Overview of CNC Cutting Technologies

CNC cutting is a modern manufacturing process where computer-controlled machines precisely cut materials into specific shapes and sizes. This technology improves accuracy, repeatability, and efficiency across various industries like metal fabrication, automotive, aerospace, and more.

There are three primary CNC cutting methods widely used today: laser cutting, waterjet cutting, and plasma cutting. Each offers unique advantages depending on the material and project requirements.

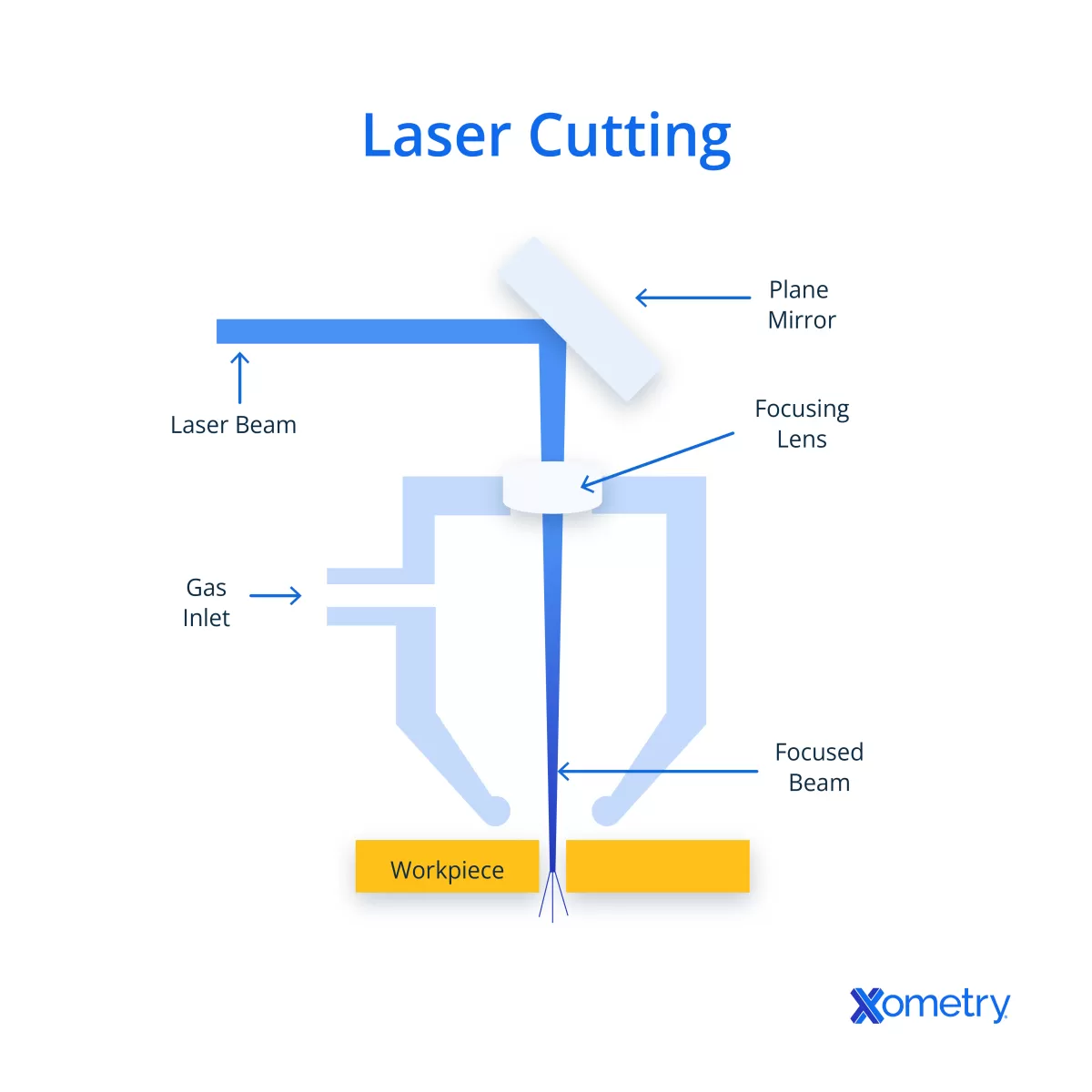

Laser cutting uses a focused beam of light to melt or vaporize material. It’s known for its high precision and clean cuts, especially on metals, plastics, and thin materials.

Waterjet cutting employs a high-pressure jet of water mixed with abrasive particles. This method cuts through almost any material, including thick metals, stone, and glass, without generating heat.

Plasma cutting works by sending an electrical arc through compressed gas to ionize it into plasma. It’s a fast and cost-effective way to cut conductive metals like steel and aluminum, especially useful for thicker materials.

Comparing these CNC cutting technologies helps you select the right method based on factors like precision, material compatibility, cost, and application. At HYCNC, we understand how important it is to match your cutting technology to your project’s needs for the best results.

Key Comparison Factors

When deciding between laser vs waterjet vs plasma CNC cutting, several factors come into play. Understanding these can help you pick the best fit for your project.

Precision and Cut Quality

Laser cutting stands out for its exceptional precision and smooth edges, making it ideal for detailed designs and fine cuts. Waterjet cutting is also precise but offers a slightly rougher edge, which is perfect for thicker or heat-sensitive materials. Plasma cutting provides faster cuts but with less accuracy and a rougher finish, better suited for thicker metal where detail is less critical.

Speed and Productivity

Plasma cutting leads in speed, especially on thicker metals, helping you finish jobs faster. Laser cutting is slower than plasma but faster than waterjet for thin to medium materials. Waterjet cutting tends to be the slowest, but it’s versatile and can handle complex cuts without causing heat damage.

Material Compatibility

Waterjet cutting is the most versatile — it can cut metals, stone, glass, composites, and even rubber. Laser cutting works best with metals, plastics, and wood but struggles with very thick or reflective materials. Plasma cutting is mostly limited to electrically conductive metals and works great on thick steel and aluminum.

Cost Analysis

Plasma cutting uses less expensive equipment and has lower operational costs, making it budget-friendly for heavy metal fabrication. Laser cutting offers high precision but often comes with higher upfront and maintenance costs. Waterjet cutting falls in the middle, with moderate equipment costs but higher operating expenses due to abrasive materials.

Safety and Environmental Considerations

Waterjet cutting is the safest option—no heat or harmful gases, just clean water and abrasive materials. Laser and plasma cutting both generate fumes and require ventilation systems and protective gear to ensure safety and environmental compliance.

Applications

- Laser cutting: Electronics, aerospace, custom signage, and fine metal fabrication

- Waterjet cutting: Aerospace, automotive parts, stone and tile, materials sensitive to heat

- Plasma cutting: Heavy metal fabrication, construction, shipbuilding where fast, thick metal cuts are needed

Clear knowledge of these factors ensures you get the right CNC cutting technology for your project. For a deeper dive into waterjet vs laser cutting, check out our detailed guide Waterjet Cutting vs Laser Cutting Service Which is Best.

Pros and Cons Table

| Cutting Method | Pros | Cons | Best Use Cases |

|---|---|---|---|

| Laser Cutting | – High precision and clean edges – Fast cutting for thin to medium materials – Minimal material waste |

– Limited on thick materials – Higher upfront equipment cost – Not ideal for reflective metals |

Precision parts, fine details, thin metals, plastics |

| Waterjet Cutting | – Works on almost any material – No heat-affected zones – Great for thick materials and delicate composites |

– Slower than plasma and laser – Higher operating costs (abrasive use) – Requires water management |

Thick metals, stone, glass, composites, heat-sensitive materials |

| Plasma Cutting | – Very fast for thick conductive metals – Lower equipment cost – Easy to operate |

– Lower precision and rougher edges – Limited to electrically conductive materials – Heat-affected zones can cause warping |

Thick steel, aluminum sheets, quick cuts, heavy fabrication |

This table gives you a quick glance at how each CNC cutting technology fares in terms of performance, cost, and ideal applications. Knowing these pros and cons can help you pick the right method that fits your specific metal fabrication or industrial cutting needs.

How to Choose the Right CNC Cutting Method

Picking the best CNC cutting method starts with understanding your specific project needs. Here’s how to break it down:

Assess Your Project Needs

- Material type and thickness: Laser cutting works great with thin metals and plastics, waterjet shines with thick and heat-sensitive materials, while plasma is ideal for thicker steel and metals.

- Precision needed: If your project demands tight, clean cuts, laser cutting is usually the best choice. Waterjet also offers good precision but is slower. Plasma cuts faster but with less accuracy.

- Cut complexity: For intricate shapes and fine details, laser and waterjet handle complexity better than plasma.

Budget Considerations

- Initial investment: Plasma cutters tend to be less expensive upfront compared to laser and waterjet machines.

- Operating costs: Waterjet can be costly due to abrasive materials and maintenance, while laser and plasma have different energy demands.

- Long-term value: Factor in cut quality and speed since slow or low-quality cuts can add cost down the road.

Shop Environment

- Space and ventilation: Plasma cutting produces smoke and fumes, requiring good ventilation. Laser machines need safety enclosures but produce less dust. Waterjet generates a lot of water and slurry, demanding proper cleanup systems.

- Noise levels: Plasma is louder compared to the relatively quieter laser and waterjet processes.

Outsourcing vs In-House

- Volume and frequency: If your cutting needs are occasional or low volume, outsourcing could save costs and avoid heavy equipment investment.

- Control and turnaround time: In-house CNC cutting may be better for quick changes and tight deadlines.

Decision Framework

To decide, weigh these factors based on your priorities:

- Start with the material and precision requirements.

- Factor in budget limits and operating costs.

- Consider your workshop’s setup and safety needs.

- Think about whether you want full control via in-house cutting or the flexibility of outsourcing.

Taking these steps will help you choose the CNC cutting method that fits your project perfectly—ensuring quality results, cost-effectiveness, and smooth production.

Why Choose HYCNC for CNC Cutting Solutions

At HYCNC, we bring extensive expertise in laser, waterjet, and plasma CNC cutting, making us a trusted partner for your metal fabrication needs. We understand the local market and tailor solutions that fit industries across the United States, whether you’re in manufacturing, construction, or custom fabrication.

We offer flexibility to handle both small runs and large projects. Our team works closely with you to choose the right cutting method based on your material, budget, and deadlines. This hands-on approach ensures you get precision cutting solutions that match your exact specifications.

Quality assurance is key at HYCNC. We use the latest CNC cutting technology and perform rigorous inspections to deliver clean, precise cuts with minimal waste. Our commitment means less downtime and more productivity for your business.

Ready to improve your CNC cutting process? Contact HYCNC today to discuss how we can meet your project goals with reliable, cost-effective CNC cutting services tailored for U.S. clients.