Are you wondering which ISO standards can elevate your manufacturing game? Choosing the right standards can transform your operations, ensuring quality, safety, and global competitiveness.

As a manufacturing expert, I’ve seen firsthand how ISO compliance drives efficiency and trust. This guide, rooted in real-world experience, breaks down the most common ISO standards for manufacturers, with practical insights to help you succeed.

From ISO 9001 to ISO 14001, you’ll discover what these standards mean, why they matter, and how HYCNC leverages them for top-tier CNC processing.

Ready to boost your manufacturing excellence? Let’s get started!

What Are ISO Standards and Why They Matter in Manufacturing

Have you ever wondered why some manufacturers consistently deliver high-quality products while others struggle? The answer often lies in ISO standards. These standards, set by the International Organization for Standardization (ISO), serve as global benchmarks that help businesses maintain consistent quality, safety, and environmental responsibility.

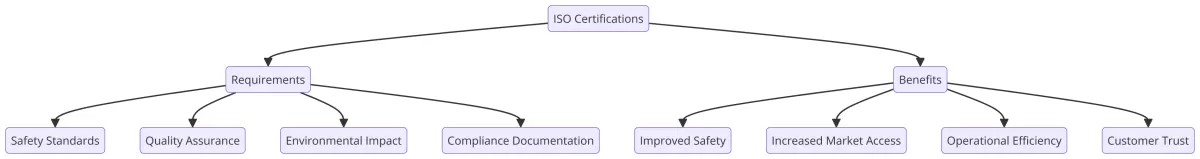

ISO standards are crucial in manufacturing because they:

- Ensure quality by defining clear management system requirements

- Promote safety to protect workers and reduce accidents

- Support environmental responsibility through eco-friendly processes

- Boost market credibility by meeting internationally recognized standards

Following ISO standards comes with many benefits including improved efficiency, reduced waste, and ensuring regulatory compliance. Plus, companies that adopt these standards win greater customer trust, paving the way for stronger business relationships and global market access.

In short, ISO standards help manufacturers like HYCNC streamline operations, maintain exceptional quality, and stay competitive in the fast-evolving manufacturing landscape.

Top 5 Common ISO Standards in Manufacturing

When it comes to manufacturing, certain ISO standards keep popping up because they cover crucial aspects like quality, environment, safety, and industry-specific requirements. Here are the top 5 common ISO standards you’ll see across the US manufacturing landscape, along with how HYCNC puts them into practice.

ISO 9001 Quality Management System

ISO 9001 focuses on consistent quality and customer satisfaction. It sets the bar for managing processes that deliver reliable products. At HYCNC, this standard ensures every CNC machining project meets strict quality checks, minimizing errors and keeping customer specs tight.

ISO 14001 Environmental Management System

ISO 14001 helps manufacturers manage environmental responsibilities effectively, reducing waste and energy use. HYCNC applies this by integrating eco-friendly practices within CNC workflows—cutting down emissions and recycling scrap materials to support sustainability goals.

ISO 45001 Occupational Health and Safety

Worker safety is a big deal, and ISO 45001 provides the framework to protect employees and reduce workplace hazards. HYCNC maintains strict safety protocols in machining operations, from machine maintenance to employee training, ensuring a safe shop floor for all.

IATF 16949 Automotive Quality Management

Specifically designed for the automotive sector, IATF 16949 builds on ISO 9001 with added focus on defect prevention and continuous improvement. For HYCNC, this means delivering precise CNC parts that meet auto industry specs, supporting manufacturers’ drive for zero-defect components.

ISO 13485 Medical Devices Quality Management

This standard governs quality requirements for medical device manufacturing. It demands rigorous process control and documentation. HYCNC serves medical clients by adhering to ISO 13485, guaranteeing CNC machined parts meet the strict standards needed for life-saving devices.

These standards let manufacturers like HYCNC deliver trusted, compliant, and efficient services, making ISO certification a must-have for staying competitive in today’s market. For more on optimizing manufacturing processes, check out our insights on design for manufacturing and assembly.

How to Implement ISO Standards in Manufacturing

Implementing ISO standards in manufacturing starts with identifying which standards fit your industry and business needs. Not every standard applies to every operation, so focus on those that improve your quality, safety, and environmental impact.

Next, conduct a gap analysis to compare your current processes against the ISO requirements. This shows where you’re strong and where improvements are needed.

From there, develop a clear implementation plan. This should include:

- Training programs for your team

- Documentation updates

- Adjustments to workflows and processes

Involving your employees early helps make the changes stick.

Once your plan is underway, engage third-party auditors to verify your compliance and grant certification. Their unbiased review ensures you meet all the necessary ISO standards.

After certification, it’s important to keep up with regular internal audits and continuous improvement cycles. This keeps your manufacturing processes aligned with ISO requirements and evolving industry best practices.

At HYCNC, we integrate ISO standards directly into our CNC machining workflows, ensuring consistent quality and efficiency. Our approach makes ISO part of the daily routine, not just a checkbox for audits, helping us deliver top-notch CNC services you can trust.

Benefits of ISO Certification for Manufacturers

Getting ISO certified gives manufacturers a real edge in today’s competitive market. It shows customers and partners you meet global standards, which builds strong trust and opens doors to new business opportunities worldwide.

ISO certification also helps save money by cutting down waste and boosting efficiency. Streamlined processes mean less scrap material, fewer mistakes, and better use of time and resources. This aligns perfectly with regulations, so you avoid fines and stay ahead of compliance requirements.

Most importantly, consistent quality from ISO standards keeps customers happy. They know what to expect every time they order, which strengthens loyalty and repeat business.

Take HYCNC as an example. By integrating ISO principles into their CNC machining services, they enhanced their reputation for reliability and precision in the US manufacturing market. This boosted their credibility and helped them stand out among competitors.

Key benefits include

- Competitive advantage with global recognition

- Cost savings from reducing waste and improving efficiency

- Easier regulatory compliance

- Higher customer satisfaction through consistent quality

- Strengthened brand reputation like HYCNC’s success in CNC service

For manufacturers in the United States, embracing ISO certification isn’t just a checkbox—it’s a smart business move that delivers real results.

Challenges and Solutions in Achieving ISO Certification

Getting ISO certification in manufacturing isn’t always easy. One of the biggest hurdles is the high initial costs. Investing in new systems, training, and audits can feel costly upfront. But focusing on the return on investment (ROI) helps—think of how improved efficiency and waste reduction save money over time.

Another common challenge is the complex paperwork and documentation required. This can slow down the process and overwhelm teams. Thankfully, digital tools and consultants simplify this by organizing documents and streamlining workflows, making compliance smoother.

Employee training is key, too. Without regular programs and clear communication, it’s tough to keep everyone on the same page about ISO standards. Consistent training sessions and easy-to-understand materials help build confidence and compliance.

At HYCNC, we’ve tackled these challenges by integrating ISO standards directly into our CNC machining processes. We use tailored training, leverage software tools for documentation, and focus on communicating the benefits across teams. This approach keeps certification on track while minimizing disruption to our production.

By addressing costs smartly, simplifying paperwork, and investing in ongoing training, manufacturers can overcome certification hurdles and enjoy the full benefits of ISO standards.