Initial Purchase Costs

When considering the true cost of owning a laser cutter, the initial purchase price is a big factor. Laser cutters come in different types, each suited for specific materials and applications—and their costs vary widely.

CO2 Laser Cutters are popular for cutting non-metal materials like wood, acrylic, and fabric. They’re affordable for small businesses and hobbyists, typically ranging from $3,000 to $16,000 depending on size and features.

Fiber Laser Cutters specialize in precision metal cutting, ideal for steel, aluminum, and other metals. These machines are more expensive, with prices starting around $25,000 and reaching up to $600,000 for industrial-grade models.

Diode Laser Cutters offer a budget-friendly entry point for beginners or hobbyists working on smaller projects. They usually cost between $500 and $2,000 but are limited in power and material compatibility.

Several factors influence laser cutter prices, including:

- Power and capacity: Higher wattage and bigger cutting areas cost more but improve cutting speed and material capability.

- Brand and quality: Established brands offer reliability and support, often at a premium price.

- Automation and features: Options like autofocus, rotary attachments, and advanced software add to the cost but boost efficiency and versatility.

Understanding these elements helps you weigh upfront costs against your project needs and long-term goals.

Hidden Operational Costs

Owning a laser cutter means more than just the upfront price—you also need to consider hidden operational costs that add up over time.

Electricity Usage

Laser cutters, especially CO2 models, can cost between $1 and $3 per hour to run, depending on their power and how efficient they are. Fiber lasers usually use less electricity, making them cheaper to operate in that respect. The more powerful your machine, the higher the electricity bill, so it’s important to factor that in based on your workload.

Material Costs and Waste

Materials like wood, acrylic, and metals aren’t cheap. Plus, inefficient nesting—the way parts are arranged on the material—can lead to 10%–50% waste. This lost material is money down the drain. Optimizing layouts can save a good chunk here.

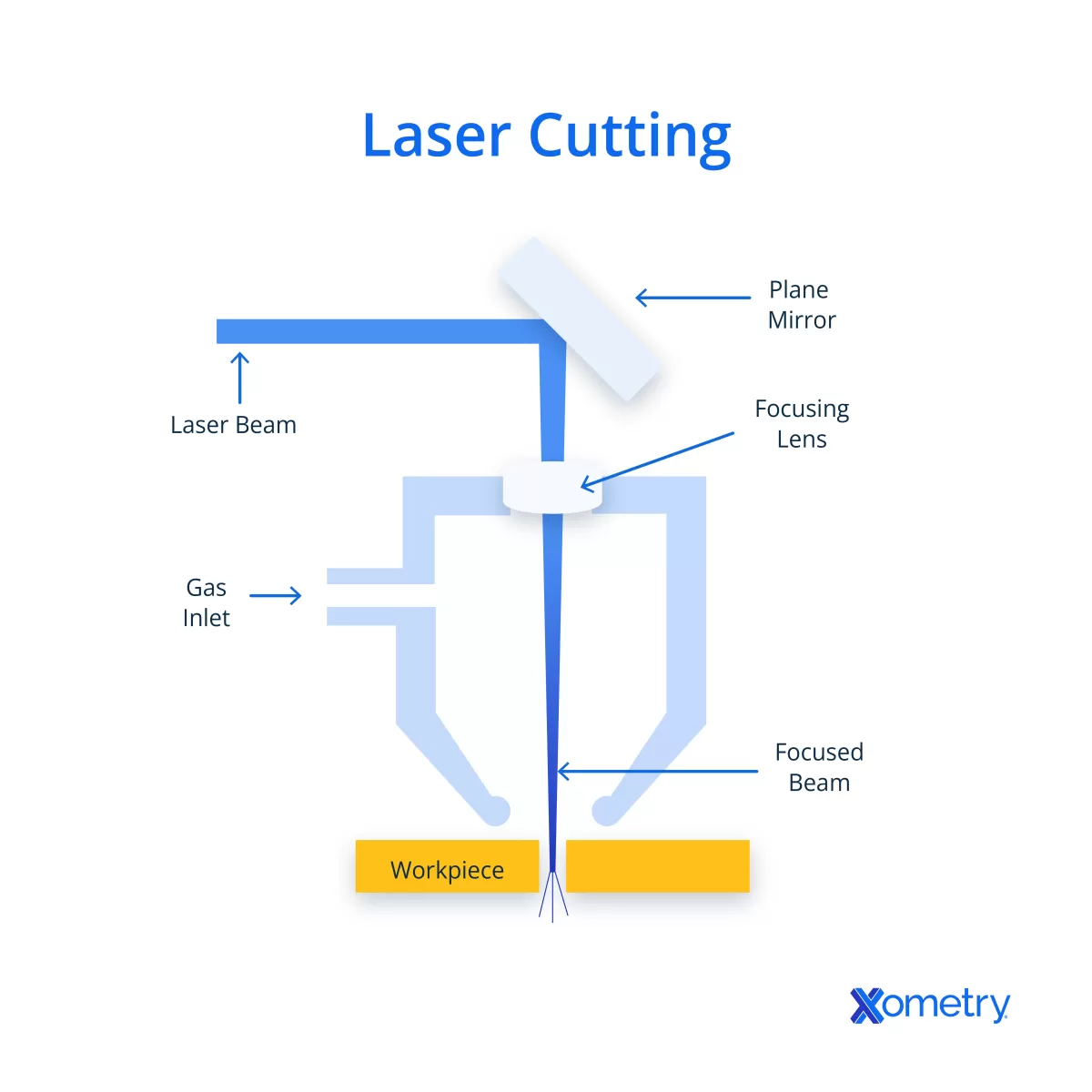

Assist Gases

Many laser cutters use assist gases like oxygen or nitrogen to improve cutting speed and quality. Oxygen is generally less expensive but works best with steel, while nitrogen is pricier and often used for cleaner cuts or different metals. Gas consumption varies by machine and project, so these costs can add up quickly and impact your budget.

Understanding these hidden costs helps paint a clearer picture of what it truly takes to run a laser cutter daily and keep your projects profitable. For detailed material specifics on metals, check out our resources on laser cut steel and laser cut aluminum.

Maintenance and Upkeep Expenses

Owning a laser cutter means regular maintenance to keep it running smoothly. Daily tasks often include checking and aligning the lens and nozzle to ensure clean, accurate cuts. Protective lens covers, which cost around $10 to $20 each, help avoid damage and save you money on replacements in the long run.

You’ll also need scrap bins and a dust collection system to manage leftover materials and keep the workspace clean. Replacement parts like sacrificial slats and nozzles typically cost about $1 to $1.50 per pound, depending on usage.

Another key factor is the laser tube, which has a lifespan ranging from 2,000 to 30,000 hours based on the type and maintenance. Replacing or servicing the tube is one of the bigger expenses, so tracking hours is important.

On average, annual maintenance costs run between 5% and 10% of your machine’s purchase price. Staying on top of preventive maintenance not only avoids costly repairs but also extends the life of your laser cutter, making it a wise investment for long-term savings.

Additional Investment Considerations

When owning a laser cutter, it’s not just the machine cost you should think about. Space and storage requirements are major factors. Larger machines need plenty of floor space, so you’ll want to plan for that ahead of time. Plus, you’ll need room to store raw materials like wood, acrylic, or metal safely and accessibly.

Training is another essential expense. The learning curve varies by machine type, but initial operator training costs can add up, especially if you’re new to laser cutting. Don’t forget ongoing skill development — keeping up with software updates and new techniques helps you get the most out of your investment.

Safety and ventilation are a must. Proper fume extraction systems are key to maintain a safe work environment and meet local safety standards. This keeps harmful fumes away from you and your workspace and ensures you stay compliant with regulations.

In short, budgeting for these additional investments is critical when considering the true cost of owning a laser cutter.

Time and Productivity Factors

Owning a laser cutter means faster results and more control over your projects. You can quickly produce prototypes and parts without waiting on outside vendors, which speeds up your entire workflow. This rapid turnaround is a big plus if you need to meet tight deadlines or make last-minute design tweaks.

Having your own machine also means better control over production quality. You can monitor every step and adjust settings on the fly to get exactly what you want, which is harder when outsourcing.

Keep in mind, though, owning a laser cutter does take some time investment. Setting up the machine, programming cuts, and regular operation require skill and focus, especially at the start.

When comparing in-house cutting vs outsourcing, consider:

- In-house: More control, faster turnaround, potentially lower cost long term, but requires upfront investment and ongoing time for operation and maintenance.

- Outsourcing: No machine maintenance or training needed, no upfront costs, access to expert services and advanced tech, but longer lead times and less control over quality.

Balancing these factors is key to deciding if owning a laser cutter fits your business needs and production goals.

ROI and Long-Term Value

When considering the true cost of owning a laser cutter, it’s important to look beyond the upfront price. The total cost of ownership (TCO) helps you understand what you’ll actually spend over time. Here’s a simple way to calculate it:

TCO = Initial Purchase Cost + (Annual Operating Costs × Number of Years) + Maintenance + Training – Resale Value

This formula covers everything from power bills and material costs to regular upkeep and eventual resale.

Owning a laser cutter makes the most sense if you’re handling high-volume production. Over time, the savings on each cut add up, lowering your per-part costs and giving you greater control over quality and turnaround times.

Still unsure whether to buy? Using HYCNC’s CNC processing services can save you money if your needs are occasional or if you want access to advanced machines without the hassle of ownership. They can handle everything from laser cutting steel to aluminum with precision, helping you focus on your business instead of machine management.

For more detailed info on materials, check out HYCNC’s pages on laser cut steel and laser cut aluminum.

Owning vs Outsourcing A Cost Comparison

When deciding between owning a laser cutter or outsourcing your laser cutting needs, it’s important to weigh the costs and benefits carefully.

Benefits of Owning a Laser Cutter

- Full Control and Flexibility: Having your own laser cutter means you can run jobs anytime without waiting on a third party. You control speed, quality, and scheduling.

- Lower Per-Part Costs Over Time: While the initial purchase and maintenance costs add up, the cost per piece usually drops significantly if you’re cutting frequently or in high volumes.

- Customization and Quick Changes: Make quick adjustments on the fly without extra fees or delays, which is great for prototyping or varied production runs.

Advantages of Outsourcing to HYCNC

- No Upfront Investment: Outsourcing laser cutting means no large equipment purchase or maintenance expenses. You simply pay per job.

- Access to Advanced Technology and Expertise: Providers like HYCNC use high-end CO2 and fiber laser cutters with experienced operators, ensuring precision and quality that might be costly to match on your own.

- Reduced Operational Hassles: No need to worry about electricity, repairs, or training—HYCNC handles it all.

When to Buy vs When to Outsource

| Scenario | Buy a Laser Cutter | Outsource to HYCNC |

|---|---|---|

| You have high volume or frequent use | Yes, to save on long-term costs | No, ownership makes more sense |

| You need fast turnaround and control | Yes, immediate access to machine | No, may cause delays waiting on |

| Limited budget or infrequent jobs | No, upfront and maintenance costs | Yes, pay only when needed |

| Require specialized metals cutting | Maybe, if running consistent steel or aluminum jobs (see laser cut steel and laser cut aluminum) | Yes, for occasional or complex materials |

In , if you’re a heavy user aiming for long-term savings and flexibility, owning a laser cutter makes financial sense. For smaller shops, hobbyists, or those needing specialized parts without the hassle of maintenance, outsourcing to HYCNC is often more cost-effective and less risky.

FAQs About the True Cost of Owning a Laser Cutter

How much does a laser cutter cost upfront

Laser cutter purchase prices vary by type. You can expect to pay around $500 to $2,000 for a diode laser cutter (great for beginners), $3,000 to $16,000 for a CO2 laser cutter (perfect for wood, acrylic, and other non-metals), and $25,000 up to $600,000 for fiber laser cutters designed for precision metal work.

What are the ongoing costs of running a laser cutter

Operating costs include electricity (about $1 to $3 per hour for CO2 models, less for fiber), materials like wood, acrylic, or metal, assist gases (oxygen and nitrogen), and maintenance parts such as lenses, nozzles, and laser tubes. Don’t forget the time spent on upkeep, daily cleaning, and occasional part replacements.

How long does a laser cutter last

Laser cutter lifespans vary. For example, CO2 laser tubes generally last between 2,000 and 30,000 hours depending on quality and care. Regular maintenance can extend the life and keep the machine running smoothly.

Is it cheaper to outsource laser cutting to HYCNC

Outsourcing to HYCNC can be cost-effective if you don’t want to handle upfront costs, maintenance, or training. They offer advanced CNC machining and laser services with professional expertise, which can save you money if your needs are occasional or if you want to avoid the hassle of owning and maintaining your own laser cutter.

What materials can a laser cutter process

Laser cutters can handle a wide range, including wood, acrylic, fabric, leather, paper, and various metals (mainly with fiber lasers). CO2 lasers excel with non-metals, while fiber lasers are best for cutting and engraving metals. Diode lasers work well for thin materials and beginner projects.