Are you looking to streamline your CAD designs for better performance and cost savings? Mastering design optimization in CAD can transform your workflow, making your products more efficient and CNC-ready.

As a manufacturing professional, I understand the challenges of balancing innovation with practicality. That’s why I’m sharing proven strategies and tools—backed by real-world experience with HYCNC’s CNC solutions—to help you optimize designs like a pro.

In this guide, you’ll discover practical techniques, top CAD tools, and insider tips to enhance your designs for CNC manufacturing. Ready to elevate your process? Let’s get started!

What is Design Optimization in CAD

Design optimization in CAD refers to the process of improving a digital model to meet specific performance, cost, or manufacturing goals. It involves adjusting design parameters systematically to create the most efficient, effective, or lightweight structure while maintaining required functionality and durability.

Key Objectives of Design Optimization in CAD

- Enhance Performance: Improve strength, durability, or functionality without adding unnecessary complexity.

- Reduce Material Usage: Minimize weight and waste by optimizing geometry and material distribution.

- Lower Manufacturing Costs: Simplify designs to speed up CNC machining and reduce tooling expenses.

- Ensure Manufacturability: Design parts that can be efficiently produced with existing CNC processes.

- Accelerate Development: Shorten design cycles by automating iterations and simulations.

Common Techniques in CAD Design Optimization

- Parametric Optimization: Adjusting design parameters such as dimensions, angles, and material properties to reach the best performance.

- Topology Optimization: Algorithm-driven reshaping of material layout to achieve the lightest or strongest structure.

- Generative Design: Using AI-powered tools to explore thousands of design alternatives based on set constraints and goals.

- Finite Element Analysis (FEA): Simulating real-world forces and stresses to predict how a design will perform before manufacturing.

By applying these techniques within CAD software, engineers and designers can create optimized models ready for CNC machining that save resources and deliver superior results.

Benefits of CAD Design Optimization for CNC Processing

Optimizing your designs in CAD before sending them to CNC machines offers clear advantages that directly impact your bottom line and product quality.

Reduced Material Costs

By refining your design, you can cut down on unnecessary material use. CAD design optimization helps create lightweight parts without sacrificing strength, saving you money on raw materials.

Enhanced Performance

Better designs mean parts that function exactly as intended. Using techniques like topology optimization and finite element analysis (FEA), you can improve durability and efficiency, leading to higher-performing products.

Faster Time-to-Market

With optimized CAD files, CNC machines work more efficiently. Designs that are easier to manufacture reduce trial and error, accelerating production and speeding up your time-to-market.

Sustainability

Design optimization supports sustainability goals by limiting waste and lowering energy consumption during manufacturing. Lightweight, stronger parts also contribute to long-term eco-friendly product use.

Case Study

A U.S.-based manufacturing company used generative design in Autodesk Fusion 360 to optimize parts for CNC milling. They reduced material use by 30%, cut machining time by 20%, and significantly lowered production costs—all while improving part strength. This demonstrates how CAD design optimization makes CNC processing smarter and more cost-effective.

Key Techniques for Design Optimization in CAD

When it comes to design optimization in CAD, several proven techniques help improve your models for better CNC machining outcomes. Here’s a quick look at the most effective methods we use:

Parametric Optimization

This technique adjusts design parameters like dimensions and shapes automatically. It helps find the best combination of variables to meet specific goals such as weight reduction or strength improvement. It’s great for making quick iterations without starting from scratch.

Topology Optimization

Topology optimization focuses on removing unnecessary material while keeping structural integrity. It’s a smart way to create lightweight parts that still perform well under stress, making your designs CNC-friendly and cost-effective.

Generative Design

Generative design uses AI algorithms to explore many design alternatives based on your input goals and constraints. The software suggests innovative shapes that may not be obvious but are perfect for CNC machining and can improve performance or cut costs.

Finite Element Analysis (FEA)

FEA simulates real-world conditions to test how your design handles stress, heat, or vibration. It points out weak spots early in the process, so you can improve your CAD model before sending it for CNC manufacturing.

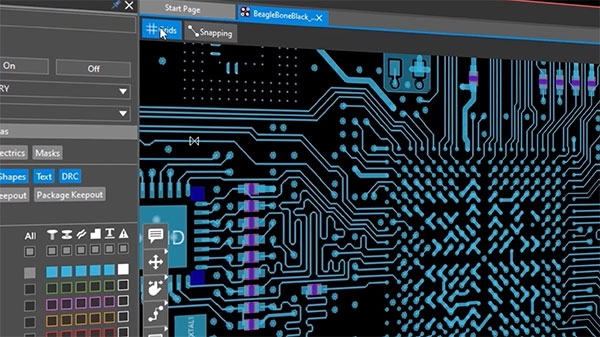

Integration with CNC Workflows

Optimized CAD designs need a smooth path to CNC machining. Good CAD software integrates directly with CNC programming tools, enabling easier export of files and better communication between design and production teams.

Using these techniques together gives you designs that are stronger, lighter, and faster to produce—exactly what’s needed for CNC machining success.

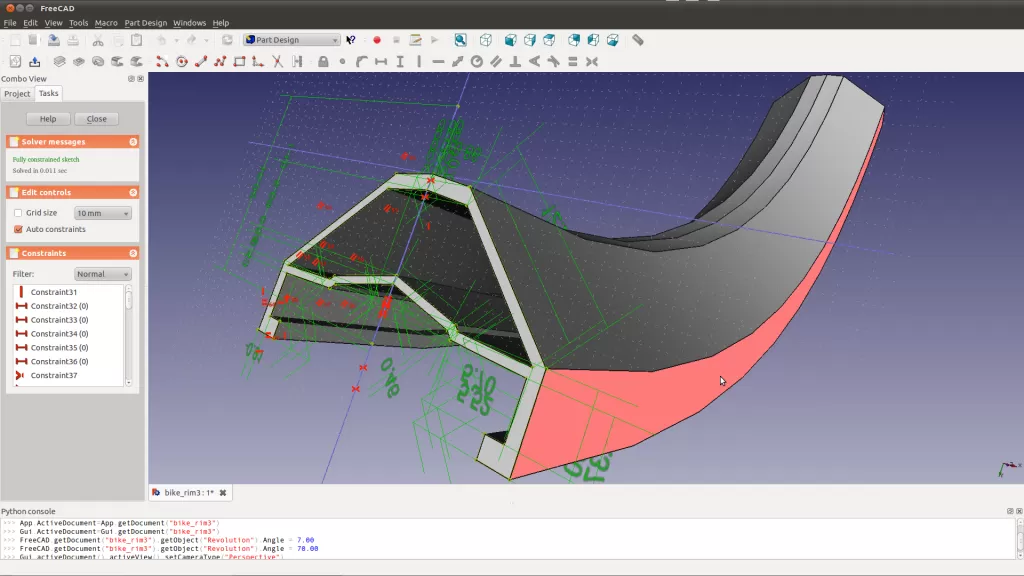

Top CAD Tools for Design Optimization

When it comes to CAD design optimization, picking the right software can make a big difference, especially if you’re working with CNC machining. Here’s a quick look at some of the top tools used in the U.S. market and what makes them stand out.

SolidWorks

- Strengths: Great for parametric optimization and detailed Finite Element Analysis (FEA).

- Why it works: User-friendly interface and strong simulation tools help refine designs fast.

- Compatibility: Works well with HYCNC’s CNC services for smooth file transfers and manufacturability checks.

Autodesk Fusion 360

- Strengths: Combines CAD, CAM, and CAE in one platform, which is perfect for generative design for CNC and quick iterations.

- Why it works: Cloud-based setup allows easy collaboration and access from anywhere in the U.S.

- Compatibility: HYCNC supports Fusion 360 files, speeding up CNC programming and setup.

PTC Creo

- Strengths: Strong in topology optimization in CAD and handles complex assemblies with ease.

- Why it works: Advanced simulation features help balance light-weight designs and durability.

- Compatibility: Optimized for integration with CNC workflows like those at HYCNC, including DFM support.

Ansys

- Strengths: Known for deep FEA and multiphysics simulations, ideal for heavy-duty or high-stress parts.

- Why it works: Provides detailed insights into performance before cutting any material.

- Compatibility: Can export ready-to-machine files that fit with HYCNC’s manufacturing standards.

Features to Look For

When choosing CAD software for optimizing your CNC designs, focus on these:

- Robust simulation and analysis tools (FEA, thermal, stress)

- Parametric and topology optimization capabilities

- Easy export options compatible with CNC services like HYCNC

- Cloud support for collaboration and updates

- User-friendly interface suited to your workflow

Compatibility with HYCNC

HYCNC works seamlessly with these CAD platforms, ensuring your optimized designs translate directly into efficient CNC machining. This includes ready-to-go CAM files, design for manufacturability checks, and fast turnarounds that keep your project moving.

Comparison Table

| Software | Key Strengths | CNC Compatibility | Cloud-Based | Best For |

|---|---|---|---|---|

| SolidWorks | Parametric, FEA | High | No | Detailed mechanical parts |

| Autodesk Fusion 360 | Generative design, CAM integration | High | Yes | Quick prototyping, collaboration |

| PTC Creo | Topology optimization | High | No | Complex assemblies |

| Ansys | Advanced FEA, multiphysics | Moderate | No | Stress-heavy components |

Choosing the right CAD tool sets the stage for successful design optimization, cutting down production issues, and improving final part performance with HYCNC’s CNC services in the U.S. market.

Step-by-Step Guide to Optimizing Designs in CAD for CNC

Optimizing your designs in CAD for CNC machining can seem complex, but breaking it down makes the process manageable and effective. Here’s a clear step-by-step guide to get you started:

1. Define Design Goals

Before you dive into CAD software, clearly outline what you want to achieve. Are you aiming to reduce material use, improve strength, or simplify assembly? Setting specific goals helps guide every following step.

2. Setup Parameters

Input critical parameters into your CAD model, such as material types, thickness, load requirements, and machining constraints. This setup is crucial for parametric optimization and simulation accuracy.

3. Run Simulations

Use CAD simulation tools like Finite Element Analysis (FEA) to test your design under real-world conditions. Simulations reveal stress points, potential failures, and opportunities to improve performance.

4. Analyze and Refine Design

Review simulation results carefully. Adjust your design to fix weak spots, reduce weight, or enhance durability without compromising manufacturability. Repeat this step until you meet your design goals.

5. Export Files

Once optimized, export your design files in formats compatible with CNC machines, such as STEP or IGES. Make sure to verify the file integrity for smooth CAM programming.

Pro Tips

- Use parametric optimization for quick changes and iterations.

- Consider generative design methods to explore innovative shapes.

- Keep manufacturability in mind by integrating Design for Manufacturability (DFM) principles early—learn more about this in our Design for Manufacturing and Assembly guide.

- Test different materials virtually to find the best balance of cost and performance.

Following these steps will help you create CAD models that not only look good but are CNC-ready, saving time and reducing costly mistakes during manufacturing.

Challenges and Solutions in CAD Design Optimization

Design optimization in CAD isn’t always straightforward. You’ll run into a few common challenges, but the good news is there are smart solutions for each.

Computational Costs

Running complex simulations and optimizations can eat up a lot of computing power, slowing down your workflow. To handle this, many teams are moving toward cloud-based CAD solutions. These platforms offer powerful processing without needing high-end local machines, letting you run heavy simulations faster and from anywhere.

Balancing Complexity With Manufacturability

Optimized designs can sometimes become too complex, making them hard or expensive to manufacture. This is where Design for Manufacturability (DFM) support becomes crucial. Using CAD tools with built-in DFM features helps you keep your designs practical and easier to machine, reducing costly revisions. To learn more about practical DFM approaches, check out our guide on Design for Manufacturing and Assembly for Easier Sheet Metal Fabrication.

Learning Curve

Mastering CAD design optimization takes time, and the software can feel overwhelming at first. The best way to tackle this is through tutorials, online courses, and expert support. Many CAD providers offer step-by-step training and community forums, which are great for troubleshooting and picking up tips from experienced users.

By addressing these challenges head-on with cloud tech, DFM tools, and ongoing learning, you can get the most out of your CAD design optimization with less hassle.

The Future of CAD Design Optimization

The future of CAD design optimization is looking smarter and faster thanks to AI and machine learning. These technologies help automate complex design decisions, making it easier to find the best balance between performance, cost, and manufacturability. With AI, CAD software can predict how a design will behave in real-world conditions and suggest improvements without waiting for manual input.

Additive manufacturing is changing the game by allowing designs that were once impossible with traditional CNC machining. This opens new doors for lightweight structures and complex geometries optimized right inside CAD, pushing innovation in industries like aerospace and automotive.

Industry 4.0 is another major influence, connecting CAD, CNC machines, and production lines through smart, data-driven workflows. This integration means designs optimized in CAD can be seamlessly sent to CNC machines like those at HYCNC for faster, more precise manufacturing.

At HYCNC, we’re embracing these cutting-edge solutions to deliver not just optimized designs but also rapid turnarounds and sustainable processes. As we look ahead, expect more intelligent CAD tools that deeply link with manufacturing, reducing waste while boosting efficiency. If you want to stay competitive, leveraging AI-driven CAD optimization combined with innovative CNC services like HYCNC is key to success in the U.S. market and beyond.

Why Choose HYCNC for CAD-Optimized CNC Processing

When it comes to CAD design optimization for CNC machining, HYCNC stands out for several reasons. We bring deep expertise in both design and manufacturing, ensuring your optimized CAD files translate perfectly into high-quality CNC parts.

Expertise

Our team knows the ins and outs of CAD design optimization techniques like parametric and topology optimization. This experience helps us identify the best ways to improve your designs for CNC machining without compromising quality or function.

Seamless Integration

HYCNC works directly with your CAD files, supporting the latest software formats. We integrate design optimization smoothly with CNC workflows, which means fewer errors and faster transitions from design to production.

Cost-efficiency

Optimized designs mean less waste and reduced material costs in CNC machining. We help you save money by cutting down on excess material use and preventing costly design flaws before manufacturing starts.

Sustainability

Reducing material waste benefits the environment. At HYCNC, we focus on sustainable manufacturing practices, ensuring your CAD optimized parts not only perform well but are eco-friendly too.

Fast Turnarounds

We understand that time to market matters. HYCNC offers quick, reliable CNC processing so that once your CAD design is optimized, we get your parts ready without delays.

Ready to Optimize Your CNC Projects

Partner with HYCNC to bring your CAD designs to life with optimized, efficient CNC machining. Get in touch today to see how we can improve your manufacturing process and product quality.

For tips on making designs easier to manufacture, check out our guide on Design for Manufacturing and Assembly.