What is a Face Mill

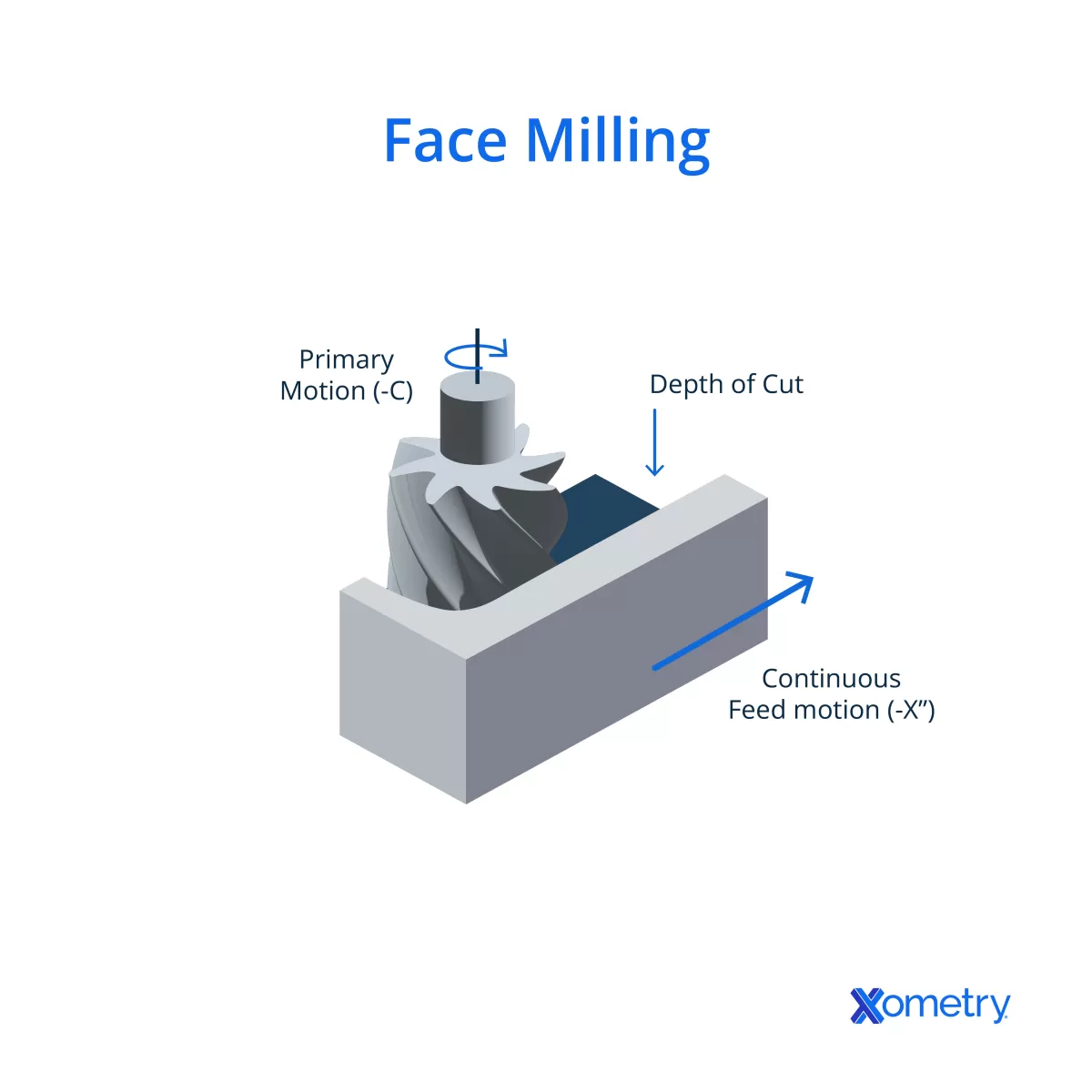

A face mill is a type of CNC milling tool designed primarily for cutting flat surfaces quickly and efficiently. It features multiple cutting teeth arranged around the periphery of a large, circular body, allowing it to remove material across a wide area in one pass. This makes face mills ideal for the face milling process, where large, flat surfaces need to be smoothed or sized.

Key Features

- Large diameter cutting head with multiple indexable inserts

- Cutting edges positioned on the outer rim and sometimes on the face itself

- Designed for high material removal rates

- Often made from carbide or high-speed steel with durable coatings

Common Types

- Indexable face mills with replaceable inserts

- Solid carbide face mills for precision work

- Shell face mills used with arbors to hold the cutter

Applications

- Flattening large workpiece surfaces

- Removing stock quickly in roughing operations

- Preparing metal surfaces before finishing

- Machining large castings and plates

Advantages

- High material removal rate saves machining time

- Good for creating smooth, flat surfaces

- Insert change reduces downtime and cost

- Durable and efficient for heavy-duty milling

Disadvantages

- Less effective on complex or detailed shapes

- Requires a powerful machine due to cutting forces

- Surface finish quality may not match finer milling tools without additional passes

- Larger tool size means higher initial cost and setup time

Face mills are essential in CNC machining when speed and surface flatness are priorities, especially on large parts made from metals like aluminum, steel, and cast iron. Understanding their strengths and limitations helps in selecting the right tool for your milling projects.

What is an End Mill

An end mill is a versatile cutting tool used in CNC milling machines to remove material by cutting in multiple directions. Unlike face mills that mainly cut on the tool’s face, end mills cut with their sides and bottom, making them ideal for detailed work like pockets, slots, and profiles.

Key Features

- Cylindrical shape with cutting edges on the sides and tip

- Available in various flute counts (typically 2 to 8)

- Made from high-speed steel (HSS) or carbide for durability

- Can be coated for better resistance and heat management

Common Types

- Square End Mills: Flat cutting tip for sharp edges and clean slots

- Ball Nose End Mills: Rounded tip for 3D contouring and curved surfaces

- Tapered End Mills: Angled sides for molds and complex shapes

- Roughing End Mills: Chunky teeth for fast material removal

Applications

- Cutting slots, pockets, and contours in metals and plastics

- Precision milling for prototypes or small-batch parts

- Detailed engraving and finishing processes

- Works well on steel, aluminum, and other common CNC materials

Advantages

- Great for 3D shaping and detailed machining

- Flexible in cutting direction, allowing side and end cuts

- Suitable for a wide range of materials

- Easier to find and more affordable than some specialized cutters

Disadvantages

- Slower bulk material removal compared to face mills

- Tool wear can increase on tougher materials when used continuously

- Requires careful selection of flute type and coating for optimal performance

End mills are a cornerstone of CNC machining, balancing precision and versatility for everyday milling tasks. For more on tool selection, check out our guide on tool selection for CNC.

Face Mill vs End Mill Key Differences

Here’s a clear comparison to help you understand the key differences between a face mill and an end mill:

| Feature | Face Mill | End Mill |

|---|---|---|

| Cutting Orientation | Primarily horizontal (face milling) | Mainly vertical (end milling) |

| Tool Design | Larger diameter, multiple cutting inserts | Smaller diameter, single/multi-fluted solid tool |

| Material Removal | Removes a large surface area quickly | Removes material more precisely and in smaller amounts |

| Surface Finish | Good for flat surfaces, moderate finish | Better for detailed finishing and contours |

| Versatility | Best for roughing and flattening large surfaces | More versatile for pockets, slots, contours |

| Cost-Effectiveness | Efficient for big jobs, fewer tool changes | Ideal for detailed work but may need several tools |

Face mills excel when you need to clear big, flat areas fast. End mills shine in versatility, working on curves, slots, and detailed cuts with greater precision. Knowing these differences helps you pick the right tool for your CNC milling needs and get the job done right the first time.

When to Use a Face Mill

Face mills are your go-to for quickly removing large amounts of material from flat surfaces. They shine in jobs where you need to create a smooth, even finish on big, flat workpieces. Think about prepping metal plates, leveling surfaces, or cleaning up large parts before finishing.

Ideal scenarios for face milling:

- Surfacing large steel or aluminum plates

- Preparing flat faces on castings or forgings

- When speed and flatness are more important than intricate detail

Best materials for face milling:

- Steel and stainless steel

- Aluminum and other soft metals

- Cast iron

Tips for optimal face mill use:

- Use the right insert type for your material—carbide inserts work great for durability and heat resistance

- Keep your feed rates steady but aggressive enough to take advantage of the tool’s multiple cutting edges

- Maintain proper depth of cut to avoid chatter and extend tool life

- Check your machine rigidity, as face milling demands a stable setup for the best surface finish

Using a face mill smartly means faster roughing and a good foundation for finishing passes with other tools like end mills. It’s all about maximizing material removal while keeping your workflow efficient.

When to Use an End Mill

End mills are your go-to choice for detailed, precision work in CNC milling. They’re ideal when you need to cut slots, pockets, contours, or intricate shapes in a variety of materials. Whether you’re working with aluminum, steel, plastic, or hardwood, end mills deliver tight tolerances and smooth finishes.

Ideal Scenarios for End Mill Use

- Detailed shaping and profiling

- Slotting and pocketing

- Engraving and contouring

- 3D surface milling

- Cutting narrow channels or grooves

Best Materials for End Mills

- Aluminum and softer metals

- Stainless steel and hardened alloys

- Plastics and composites

- Wood and MDF

Tips for Optimal Use

- Use the right flute count for your material — more flutes for harder materials, fewer for softer ones to prevent clogging

- Choose coatings like TiN or TiAlN to extend tool life and improve performance

- Keep your feeds and speeds balanced to avoid tool wear and achieve a clean surface finish

- Maintain proper coolant flow to reduce heat and chip buildup

With the right setup, end mills help you get precise cuts and excellent surface finishes, especially for complex or fine milling tasks.

How to Choose the Right Tool for Your CNC Project

Picking the right tool for your CNC project can make a huge difference in quality, efficiency, and cost. Here’s what you should keep in mind:

Factors to Consider

- Material Type: Different materials require different cutting tools. Use face mills for large, flat surfaces on softer metals like aluminum. End mills work well for detailed harder materials like steel or titanium.

- Cutting Depth and Width: Face mills cover wider areas quickly but are bulky. End mills are better for deep, precise cuts and smaller features.

- Surface Finish Needed: If you want a smooth finish, choose the tool designed for fine cuts. End mills usually provide better surface finishes on complex shapes.

- Machine Compatibility: Check your CNC machine’s speed and power limits. Face mills typically need higher horsepower, while end mills are more versatile.

- Cost and Tool Life: Indexable face mills might be cost-effective for big jobs, while solid end mills can last longer in detailed work.

HYCNC Recommendation

At HYCNC, we recommend starting with a clear idea of your project goals and materials. Our team helps you match the best tool whether it’s a face mill for fast, broad material removal or an end mill for precision and detail work.

Case Study Example

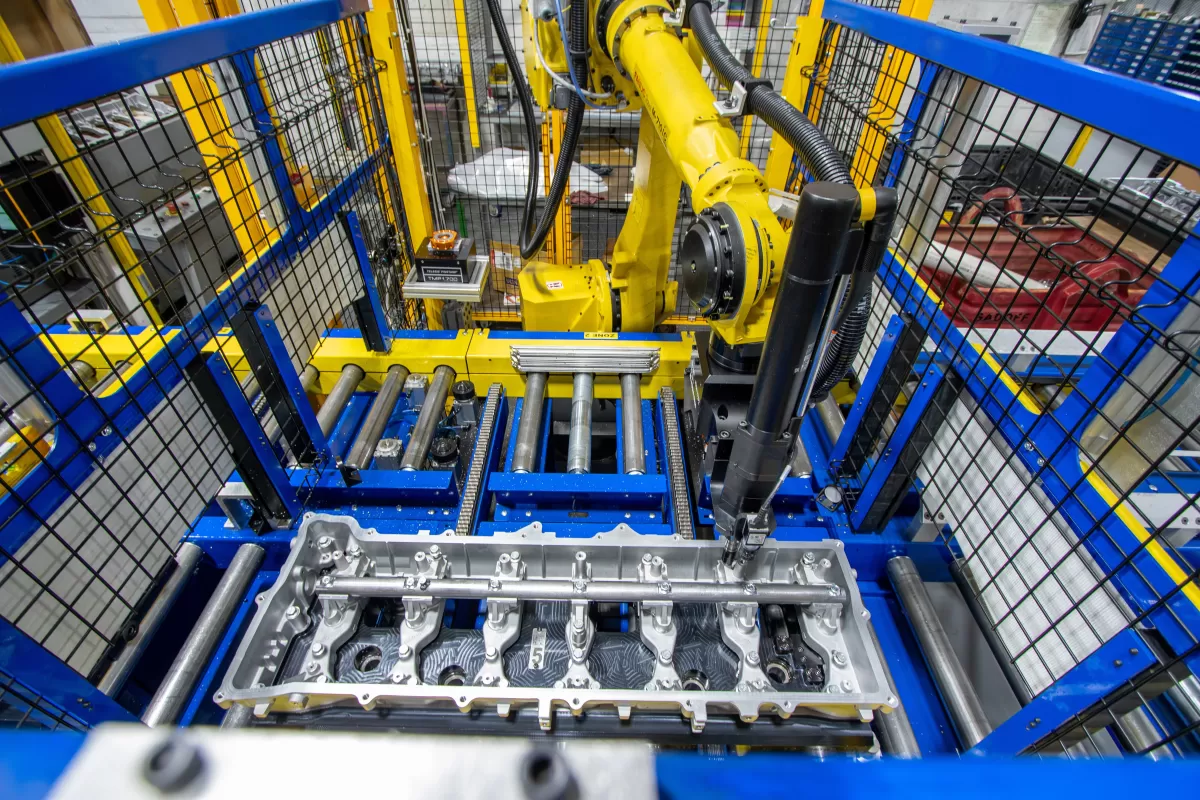

A U.S.-based manufacturing client needed to machine large aluminum plates and intricate steel parts. We suggested using face mills for the aluminum plates, speeding up the roughing process and reducing cycle time by 30%. For the steel parts, we used carbide end mills to achieve sharp edges and tight tolerances. This combo helped them finish projects faster without compromising quality.

Choosing the right tool saves you time and money. If you’re unsure, talk to CNC experts like us at HYCNC — we make the tool selection process easy and effective.

Best Practices for CNC Milling with Face and End Mills

To get the most out of your face mill and end mill tools, following some key best practices is essential. Here’s how to keep your CNC milling smooth and efficient:

Optimize Cutting Parameters

- Adjust speed and feed rates based on the tool type and material. Face mills usually handle higher speeds and deeper cuts, while end mills need more precise control.

- Use the right depth of cut to avoid tool wear or part damage. Shallow passes with end mills ensure accuracy, whereas face mills can take heavier cuts for faster material removal.

Use Appropriate Coatings

- Select tools with coatings like TiN, TiAlN, or carbide inserts. These reduce friction, improve tool life, and support high-speed machining.

- Coatings also help maintain better surface finish by minimizing heat buildup during milling.

Maintain Tools Regularly

- Inspect cutters for wear or chipping before every job. Worn tools not only reduce surface quality but also raise costs due to poor precision.

- Sharpen or replace tools promptly to maintain consistent performance.

Avoid Common Mistakes

- Don’t overload the tool. Even tough face mills can break under excessive feed rates.

- Avoid using the wrong tool for the material—hard metals require specific carbide tools, while softer materials can handle less robust cutters.

- Always secure your workpiece properly to reduce vibration and improve surface finish.

By sticking to these practices, you’ll boost the efficiency, accuracy, and longevity of your CNC milling tools, leading to better parts and lower costs. For more on fine-tuning your milling process and getting a great surface finish, check out our guide on good surface finish for CNC machined parts.

Why Choose HYCNC for Your CNC Milling Needs

When it comes to CNC milling tools and precision machining, HYCNC stands out as a reliable partner for your projects. We specialize in both face mill and end mill applications, offering expert guidance on tool selection and machining techniques that match your needs. Our team understands the local market demands and focuses on delivering high-quality parts with excellent surface finish and tight tolerances.

At HYCNC, we provide comprehensive CNC machining services including high-speed machining, indexable milling inserts, and custom milling cutter solutions. Whether you’re working on prototype parts or volume production, we tailor our approach to maximize your efficiency and minimize costs.

Why choose us?

- Expert advice on choosing the right face mill or end mill based on your material and design

- Advanced CNC equipment and up-to-date machining techniques

- Consistent quality control to ensure precision and reliability

- Quick turnaround times to keep your projects on schedule

- Friendly, local customer support dedicated to your success

Ready to improve your milling results? Contact HYCNC today to get started and experience the difference expert CNC milling tools and services can make for your next project.

For more insight on CNC milling and part design, check out our guide on CNC milling part design.