What Is Surface Roughness and Why It Matters

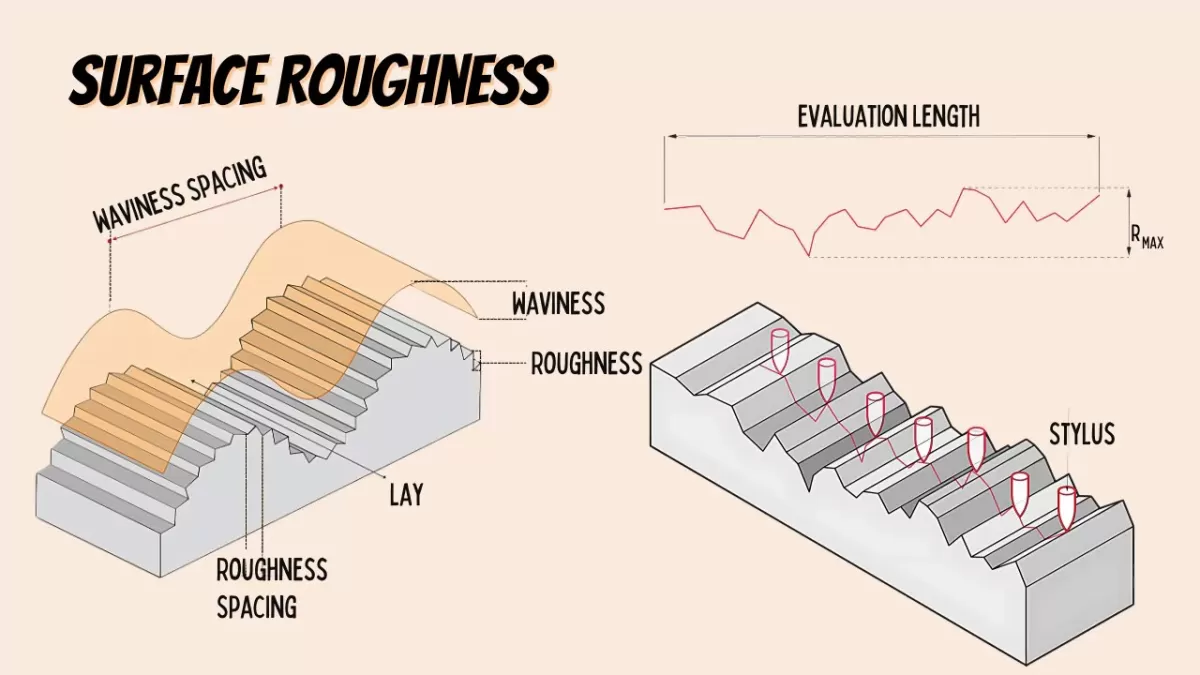

Surface roughness refers to the small-scale texture of a material’s surface, measured by the vertical deviations from its ideal form. In manufacturing, surface roughness plays a crucial role because it directly affects how parts fit together, perform, and last.

Understanding surface texture means looking at three key components:

- Roughness: The fine, closely spaced irregularities.

- Waviness: Larger, more widely spaced surface deviations.

- Lay: The direction or pattern of the surface texture.

These elements impact more than just appearance. Surface roughness influences product performance by affecting friction, wear resistance, and even corrosion. In industries like aerospace, automotive, and medical devices, the right surface finish ensures durability, safety, and aesthetic quality.

CNC machining demands precise control over surface roughness because even minor deviations can cause part failure, assembly problems, or poor functionality. Accurate roughness control guarantees components meet tight tolerances and perform reliably in their intended applications.

Understanding Surface Roughness Parameters

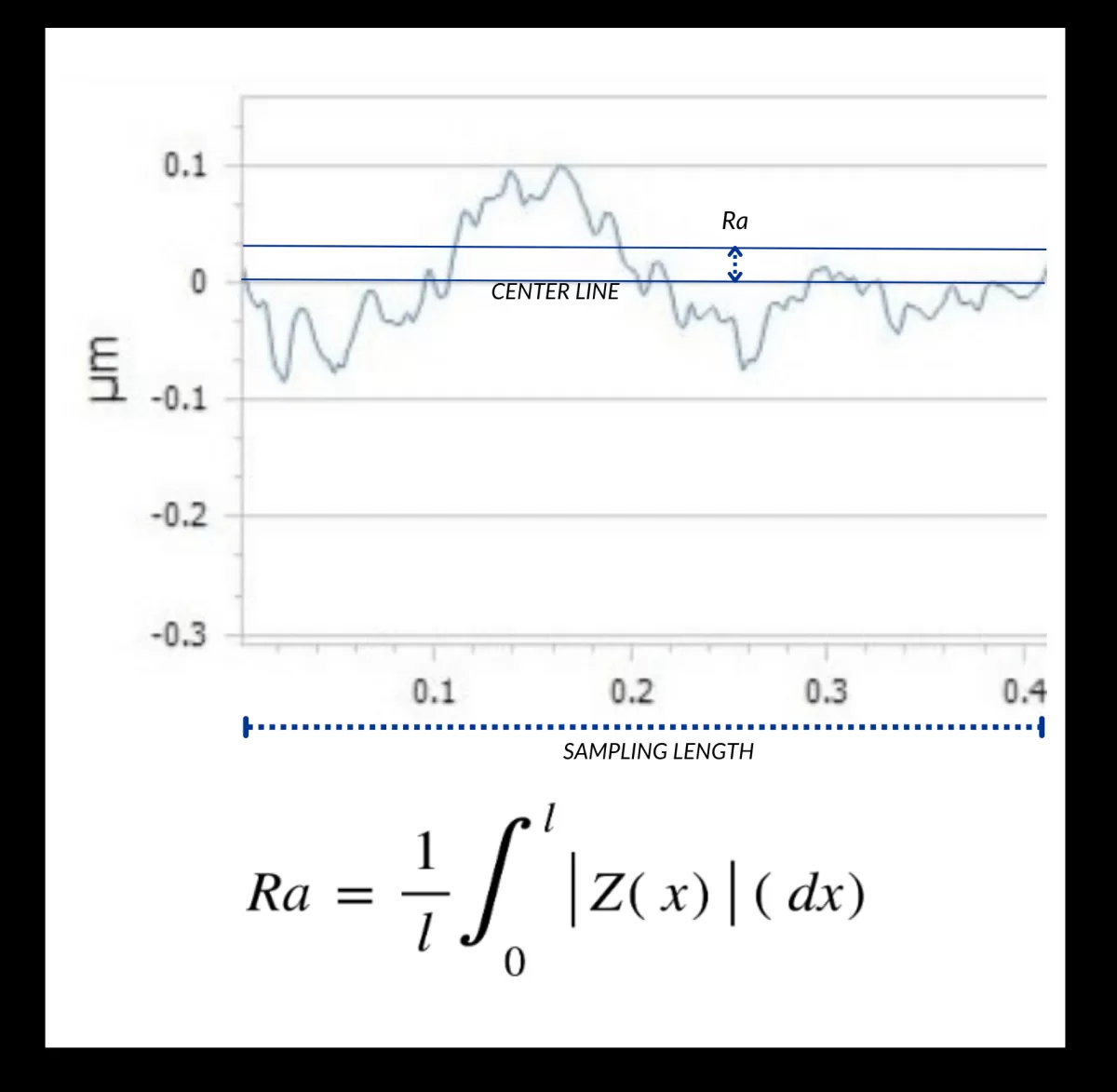

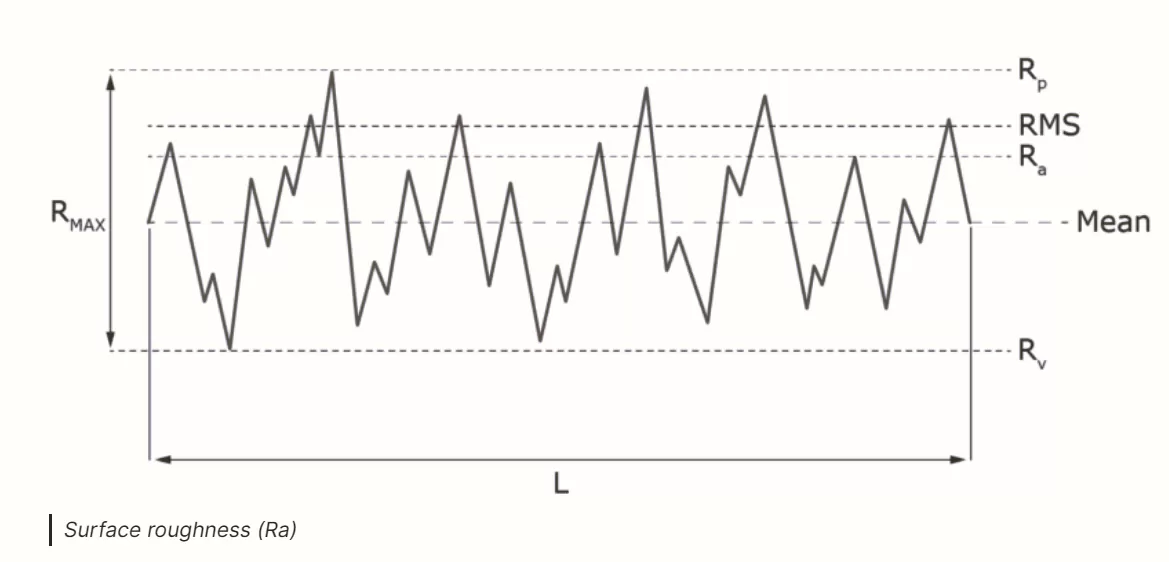

When talking about surface roughness, several key parameters come up often: Ra, Rz, Rq, and Sa. These help describe the texture of a surface after machining.

- Ra (Average Roughness): This is the most common measurement. It calculates the average height differences on a surface in a straight 2D line.

- Rz (Average Maximum Height): It measures the average of the highest peaks and lowest valleys over a set length, giving insight into extreme surface variations.

- Rq (Root Mean Square Roughness): This is similar to Ra but uses the square root of the average of the squared deviations, making it more sensitive to bigger irregularities.

- Sa (Arithmetical Mean Height): Unlike the others, Sa is a 3D measurement that evaluates roughness over an area, not just a line.

The difference between 2D and 3D surface roughness measurements is important. 2D measurements (like Ra, Rz, and Rq) analyze surface texture along a line, which fits many CNC machining quality checks. But 3D parameters like Sa offer a fuller picture by assessing the entire surface area, which is useful for complex geometries and high-precision parts.

These parameters directly impact CNC machining results. For example, the chosen roughness affects tool wear, machining speed, and part function, including how parts fit or look. That’s why industries follow standards like ISO 4287, which defines roughness parameters and measurement methods, and ASME B46.1, which sets surface texture standards in the U.S.

Understanding these parameters helps you communicate effectively with your CNC shop, ensuring your parts meet exact surface finish requirements for performance and durability. For deeper insight, check our good surface finish for CNC machined parts.

How to Measure Surface Roughness

Measuring surface roughness is key to making sure your CNC-machined parts meet quality standards. There are two main ways to do this: contact and non-contact methods.

Contact Methods

- Stylus-based profilometers are the most common here. They use a tiny needle that physically traces the surface to record roughness.

- Pros: Accurate for many surfaces, relatively affordable, and widely accepted in the industry.

- Cons: Can’t be used on very soft or delicate materials as the stylus might damage the surface. Also, slower and might miss very fine details over large areas.

Non-contact Methods

- Optical profilometry and laser scanning use light or lasers to scan the surface without touching it.

- Pros: Fast, safe for delicate or soft materials, and can cover larger areas quickly. 3D measurements are easier to obtain here.

- Cons: More expensive equipment and can be sensitive to surface reflectivity or transparency.

Choosing the Right Method for CNC Parts

- For precision CNC parts where surface integrity is critical, stylus profilometers are a reliable choice.

- If you need fast inspection or work with softer materials, non-contact methods can save time and reduce risk of damage.

- Consider your part material, size, and finish requirements when selecting your measurement tool to get the best results.

Using the right surface roughness measurement helps ensure your parts perform well and look great.

Surface Roughness Chart and Standards

Surface roughness charts are essential tools for understanding and controlling the finish of machined parts. Common measurements like Ra (average roughness), Rz (average peak-to-valley height), and RMS (root mean square) give clear numbers that describe a surface’s texture.

In the CNC machining industry, surface roughness usually falls within a range of about 3.2 to 0.4 micrometers (µm) Ra. This range covers everything from standard machine finishes to high-precision parts requiring very smooth surfaces.

How to Use Surface Roughness Charts for Quality Control

- Compare actual measurements to the chart values to check if your part meets specs.

- Understand Ra vs. Rz: Ra is widely used, but Rz gives extra detail on peak and valley extremes.

- Follow industry standards like ISO 4287 and ASME B46.1 for consistent measurement and reporting across suppliers and customers.

By referencing these charts, you can quickly spot problems and ensure your parts match the required surface texture for optimal performance.

For convenience, you can download a detailed surface roughness chart that helps simplify this process and keeps quality control straightforward.

Factors Affecting Surface Roughness in CNC Machining

Getting the right surface roughness starts with understanding what influences it during CNC machining. Here are the key factors:

Tool Selection and Condition

- Sharp, well-maintained cutting tools produce smoother finishes.

- Worn or damaged tools cause rough surfaces and imperfections.

Machining Parameters

- Cutting speed: Higher speeds often improve surface finish but can increase tool wear.

- Feed rate: Slower feed rates usually give better surface quality.

- Depth of cut: Shallower cuts help reduce surface roughness, especially on fine features.

Material Properties

- Hardness and grain structure affect how the material responds to cutting.

- Softer materials may smear, while harder ones might lead to tool chatter, both impacting finish.

Coolant Use and Chip Management

- Proper coolant flow reduces heat and flushes chips away, preventing scratches and burn marks.

- Managing chips effectively avoids recutting, which can damage the surface.

In short, balancing these factors is essential for achieving precise CNC machining surface roughness that meets your quality needs.

Achieving Optimal Surface Roughness with CNC Machining

Getting the best surface roughness in CNC machining comes down to a few key practices during milling and turning. Keeping tools sharp and using the right cutting speeds and feeds helps produce smoother finishes right off the machine. Consistent tool pressure and avoiding vibrations are also crucial to minimize surface flaws.

Post-processing steps can take your surface finish even further. Grinding, polishing, and plating are common techniques to refine roughness and improve durability or aesthetics. These steps add value, especially for parts needing tight tolerances or cosmetic appeal.

At HYCNC, we focus on precision throughout the entire process. From choosing the right tools to utilizing advanced CNC equipment, we control every detail to deliver top-notch surface finishes. Our quality control follows strict ISO and ASME standards, so you get consistency every time.

For example, we recently worked on aerospace components where smooth surface finishes are critical for aerodynamic efficiency. By combining fine-tuned machining parameters with targeted polishing, we achieved surfaces well within the required roughness range, improving both performance and lifespan.

If you want precise, reliable surface finishes on your CNC parts, HYCNC is ready to deliver solutions tailored to your needs.

Common Challenges and Solutions in Surface Roughness

In CNC machining, surface roughness issues often come from problems like tool chatter, vibrations, or material expansion during cutting. These factors can leave unwanted marks and uneven textures on your parts.

Here are some quick tips to reduce surface imperfections:

- Keep tools sharp to avoid dragging or tearing the surface

- Use proper cutting speeds and feeds to minimize vibrations

- Secure the workpiece tightly to prevent movement

- Control the temperature during machining to reduce material expansion

- Apply the right coolant to flush away chips and cool the cutting zone

At HYCNC, we go a step further with advanced tools, including AI-driven surface roughness prediction. This helps us anticipate issues before they happen and adjust processes in real-time for the smoothest finishes. This proactive approach means fewer defects and better-quality surface finishes for your parts every time.

Applications of Surface Roughness in Key Industries

Surface roughness plays a big role across several key industries, impacting both performance and quality.

Aerospace

Smooth surface finishes are crucial for aerospace parts. They help reduce drag and improve aerodynamic efficiency, leading to better fuel economy and overall performance.

Automotive

In the automotive world, surface roughness affects both durability and looks. A finely finished surface helps parts last longer and keeps vehicles looking sharp and polished.

Medical

For medical implants and instruments, surface roughness is about safety and biocompatibility. The right texture helps implants integrate with the body and ensures medical tools work reliably without causing damage.

Electronics

In electronics, controlling surface roughness helps reduce electrical resistance, especially in semiconductor components. This improves device efficiency and reliability.

No matter the industry, understanding and controlling surface finish is key to making parts that do their job well and last longer.

Why Choose HYCNC for Precision Surface Finishes

At HYCNC, we bring years of CNC machining expertise to every project, ensuring your parts get the precise surface roughness and finish you need. We use advanced equipment, including the latest CNC mills and lathes, paired with state-of-the-art quality control processes that catch any surface imperfections early on.

Our team understands the importance of meeting strict industry standards. That’s why we follow ISO and ASME surface roughness guidelines closely, so you can trust your parts will perform reliably and look great. Whether you need tight tolerances or smooth finishes, HYCNC delivers consistent results every time.

If you’re looking for custom machining solutions with a focus on precision surface finishes, contact HYCNC today. We’re ready to help optimize your part performance with the right surface texture, tailored to your industry and application needs.

Frequently Asked Questions

What is the difference between Ra and Rz

Ra measures the average surface roughness, giving a simple overall value of how smooth a surface is. Rz, on the other hand, looks at the average peak-to-valley height over a sampling length, so it captures the extreme roughness better. Both are important, but Ra is most commonly used for quick checks, while Rz gives a deeper picture for precise control.

How does surface roughness affect CNC part performance

Surface roughness directly impacts how parts fit, move, and wear over time. A rougher surface can cause higher friction, reduce durability, and even affect the aesthetics of the part. For CNC machined components, maintaining tight surface roughness tolerances ensures better performance, longer life, and meeting industry standards.

What are the best tools for measuring surface roughness

There are two main types:

- Contact methods like stylus profilometers are widely used for their accuracy and reliability on most surfaces.

- Non-contact methods such as optical profilometers or laser scanners offer faster, high-resolution measurement and work well when contact isn’t an option.

Choosing the right tool depends on your part size, shape, and required precision.

How can HYCNC help improve my part’s surface finish

At HYCNC, we use advanced CNC machining equipment paired with thorough quality control based on ISO and ASME standards. Our team tweaks tool selection, machining settings, and uses post-processing like polishing to hit exact surface roughness targets. We’ve successfully delivered smooth, precise finishes for aerospace, automotive, and medical parts — ensuring your parts not only meet but exceed expectations. Reach out to us to get a custom surface finish plan tailored to your needs.