Are you struggling to decide between CNC machining and casting for your manufacturing project? Choosing the right process can transform your production, balancing cost, precision, and speed to meet your goals. As experts in the field, HYCNC brings real-world insights to guide you through this critical decision. Whether you’re prototyping a custom part or scaling up for thousands, understanding CNC vs. cast is key to success. In this guide, we’ll break down the differences, benefits, and best uses to help you choose wisely. Let’s dive in!

CNC Machining

What Is CNC Machining

CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process where computer software controls machine tools—like mills, lathes, or routers—to shape raw materials into precise parts. CNC machines follow programmed instructions to cut, drill, or mill metals and plastics with high accuracy. This process is widely used in industries like aerospace, automotive, and medical devices, where precision matters most.

Key Advantages of CNC Machining

-

High Precision and Consistency

CNC machining delivers tight tolerances and repeatable results, ideal for parts that require exact measurements.

-

Flexibility

Easy to switch between different designs or prototypes without the need for new tooling.

-

Material Variety

Works well with metals like aluminum, steel, titanium, and various plastics.

-

Speed for Low to Medium Volumes

Quick setups make it cost-effective for smaller production runs and prototyping.

-

Automation and Reduced Human Error

Computer control minimizes mistakes and helps maintain quality over long production runs.

Limitations of CNC Machining

-

Higher Cost for Large Volumes

For very high-volume production, CNC machining can be more expensive compared to casting.

-

Material Waste

CNC is a subtractive process, which means it cuts away material, leading to more waste compared to casting.

-

Complexity Limits

While capable of intricate parts, extreme internal geometries or hollow parts can be challenging.

-

Setup Time for Complex Jobs

Programming and machine setup can take time, especially for complicated parts.

Understanding what CNC machining can and cannot do helps determine when it’s the best fit for your manufacturing needs. Next, we’ll explore the casting process and how it compares.

Casting

What Is Casting

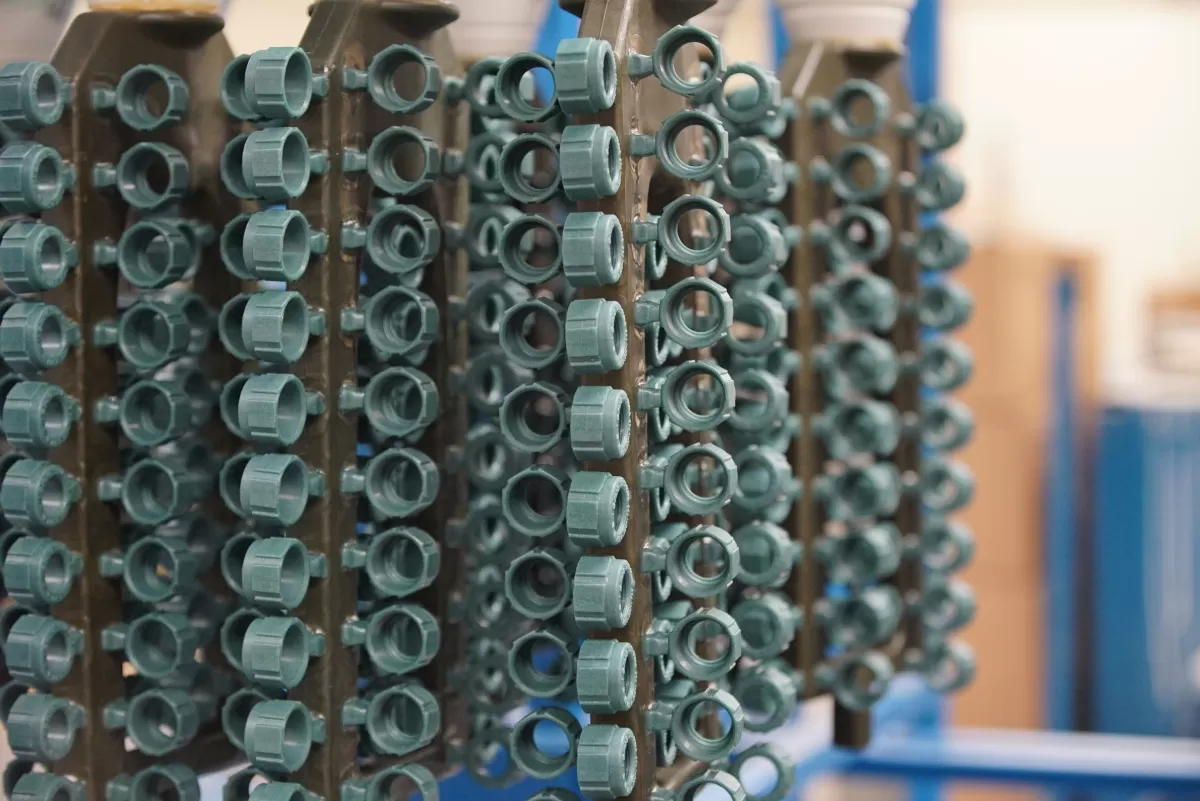

Casting is a manufacturing process where molten metal is poured into a mold to create a specific shape. Once the metal cools and solidifies, the mold is removed, revealing a shaped part. There are various casting methods like die casting, sand casting, and investment casting, each suited for different needs. Casting is widely used for making complex shapes and large production runs.

Key Advantages of Casting

- Cost-Effective for High Volumes: Casting is ideal when producing large quantities, bringing down the cost per part.

- Complex Shapes Possible: It can create parts with intricate geometries that would be tough or expensive to machine.

- Material Diversity: Casting works with a wide range of metals including aluminum, steel, and brass.

- Big Part Sizes: Casting can produce larger parts more easily than CNC machining.

- Good for Mass Production: Especially with processes like die casting, you get fast cycle times once the mold is ready.

Limitations of Casting

- Lower Precision: Compared to CNC machining, casting parts usually require extra finishing to meet tight tolerances.

- Longer Lead Times: Mold design and tooling can add significant upfront time before production.

- Surface Finish: Cast surfaces often need post-processing to improve smoothness.

- Less Flexible for Small Runs: Setup costs make casting less practical for low-volume or prototype work.

- Potential Defects: Issues like porosity or shrinkage can occur, affecting the part’s strength and finish.

Casting is a solid choice when you need bulk production of complex shapes and can allow some flexibility on precision and finish. But for tight tolerances and quick turnarounds, CNC machining might be a better fit.

CNC Machining vs Casting Key Comparison Factors

When comparing CNC machining vs casting, several key factors help you decide which process fits your project best.

Precision and Tolerances

CNC machining offers high precision with tight tolerances—perfect when you need exact dimensions and detailed features. Casting can produce complex shapes but usually has looser tolerances, meaning parts might need extra finishing to meet precise specs.

Production Volume

Casting shines for high-volume production because it’s cost-effective once molds are made. For low to medium volumes, CNC machining is more flexible since there’s no need for tooling, making it ideal for prototypes or smaller runs.

Cost Considerations

Initial costs for casting can be higher due to mold creation, but unit costs drop significantly with volume. CNC machining has lower startup costs but can get expensive for large runs because each part is individually machined.

Material Versatility

CNC machining works with a wide range of metals and plastics, offering more material options. Casting is mostly used with metals like aluminum, steel, and zinc, particularly in processes like die casting. For details on casting materials, check out Metal Casting.

Design Complexity

Casting can create complex internal geometries and shapes hard to machine. However, CNC machining excels at sharp edges and detailed features that can be challenging or impossible for casting.

Lead Time

CNC machining often has shorter lead times since it skips mold making. Casting requires time to design and produce molds, so it takes longer up front, but speeds up for large batches.

Surface Finish and Post Processing

Parts from CNC machining typically have a smoother surface straight off the machine. Cast parts might need extra machining or polishing to reach the desired finish, especially for high-precision applications.

Understanding these factors helps you pick the right approach, whether it’s precision CNC machining or efficient casting methods like Die Casting.

When to Choose CNC Machining vs Casting

Best Scenarios for CNC Machining

CNC machining shines when you need high precision and tight tolerances. It’s ideal for:

- Low to medium production volumes

- Prototyping and custom parts

- Parts requiring complex shapes with exact dimensions

- Materials that are tough to cast, like certain metals and plastics

- Quick turnaround times where design changes might happen

If your project needs precise, repeatable details and faster setup, CNC machining is often the way to go.

Best Scenarios for Casting

Casting works best when you’re producing large volumes of parts, especially if they’re simpler in design but bulky or heavy. Good uses include:

- High-volume production runs to reduce per-part cost

- Parts with complex internal geometries that are hard to machine

- Metals like aluminum, zinc, or magnesium used in die casting

- Shapes that don’t need super tight tolerances straight off the mold

- Applications where surface finish can be improved later

Casting provides great value when you want to scale, thanks to its cost benefits at volume.

Combining CNC Machining and Casting

Sometimes the best solution is a mix of both. For example:

- Use casting to create the basic shape at scale

- Then apply CNC machining to add precision features or tight tolerances

- This hybrid approach works well for automotive parts, aerospace components, and medical devices

- You get the cost benefits of casting and the accuracy of CNC machining

Combining processes lets you optimize cost, quality, and speed based on your project needs. For more on casting options, check out our metal casting services and die casting benefits.

Why Choose HYCNC for CNC Machining and Casting

Expertise and Capabilities

At HYCNC, we bring years of experience in both CNC machining and casting. Our team knows the ins and outs of precision CNC machining and various casting methods like die casting and investment casting. This expertise lets us handle projects of all sizes and complexities with confidence, delivering parts that meet tight tolerances and high-quality standards every time.

Customized Solutions

We understand that no two projects are alike. That’s why HYCNC offers tailored solutions to fit your specific needs. Whether you need low-volume CNC machining or high-volume casting, we can customize the process, materials, and finishes to match your requirements. Our goal is to make sure you get exactly what you need without overpaying or waiting too long.

Fast Turnaround and Competitive Pricing

Speed matters in manufacturing, and so does cost. At HYCNC, we balance fast turnaround times with competitive pricing. Thanks to our efficient workflows and advanced equipment, we reduce lead times without cutting corners. Plus, our pricing is transparent and fair, helping you manage budgets while still getting quality parts.

Global Reach and Local Support

No matter where you are in the U.S., HYCNC is ready to support you. We have a strong local presence combined with a global network that helps optimize shipping and logistics. This means you get reliable, timely delivery paired with personalized service from folks who understand your market and expectations.

Choosing HYCNC means partnering with a provider that knows CNC machining vs casting inside out and is committed to your success.

Case Studies CNC Machining and Casting in Action

Case Study 1 CNC Machining for Aerospace Prototypes

We worked with an aerospace company needing high-precision prototypes quickly. Using CNC machining, we delivered complex parts with tight tolerances, ensuring the components met strict aerospace standards. The fast turnaround helped speed up their design validation process and reduced overall development time.

Case Study 2 Die Casting for Automotive Components

For a major automotive supplier, we provided high-volume die casting services. This allowed them to produce thousands of durable metal parts with excellent surface finish and consistent quality. The casting process helped cut costs and shorten lead times compared to machining every piece, making it ideal for large production runs.

Case Study 3 Combining Processes for Medical Devices

A medical device manufacturer needed parts that required intricate shapes and precise finishes. We combined casting for the basic shapes with CNC machining for the final details and tolerances. This hybrid approach ensured the best of both worlds—cost-effective production with the precision needed for safe, reliable medical tools.

These real-world examples show how CNC machining and casting can be used individually or together to meet different industry needs, especially here in the U.S. where quality and speed are key.

How to Decide A Practical Guide

Choosing between CNC machining vs casting depends on your specific project needs. Here’s a simple way to decide:

Assess Your Project Needs

- Volume: For low to medium production runs, CNC machining is often ideal. For high-volume parts, casting usually saves time and cost.

- Precision: If your part requires tight tolerances and high accuracy, CNC machining is the better choice.

- Material: Some materials work better with casting, like certain metals used in die casting, while others suit CNC machining better.

- Design complexity: Casting handles complex shapes and internal cavities well, while CNC machining excels with parts needing smooth finishes and sharp edges.

Consult with HYCNC Experts

We’re here to help you find the right fit. Our team analyzes your design, budget, and timeline to recommend the best manufacturing process—whether it’s CNC machining, casting, or a mix of both. Talking to us early can save you time and money.

Consider Hybrid Approaches

Sometimes the best solution combines the strengths of both processes. For example:

- Start with casting for the rough shape to save cost on large quantities.

- Finish with precision CNC machining to achieve the exact dimensions and surface finish you need.

This hybrid approach is common in industries like automotive and aerospace, where both accuracy and efficiency matter.

If you want more details about our casting options, check out our metal casting services. For die casting specifically, visit our die casting services.

Making the right choice upfront ensures your project runs smoothly and delivers the results you expect.

FAQs

What Materials Can HYCNC Use for CNC Machining and Casting

At HYCNC, we work with a wide range of materials to fit your project needs. For CNC machining, we handle aluminum, stainless steel, brass, plastics, titanium, and more. For casting, we offer options like aluminum die casting, investment casting with steel and alloys, and zinc or magnesium depending on the application. This versatility lets us deliver the right material strength and finish for your parts.

How Does HYCNC Ensure Quality in Both Processes

Quality is a top priority at HYCNC. We use advanced inspection tools like CMM (Coordinate Measuring Machines) and in-process monitoring to check tolerances and surface finishes. Both our CNC machining and casting undergo strict quality control protocols to meet your specs consistently. Plus, our skilled team performs thorough final inspections before parts leave our facility.

What Is the Typical Lead Time for CNC Machining vs Casting with HYCNC

Lead times depend on complexity and volume, but here’s a general idea:

- CNC machining typically takes 1 to 3 weeks, making it ideal for fast turnaround or low-volume runs.

- Casting usually requires 4 to 8 weeks due to mold creation and cooling processes, which suits larger volume production.

We always work to optimize schedules based on your deadlines.

Can HYCNC Handle Both Prototyping and Mass Production

Yes, HYCNC is built to support both ends of the spectrum. Whether you need a few prototype parts to test your design or large-scale production to fulfill orders, we have the resources and expertise. Our flexible setup means scaling from low-volume CNC machining to high-volume casting or combining both as your project grows.

How Do I Get a Quote from HYCNC for My Project

Getting a quote is simple. Reach out through our website or contact our team directly with your design files and project details. We’ll review your needs, recommend the best process—CNC machining, casting, or a hybrid—and provide a competitive quote quickly. We’re here to help you make the right choice and get your project moving.