What is a Coordinate Measuring Machine CMM

A Coordinate Measuring Machine (CMM) is a computer-controlled device used to precisely measure the physical geometry of an object. It captures accurate dimensions by probing specific points on a part’s surface and comparing those measurements to the intended design.

Key components of a CMM include:

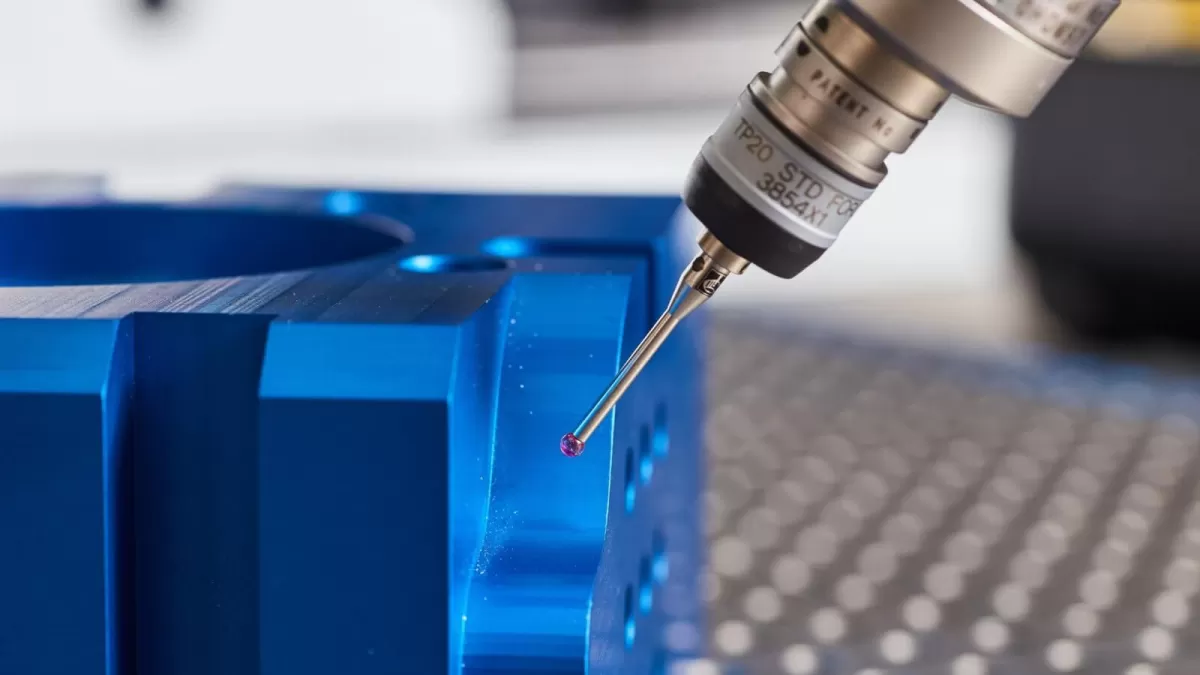

- Probes that touch or scan the part to gather data

- Software that processes measurements and analyzes results

- Fixturing systems to hold the part securely during inspection

There are several types of CMMs designed for different applications:

- Bridge CMMs, which have a moving bridge structure over a fixed table

- Gantry CMMs, large machines with a gantry frame ideal for big parts

- Horizontal arm CMMs allowing easier access to certain geometries

- Portable CMMs, handheld devices for on-site measurements

- Optical CMMs, using cameras and lasers for non-contact measurement

Unlike traditional measurement tools like calipers or micrometers, CMMs offer automated, highly precise 3D measurements, making them essential for modern quality control and dimensional accuracy in manufacturing.

How Does CMM Inspection Work

CMM inspection starts with setting up and calibrating the machine. This includes aligning the probe and securely fixturing the part to make sure measurements are accurate and repeatable. Proper setup is crucial because even small misalignments can throw off results.

Next, the CMM collects data either through contact or non-contact measurement methods. Contact probes physically touch the part, while non-contact options like lasers or scanners gather data without touching the surface. Both provide precise dimensional accuracy depending on the part’s shape and material.

Once the data is collected, it’s analyzed by comparing measurements against CAD models and manufacturing tolerances. This step helps identify any deviations and ensures parts meet design specifications.

Detailed reports are generated showing feature lists, tolerances, pass/fail status, and GD&T (Geometric Dimensioning and Tolerancing) analysis. These reports are vital for quality control and compliance with standards like ISO and AS9100.

CMM inspections usually happen in controlled environments where temperature and humidity are carefully managed. These factors impact measurement precision, so keeping them stable helps maintain consistency.

Advanced software plays a big role in automating the entire process—handling data collection, analysis, and reporting swiftly and accurately. It also supports complex calculations and trend tracking, making CMM inspection a powerful tool for manufacturers focused on quality and efficiency.

Benefits of CMM Inspection

CMM inspection offers unmatched accuracy, measuring parts down to micrometer-level precision. This means you get reliable, consistent results every time, ensuring your products meet exact specifications.

It also saves time by automating the measurement process. Instead of manual checks that can slow production, CMM inspection speeds things up without sacrificing quality.

Another big plus is reducing human error. With a computer-controlled system, variability from different operators is minimized, leading to more consistent outcomes.

By catching issues early, CMM inspection helps cut costs by reducing the need for rework and minimizing waste during manufacturing.

Finally, CMM inspection supports stronger quality control. It aligns with industry standards like ISO and AS9100, helping you stay compliant and delivering parts that meet strict tolerance and dimensional accuracy requirements.

Applications of CMM Inspection

CMM inspection plays a crucial role across many industries, including automotive, aerospace, medical, and manufacturing. These sectors rely on precise measurements to keep products safe, reliable, and up to standard.

Common Use Cases

- First Article Inspection: Verifying a prototype or initial part meets design specs before mass production.

- In-Process Inspection: Checking parts during production to catch issues early.

- Final Inspection: Ensuring finished products comply with required tolerances and quality standards.

- Reverse Engineering: Measuring existing parts to create accurate CAD models or replacements.

- Process Capability Studies: Analyzing how well a manufacturing process consistently produces parts within set limits.

Real World Example from HYCNC

At HYCNC, we provide top-tier CMM inspection services that guarantee precision for CNC machined parts. Our inspections help automotive and aerospace clients maintain strict dimensional accuracy, reducing delays and costly rework. Using advanced CMM technology, we ensure your parts meet all specifications, so you can trust the quality every step of the way.

Why Choose HYCNC for CMM Inspection Services

At HYCNC, we bring deep expertise in both CNC machining and CMM inspection, making us uniquely qualified to handle your precision measurement needs. Our team understands the challenges in manufacturing and uses state-of-the-art equipment paired with advanced software to deliver accurate, reliable results every time.

We know speed matters, so we offer a fast turnaround—usually within one to three business days—without cutting corners. Every inspection includes comprehensive reporting to give you clear insights, including detailed tolerance and GD&T analysis.

Quality is at the core of everything we do. HYCNC follows strict ISO-compliant processes to ensure your parts meet the highest standards when it comes to dimensional accuracy and quality control.

Ready to improve your inspection process? Contact HYCNC today for a free quote and see how our CMM inspection services can help your business stay precise and efficient.

Common Challenges and Solutions in CMM Inspection

CMM inspection offers great precision, but it does come with a few challenges, especially for businesses new to this technology.

Common Challenges:

- High initial costs: Investing in CMM equipment and training skilled operators can be expensive upfront.

- Need for skilled operators: Accurate measurements require experienced staff who understand both the machine and the inspection process.

- Limitations with soft materials: Measuring flexible or soft parts can be tricky because probes might deform the material.

- Complex shapes: Parts with intricate features or tight spaces can be tough to measure accurately without specialized setups.

Effective Solutions:

- Modular fixturing: Customizable fixtures hold parts securely, helping with complex shapes and preventing movement during inspection.

- Advanced software: Modern CMM software improves data analysis, automates measurements, and compensates for challenges like soft materials.

- Regular calibration: Routine machine calibration ensures consistent accuracy and catches issues before they affect results.

At HYCNC, we know these challenges well. We tackle them by providing tailored solutions such as custom fixturing and using the latest software updates. Our team’s experience with both CNC machining and CMM inspection means we quickly adapt to complex parts, keeping your quality control on point without delays.

FAQs About CMM Inspection

Difference Between Contact and Non Contact CMM Inspection

Contact CMM uses a physical probe that touches the part to measure dimensions. It’s very precise for solid, durable materials. Non contact CMM uses lasers or cameras to scan the part without touching it, which works better for delicate or soft materials and complex shapes. Both have their place depending on your part and measurement needs.

Accuracy of CMM Inspection

CMM inspections deliver micrometer-level precision, making them far more accurate than traditional tools like calipers or gauges. This level of accuracy ensures your parts meet tight manufacturing tolerances and quality standards every time.

Industries Benefiting Most From CMM Inspection

CMM inspection is widely used in industries where precision is crucial, such as automotive, aerospace, medical devices, and manufacturing. If your product requires strict dimensional accuracy or compliance with standards like ISO or AS9100, CMM inspection is a must-have.

Typical Duration of CMM Inspection

Most CMM inspections can be completed within one to three business days depending on the part’s complexity and the scope of measurement. At HYCNC, we specialize in fast turnaround without sacrificing accuracy.

Reasons to Choose HYCNC for CMM Inspection Services

- Expertise: Deep knowledge in CNC machining and precision measurement.

- Advanced Equipment: Cutting-edge CMM machines and software for reliable results.

- Fast Turnaround: Quick reporting so you can keep your projects on track.

- Quality Commitment: ISO-compliant processes ensuring consistent quality every time.

- Customized Solutions: Tailored inspection plans to fit your exact needs.

If you want precise, reliable CMM inspection support, contact HYCNC for a free quote and see how we can help your business stay on point.