Are you struggling to pick the perfect CNC router bits for your next project? Choosing the right bits can transform your woodworking, metal, or stone creations, delivering precision and efficiency every time. As a CNC expert, I’ve seen how the right tools make all the difference—based on years of real-world experience at HYCNC. In this guide, you’ll discover the essential types of CNC router bits, their applications, and expert tips to select the best ones for your needs. Dive in and unlock the secrets to mastering your CNC router projects with HYCNC’s top-quality bits!

Understanding CNC Router Bits

CNC router bits are the cutting tools used in CNC machines to shape, carve, and engrave a variety of materials. These bits rotate at high speeds, allowing the CNC router to precisely remove material and create detailed designs and cuts.

How CNC Router Bits Work

CNC router bits work by spinning rapidly while being guided by computer-controlled movements. The bit’s sharp edges cut away material based on the design programmed into the CNC machine. Different bit shapes and sizes allow for various cuts—ranging from fine engraving to deep channeling—making them essential for precise machining tasks.

Common Materials of CNC Router Bits

CNC router bits come in several materials ideal for different applications:

- Tungsten Carbide: Known for durability and heat resistance, perfect for cutting wood, plastics, and soft metals.

- High-Speed Steel (HSS): A budget-friendly option, suitable for softer materials and lighter use.

- Diamond-Tipped: Ideal for cutting extremely hard materials like stone and composites with precision.

Key Features to Consider

When choosing CNC router bits, consider these critical features:

- Material Compatibility: Match the bit material to what you’ll be cutting.

- Bit Shape and Size: Select the shape and diameter that fit your project’s required detail and depth.

- Flute Design: The number and style of flutes affect chip removal and cutting speed.

- Coatings: Coatings like titanium nitride improve bit life and cutting efficiency.

Understanding these basics about CNC router bits sets the foundation for choosing the right tools that enhance your CNC machining projects. For reliable performance, HYCNC offers a wide selection of CNC router bits crafted from premium materials, ensuring precision and durability.

Types of CNC Router Bits and Their Applications

When it comes to CNC router bit types, choosing the right one depends heavily on the material and the job you need to do. Here’s a quick overview of the most common bit types and where they shine.

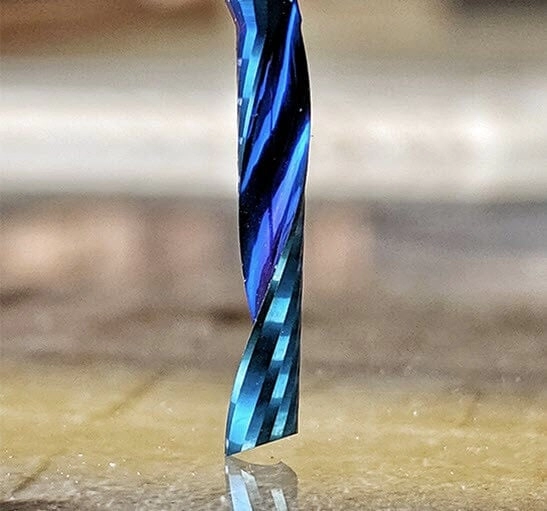

- Spiral Router Bits: These are versatile and great for cutting through wood, plastic, and soft metals. Their spiral design helps clear chips efficiently, making for smoother cuts.

- V-Bit Engraving: Perfect for detailed carving and engraving, especially in wood and soft materials. They create sharp, precise lines ideal for signs or decorative work.

- Compression Bits CNC: These bits are designed for laminate and plywood. They combine upward and downward cutting edges to prevent chipping on both sides of the material.

- Wood Carving Router Bits: Specifically shaped for decorative carving and shaping wood, these bits help achieve fine detail work with ease.

Different materials call for different bit features. For instance, tungsten carbide bits last longer and handle tougher materials like hardwood and certain plastics without dulling quickly.

At HYCNC, we offer specialized CNC router bits designed to meet the demands of different materials and projects. Whether you need tungsten carbide bits for heavy-duty tasks or custom bits for unique designs, our selection supports precision and durability to elevate your CNC machining results.

How to Choose the Right CNC Router Bit

Picking the right CNC router bit can make a huge difference in your project’s quality and efficiency. Here are some key factors to consider:

- Material you’re cutting: Different bits work better on wood, plastics, or metals. For example, tungsten carbide bits are great for hardwood and tougher materials, while spiral router bits excel in clean cuts for softwood and laminates.

- Bit shape and type: Choose based on the cut you want — V-bit engraving for fine details, compression bits CNC for laminates to reduce chipping, or flat end mills for straight cuts.

- Bit size and length: The diameter affects the detail level and cut width. Longer bits reach deeper but may vibrate more, so balance length with your project needs.

- CNC machine compatibility: Match the shank size with your router collet and make sure your machine can handle the bit speed and feed rates.

Tips for Beginners

- Start simple with good all-around router bits like spiral bits or straight bits for woodworking.

- Avoid cheap bits — they wear out fast and can ruin your material.

- Keep spare bits handy for quick changes.

- Always check your bit for damage or buildup before use.

HYCNC’s Expert Recommendations

At HYCNC, we suggest starting with high-quality tungsten carbide bits for long life and cleaner cuts. Our specialists can help you pick the right bit based on your material and project. We back this with custom options if you have unique needs. Feel free to contact us to get expert advice tailored for your CNC machining jobs in the U.S. market.

Best Practices for Using CNC Router Bits

Setup and Safety

Before you start, always double-check that your CNC router bits are properly installed. Tighten the collet securely to avoid vibrations or bit slipping. Wear safety gear like goggles and hearing protection—these tools spin fast and chips can fly. Make sure your workpiece is firmly clamped to prevent movement during cutting. Also, keep your workspace clean and free of debris for safer operation.

Optimizing Performance

To get the best results:

- Match the CNC router bit type to your material and project needs.

- Use the right spindle speed and feed rate; too fast can burn your material, too slow can cause wear.

- Keep bits sharp—dull bits reduce quality and increase wear on your machine.

- Use cooling or air blowing if possible to clear chips and keep the bit cool.

Regular maintenance and cleaning of bits will extend their life and improve your cutting quality.

Troubleshooting Common Issues

If you notice rough cuts, burning, or splintering:

- Check if the bit is dull or damaged and replace it if needed.

- Adjust feed rates or spindle speeds—they might be too aggressive or too slow.

- Ensure the workpiece is secure to reduce vibration.

- Inspect your machine for loose parts or worn components that might affect accuracy.

By following these practices, you’ll keep your CNC router bits working smoothly and produce cleaner, more precise cuts every time.

Why Choose HYCNC for CNC Router Bits

When it comes to CNC router bits, HYCNC stands out for three main reasons: quality, pricing, and customer support.

Quality and Customization

HYCNC uses top-grade materials like tungsten carbide to make durable bits that hold up against tough jobs. Their CNC router bits are crafted with precision to ensure consistent performance, which is crucial whether you’re working with wood, plastics, or composites. Plus, they offer customization options tailored to your specific needs, so you get bits that fit your exact project requirements.

Competitive Pricing and Bulk Availability

If you’re managing a workshop or business, cost matters. HYCNC provides competitive pricing on their CNC router bits without cutting corners on quality. They also support bulk orders, making it easier and more affordable to stock up on the bits you use most. This is perfect for contractors and woodworking shops that require reliable supply at a good price.

Customer Support and Expertise

HYCNC isn’t just a supplier—they’re a partner. Their team understands CNC machining inside and out and offers expert advice to help you pick the right CNC router bit types for your projects. Whether you’re a beginner or a seasoned pro, their support team is ready to answer questions, troubleshoot issues, and ensure you get the best results from your tools.

Choosing HYCNC for your CNC router bits means getting reliable products backed by knowledgeable service—helping you get the job done right and on time.

FAQs

What are the most common CNC router bit types?

The most common types include spiral router bits, V-bit engraving tools, compression bits CNC, and wood carving router bits. Each serves a different purpose, from cutting clean edges to detailed engraving.

Which CNC router bit materials work best?

Tungsten carbide bits are the top choice for durability and precision. They handle hardwoods, plastics, and even aluminum well. High-speed steel bits work but wear out quicker.

How do I choose the right CNC router bit?

Consider the material you’re cutting, the type of cut you want, and your machine’s capabilities. For beginners, start with versatile bits like spiral bits and V-bits for engraving.

Can I use the same bit for wood and metal?

Generally, no. Wood bits and metal bits have different designs and materials. Using the wrong bit can damage your machine or the material.

How often should I replace CNC router bits?

Replace bits when you see signs of wear like chipping, dull edges, or poor cut quality. Regular inspection helps keep your work smooth and accurate.

What makes HYCNC’s router bits stand out?

HYCNC offers quality bits made from premium materials, customizable options, bulk pricing, and expert support tailored for U.S. customers and industries.

If you want a more detailed CNC bit selection guide or tips on CNC machining, just reach out—we’re here to help!