Are you struggling to machine thin-walled parts without deformation or vibration? Choosing the right CNC workholding solutions can make all the difference in achieving precision and efficiency.

As a CNC machining expert, I’ve seen firsthand how the right workholding techniques transform challenging projects into seamless successes. With years of industry experience, I’m sharing proven strategies to help you tackle thin-walled machining like a pro.

In this guide, you’ll discover the best CNC workholding solutions, from vacuum chucks to custom soft jaws, tailored for delicate parts in industries like aerospace and medical. Ready to boost accuracy and cut scrap rates?

Let’s dive in!

Mastering CNC Workholding for Thin-Walled Parts with HYCNC

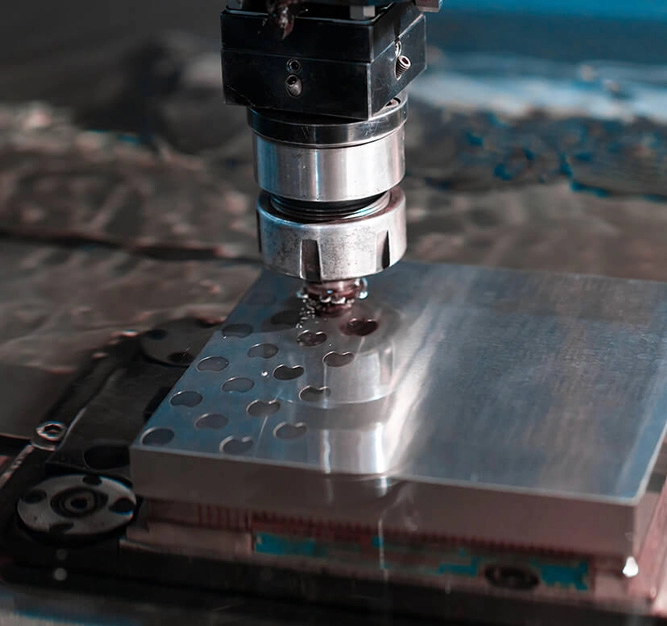

Thin-walled parts present unique challenges in CNC machining. Their delicate structure makes them prone to deformation, vibration, and precision setbacks during the cutting process. Because these parts have low rigidity, even minor forces from clamping or machining can cause bending or shifting, leading to costly scrap and rework. That’s why specialized CNC workholding solutions are essential. They ensure the part stays stable and accurate without adding unnecessary stress.

At HYCNC, we understand these difficulties and have developed innovative workholding systems tailored specifically for thin-walled parts. Our solutions focus on minimizing mechanical stress and vibration while maximizing precision and efficiency. By leveraging advanced technology and custom designs, HYCNC helps you achieve consistent quality and reduce material waste, even with the most challenging thin parts.

Understanding Thin-Walled Parts and Their Machining Challenges

Thin-walled parts are components with walls that have a small thickness compared to their overall size. Because of their low structural strength, these parts are prone to bending, warping, and deformation during machining. They require extra care to avoid damage, especially since even slight pressure or vibration can affect their shape.

These parts are common in industries like aerospace, automotive, medical devices, and electronics, where lightweight and precision components are essential. Machining thin-walled parts brings key challenges:

- Vibration and tool chatter that can damage the surface and reduce accuracy

- Workpiece shifting due to low rigidity, causing misalignment and rejects

- High scrap rates because of deformation or poor fixturing during cutting

Understanding these challenges is critical to selecting the right CNC fixturing solutions that maintain precision and improve efficiency when working with thin-walled machining.

Top CNC Workholding Solutions for Thin-Walled Parts

Vacuum Chucks

Vacuum chucks use suction to hold parts firmly without applying mechanical pressure that can deform thin walls. This method is great for flat or complex shapes where clamping forces can cause bending or vibration. You’ll often see vacuum chucks used in tough 5-axis CNC machining, especially for aerospace components where precision is key. At HYCNC, our vacuum chuck systems feature high holding power with easy setup and stable performance, helping reduce scrap rates and improve accuracy.

Custom Soft Jaws

Soft jaws clamp gently by conforming to the unique contours of your part, using low-force gripping that keeps thin walls from warping. These jaws are often made from aluminum or other soft materials that can be customized to fit the shape exactly. HYCNC designs custom soft jaws to match your part’s profile perfectly, ensuring solid yet safe workholding that enhances machining precision without causing damage or distortion.

Adhesive Fixturing

Using adhesives like double-sided tape, special glue, or wax provides a non-mechanical way to secure delicate thin-walled parts during machining. This temporary bond avoids clamping pressure but requires a balance—adhesives hold well but can be tricky to clean up afterward. For thin-walled machining, we recommend best practices like choosing the right adhesive for your material and ensuring even pressure distribution to avoid shifting or movement during cutting.

Low-Melting-Point Alloys

These alloys melt at low temperatures and fill voids inside hollow or complex thin-walled parts to give added internal support. Once cooled, they hold the part rigid without squeezing from outside. For example, Harmonic Drive LLC uses a “lollipop” method with these alloys to stabilize flexsplines during machining. HYCNC leverages our experience with alloy-based fixturing to provide internal bracing that minimizes vibration and deformation on challenging thin parts.

Modular and Zero-Point Clamping Systems

Modular fixturing and zero-point clamping allow fast, repeatable setups ideal for multi-axis CNC machines working on thin-walled parts. These systems provide flexibility to switch between different parts or orientations quickly, boosting efficiency while maintaining consistent holding strength. HYCNC’s modular workholding solutions are designed to reduce setup time and give precise positioning, helping keep thin parts stable and improving overall machining workflow.

Benefits of Effective Workholding for Thin-Walled Parts

Using the right CNC workholding solutions for thin-walled parts delivers clear advantages in precision, quality, and efficiency. Here’s why it matters:

-

Improved Precision and Accuracy

Proper workholding keeps thin-walled parts stable and reduces movement, which means less deformation and higher dimensional accuracy. This is key for industries like aerospace and medical where tolerances are tight.

-

Reduced Scrap Rates and Material Waste

When deformation and tool chatter are minimized, fewer parts get scrapped. Efficient fixturing saves your materials and budget by cutting down on costly mistakes.

-

Enhanced Machining Efficiency and Tool Life

Stable holding reduces machining time since parts don’t need frequent adjustments. It also extends tool life by preventing excessive vibration and tool wear during cutting.

-

Real-World Success

For example, HYCNC helped an aerospace client cut part deformation by 30% using tailored vacuum chucks and custom soft jaws. This improvement translated into smoother production and significant cost savings.

Effective workholding isn’t just a nice-to-have—it’s a must for machining thin, delicate parts right the first time. HYCNC’s solutions are designed to tackle these challenges head-on, making your operations leaner and more precise.

Choosing the Right Workholding Solution for Your Needs

Picking the best CNC workholding solution for thin-walled parts depends on several key factors:

- Part Geometry: Complex shapes might need vacuum chucks or custom soft jaws to hold without causing deformation. Simple flat parts often work well with vacuum fixturing.

- Material Type: Softer or more flexible materials benefit from low-force clamping like adhesive fixturing or soft jaws. Harder metals may require modular clamping systems.

- Production Volume: High-volume runs call for repeatable, fast setups like zero-point clamping systems. Smaller batches may use adhesives or alloy fixturing for quick, precise holding.

- CNC Machine Type: Multi-axis CNC machines often pair best with modular and vacuum workholding for accessibility and stability.

Here’s a quick comparison:

| Workholding Type | Best For | Pros | Considerations |

|---|---|---|---|

| Vacuum Chucks | Flat/complex thin parts | Low deformation, easy setup | Requires flat surfaces |

| Custom Soft Jaws | Irregular shapes, delicate parts | Low-force clamping, contour fit | Material wear over time |

| Adhesive Fixturing | Very thin, delicate components | Secure hold, minimal stress | Cleanup, limited reusability |

| Low-Melting-Point Alloys | Internal support during machining | Strong internal grip | Cleanup and setup time |

| Modular and Zero-Point Systems | Multi-axis, high-volume runs | Fast setup, repeatability | Initial investment cost |

At HYCNC, we customize your workholding based on your part’s unique demands, machining style, and production goals. Our team evaluates your thin-walled components and matches them with the ideal combination—whether that’s vacuum chucks, soft jaws, or modular fixturing—to ensure precision, reduce scrap, and boost efficiency.

If you’re unsure which method fits your needs, reach out to us. HYCNC’s experience with aerospace, automotive, and medical parts means we know what works and can tailor a solution that fits your machining process perfectly.

Why Choose HYCNC for CNC Workholding Solutions

At HYCNC, we specialize in precision machining, serving key industries like aerospace, automotive, and medical. We understand the unique challenges that come with thin-walled parts, so our workholding solutions are fully customizable to fit your exact part requirements.

Our advanced CNC equipment and AS9100-certified quality processes ensure every project meets the highest standards. We’re not just about the tools — we focus on delivering reliable results that improve accuracy and reduce scrap rates.

Many of our customers have seen real improvements. From cutting down deformation to speeding up setups, our custom workholding systems make a difference in both quality and efficiency. When you choose HYCNC, you’re getting expert support backed by proven success in thin-walled machining.

Best Practices for Machining Thin-Walled Parts

Machining thin-walled parts needs a careful approach to avoid deformation and maintain precision. Here’s how we do it at HYCNC to get the best results every time.

Optimize Feeds and Speeds

- Use slower feeds and spindle speeds to reduce vibration and tool chatter.

- Adjust cutting parameters gradually to find the sweet spot where the part stays stable but machining stays efficient.

- Avoid aggressive cuts that can flex or damage the thin walls.

Use Damping Techniques

- Add vibration dampers or special fixturing materials to absorb and reduce vibration.

- Soft jaws or vacuum chucks at HYCNC are designed to minimize mechanical impact while holding parts firmly.

- Proper damping extends tool life and improves surface finish.

Choose Multi-Axis CNC Machines

- Multi-axis CNC machining means fewer setups and better access, which cuts down on handling and part shifting.

- It allows us to machine complex thin-walled parts more accurately—less movement equals less risk of deformation.

- Check out our article on why 5-axis CNC is ideal for complex parts for more insights.

Focus on Consistent Wall Thickness

- Maintaining uniform wall thickness keeps parts strong and stable during machining.

- We use real-time monitoring and precision programming to ensure walls don’t get too thin or uneven.

- Consistent walls reduce scrap rates and improve part quality.

At HYCNC, these strategies combined help us deliver precise, deformation-free thin-walled parts that meet demanding US market standards every time.

Elevate Your CNC Machining with HYCNC

When it comes to CNC workholding solutions for thin-walled parts, choosing the right approach makes all the difference. Whether it’s vacuum chucks, custom soft jaws, adhesive fixturing, low-melting-point alloys, or modular zero-point clamping systems, each method targets the unique challenges thin-walled parts bring.

At HYCNC, our innovative workholding systems are designed to improve precision, reduce deformation, and boost machining efficiency. We understand the demands of industries like aerospace, automotive, and medical where accuracy and reliability are critical. That’s why our solutions focus on minimizing vibration, preventing part shifting, and protecting delicate geometries throughout the machining process.

Ready to take your thin-walled CNC machining to the next level? Contact HYCNC today for a consultation or to request a quote. We’re here to help you find the perfect fixturing solution to meet your specific needs and boost your production quality.

FAQs

What are the best workholding solutions for thin-walled parts?

The top solutions include vacuum chucks, custom soft jaws, adhesive fixturing, low-melting-point alloys, and modular zero-point clamping systems. Each offers low-force clamping and vibration reduction, which help prevent deformation and maintain precision.

How can I prevent deformation when machining thin-walled parts?

Use specialized workholding that applies minimal pressure, like vacuum chucks or soft jaws. Also, optimizing feeds and speeds, employing damping techniques, and using multi-axis CNC machines can reduce vibration and tool chatter, minimizing deformation.

Does HYCNC offer custom fixtures for specific part geometries?

Yes, HYCNC custom designs workholding solutions tailored to your part’s shape and material. Whether it’s a unique aerospace component or a delicate medical part, we ensure a precise fit that protects the thin walls during machining.

What industries benefit most from specialized workholding for thin-walled parts?

Aerospace, automotive, medical, and electronics industries rely heavily on thin-walled parts. These sectors gain the most from advanced CNC fixturing because accuracy and minimal deformation are critical for their high-quality standards.

How does vacuum chuck technology work for CNC machining?

Vacuum chucks use suction to hold parts firmly without mechanical clamping force. This reduces stress on thin-walled components, lowers deformation risk, and is great for flat or complex shapes, especially in 5-axis CNC machining setups.