Are you struggling to streamline your sheet metal fabrication process? Applying Design for Manufacturing and Assembly (DFMA) can transform your designs, slashing costs and boosting efficiency.

As a leader in CNC sheet metal processing, HYCNC understands the challenges of creating parts that are both functional and cost-effective. With years of industry expertise, we’re here to share proven strategies that go beyond the basics.

In this guide, you’ll discover how DFMA principles simplify sheet metal design, optimize CNC fabrication, and ensure seamless assembly. Whether you’re an engineer or manufacturer, these actionable insights will elevate your projects.

Ready to save time and money? Let’s dive in!

Understanding DFMA in Sheet Metal Fabrication

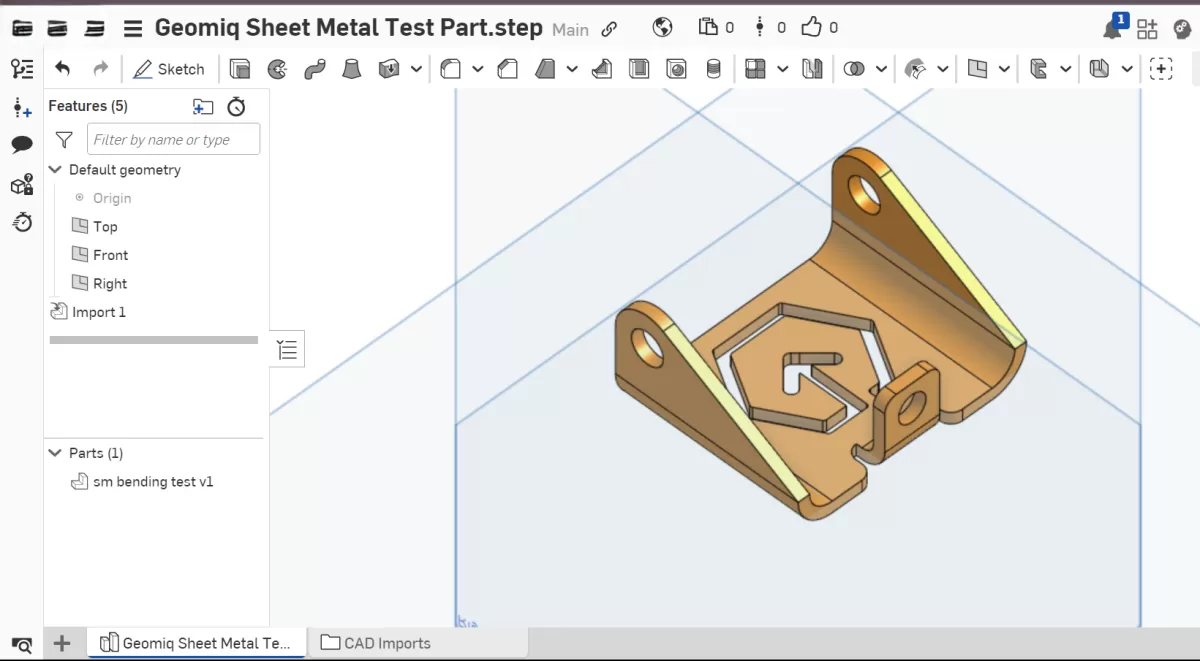

Design for Manufacturing and Assembly (DFMA) is all about creating products that are easier and more cost-effective to make and put together. In sheet metal fabrication, DFMA focuses on designing parts that simplify cutting, bending, and assembling processes without sacrificing quality or performance.

Core Principles of DFMA

At its core, DFMA aims to reduce complexity, minimize the number of parts, and make each component easier to produce and assemble. This includes using standard materials, avoiding unnecessary features, and designing parts that fit together smoothly. The result is less time spent on manufacturing and assembly, which saves money and improves reliability.

Why DFMA Matters for Sheet Metal

Sheet metal fabrication can be tricky with tight tolerances, complex bends, and assembly challenges. Applying DFMA helps avoid common pitfalls like difficult welds, excessive fasteners, or costly custom tooling. By focusing on ease of manufacturing and assembly from the start, companies can reduce errors, speed up production, and boost product quality.

Industry Applications

DFMA principles are widely used across industries like automotive, aerospace, electronics, and construction, where precision sheet metal design and CNC sheet metal processing are critical. These sectors benefit from faster turnaround, lower costs, and consistent quality that DFMA-driven fabrication delivers. Whether it’s a simple bracket or a complex enclosure, designing with DFMA in mind makes a big difference.

Key DFMA Strategies for Easier Sheet Metal Fabrication

Using design for manufacturing and assembly (DFMA) in sheet metal fabrication starts with smart strategies that save time and cut costs. Here’s how to make your process smoother and more efficient:

Material Selection for Cost and Functionality

- Choose materials that balance price and performance. Common options like steel, aluminum, and stainless steel offer good durability without breaking the budget.

- Avoid exotic or specialty metals unless absolutely necessary—they increase costs and processing time.

- Think about material thickness early to reduce waste and simplify bending or cutting.

Simplifying Part Design

- Keep designs straightforward with fewer bends, holes, and complex features.

- Use standard shapes and sizes whenever possible to speed up fabrication.

- Minimize the number of separate parts—fewer components mean easier manufacturing and assembly.

Optimizing for CNC Processes

- Design parts that work well with CNC sheet metal processing, like laser cutting and bending.

- Avoid tight internal corners or features that require special tools, which can slow production.

- Plan for smooth tool paths to reduce machining time.

Incorporating Tolerances

- Set realistic tolerances that don’t require expensive precision unless your application demands it.

- Looser tolerances cut costs and improve yield, but be sure they fit your product’s function.

- Communicate tolerance needs clearly to avoid manufacturing errors and rework.

Enhancing Assembly Efficiency

- Design parts to fit together easily, with clear alignment features or snaps.

- Reduce fasteners by using tabs and slots or welding where practical.

- Think about how parts will be accessed during assembly to reduce labor time.

Applying these DFMA principles makes sheet metal fabrication less complicated and more cost-effective. It ensures your designs work well on CNC machines, are easy to build, and keep your production on schedule.

HYCNC’s Role in DFMA-Driven Sheet Metal Fabrication

When it comes to using design for manufacturing and assembly for easier sheet metal fabrication, HYCNC plays a key role. Their advanced CNC capabilities ensure precision sheet metal design with tight tolerances, helping to reduce errors and material waste. Whether it’s laser cutting optimization or sheet metal bending, their machinery handles complex tasks smoothly, speeding up production without sacrificing quality.

HYCNC also offers collaborative design support. They work closely with your design team to review CAD files for manufacturability and assembly efficiency. This proactive approach means potential issues get caught early, and your design is optimized for cost-effective sheet metal production from the start.

The result? Significant cost and time savings. With HYCNC, you avoid delays caused by redesigns or tooling problems. Their efficient CNC sheet metal processing streamlines your project timeline, making your manufacturing workflow simpler and more predictable.

Practical Tips for Implementing DFMA with HYCNC

When you’re working on sheet metal fabrication, using Design for Manufacturing and Assembly (DFMA) can save you time and money. Here’s how you can make the most of DFMA with HYCNC’s CNC sheet metal processing services.

Use CAD Software with DFM Tools

Start with the right CAD software that includes DFM (Design for Manufacturing) tools. These tools help spot manufacturing issues early, like difficult bends or tight tolerances that could drive up costs. With HYCNC, you can upload your precision sheet metal designs and get feedback to optimize for laser cutting and bending right away.

Avoid Common Design Mistakes

Keep your sheet metal parts simple and practical to avoid headaches later. Some common slip-ups to watch for:

- Overcomplicated geometry that slows CNC machining

- Neglecting standard sheet metal bending guidelines

- Using unnecessary small features that create extra processing steps

- Ignoring material selection, causing higher fabrication costs

By sidestepping these mistakes, your parts will be easier to produce and assemble, cutting turnaround time.

Leverage HYCNC’s Expertise

HYCNC isn’t just about running CNC machines—they work with you throughout the design process. Take advantage of their collaborative design support to refine your sheet metal fabrication plans with DFMA in mind. This hands-on partnership helps ensure your parts are optimized for both manufacturing and assembly, reducing waste and boosting efficiency.

Following these tips with HYCNC can streamline your project from design to finished product, making sheet metal fabrication smoother and more cost-effective.

Case Study HYCNC’s DFMA Success in Action

At HYCNC, we put Design for Manufacturing and Assembly (DFMA) into practice every day to make sheet metal fabrication smoother and more cost-effective. Recently, we worked with a client needing custom sheet metal brackets that required precision and quick turnaround.

Real-World Example

The client came with a complex design that traditionally would take longer to produce and cost more due to multiple bending and welding steps. By applying DFMA principles, we simplified their design to reduce the number of parts and assembly steps. We optimized material choice and adjusted features to fit our CNC sheet metal processing capabilities perfectly.

Results

- Production time cut by 30% thanks to fewer complex bends and easier assembly

- Material waste reduced by 20% through smarter sheet layout and material selection

- Lower overall costs without sacrificing strength or quality

- Improved product reliability with tighter tolerances and better fit

- Streamlined assembly, making it easier for the client’s team to put parts together

This project highlights how using DFMA strategies with HYCNC’s advanced CNC capabilities leads to faster, cleaner, and more affordable sheet metal fabrication. For more on sheet metal design improvements, check out our sheet metal bracket guide.