Why Reverse Engineering is Critical for CNC Professionals

If you work in CNC machining, you know how important it is to accurately replicate and improve parts. Reverse engineering plays a vital role here. It allows CNC professionals to create precise digital models from existing physical components, especially when original designs or CAD files are missing. Without reverse engineering, reproducing complex parts or improving designs can become time-consuming and costly.

Reverse engineering CNC processes help you:

- Understand the exact specifications and geometry of parts

- Quickly adapt or improve designs based on real-world use

- Save time in product development by starting with accurate 3D scans

- Ensure precision reverse engineering to maintain quality and functionality

- Reduce manufacturing costs by analyzing and optimizing existing parts

- Stay competitive by leveraging competitor product analysis and insights

In short, reverse engineering is an essential skill in CNC manufacturing that bridges the gap between physical components and digital production, helping professionals deliver high-quality CNC part replication efficiently.

Top 10 Tips for Effective Reverse Engineering in CNC Manufacturing

-

Start with Accurate 3D Scanning

Good reverse engineering begins with precise 3D scanning. Use high-quality 3D scanning tools to capture every detail of the part. This ensures your digital model reflects the real object as closely as possible, reducing errors down the line.

-

Choose the Right Reverse Engineering Software

Not all reverse engineering software is built the same. Pick software that fits your CNC part replication needs, offers ease of use, and supports accurate CAD modeling. This makes the process smoother and more efficient.

-

Understand the Part’s Functionality

Before modeling, take time to understand what the part does. Knowing its function helps you identify critical features and tolerances, which is essential for effective CNC machining later.

-

Prioritize Precision in Measurements

Precision reverse engineering demands careful measurement. Double-check all dimensions and use reliable tools to avoid costly mistakes during manufacturing.

-

Create a Detailed CAD Model

Once you have accurate data, build a clear, detailed CAD model. This will serve as the blueprint for CNC machining and help spot potential issues early.

-

Validate the Digital Model

Don’t skip validation. Verify that your CAD model matches the original part by comparing dimensions and features. This step helps catch any inaccuracies before production.

-

Test for Manufacturability

Assess whether the design can be efficiently manufactured with your CNC equipment. Make adjustments if necessary to ensure smooth production.

-

Optimize for Cost and Efficiency

Look for ways to reduce manufacturing costs without compromising quality. Simplify designs or select materials that balance performance with budget.

-

Leverage Competitor Analysis

Analyzing competitor products can provide valuable insights. Reverse engineering competitor parts helps you identify improvements and stay competitive in the market.

-

Partner with Experts for Complex Projects

When dealing with complicated parts, teaming up with reverse engineering specialists can save time and improve results. Their experience ensures precision and efficiency, especially in challenging projects.

Following these tips can significantly improve your reverse engineering CNC process, resulting in better quality parts and more efficient manufacturing.

Common Challenges in Reverse Engineering and How to Overcome Them

Reverse engineering in CNC manufacturing isn’t without its hurdles. Here are some common challenges you might face and practical ways to tackle them:

-

Inaccurate 3D Scanning Data

Poor scans lead to flawed models. To fix this, invest in high-quality 3D scanning for manufacturing and double-check scan settings before capturing.

-

Complex Part Geometry

Intricate designs can be tough to capture and model. Break down the part into smaller sections to scan and model separately, then assemble them digitally.

-

Missing Design Information

Without blueprints or specs, understanding the part’s function gets tricky. Study the part carefully and, if possible, consult with engineers or operators who know the part well.

-

Precision Issues

Small deviations add up, especially for tight-tolerance CNC parts. Always prioritize precision reverse engineering by calibrating equipment regularly and cross-verifying measurements.

-

Software Compatibility

Not all reverse engineering software fits every workflow. Choose tools that integrate well with your existing CAD modeling systems to avoid extra steps.

-

Manufacturing Constraints

Sometimes the reverse-engineered design isn’t easy or cost-effective to produce. Early on, test for manufacturability and adjust designs to balance efficiency and quality.

By anticipating these issues and using the right reverse engineering tools, you can smooth the process and get accurate CNC part replication every time.

How HYCNC Enhances Your Reverse Engineering Process

When it comes to reverse engineering CNC parts, HYCNC brings a lot to the table. They combine precise 3D scanning technology with expert CAD modeling to ensure your digital replicas are spot on. Whether you’re working with complex components or simple parts, their team knows how to capture every detail without guesswork.

HYCNC also uses advanced reverse engineering software that meshes well with popular CNC machining platforms, making the transition from model to production smooth and fast. This reduces errors, speeds up the manufacturing process, and helps keep costs down.

Plus, they have years of experience in precision reverse engineering, so they understand how important accuracy is for your parts to function properly. If you’re looking to replicate competitor products or improve existing designs, HYCNC can help by offering expert insights and tailored solutions.

Partnering with HYCNC means you get access to the latest reverse engineering tools, skilled technicians, and personalized service — all focused on making your CNC part replication as efficient and reliable as possible. This makes them a solid choice for U.S. manufacturers aiming to stay competitive and cut manufacturing costs without sacrificing quality.

Tools and Technologies for Reverse Engineering Success

Having the right tools and technology is key to effective reverse engineering in CNC manufacturing. Here are some essentials that can make the process smoother and more accurate:

-

3D Scanners: These capture precise measurements of the physical part quickly. Laser scanners and structured light scanners are popular choices for detailed 3D scanning for manufacturing.

-

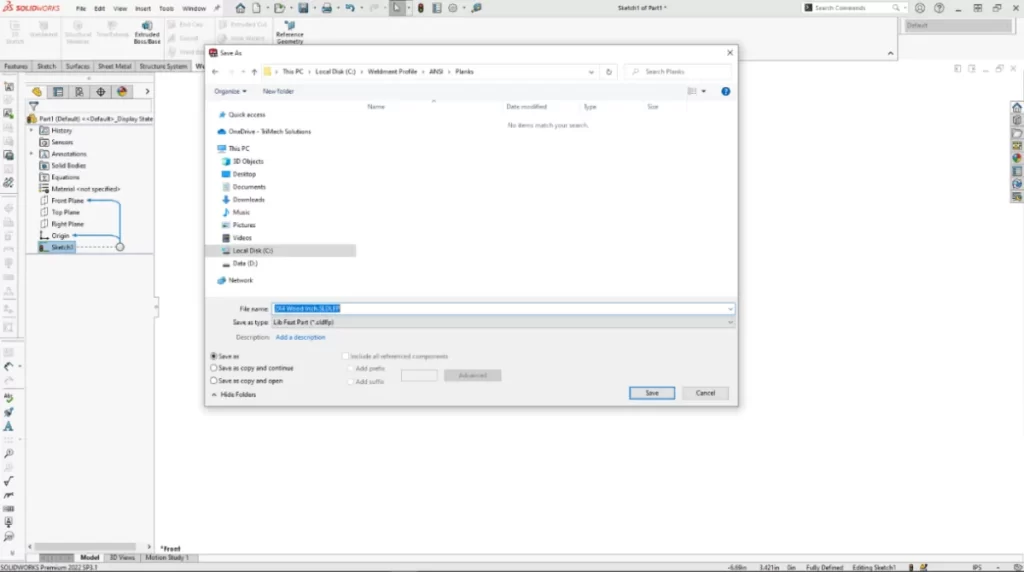

Reverse Engineering Software: Tools like Geomagic Design X, SolidWorks, and Autodesk Fusion 360 help convert scanned data into usable CAD models. Choosing software that suits your skill level and project needs is crucial.

-

CAD Modeling Tools: Software with robust CAD modeling features ensures the digital model replicates the original part’s details accurately. It also allows for design tweaks to improve performance or manufacturability.

-

Measurement Instruments: For precision reverse engineering, tools like calipers, micrometers, and CMM (Coordinate Measuring Machines) validate critical dimensions that scanners might miss.

-

Simulation Software: Testing the model under virtual conditions helps predict how it will perform during manufacturing, highlighting any design issues early.

-

Collaboration Platforms: Cloud-based solutions enable teams to share files and updates instantly, speeding up the revision and approval cycles.

Using a combination of these tools helps CNC professionals accurately replicate parts, reduce manufacturing costs, and shorten lead times. At HYCNC, we integrate the latest technologies to enhance your reverse engineering projects and deliver reliable solutions tailored to your needs.

FAQs

What is reverse engineering in CNC manufacturing?

Reverse engineering in CNC involves analyzing an existing part to create a digital model, which helps in replication or improvement using CNC machining.

Why is 3D scanning important for reverse engineering?

3D scanning captures precise measurements of a part quickly, making it easier to build accurate CAD models and save time in the manufacturing process.

Can any reverse engineering software work for CNC projects?

Not all software fits every project. It’s important to choose tools optimized for precision reverse engineering and compatible with your CNC systems.

How do I ensure accuracy during reverse engineering?

Focus on precise measurements, use reliable scanning technology, and validate your digital models regularly to avoid errors.

What are common challenges in reverse engineering CNC parts?

Challenges include complex geometries, incomplete data from scans, and ensuring manufacturability. Partnering with experts or using advanced tools can help overcome these issues.

How does reverse engineering help reduce manufacturing costs?

By optimizing designs and improving material use, reverse engineering can identify cost-saving opportunities while maintaining part quality.

Is it necessary to understand the part’s function during reverse engineering?

Yes, knowing how a part works helps in creating accurate models and ensures the CNC-machined part will perform as needed.

Can HYCNC assist with complex reverse engineering projects?

Absolutely. HYCNC offers expert support and advanced tools to handle intricate CNC reverse engineering tasks efficiently.

If you want to learn more about our CNC services and how we can streamline your reverse engineering needs, feel free to contact us anytime.