What Are Minimum and Maximum Part Sizes in CNC Machining

In CNC machining, minimum and maximum part sizes refer to the smallest and largest dimensions of parts that a machine can effectively produce in milling or turning processes. The minimum part size relates to the tiniest features or overall dimensions that can be accurately machined without compromising quality or tool effectiveness. On the other hand, the maximum part size is limited by the physical size of the machine’s work envelope—the space within which the machine operates—as well as the reach and capacity of the cutting tools.

Typical minimum part sizes can be as small as a few millimeters, depending on the precision of the tools and the stability of the material. Maximum sizes might range from several inches to several feet, constrained by the X, Y, and Z axis limits of the CNC equipment. Both these size limits play a critical role in ensuring proper tool access and maintaining part accuracy. If a part is too small, tooling becomes a challenge, and if it’s too large, the machine might not physically accommodate it or maintain precision throughout machining.

Understanding these size boundaries is important for designing parts that can be reliably and cost-effectively manufactured using CNC milling or turning processes.

Why Do Minimum Part Size Limits Exist

Minimum part size limits in CNC machining come down to a few key factors that affect quality, cost, and feasibility.

First, tool limitations play a big role. Very small parts often require specialized, tiny cutting tools that can be expensive and wear out quickly. These tools also demand precise setups, which add to the overall machining cost.

Next, there are material stability concerns. When parts get too small or thin, the material can warp, flex, or even break during machining. This instability makes it hard to keep tight tolerances and can lead to scrap parts.

Clamping and fixturing tiny parts is another challenge. Holding a small piece securely without damaging it or causing movement during the process requires custom fixtures or special attention. This again adds to lead time and cost.

At HYCNC, we often handle small parts like those measuring 30mm by 20mm by 5mm. For these, we use advanced equipment and tailored fixturing solutions to ensure precision while managing the cost and complexity. But below that size, it becomes much harder to maintain quality without driving up prices significantly.

Understanding these limits helps us guide you toward designs that stay within practical size ranges, keeping your parts cost-effective and reliable.

Why Do Maximum Part Size Limits Exist

Maximum part size limits mainly come down to the physical boundaries of CNC machines. Every CNC mill or lathe has a set work envelope—the maximum travel distance along X, Y, and Z axes. If your part is too big, it simply won’t fit inside this space for machining.

Tool reach also plays a role. Long tools needed to reach deep or wide areas can flex or deflect during cutting, which lowers precision and surface quality. This limits how large a part can be machined accurately without special setups.

Material weight is another consideration. Very large parts can be heavy and awkward to handle, requiring extra equipment or special fixturing to hold them safely and securely during machining. This adds complexity and cost.

At HYCNC, we handle large, complex parts using advanced 5-axis machines that expand our work envelope and improve tool access. These machines allow us to work on bigger components while maintaining precision, making it possible to manufacture parts that would otherwise exceed typical size limits.

For more on handling complex shapes and parts, check out our post on why 5-axis CNC for complex parts.

Impact of Part Size Limits on Design and Manufacturing

Part size limits play a big role in how you design and manufacture CNC machined parts. When you keep the minimum and maximum CNC machining size limitations in mind, it makes your design more practical and easier to produce.

Design for manufacturability means adjusting your geometry and tolerances to fit what the machine can handle. For example, ultra-tight tolerances on very small or very large parts can cause more rejects and longer machine time. So, balancing precision with what’s necessary helps keep costs down.

Speaking of cost, the size of your part directly affects machining time and tool wear. Larger parts take more time to mill or turn, and tools wear out faster when dealing with big volumes or hard materials. Smaller parts might require specialized, delicate tooling, which can also bump up price.

Material choice also impacts size feasibility. Aluminum parts are easier to machine in larger sizes than steel because aluminum cuts faster and puts less strain on tools. Steel tends to increase machining time and tool cost, especially with bigger parts.

Here’s a real example: at HYCNC, we worked with a customer who redesigned their aluminum housing to fit within our standard maximum size. This smart move reduced machining hours by 30%, lowered tooling costs, and sped up delivery. By respecting CNC part size limits, they achieved better quality and saved money.

Overall, keeping part sizes within recommended limits leads to smoother manufacturing and better cost control, without sacrificing quality.

How HYCNC Addresses Part Size Challenges

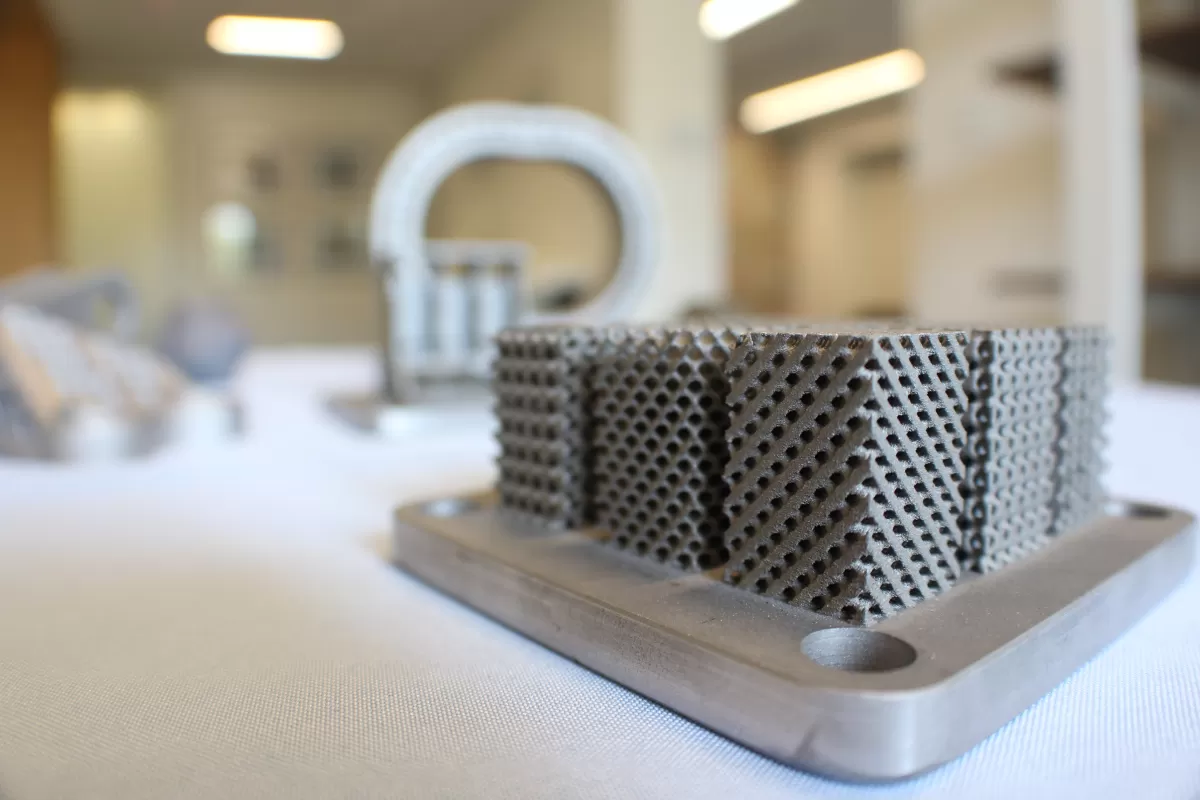

At HYCNC, we handle minimum and maximum part size challenges with advanced CNC equipment designed for flexibility and precision. Our machines include 5-axis CNC centers that allow us to reach tight spots and manage complex geometries efficiently, overcoming tool access and work envelope limits.

We also use specialized tooling and setups tailored for small or large parts, ensuring stable machining without sacrificing quality. This flexibility helps us keep costs down while maintaining tight tolerances.

To help your design fit our manufacturing capabilities, we offer free Design for Manufacturability (DFM) analysis. This service helps identify any size-related issues early on and suggests adjustments that save time and money during production.

Additionally, HYCNC meets strict quality standards like ISO 9001 and IATF 16949, ensuring consistent precision and reliability across all part sizes. This commitment means you can trust us to deliver quality CNC machining whether your parts are tiny or large and complex.

For more advice on optimizing your CNC part design, check out our CNC milling part design tips to get the most out of your machining.

Practical Tips for Designing Within CNC Size Limits

When designing parts for CNC machining, keeping size limits in mind can save you time and money. Here are some practical tips to help your design fit within CNC machining size constraints:

-

Use larger diameter tools when possible

Bigger tools are generally more durable and remove material faster. This leads to shorter machining times and lower tooling costs, making your project more efficient.

-

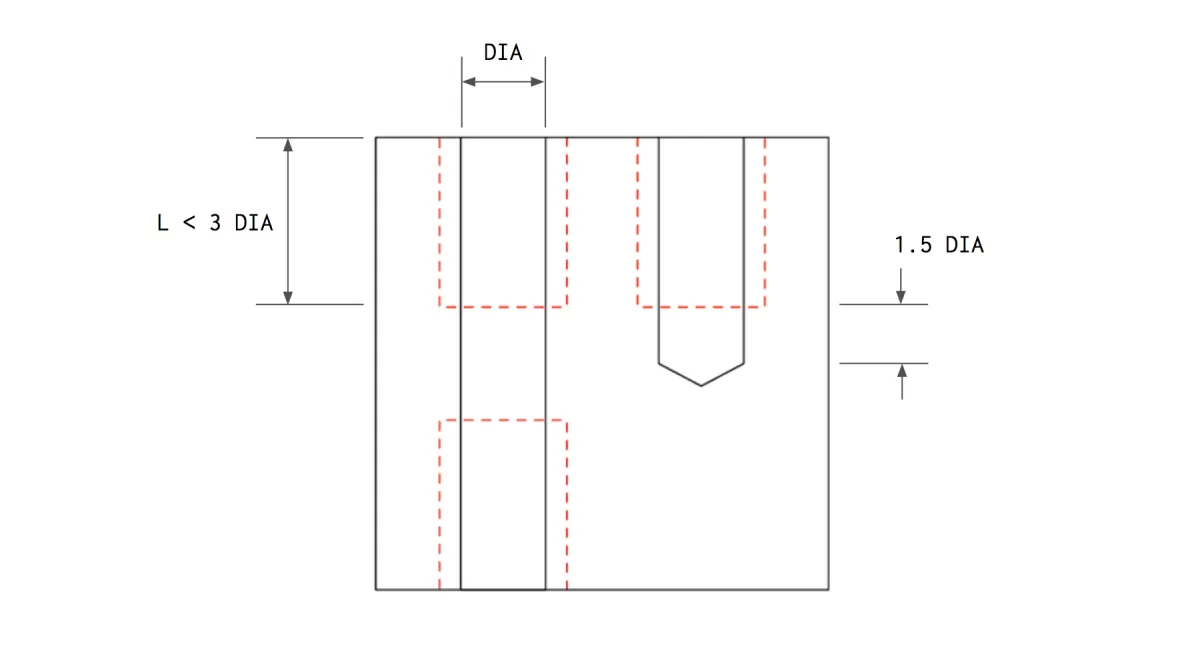

Keep cavity depth-to-width ratios reasonable

Try not to exceed a 4:1 depth-to-width ratio for pockets or cavities. Going deeper than this can cause tool deflection, poor surface finish, and accuracy issues.

-

Avoid overly tight tolerances unless necessary

Tight tolerances increase machining time and cost. Only specify them when the part’s function demands it to balance quality and cost effectively.

-

Consult HYCNC engineers early in the design phase

Early conversations with our team help identify potential size or tooling limitations before production starts. We provide tailored advice to optimize manufacturability and reduce unexpected challenges.

Following these tips ensures your parts are designed for smooth CNC milling or turning, respecting the minimum and maximum part size CNC limits. For more insights on part design and manufacturability, check out our CNC milling part design guide.