Are you struggling to achieve a good surface finish for your CNC machined parts? A flawless finish can elevate the performance, durability, and aesthetics of your components, making all the difference in your project’s success.

As a CNC machining expert, I’ve seen firsthand how the right surface finishing techniques can transform parts for industries like aerospace, automotive, and medical. With HYCNC’s cutting-edge technology and know-how, I’ll share practical insights that go beyond the basics to help you get mirror-smooth results every time.

In this guide, you’ll discover proven strategies, common pitfalls to avoid, and how to choose the perfect CNC machining surface finish for your needs.

Let’s get started!

Understanding Surface Finish in CNC Machining

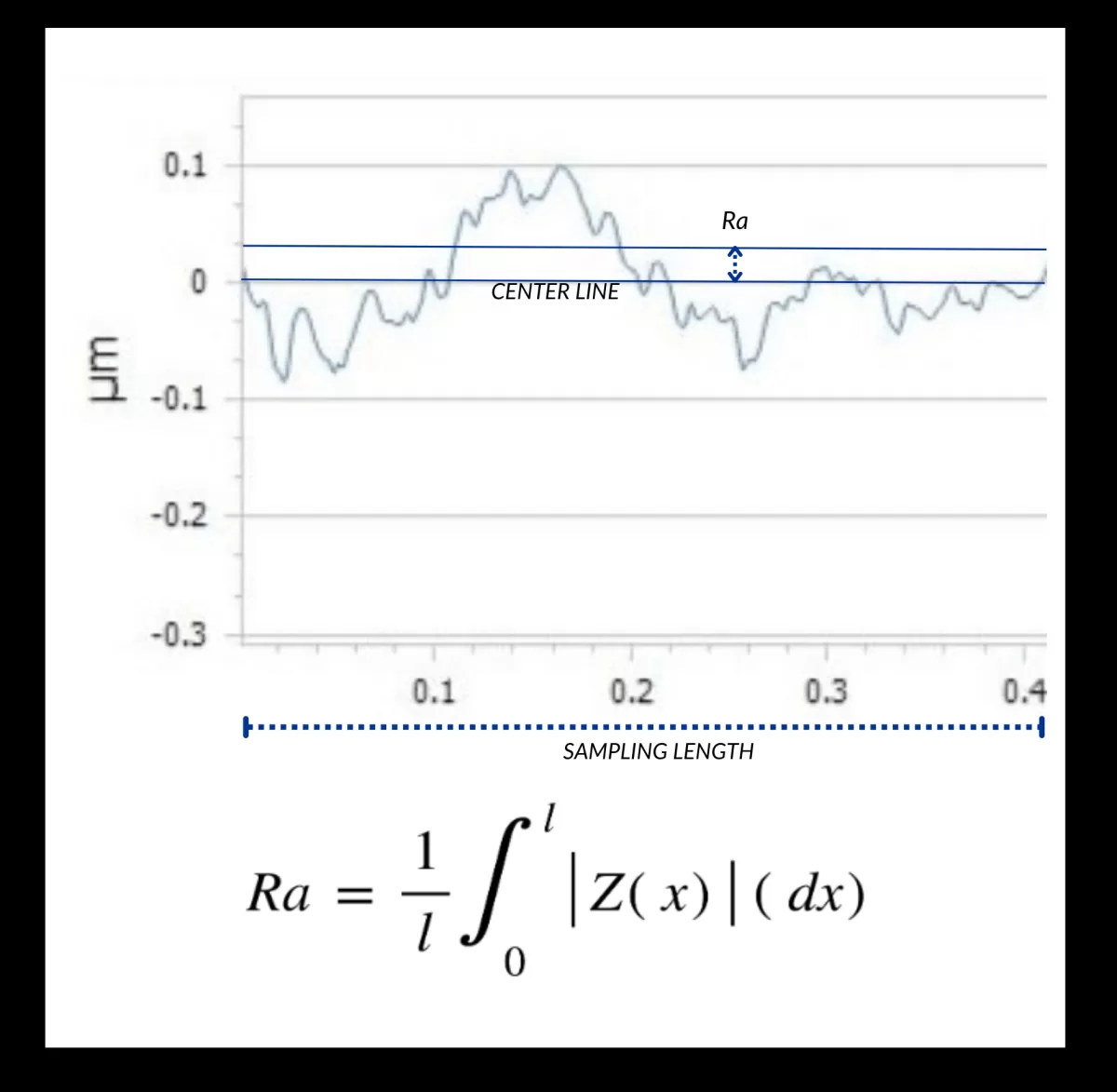

Surface finish refers to the texture and smoothness of a CNC machined part’s surface. It’s typically measured by parameters like Ra (average roughness), Rz (average maximum height), and RMS (root mean square roughness). These values give a clear picture of how rough or smooth the surface is on a microscopic level.

Why does surface finish matter? A good finish directly affects how a part performs. For example, smoother surfaces reduce friction, which helps with wear resistance and extends component life. It also plays a big role in preventing corrosion by minimizing areas where moisture or contaminants can settle.

High-quality surface finishes are critical in industries where precision and reliability are non-negotiable. Aerospace parts must meet strict tolerances for safety and efficiency. Medical devices require smooth surfaces for biocompatibility and easy cleaning. Automotive components benefit from fine finishes to improve durability and reduce noise or vibration. Each of these fields demands surface finish quality that goes beyond basic functionality to ensure peak performance.

Factors Affecting Surface Finish Quality

Several key factors impact the surface finish quality in CNC machining. Understanding these helps get the smooth, precise results you need.

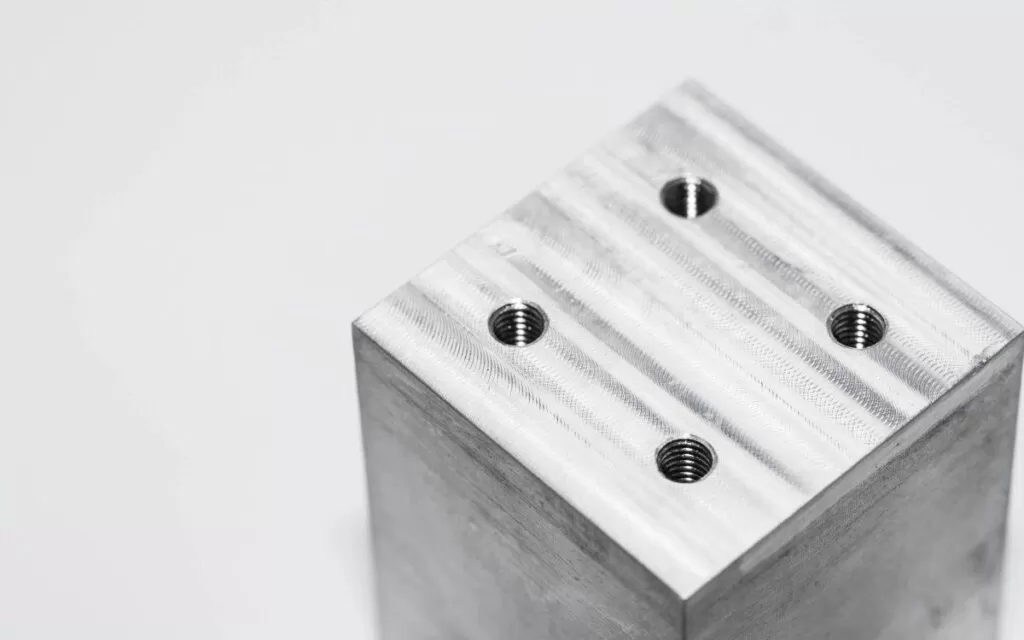

Material Selection

Different materials respond differently to machining. For example:

- Aluminum often machines smoothly, giving a cleaner finish.

- Stainless steel is tougher and can be prone to work hardening, which may affect surface roughness.

Choosing the right material based on your finish requirements is crucial.

Cutting Parameters

Cutting speed, feed rate, and depth of cut play a huge role:

- Higher cutting speeds can improve finish but may increase heat.

- Slower feed rates usually lead to smoother surfaces.

- Shallow depth of cut helps avoid tool marks and chatter marks.

Balancing these parameters is key to achieving the right CNC machining surface roughness.

Tool Selection

The type and quality of cutting tools matter a lot. For instance:

- Sharp end mills provide cleaner edges.

- Face mills are great for flat surfaces.

- Diamond-tipped tools offer excellent wear resistance and can help get an ultra-smooth finish, especially on hard materials.

Machining Process

Your process choice affects surface finish too:

- Milling generally offers versatility but may leave tool marks.

- Turning can produce smoother finishes on round parts.

- Grinding delivers the finest finishes but adds cost and time.

Workholding and Vibration

Stability during machining is critical:

- Secure workholding minimizes movement and deflection.

- Reducing vibration or chatter helps avoid surface imperfections.

Good machine setup and using vibration-dampening fixtures improve overall surface finish quality dramatically.

Keeping these factors in check is how we ensure top-notch surface finish quality on every CNC machined part.

Popular Surface Finishing Techniques for CNC Machined Parts

When it comes to CNC machining surface roughness and aesthetics, choosing the right finishing technique is key. Here are some popular options you’ll often see in the U.S. market:

As-Machined Finish

- This is the natural state right after machining.

- Pros: It’s cost-effective and keeps tight tolerances.

- Cons: Tool marks and slight roughness are usually visible, which might not work for high-end parts.

Bead Blasting

- Uses tiny beads blasted onto the surface to create a matte or satin look.

- Great for adding a consistent finish that’s easy on the eyes.

- Limitations: Doesn’t improve corrosion resistance or remove deep tool marks.

Anodizing

- Common for aluminum and titanium parts, anodizing adds a protective oxide layer.

- Comes in two main types: Type II (standard) and Type III (hard, thicker coating).

- Benefits: Enhances corrosion resistance and offers color options while keeping the surface durable.

Polishing

- Produces a mirror-like, glossy finish ideal for parts where appearance matters.

- Perfect for high-gloss applications like medical devices or consumer electronics.

- Note: Polishing can raise costs due to the extra labor involved.

Powder Coating

- A tough, colorful finish that’s applied electrostatically then cured with heat.

- Works for almost any metal, offering scratch and corrosion resistance.

- Keep in mind, powder coating can add thickness and extra cost to parts.

Electroless Nickel Plating

- Provides uniform corrosion resistance without needing an electric current.

- Great for complex shapes where consistent coverage is crucial.

- Often used in industries like aerospace and automotive for durability.

Passivation

- Ideal for stainless steel parts, it removes surface contaminants to boost rust resistance.

- Common in medical and aerospace because it ensures cleaner, longer-lasting components.

Brushing and Electropolishing

- Brushing offers a textured, satin look that hides fingerprints and scratches.

- Electropolishing smooths out microscopic peaks, improving cleanliness and corrosion resistance—perfect for stainless steel parts.

Using the right surface finishing technique can make all the difference in your CNC machined parts’ performance and look. Whether you want a smooth feel, corrosion resistance, or just better aesthetics, these finishes cover the bases for most industries in the U.S.

How to Ensure a Good Surface Finish

Getting a great surface finish on CNC machined parts takes more than just running the machine. Here’s what you need to focus on:

Optimizing Cutting Parameters

- Adjust the cutting speed to reduce heat and tool wear.

- Set the feed rate carefully; too fast causes roughness, too slow can ruin efficiency.

- Control depth of cut to avoid tool deflection and chatter, which hurt the finish.

Toolpath Strategies

- Use smooth, consistent tool paths to prevent sudden direction changes.

- Steady material removal helps avoid marks and uneven surfaces.

Chip Evacuation

- Clear chips quickly to stop them from being cut again, which can scratch and damage the surface.

- Use proper coolant flow or air blasts for better chip removal.

Pre-Finishing Preparation

- Always clean the part beforehand to remove dirt or oil.

- Deburr sharp edges to prevent rough spots.

- Check that the material is compatible with your finishing methods.

Post-Processing Techniques

- Combine finishing methods like anodizing followed by bead blasting for better protection and appearance.

- Use polishing or electropolishing to get that smooth, mirror-like surface when needed.

Following these steps helps ensure your CNC machined parts meet the surface finish quality required for your project, whether it’s for automotive, aerospace, or general industrial use.

Choosing the Right Surface Finish for Your Project

Picking the right surface finish depends a lot on what the part will do. For precision gears or high-performance components, a smooth finish around 0.4 µm Ra is usually needed to reduce friction and wear. On the other hand, less critical parts might be fine with a rougher finish, like 3.2 µm Ra, which costs less and is quicker to produce.

You also have to balance cost, look, and how the part performs. Generally, the smoother the finish, the more time and money it takes. So, it’s about finding the sweet spot between good enough and overdoing it.

Different industries have unique needs too. For instance:

- Food processing parts need finishes that are easy to clean and prevent bacteria buildup.

- Medical devices often require ultra-smooth, corrosion-resistant surfaces.

- Consumer electronics might focus more on appearance with polished or coated finishes.

Understanding these factors helps you choose a surface finishing technique that fits your budget, meets industry standards, and keeps your parts performing as expected. For more info on surface finishing options and how to match them to your project, check out our surface finishing services.

Why Choose HYCNC for Superior Surface Finishes

At HYCNC, we use advanced CNC machining technology that ensures top-notch surface finish quality for every part. Our team has deep expertise in surface finishing, meaning we know how to hit tight tolerances and deliver smooth, consistent results that meet your project requirements.

We serve a wide range of industries, including automotive, aerospace, and medical, offering customized finishing solutions tailored to each sector’s standards and expectations. Whether you need corrosion resistance, precise roughness values, or a high-gloss appearance, we’ve got you covered.

One big advantage of working with HYCNC is our fast turnaround. We can deliver high-precision parts in as little as five days, keeping your production on track without sacrificing quality.

For example, we recently worked on an automotive component where we achieved an impressive 0.8 µm Ra surface finish. This level of smoothness helped improve the part’s performance by reducing friction and wear, proving our capability to meet demanding surface finish standards for precision parts.

Choosing HYCNC means reliable, high-quality surface finishes that fit your budget and timeline.

Common Mistakes to Avoid for Optimal Surface Finish

Getting a good surface finish on CNC machined parts means steering clear of a few common mistakes. Here’s what to watch out for:

-

Wrong cutting parameters: Running your machine too fast or using too aggressive feed rates can cause chatter—those annoying vibrations that leave rough, uneven surfaces. Always balance speed and feed for smooth cutting.

-

Poor toolpath programming: Jerky or sudden changes in tool direction can result in uneven cuts and visible marks on the surface. Plan your toolpaths for steady, consistent movement to keep finishes clean.

-

Bad chip evacuation: If chips aren’t cleared properly, they can get caught between the tool and the part, scratching or denting the surface. Use efficient coolant flow and chip removal strategies to avoid this.

-

Environmental issues: Temperature swings and contamination (like dust or oil) can affect machining precision and surface quality. Keep your workspace clean and stable to maintain the best results.

Avoiding these pitfalls helps maintain consistently high surface finish quality, saving time and money on rework or additional finishing. For more on surface finishing techniques and CNC machining best practices, check out our surface finishing services.