRPO in CNC Machining

Mild steel HRPO is widely used across various industries because of its excellent machinability and cost-effectiveness. You’ll find it in automotive parts, construction, machinery, and even appliances where precision and strength matter. Its corrosion resistance after pickling and oiling makes it a reliable choice for parts exposed to wear and tear.

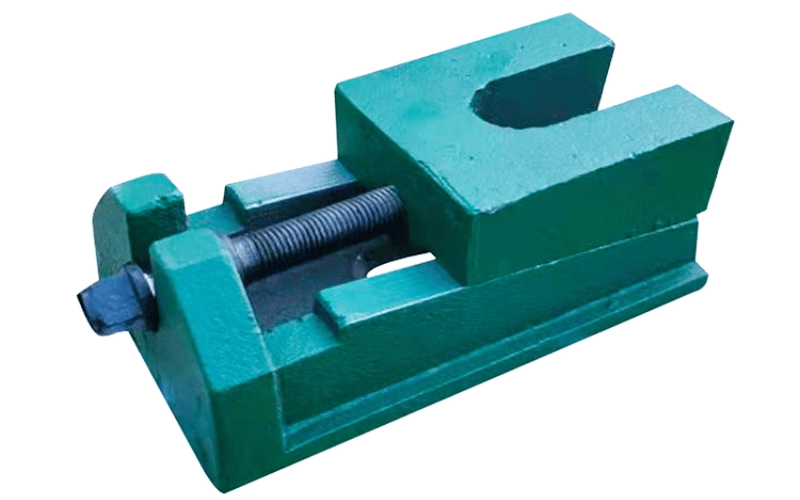

When it comes to CNC machining, mild steel HRPO is perfect for cutting, drilling, milling, and turning. Its consistent thickness and smooth surface help reduce tool wear, which means faster production and less downtime. Components like brackets, frames, gears, and housings are commonly made from HRPO mild steel.

At HYCNC, we specialize in processing HRPO mild steel with advanced CNC technology. Our experienced team handles everything from prototype runs to large-scale machining jobs, ensuring tight tolerances and smooth finishes. Whether you need custom cuts or complex shapes, HYCNC delivers precision and quality that meet local manufacturing demands.

Why Choose HYCNC for HRPO Mild Steel CNC Machining

When it comes to CNC machining HRPO mild steel, HYCNC stands out with advanced CNC technology and deep expertise. We use state-of-the-art machines that deliver precise cuts and consistent results, perfect for the demands of hot rolled pickled steel. Our team knows the specific challenges of machining HRPO steel and tailors processes to get the best finish and performance.

Quality control is a top priority. Every project undergoes strict inspection to ensure your parts meet exact specs, reducing waste and downtime. Plus, we offer customization options to fit your unique manufacturing needs, whether it’s custom dimensions, surface finishes, or batch sizes.

If you’re looking for reliable CNC machining steel services that combine skill, technology, and quality for your HRPO mild steel projects, HYCNC is your local go-to. Reach out today and see how we can bring your designs to life with precision and efficiency.

Benefits of Using Mild Steel HRPO in Manufacturing

Mild steel HRPO is a go-to choice for manufacturers because it offers cost-effectiveness and versatility. It’s more affordable than many other steel types while still delivering reliable strength and flexibility for various projects.

When it comes to CNC machining, HRPO mild steel stands out for its machining efficiency. Thanks to its smooth, pickled surface and consistent thickness, it cuts cleaner and faster, reducing tool wear and saving time on precision steel machining. This means quicker turnaround without compromising on quality.

Plus, products made from mild steel HRPO tend to have longer lifespans because the pickling process removes scale and rust, improving corrosion resistance. That makes it a solid pick for parts that need to hold up over time — especially in industries like automotive, construction, and manufacturing equipment.

Real-world Examples

- Automotive parts like brackets and panels rely on HRPO mild steel for strength and easy CNC processing.

- Industrial machinery uses it for components needing accuracy and durability.

- Fabricated furniture often incorporates HRPO steel due to its smooth finish and paint-ready surface.

If you want a steel that balances price, quality, and performance for CNC machining, mild steel HRPO is a smart choice.

How to Source High-Quality Mild Steel HRPO

Finding reliable suppliers for mild steel HRPO is key to getting the best quality CNC machining steel. Here are some tips to help you source the right material:

- Verify supplier reputation: Look for vendors with positive reviews, certifications, and a proven track record in delivering consistent HRPO mild steel.

- Check material certifications: Always ask for mill test reports or quality certificates to confirm the steel meets industry standards.

- Request samples or test runs: Before bulk orders, test small batches to ensure the steel’s machining properties match your needs.

- Consider local suppliers: Sourcing from U.S.-based companies can reduce lead times, lower shipping costs, and provide better customer support.

At HYCNC, we prioritize quality assurance by carefully selecting steel suppliers who meet strict criteria. Our team inspects all incoming HRPO mild steel for consistency and performance before it reaches our CNC machining floor. This approach ensures you get durable, corrosion-resistant steel ready for precision CNC manufacturing.

For local businesses looking for dependable steel machining solutions, HYCNC offers both material sourcing and expert CNC processing services—all with fast turnaround times and reliable support tailored to the U.S. market.

FAQs About Mild Steel HRPO

Here are answers to some common questions about mild steel HRPO to help you get the details fast and clear.

What does HRPO stand for in mild steel?

HRPO means Hot Rolled Pickled and Oiled. It’s a process where steel is hot rolled, then pickled to remove rust and scale, and finally oiled to prevent corrosion.

Is mild steel HRPO good for CNC machining?

Yes, mild steel HRPO is great for CNC machining because it’s easy to cut, shape, and weld while offering good surface quality after pickling and oiling.

How does HRPO differ from regular hot rolled steel?

Regular hot rolled steel often has surface scale and rust. HRPO’s pickling step removes this, leaving a cleaner surface that improves machining and finishing results.

Can mild steel HRPO resist corrosion?

It’s more corrosion-resistant than untreated hot rolled steel due to the oil layer, but it’s not stainless steel. Additional coatings may be needed for harsh environments.

Where is mild steel HRPO commonly used?

It’s widely used in automotive parts, construction, furniture, and CNC machining projects that require precision and a smooth surface.

How do I choose a supplier for mild steel HRPO?

Look for suppliers offering consistent quality, reliable testing, and customization options. HYCNC’s sourcing standards ensure quality and fast local delivery.

If you want more help with steel or CNC machining materials, check out our detailed guides like our mild steel tube options.

Got more questions? Just reach out—we’re here to simplify your steel and CNC needs.