Understanding CNC Milling and 3D Printing

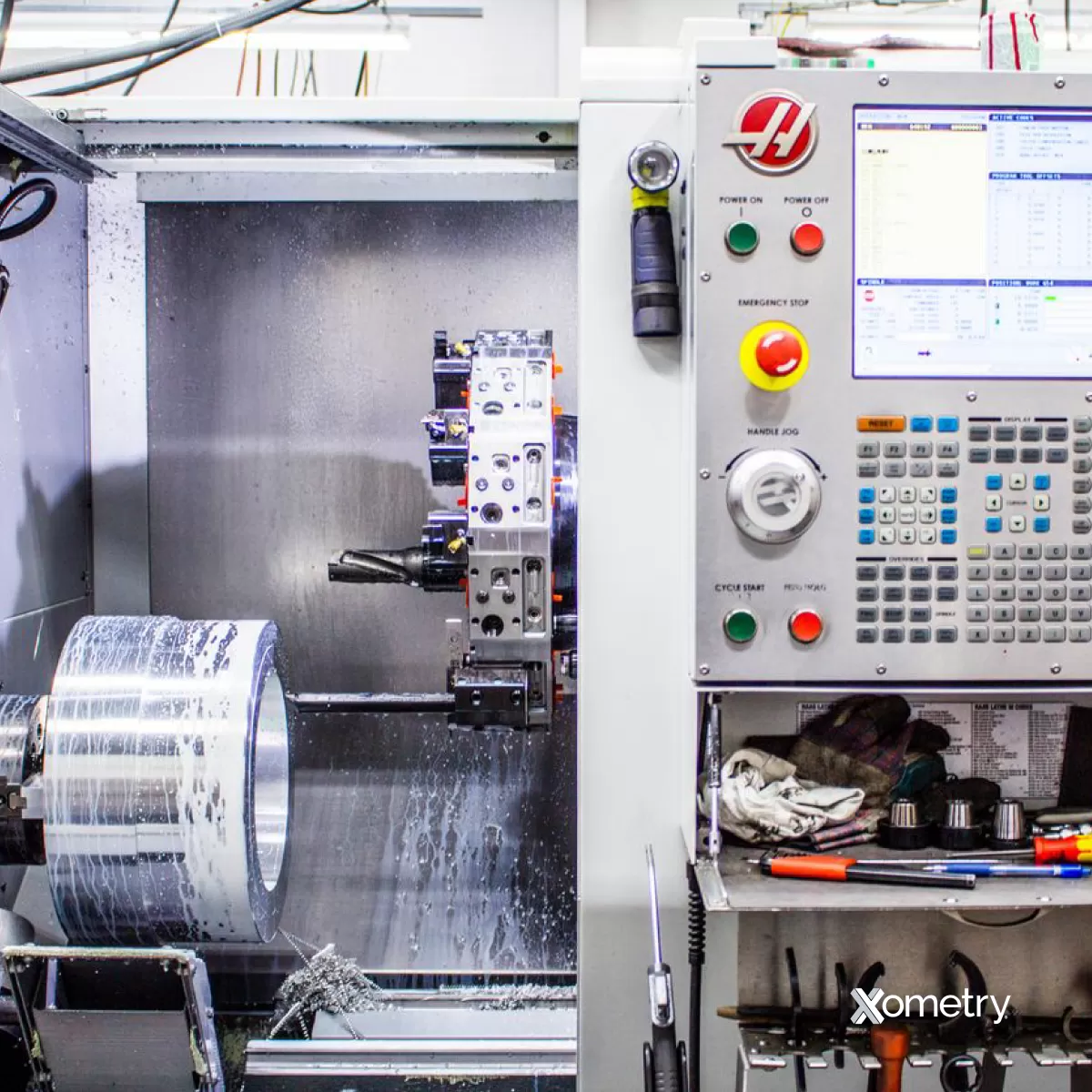

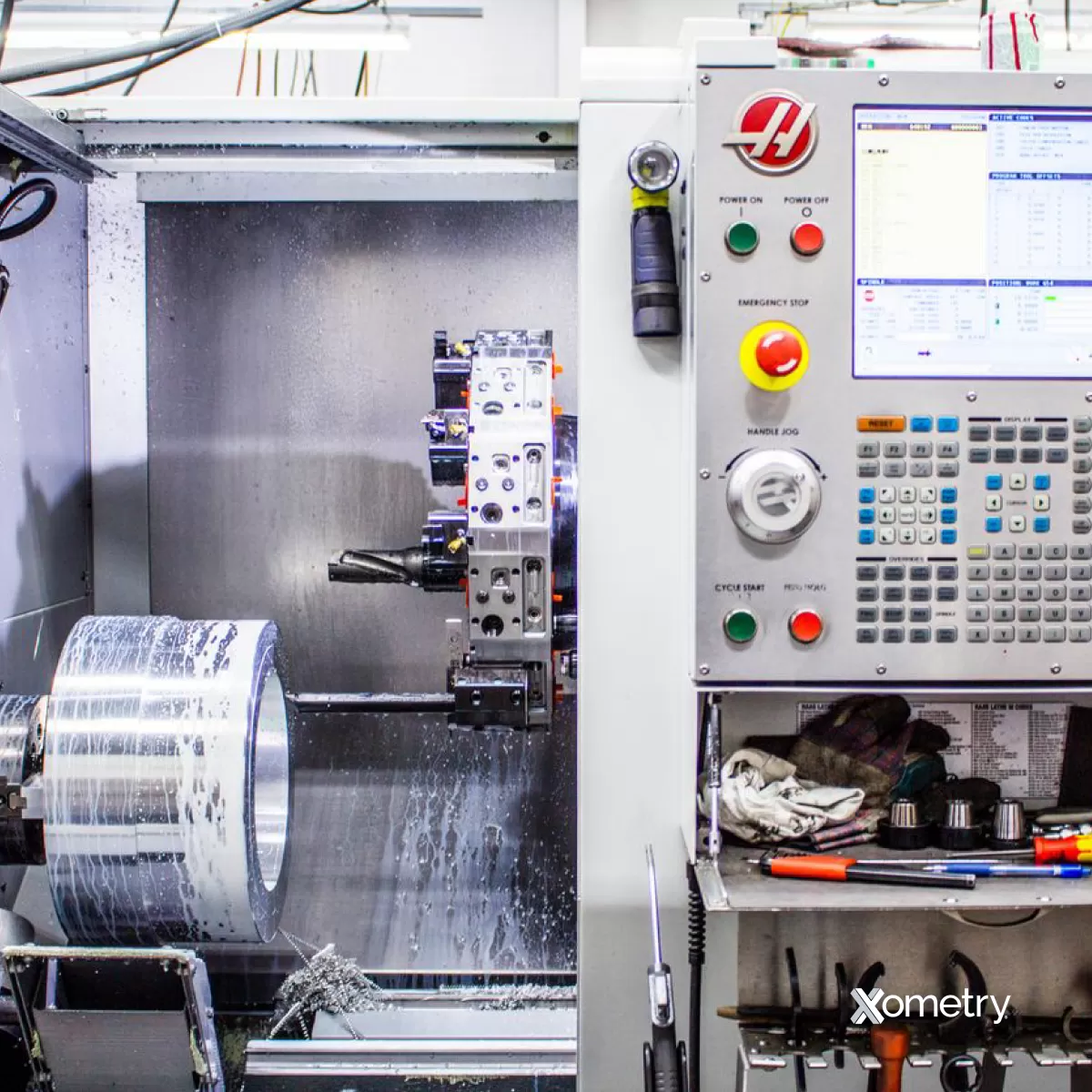

What is CNC Milling

CNC milling is a subtractive manufacturing process where computer-controlled machines remove material from a solid block, typically metal or plastic, to create a precise part. This method is known for its high accuracy and ability to produce parts with tight tolerances. CNC machining is widely used in industries requiring precision machining, such as aerospace, automotive, and medical devices. The process involves spinning cutting tools that carve out the desired shape based on a pre-programmed design.

What is 3D Printing

3D printing, or additive manufacturing, builds parts layer by layer from materials like plastics, resins, or metals. Unlike CNC milling, 3D printing adds material instead of cutting it away, allowing for complex geometries that are difficult or impossible to achieve with subtractive methods. This makes it a popular choice for rapid prototyping and low-volume manufacturing where flexibility and customization are important. Common 3D printing technologies include FDM, SLA, and SLS.

Low-Volume Production Context

Low-volume production typically refers to manufacturing runs ranging from a single prototype to a few hundred parts. In this context, speed, cost, and flexibility are critical. Both CNC milling and 3D printing serve low-volume manufacturing but have different strengths. CNC milling excels in delivering strong, precise parts with excellent surface finishes, while 3D printing offers quick turnaround and complex shape capabilities. Understanding these differences helps businesses pick the right approach to optimize production costs and timelines. For more on designing parts for CNC milling in low volumes, check out our guide on design tips for CNC milled low volume parts.

Key Differences Between CNC Milling and 3D Printing

When comparing CNC milling vs 3D printing in low-volume production, several key differences stand out. Understanding these can help you decide which method fits your project best.

Process Type

- CNC Milling is a subtractive manufacturing process. It starts with a solid block of material and removes layers with precision cutting tools to shape the part.

- 3D Printing is additive manufacturing. It builds parts layer by layer by adding material, typically using plastic, resin, or metal powders.

Precision and Tolerances

- CNC machining offers high precision and tight tolerances, often within thousandths of an inch. It’s great for parts that require exact dimensions and smooth, functional surfaces.

- 3D printing can achieve good precision, especially with advanced technologies, but generally has looser tolerances and may need post-processing for fine details.

Material Options

- CNC milling supports a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites.

- 3D printing materials are more limited, mostly focused on certain plastics, resins, and some metal powders. Material strength and finish can also vary more than CNC.

Surface Finish

- CNC parts come with a superior surface finish straight off the machine, which means less sanding or polishing.

- 3D printed parts often have a rougher finish due to the layering process and usually require additional finishing steps.

Complexity and Geometry

- 3D printing can handle complex geometries and internal features that CNC milling cannot, like intricate lattice structures or hollow cavities.

- CNC is better suited for more traditional shapes but struggles with extreme undercuts or internal passages.

Speed and Lead Time

- For simple parts, CNC milling can be faster to set up and produce when factoring in finishing needs. However, complex parts may take longer.

- 3D printing offers rapid prototyping speed without tooling, making it quick to turnaround complex designs in low-volume runs.

For a deeper dive into CNC milling part design and how it affects manufacturing, you can check out this guide. Also, to better understand how CNC milling compares with other processes, here’s a helpful read on CNC prototyping vs 3D printing.

Cost Analysis for Low-Volume Production

When it comes to low-volume manufacturing, keeping costs in check is crucial. Here’s a quick breakdown of how CNC milling and 3D printing stack up:

Setup Costs

CNC milling often comes with higher setup costs because machines need programming and tooling for each job. On the other hand, 3D printing usually has minimal setup since it builds parts layer by layer without special tooling. This can make 3D printing a better choice if you only need a few pieces.

Per-Unit Costs

Per-unit costs for CNC machining tend to be higher for small runs due to longer setup and slower speeds for complex parts. 3D printing reduces per-unit cost as no additional tooling is needed, making it cost-effective for very low volumes or prototypes.

Material Waste

CNC machining is subtractive, meaning it cuts away material, which can lead to noticeable waste depending on the part design. In contrast, 3D printing is additive and only uses the material needed, lowering material waste significantly.

HYCNC’s Cost-Effective CNC Solutions

At HYCNC, we focus on optimizing CNC machining for low-volume runs to keep costs manageable. Our advanced programming and efficient machining strategies reduce setup time and material waste. This makes CNC machining a practical choice when you need strong, precision parts without breaking the bank.

Whether you lean toward CNC or 3D printing, understanding these cost factors will help you decide the best fit for your low-volume production needs.

When to Choose CNC Milling

CNC milling is the go-to option when you need high precision and tight tolerances for your low-volume manufacturing. If your parts require strong, durable materials like metals or hard plastics that can’t be easily printed, CNC machining is usually the better choice. It’s also ideal when you want a smooth surface finish right off the machine, cutting down on extra post-processing time.

Choose CNC milling if your parts have simpler geometries that don’t need complex internal structures or if you’re working with designs where strength and repeatability are critical. It’s also a smart pick when you need faster turnaround on reliable, ready-to-use parts—especially for functional prototypes or short production runs that demand repeatable quality.

For more on designing parts optimized for CNC milling, check out our guide on design tips for CNC milled low volume parts.

When to Choose 3D Printing

3D printing is a great choice for low-volume production when you need complex geometries or rapid prototyping. It’s perfect if your parts have intricate shapes that would be tough or expensive to make with CNC milling. Since 3D printing is an additive manufacturing process, it builds parts layer by layer, reducing material waste and often cutting down on costs for small runs.

Here’s when I recommend going with 3D printing:

- You need quick turnaround times and want to get prototypes or parts fast.

- The design involves complex or custom features that CNC machines struggle with.

- You’re working with lightweight or plastic materials common in 3D printing.

- The part doesn’t require ultra-high precision or extremely smooth surface finish.

- You want to avoid high setup costs since 3D printing involves less prep work than CNC machining.

For many businesses in the US, 3D printing offers an efficient way to test designs and produce small batches without breaking the bank. If your project fits these points, 3D printing could be your best bet for affordable, flexible, and quick production.

Hybrid Approach Combining CNC and 3D Printing

For low-volume production, combining CNC milling and 3D printing can give you the best of both worlds. This hybrid approach lets you take advantage of CNC machining’s precision and strong material options while benefiting from the flexibility and speed of 3D printing for complex parts.

Here’s how the hybrid method works:

- Start with 3D printing to quickly create prototypes or complex shapes that are hard or expensive to mill. This helps speed up design validation and reduces upfront costs.

- Finish with CNC milling to fine-tune critical surfaces, add tight tolerances, or use durable materials that 3D printing can’t handle as well.

- Use 3D printing for internal features or lightweight sections and CNC for the structural, load-bearing parts.

- This reduces material waste and overall production time, making low-volume manufacturing more cost-effective.

In short, if your project needs both complex geometries and strong, precision parts, the hybrid option is a smart choice for low-volume production. It lets you stay flexible, control costs, and get reliable results fast.

How HYCNC Can Help

When you’re deciding between CNC milling and 3D printing for low-volume manufacturing, HYCNC makes the choice easier. We specialize in precision CNC machining, offering reliable, cost-effective services tailored to small batch runs. Whether you need tight tolerances on metal parts or quick turnaround on complex components, our CNC solutions help reduce material waste and keep production costs down.

Here’s how we stand out for US customers:

- Expertise in Low-Volume Production: We focus on efficient setups to lower your upfront costs and speed up delivery.

- Material Variety: From aluminum and steel to plastics, we work with a wide range of materials to fit your project needs.

- High Accuracy and Quality: Our precision machining ensures consistent parts that meet strict US industry standards.

- Cost Transparency: Clear pricing without hidden fees so you can plan your budget confidently.

If you’re looking to combine CNC milling with 3D printing for a hybrid approach, we can support that too—helping you maximize the benefits of both additive and subtractive manufacturing.

Trust HYCNC to deliver smart, localized solutions that fit your low-volume production goals. Reach out for a quote or to discuss your next project.

FAQs

What’s better for low-volume production, CNC milling or 3D printing?

It depends on your project needs. CNC milling offers great precision and material options for parts needing durability and tight tolerances. 3D printing shines in complex shapes and rapid prototyping but may have limitations with strength and finish.

How do costs compare between CNC machining and 3D printing in low-volume manufacturing?

CNC milling usually has higher setup costs but lower per-unit costs as volume increases. 3D printing has minimal setup costs, making it cheaper for very small runs but can get expensive per part if quality requirements rise.

Can CNC machining handle complex geometries like 3D printing?

CNC milling is best for parts with simpler geometries or that require precision machining. 3D printing handles complex geometries and internal features better due to its layer-by-layer additive process.

Is material waste a concern with CNC milling?

Yes, CNC milling is subtractive manufacturing, so it produces more material waste compared to additive 3D printing. However, proper planning and material choice can reduce waste significantly.

How fast is CNC milling compared to 3D printing for small batches?

3D printing can produce prototypes faster with zero setup time. CNC milling requires some setup but can machine parts quickly once running, especially if surface finish and strength are priorities.

Can I combine CNC machining and 3D printing for better results?

Absolutely. Using 3D printing for rapid prototyping and initial design validation, followed by CNC milling for final precision parts, is a smart hybrid approach many companies use.

For more detailed insights on design and production strategies, check out our CNC prototyping vs 3D printing guide and design tips for CNC milled low-volume parts.