What Are CNC Machines A Brief Overview

CNC machines are automated tools controlled by computer programs that cut, shape, and finish materials with high precision. CNC stands for Computer Numerical Control, which means the machine follows digital instructions to perform subtractive manufacturing—removing material from a workpiece to create a final part. These machines revolutionize production in industries like woodworking, metalworking, and prototyping by providing consistent quality and faster turnaround times compared to manual methods.

There are several types of CNC machines designed for different tasks and materials. The most common ones include CNC routers, CNC mills, and CNC lathes. Each type has unique features suited to specific applications, whether it’s cutting wood, machining metal, or turning parts on a rotating axis. Understanding their strengths helps companies and makers choose the right equipment for their projects.

Today, CNC machining services have become essential for businesses looking to improve accuracy, reduce waste, and scale production efficiently. Whether you’re working on custom CNC woodworking, precision CNC metal cutting, or detailed CNC prototyping, knowing what each machine offers is key to success.

CNC Router Features and Applications

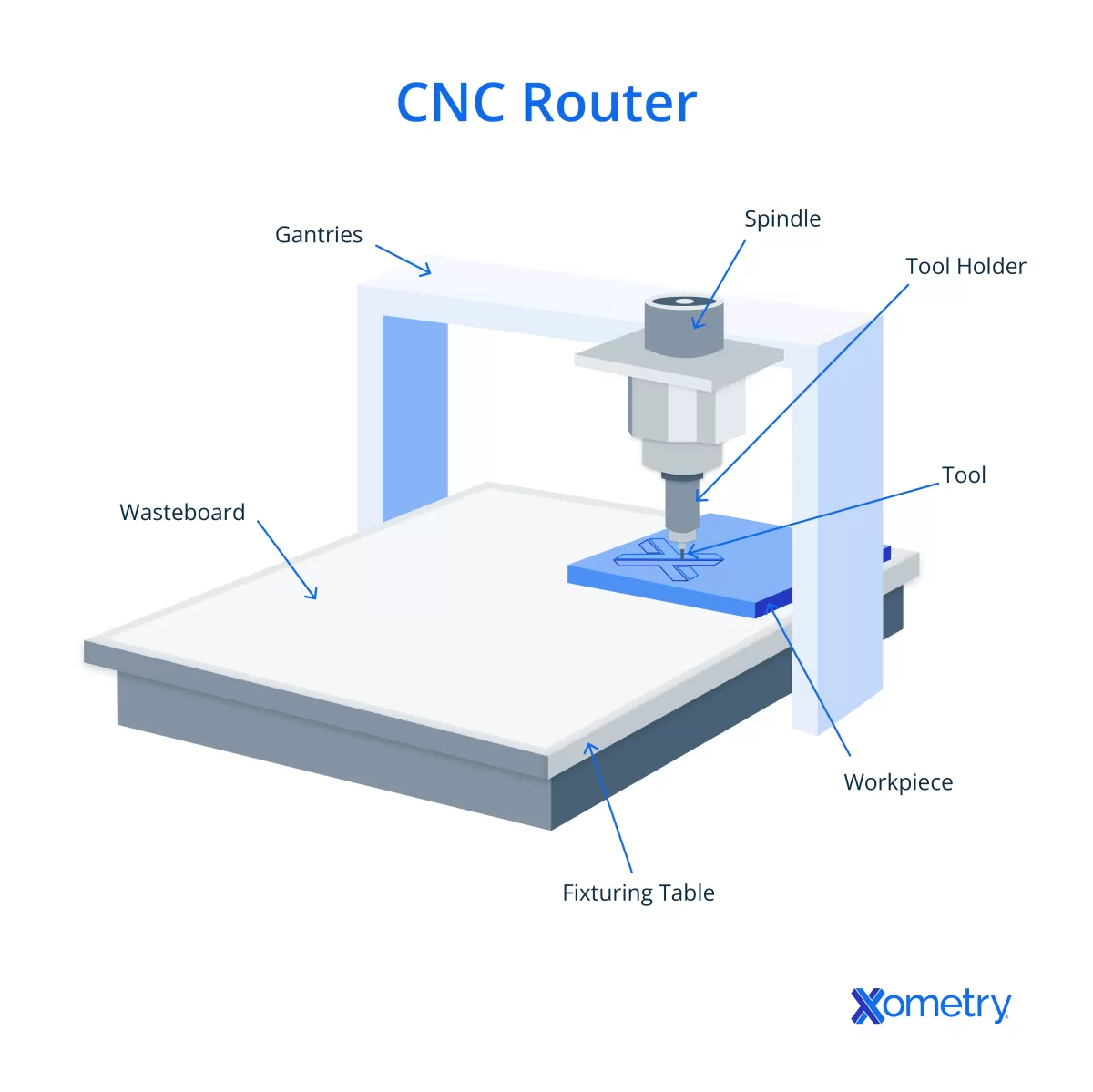

Definition

A CNC router is a computer-controlled cutting machine mainly used for carving and shaping materials like wood, plastics, and some soft metals. It works by guiding a rotating cutting tool across the material surface to create designs, patterns, or parts.

Key Features

- Large working area ideal for big sheets and panels

- High-speed spindle for fast cutting, especially in softer materials

- Multiple axis configurations (usually 3 to 5 axes) for versatile shapes

- User-friendly software that supports detailed designs and automation

Materials

- Wood and plywood

- Plastics like acrylic and PVC

- Soft metals including aluminum

- Foam and composites

Applications

- Woodworking including cabinetry, furniture, and decorative pieces

- Sign making with detailed engravings and cut-outs

- Prototyping of plastic and light metal parts

- Creating molds and fixtures for manufacturing

Pros and Cons

Pros

- Great for large, flat materials

- Faster at cutting softer materials

- Affordable entry for woodworking and signage

- Easy to program for complex shapes

Cons

- Not suitable for heavy metals or very hard materials

- Less precise than CNC mills for detailed metal parts

- Cutting depth and tool rigidity limit heavy-duty operations

HYCNC Connection

At HYCNC, we provide expert CNC router machining services tailored to your project needs. Whether you’re crafting wood furniture or plastic prototypes, we ensure accurate cuts and smooth finishes. Our local US-based service combines quick turnaround with quality that fits your budget.

CNC Mill Features and Applications

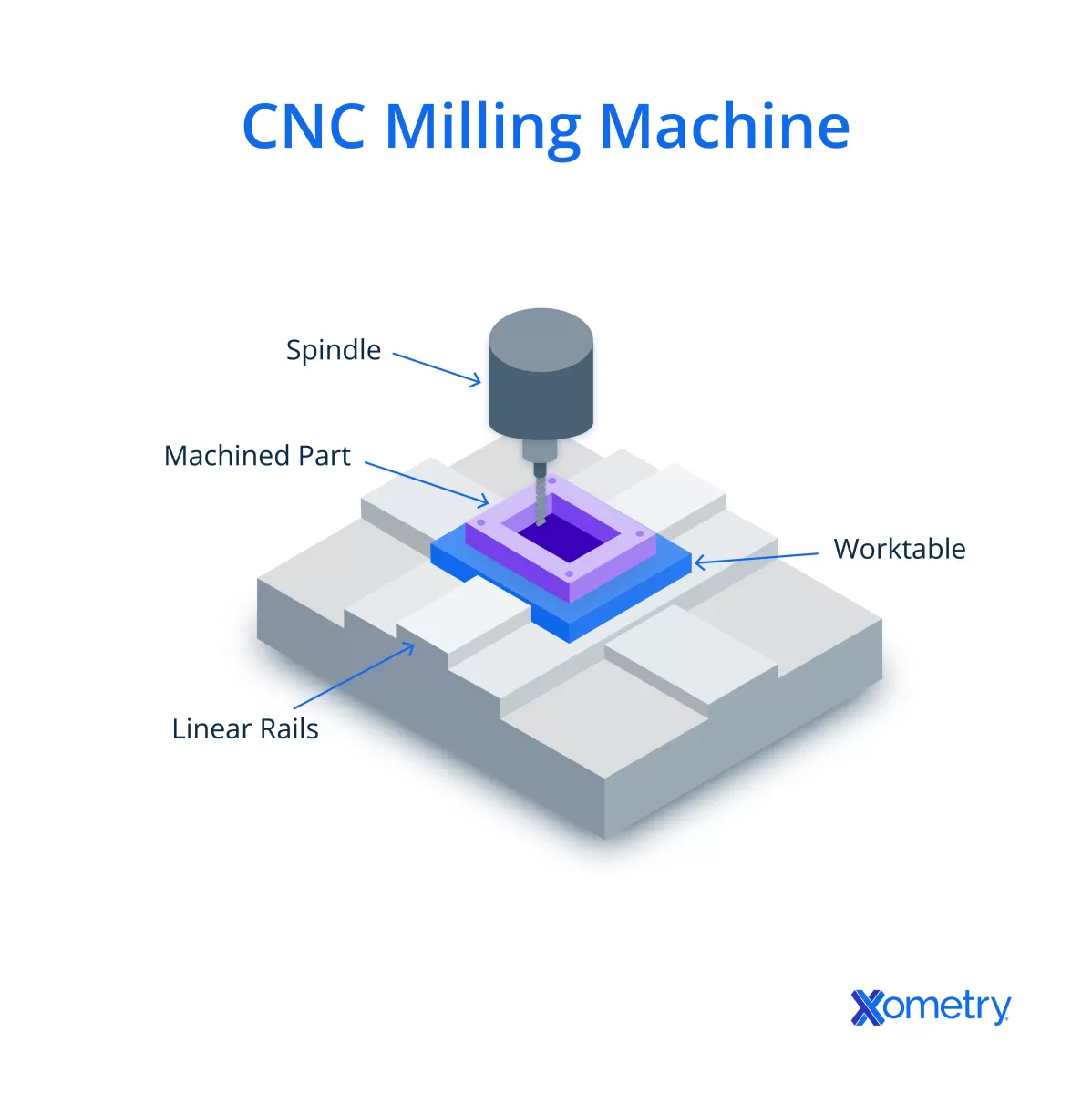

Definition

A CNC mill is a subtractive manufacturing machine designed to cut and shape solid materials with high precision. Unlike routers that often work on softer materials, CNC mills use rotating cutting tools to remove material from metal, plastic, or wood blocks to create complex parts and prototypes.

Key Features

- Precision Cutting: CNC mills offer tight tolerances, making them ideal for detailed and accurate parts.

- Multi-Axis Options: Most CNC mills operate in 3 to 5 axes, allowing complex shapes and undercuts.

- Versatile Tooling: They can switch between various cutters like end mills, drills, and taps for different operations.

- Rigid Construction: Built to handle tougher materials with minimal vibration or flexing.

Materials

- Metals (aluminum, steel, brass, titanium)

- Plastics (acrylic, nylon, polycarbonate)

- Wood and composite materials

Applications

- Precision parts for aerospace, automotive, and medical devices

- Prototyping metal components with exact specs

- Low to mid-volume manufacturing of inserts, housings, and gears

- Custom jobs requiring detailed metal or plastic machining

Pros and Cons

| Pros | Cons |

|---|---|

| High precision and repeatability | Generally slower than routers |

| Handles tougher materials | Setup can be more complex |

| Can perform milling, drilling & tapping | Higher cost for machine and tooling |

| Good for metal cutting | Requires more operator skill |

HYCNC Connection

At HYCNC, our CNC milling services focus on precision and versatility. We leverage advanced milling technology for custom metal and plastic parts that need tight tolerances and detailed finishes. If you want to see tips on milling part design and how to optimize your project, check out our blog on CNC Milling Part Design.

Whether you’re prototyping or need a reliable service for production runs, HYCNC’s CNC mill capabilities have you covered with local support and expert know-how for the US market.

CNC Lathe Features and Applications

Definition

A CNC lathe is a machine that spins a workpiece while a cutting tool shapes it. It’s mostly used for turning operations, which means it’s great at making round or cylindrical parts by removing material as the workpiece rotates. This is ideal for producing precise, symmetrical shapes like shafts, bolts, or rings.

Key Features

- Rotating Workpiece: The main feature is the spinning part, controlled precisely by the CNC system.

- Tool Turret: Holds multiple cutting tools that can quickly switch during operation.

- High Precision: Excellent for detailed turning and facing tasks.

- Automation Friendly: Can run parts in batches with minimal operator input, improving efficiency.

Materials

CNC lathes work well with a variety of materials commonly used in the U.S. manufacturing sector, including:

- Metals (steel, aluminum, brass, titanium)

- Plastics (nylon,, PVC)

- Wood (for specific lathe variations### Applications

- Producing automotive parts such as axles and gears

- Making plumbing and pipe fittings

- Manufacturing aerospace components

- Crafting custom metal parts for manufacturing and prototyping

Pros and Cons

Pros

- Great for precision turning and cutting circular parts

- Efficient for batch production

- Lower setup times for standardized parts

- Compatible with various materials commonly used in U.S. industries

Cons

- Limited to symmetrical, round shapes (not suited for complex 3D milling)

- Not ideal for flat or irregular surfaces

- Typically less versatile than CNC mills or routers for diverse tasks

HYCNC Connection

At HYCNC, we specialize in CNC lathe services tailored to U.S. businesses needing accurate, reliable turning operations. Our CNC lathe machining covers a wide range of metals and plastics, perfect for automotive, aerospace, and custom manufacturing needs. We emphasize quick turnaround, local support, and precision you can count on for your CNC metal cutting and prototyping projects.

Head to Head Comparison of CNC Router vs CNC Mill vs CNC Lathe

Here’s a quick comparison to help you see the main differences and find the right CNC machine for your needs.

| Feature | CNC Router | CNC Mill | CNC Lathe |

|---|---|---|---|

| Primary Use | Cutting, shaping wood, plastic, foam | Precision metal cutting, shaping | Turning and shaping cylindrical parts |

| Materials | Wood, plastics, composites, soft metals | Metals like aluminum, steel, brass | Metals, plastics, wood |

| Cutting Style | Mostly 2D and light 3D cutting | 3D precision contouring and profiling | Rotates workpiece for internal/external cutting |

| Accuracy | Moderate accuracy for large parts | High precision for detailed work | High precision for round objects |

| Common Applications | Furniture, sign making, cabinetry | Aerospace parts, prototypes, precision tooling | Shafts, screws, bushings |

| Speed | Faster with larger parts | Slower due to precision | Fast on repetitive round parts |

| Pros | Cost-effective, versatile on soft materials | High precision, good for complex metal parts | Excellent for turning, fast for cylindrical parts |

| Cons | Limited on hard metals, less precision | More expensive, slower | Limited to round or symmetrical parts |

Use Case Scenarios

- CNC Router is ideal if you’re working with wood, plastics, or composite materials, especially in industries like cabinetry, furniture, and sign making. It’s great for larger parts that don’t require ultra-high precision.

- CNC Mill is your go-to for metal cutting and precision prototyping. If your project involves complex geometries or requires tight tolerances, CNC milling delivers.

- CNC Lathe shines in turning tasks, making it perfect when you need to produce round parts like shafts or threaded components with efficiency and accuracy.

HYCNC Insight

At HYCNC, we understand these differences deeply. We recommend contacting us when you need expert advice on which CNC machining service suits your job best. Whether it’s woodworking with CNC routers, precision metal cutting with CNC mills, or efficient turning with CNC lathes, we’ve got you covered with tailored solutions designed for the American market.

If you’re interested in learning more about CNC milling’s precision and part design, check out our detailed guide on CNC milling part design. For a closer look at CNC routers, take a peek at our blog on CNC router bits.

Choosing the right machine impacts your project timeline, budget, and quality — so making an informed choice with HYCNC is key.

Choosing the Right CNC Machine or Service

Picking the right CNC machine or service comes down to understanding your project needs and budget. Here are some key factors to consider:

- Material Type: Different machines handle different materials better. CNC routers excel with wood, plastics, and softer metals, while CNC mills and lathes tackle harder metals and complex shapes.

- Precision Requirements: For high-precision parts, CNC mills or lathes are usually better. CNC routers are great for larger, less intricate cuts.

- Production Volume: High-volume runs might benefit from automated CNC mills, while smaller batches or prototypes could be handled by routers or lathes.

- Part Complexity: Lathes are perfect for turning symmetrical round parts, mills for detailed 3D shapes, and routers for flat, large-area cuts.

- Budget and Lead Time: CNC routers are generally more affordable, but mills and lathes provide advanced capabilities worth the investment for certain jobs.

When to Outsource CNC Machining

Outsourcing can save time and worry when:

- You lack the equipment or expertise for the job.

- You need quick turnaround or prototyping.

- The job requires specialized CNC machining services you don’t have in-house.

- Managing overhead costs is a priority.

A trusted CNC service provider like HYCNC can handle your project efficiently and help you choose the best machining method.

Local Search Tip

To find reliable CNC service providers near you, try searching with terms like “CNC machining services near me” or “local CNC router services.” Local workshops often offer competitive pricing and faster communication, which can be a big advantage for short-run or urgent projects.

If you want to learn more about CNC machine capabilities or design tips, check out HYCNC’s detailed guides on CNC milling part design and CNC router bits.

Why Choose HYCNC for Your CNC Needs

When it comes to CNC machining services, HYCNC stands out as a reliable partner for businesses and makers across the United States. Here’s why HYCNC should be your go-to CNC service provider:

-

Wide Range of CNC Machines

HYCNC offers expert services using CNC routers, CNC mills, and CNC lathes, ensuring the right machine matches your project—from woodworking to precision metal cutting and complex turning.

-

Precision and Quality You Can Trust

With advanced equipment and experienced operators, HYCNC guarantees top-notch accuracy and consistent quality for prototypes, custom parts, and production runs.

-

Local and Fast Turnaround

Based in the U.S., HYCNC understands the need for quick delivery without compromising quality. Their streamlined process cuts down lead times to keep your project on schedule.

-

Customized Solutions for Every Project

Whether you need subtractive manufacturing for small parts or large batches, HYCNC works with you to optimize design, material selection, and machining strategies to reduce costs and improve outcomes.

-

Clear Communication and Support

From initial consultation to delivery, HYCNC provides clear, friendly communication, helping you make informed decisions about your CNC prototyping or production jobs.

-

Proven Track Record and Customer Satisfaction

Many U.S. clients rely on HYCNC for their CNC automation and machining needs, appreciating the company’s reliability and dedication to meeting customer expectations.

Choosing HYCNC means partnering with a CNC machining expert who knows the local market and delivers parts that meet your exact specifications. Whether it’s a simple CNC router woodworking project or complex CNC mill precision work, HYCNC has you covered.

For more insights on CNC milling design and tips, check out Design Tips for CNC Milled Low Volume Parts.

FAQs

What is the main difference between a CNC router, mill, and lathe?

- A CNC router is great for cutting soft materials like wood and plastic with fast speeds and larger work areas.

- A CNC mill is designed for precision machining, mainly on metals and harder materials, with detailed cuts and complex shapes.

- A CNC lathe focuses on turning parts by spinning the workpiece, ideal for cylindrical or round shapes.

Can I use a CNC router for metal cutting?

- CNC routers can cut softer metals like aluminum but are not ideal for heavy-duty metal cutting. For tougher metals, a CNC mill or lathe is better suited.

Which CNC machine is best for woodworking?

- CNC routers are the go-to for woodworking. They handle large wood sheets and complex cuts efficiently.

Do CNC mills and lathes require more maintenance than routers?

- Generally, CNC mills and lathes have more moving parts and work with tougher materials, so they might need more maintenance than routers.

What materials can CNC lathes work with?

- CNC lathes work well with metals, plastics, and wood, especially when the design needs round or cylindrical shapes.

When should I outsource CNC machining services?

- Outsource when you need precision parts quickly, don’t have the equipment in-house, or want to save on costs related to machine ownership and maintenance.

Is HYCNC a reliable CNC service provider?

- Yes, HYCNC offers expert CNC machining services including router, mill, and lathe operations with fast turnaround and quality machining catering to US customers.

For more tips on CNC milling part design, check out CNC Milling Part Design Tips.