What is G Code

G code is a programming language used in CNC machining to control the movement of tools and the path they follow. Essentially, it tells the machine exactly where to move, how fast to go, and what path to take. This makes G code the backbone of toolpath control in precision manufacturing.

Some common G code commands include:

- G00 – Rapid positioning, which moves the tool quickly to a specified location

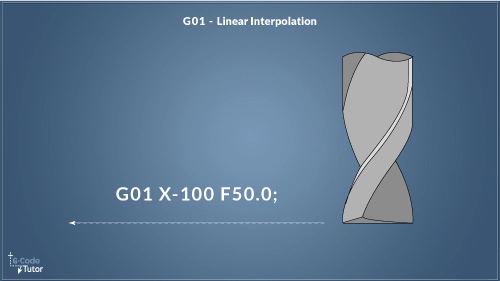

- G01 – Linear interpolation for precise, straight-line cutting at a set feed rate

- G02 and G03 – Circular interpolation commands for clockwise and counterclockwise arcs

These standardized commands help ensure consistency and accuracy across different CNC machines. While there are some variations between systems, G codes remain largely universal, playing a crucial role in achieving the exact movements required for high-quality machining and repeatable results.

What is M Code

M code is used to control machine operations that don’t involve moving the tool or workpiece. Think of it as the commands that handle the machine’s auxiliary functions—things like starting or stopping the spindle, turning coolant on or off, and other machine actions that support the cutting process.

Some common M code examples include:

- M03 – Start the spindle turning clockwise

- M04 – Start the spindle turning counterclockwise

- M05 – Stop the spindle

- M08 – Turn coolant on

- M09 – Turn coolant off

Unlike G codes, M codes can vary quite a bit between different CNC machines and manufacturers. Each machine might have its own set of M codes or use certain codes differently, so it’s important to check the machine’s manual or programming guide before writing or editing M code commands.

Key Differences Between G Code and M Code

When it comes to CNC programming, understanding the difference between G code and M code is crucial.

Purpose

G Code controls the geometry of the part—how the tool moves, where it goes, and what path it follows. Think of it as the code that directs the toolpath and cutting actions.

M Code handles the machine’s auxiliary functions, like turning the spindle on or off, controlling coolant, and managing tool changes.

Standardization

G Codes are mostly universal across different CNC machines, meaning the same G code command will work similarly on most machines.

M Codes tend to vary from one machine or manufacturer to another, as these codes control machine-specific functions.

Functionality

G Code focuses on cutting and positioning the tool precisely where it needs to be.

M Code deals with auxiliary controls that support the machining process but don’t move the tool directly.

Interdependence

G codes and M codes aren’t standalone—they work together closely. For example, a G01 code might direct the tool to cut in a straight line, while an M08 code will turn the coolant on during that cut to protect the tool and workpiece. Both are essential for efficient and accurate CNC machining.

| Feature | G Code | M Code |

|---|---|---|

| Purpose | Controls tool movement & path | Controls machine functions |

| Standardization | Universal across machines | Machine/manufacturer-specific |

| Functionality | Cutting and positioning | Spindle control, coolant, etc. |

| Role in Programming | Directs geometry and toolpath | Manages machine operations |

Understanding these differences helps in writing effective CNC programs that maximize precision and efficiency in manufacturing.

How G Code and M Code Work Together

G code and M code are like a team in CNC machining—each handles different jobs, but together they keep the machine running smoothly. G code focuses on controlling the toolpath, moving the cutting tool precisely where it needs to go. Meanwhile, M code manages the machine’s functions, like turning the spindle on or off, or switching coolant on.

For example, in a common workflow, G01 tells the machine to move the tool in a straight line for cutting, while M08 turns on the coolant to keep the tool cool and improve the cut quality. Without both codes working together, you either get movement with no machine support or machine functions without proper tool control.

Accurate coding is key to making sure parts are manufactured right the first time. Mistakes in G code can cause dimensional errors, and wrong M code commands might harm the machine or ruin the workpiece.

At HYCNC, we use advanced CAD/CAM software to create and verify both G and M codes. This approach automates programming, reduces errors, and ensures that every job meets strict quality standards. By integrating toolpath control with machine operations through precise coding, we optimize both efficiency and precision for our United States customers.

Practical Applications in CNC Manufacturing

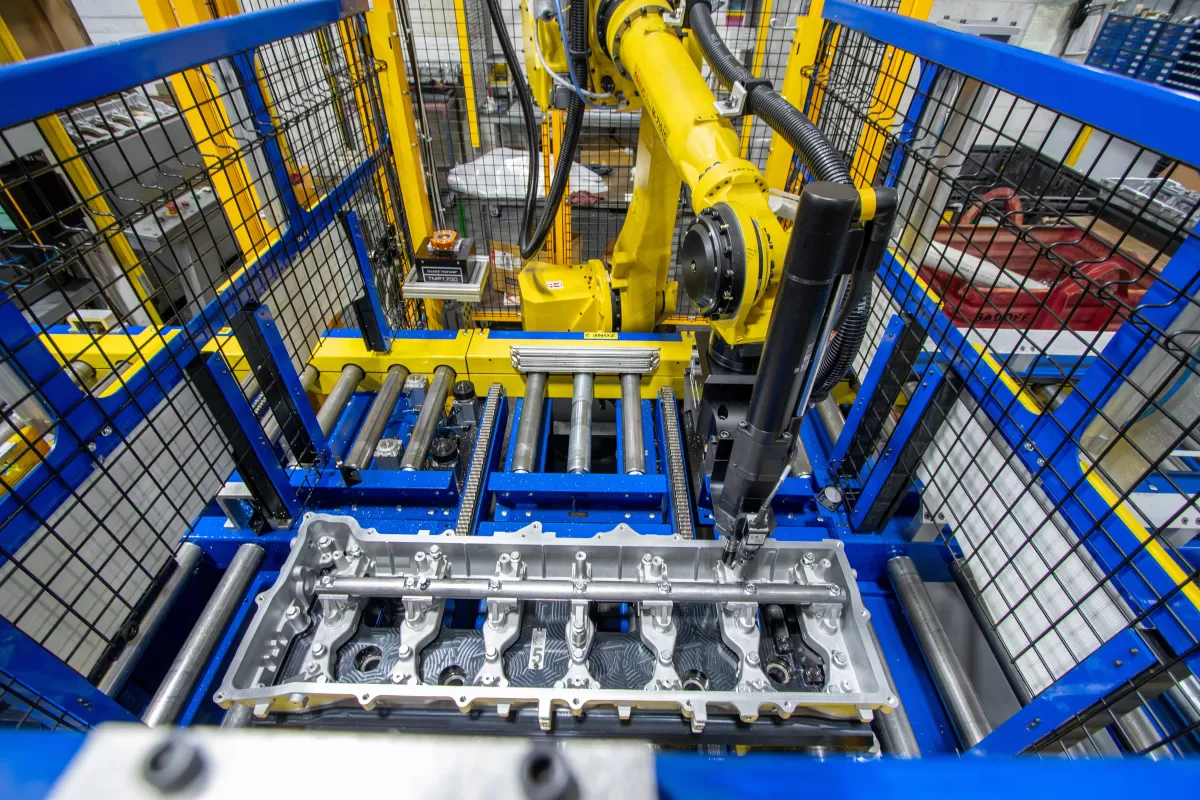

G code and M code are essential in many industries across the U.S., including aerospace, automotive, medical, and consumer goods manufacturing. These codes make it possible to control complex machining processes with high precision, whether it’s milling, drilling, turning, or managing tool changes and coolant flow.

Here are some common use cases:

- Milling and Drilling: G codes guide the cutting paths to shape parts, while M codes handle spindle speed and coolant to keep tools running smoothly.

- Turning: G codes control the rotation and tool movement on lathes, with M codes managing machine actions like tool changes or stopping the spindle.

- Tool Changes: M codes automate tool swaps, making production faster and reducing downtime.

- Coolant Management: M codes turn coolant on and off at precise times to protect tools and improve finish quality.

At HYCNC, we focus on optimizing these processes through customized CNC programming and CAD/CAM software integration. This approach ensures precise control for every job while maximizing efficiency and minimizing errors. Our expertise helps local manufacturers achieve the high-quality standards demanded by today’s market.

To learn more about efficient manufacturing strategies, you can check out our insights on sheet metal manufacturing and design improvements with Design for Manufacturing and Assembly.

Common Challenges and Tips for Using G and M Codes

When working with G code and M code in CNC machining, there are a few common challenges that can slow down your workflow or cause costly mistakes.

Challenges:

- Errors in G code: Mistakes in movement commands can lead to dimensional inaccuracies or tool crashes.

- M code compatibility: Since M codes vary by machine brand and model, using the wrong M code can cause unexpected machine behavior.

- Complex coding: Mixing G and M codes requires precision—incorrect sequences can stop the machine or ruin your part.

Tips to avoid problems:

- Always double-check your toolpaths before sending programs to the machine.

- Refer to the machine’s manual to confirm the right M codes.

- Use simulation software to catch errors early and visualize your machining process.

- Start with simple programs and gradually add complexity as you gain confidence.

For many shops, partnering with CNC programming experts can save time and ensure your G and M codes are spot-on. At HYCNC, we combine industry know-how with advanced CAD/CAM software to deliver optimized, error-free CNC programs for local businesses across the U.S.

If you’re curious about simplifying your CNC manufacturing process, check out our guide on sheet metal manufacturing for more practical tips.

The Role of CAD CAM Software in Simplifying G and M Code Programming

Gone are the days when CNC programming meant manually writing long strings of G code and M code—now, CAD CAM software takes on that heavy lifting. Instead of punching in commands line by line, these tools automate the process, transforming your digital design into precise machine instructions quickly and reliably.

Using software like Mastercam or Fusion 360, we at HYCNC can create optimized toolpaths that include both G code for movement and M code for machine functions—all generated with minimal errors. This automation speeds up programming, reduces costly mistakes, and ensures consistent quality in CNC machining.

For local manufacturers in the US, this means faster turnaround times and higher precision parts without the usual headaches of manual coding. If you want to see how design optimization works hand in hand with manufacturing, check out our guide on design for manufacturing and assembly that explains how smart CAD CAM use improves sheet metal fabrication.