Are you wondering about the differences between vector cutting and raster engraving for your next CNC project? Choosing the right laser processing technique can transform your designs, ensuring precision and efficiency.

As a CNC expert at HYCNC, I’ve seen how the right method can make or break a project. In this guide, I’ll break down vector cutting vs. raster engraving with practical insights drawn from real-world experience.

You’ll discover what each technique offers, how they work, and which is best for your materials and goals. Ready to elevate your CNC laser projects? Let’s dive in!

What Is Vector Cutting

Vector cutting is a laser cutting method where the laser follows predefined paths made up of lines and curves, known as vectors. These paths guide the laser to score, engrave, or cut through the material precisely along the outlines you design.

During the process, the laser moves exactly along these vector lines to create sharp, clean edges. Because it follows clear paths, vector cutting is fast and highly accurate—perfect for designs that rely on crisp outlines.

Key characteristics of vector cutting include:

- Precision for clean, sharp edges

- Scalability without losing quality since vectors are resolution-independent

- Faster cutting for outline-based designs

Vector cutting is commonly used for creating metal signs, jewelry pieces, and machine parts due to its accuracy and ability to handle fine details.

Materials suited for vector cutting include:

- Metals

- Acrylic

- Wood

- Paper

This method works best when you need sharp, well-defined cuts with smooth edges on materials that can be sliced cleanly.

What Is Raster Engraving

Raster engraving is a process where the laser etches designs pixel by pixel, similar to how an inkjet printer works. Instead of following vector lines, the laser moves back and forth across the material, removing surface layers line by line to create the image. This method is perfect for detailed, photorealistic designs, especially those with shading and fine textures.

Because it works pixel by pixel, raster engraving is generally slower than vector cutting but allows for great control over depth and can create 3D-like effects on the surface. Common uses include photo engravings, award plaques, and decorative pieces with textured details.

Raster engraving works well on materials like wood, leather, acrylic, and glass, where detailed textures and shading bring the design to life.

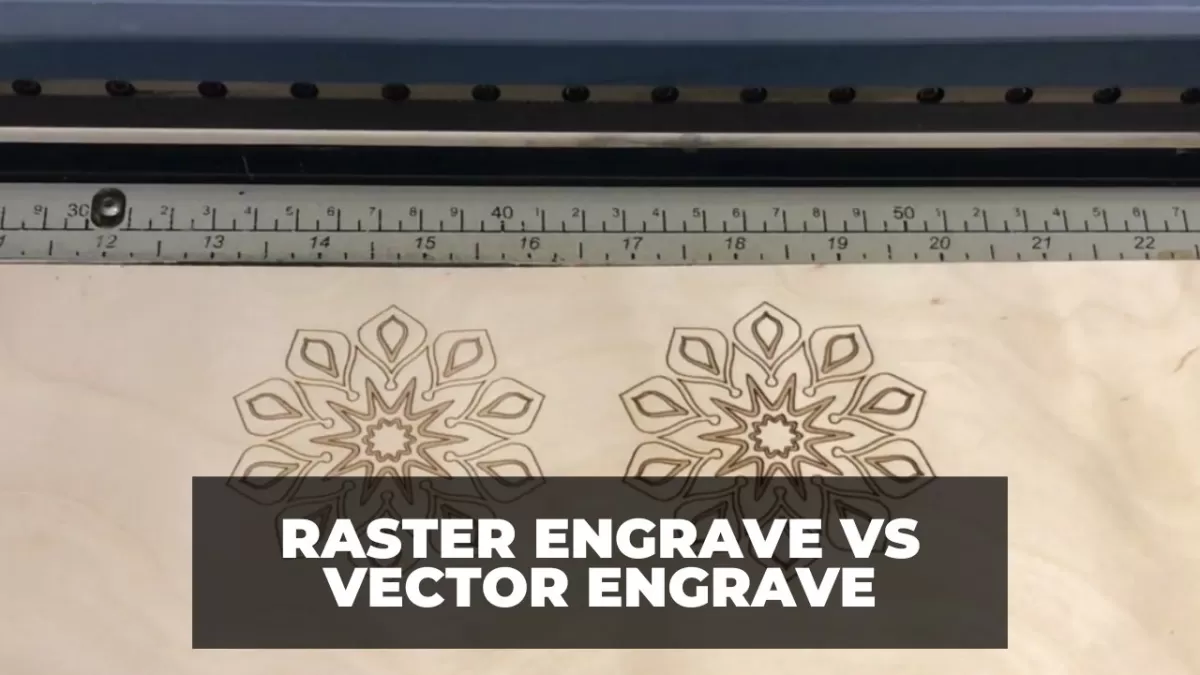

Key Differences Between Vector Cutting and Raster Engraving

When comparing vector cutting vs raster engraving, several key differences stand out in how each method works and what they’re best used for.

Technical Differences

- Vector cutting follows predefined paths made of lines and curves. The laser moves on multiple axes simultaneously, which allows for clean, precise cuts or scoring. It uses lower power for engraving or scoring and higher power when cutting through materials.

- Raster engraving works pixel by pixel, similar to how an inkjet printer operates. The laser moves back and forth line by line, mainly along the X-axis at high speed. It controls depth by adjusting grayscale values, making it ideal for creating complex shading and textures.

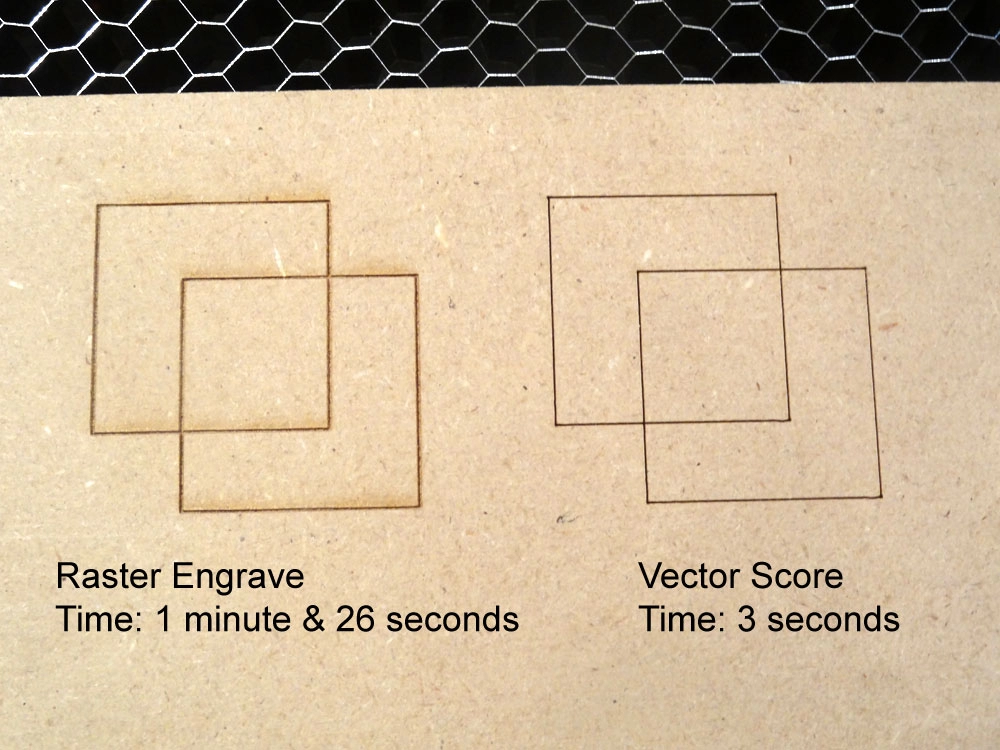

Speed and Efficiency

- Vector cutting is generally faster, especially for shapes with clear outlines and simple designs.

- Raster engraving takes more time because it works line by line, making it slower for detailed or large filled areas.

Design Suitability

- Vector is perfect for clean, sharp designs like logos, text, or geometric shapes.

- Raster shines with detailed images, gradients, photos, and textured artwork where shading is important.

Material Compatibility

- Vector cutting works best with thin or metallic materials such as metals, acrylic, wood, and paper.

- Raster engraving is better suited for softer or textured surfaces like wood, leather, glass, and acrylic.

Visual Comparison

Here’s a quick table breaking down the differences:

| Feature | Vector Cutting | Raster Engraving |

|---|---|---|

| Laser Movement | Follows vector paths, multi-axis | Line by line, pixel-based along X-axis |

| Power Use | Lower for scoring, higher for cutting | Varies for depth control via grayscale |

| Speed | Faster for outlines | Slower for detailed fills and shading |

| Best For | Sharp edges, text, logos | Photos, gradients, textured designs |

| Ideal Materials | Metals, acrylic, wood, paper | Wood, leather, glass, acrylic |

Understanding these differences helps in choosing the right laser processing method for your project’s needs. For more on preparing clean vector designs, you can check out our guide on converting to vector in Inkscape.

When to Choose Vector Cutting vs Raster Engraving

Choosing between vector cutting and raster engraving depends on your project needs.

Vector cutting is best for:

- Cutting 2D shapes like stencils or architectural models

- Engraving sharp text, logos, or simple line art

- Projects where speed and clean, precise edges matter

It’s great when you need crisp outlines or parts cut cleanly from metals, acrylic, wood, or paper.

Raster engraving works well for:

- Detailed images or photographs needing fine shading

- Textured or 3D effect engravings that add depth

- Large filled areas like letters, award plaques, or stamps

Raster shines when your design has complex gradients or requires a photo-realistic look on wood, leather, acrylic, or glass.

Hybrid projects:

Sometimes combining both is the way to go, such as cutting a sign’s shape with vector cutting and adding detailed raster engraving for logos or textures.

At HYCNC, we specialize in choosing and optimizing the right method—or both—based on your design and material. This ensures you get the best quality, speed, and finish for your laser-cut and engraved projects.

Practical Tips for Optimizing Your CNC Laser Project

Getting the best results from your CNC laser project starts with proper preparation and settings. Here are some easy tips to help:

File Preparation

- Use vector files like SVG or AI for cutting and clean line engraving. They scale without losing quality.

- For detailed images or shading, use raster files like PNG or JPG. Make sure the resolution is high to avoid blurry engravings.

- If you’re converting images to vectors, check out our guide on converting to vector in Inkscape for smooth results.

Material Selection

- Match your material to the technique: thin metals and acrylic work great with vector cutting, while wood and leather shine with raster engraving.

- Think about thickness and texture when picking your material, as these affect how well the laser engraves or cuts.

Laser Settings

- Adjust laser power and speed carefully. Higher power and slower speed for cutting thicker materials; lower power and faster speeds for scoring or light engraving.

- For raster engraving, adjust the PPI (pulses per inch) to control the engraving depth and detail—higher PPI means finer detail but takes more time.

How HYCNC Ensures Quality

- We use advanced CNC laser machines with fine-tuned controls to match your project’s needs.

- Our experienced team adjusts settings based on material and design, balancing speed and precision to deliver sharp, clean cuts and detailed engravings every time.

Common Mistakes to Avoid

- Using low-resolution raster images leads to pixelated, unclear engravings. Always start with a high-quality image.

- Incorrect line weights in vector files can cause inconsistent cutting depth or burning. Thin lines sometimes disappear; too thick lines may produce rough edges.

Following these tips will help your project look professional and save time during production. For complex designs, feel free to contact HYCNC—our experts can guide you through the best approach with your materials and laser settings.

Why Choose HYCNC for Your Laser Processing Needs

At HYCNC, we use state-of-the-art CNC laser machines designed for both vector cutting and raster engraving. This means we can handle everything from sharp, precise cuts to detailed, photorealistic engravings with ease.

We offer customized solutions tailored to your project needs. Whether you require clean, fast vector cutting or intricate raster engraving, we adjust our process to get the best results for your material and design.

Our team is committed to delivering precision, speed, and top-notch customer service. We understand the importance of quality in every job and work closely with you to ensure your project exceeds expectations.

Ready to get started? Contact HYCNC today for a quote or consultation and let us help bring your laser cutting and engraving ideas to life.

FAQs

Can a single laser machine perform both vector cutting and raster engraving

Yes, most modern CNC laser machines, including those at HYCNC, are equipped to handle both vector cutting and raster engraving. This versatility allows us to switch between cutting along vector paths and engraving pixel-by-pixel details without needing separate equipment.

Which is faster vector cutting or raster engraving

Vector cutting is generally faster because the laser follows precise paths cutting or scoring along lines and curves. Raster engraving takes more time since it etches designs pixel by pixel, moving back and forth—especially for detailed images or large fill areas.

What materials work best for each method

Vector cutting works best with metals, acrylic, wood, and paper—materials that can be cleanly cut along predefined lines. Raster engraving suits wood, leather, acrylic, and glass, where detailed etching and shading effects are preferred.

How to prepare design files for HYCNC CNC services

For vector cutting, send design files in SVG, AI, or other vector formats with clean, well-defined paths. For raster engraving, high-resolution PNG or JPG files work best to capture detail. Proper file preparation helps us deliver sharper cuts and engravings every time. You can also check out our guide on preparing text for laser cutting to optimize your files.

Can HYCNC handle hybrid projects requiring both techniques

Absolutely. We specialize in combining vector cutting and raster engraving in a single project, like cutting out shapes and engraving detailed images on the same material. This hybrid approach gives you the best of both worlds—sharp cuts with rich engraved details—to make your designs stand out.