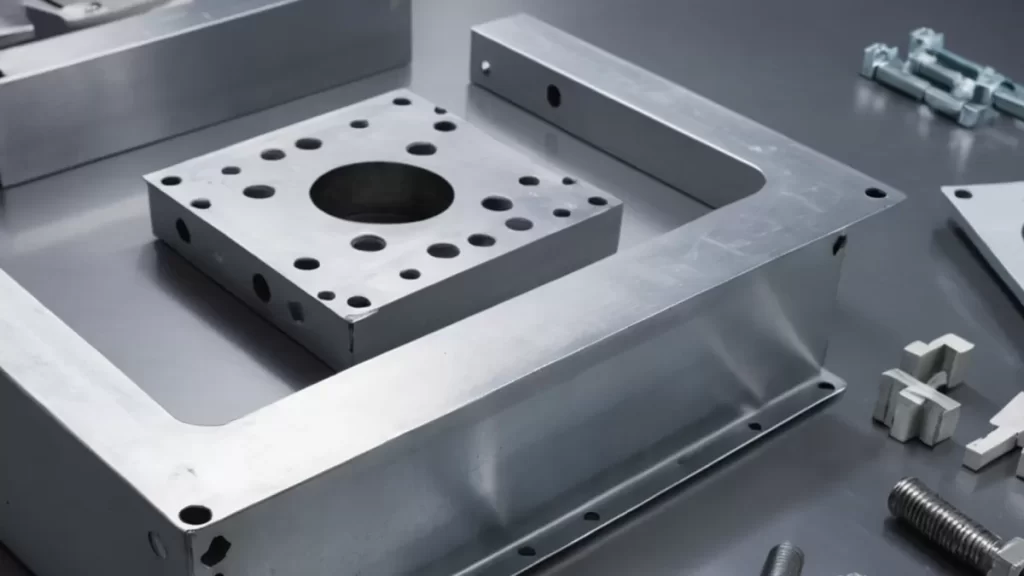

Are you struggling to perfect tapping laser-cut holes or designing for countersinking? These precision processes can elevate your CNC projects from good to exceptional. As experts in CNC machining, we at HYCNC know that getting these details right is critical for durable, professional parts. In this guide, we’ll share proven tips and real-world insights to help you master tapping and countersinking for laser-cut parts. Ready to create stronger, cleaner assemblies? Let’s dive in!

Understanding Tapping and Countersinking in Laser Cutting

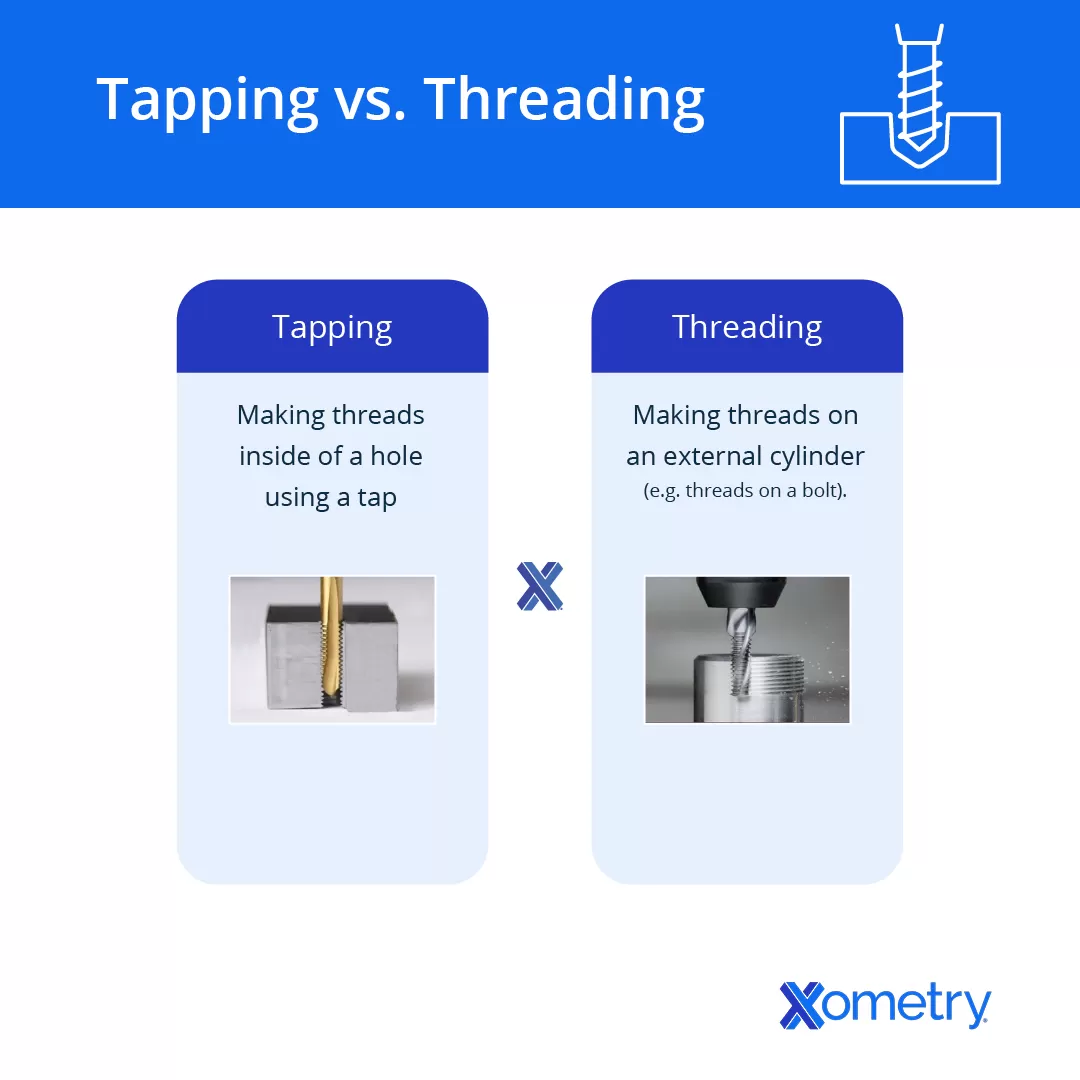

When working with laser-cut holes, two key processes often come into play: tapping and countersinking. Tapping is the method of creating internal threads within a laser-cut hole, allowing fasteners like screws or bolts to securely grip and hold parts together. Countersinking, on the other hand, involves shaping the hole with a conical recess so that fastener heads sit flush with or below the surface, providing a clean, smooth finish.

Both tapping and countersinking are critical not just for the look of your finished part, but also for its structural integrity. Properly tapped threads ensure strong connections that resist loosening, while correctly countersunk holes prevent fastener heads from protruding, reducing stress points and improving overall performance.

However, laser-cut holes bring specific challenges. The heat generated during laser cutting can cause slight warping or hardening around the edges, which complicates threading. Burrs or uneven edges might interfere with taps or countersinks, increasing the risk of tool damage or poor thread quality. Understanding these challenges is essential for designing parts that can be tapped or countersunk effectively, avoiding common pitfalls that affect both strength and appearance.

Designing for Tapping Laser Cut Holes

When designing for tapping laser-cut holes, getting the hole size and placement right is key. Holes should be slightly undersized compared to the final thread size to allow proper thread engagement. Make sure holes aren’t too close to edges or other holes to avoid cracking or weakening the material.

Different metals need different treatment:

- Mild steel: Easier to tap but watch for burrs from laser cutting.

- Stainless steel: Harder material means you might need pre-drilled holes a bit bigger and use sharp taps to avoid breakage.

- Aluminum: Softer, but prone to thread stripping if hole sizes aren’t accurate.

A couple of common problems to avoid are tap breakage and thread stripping. Broken taps can stall production, and stripped threads make fasteners unreliable.

At HYCNC, we use automated hole resizing to fine-tune your laser-cut holes before tapping. This precision step ensures the hole size perfectly matches thread requirements, improving strength and reducing failure rates. It’s a smart way to guarantee your tapped holes hold up without extra hassle.

Designing for Countersinking Laser-Cut Holes

When designing for countersinking laser-cut holes, getting the countersink angle right is crucial. Most fasteners, like SAE screws, need an 82-degree angle for a flush, secure fit. Using the wrong angle can lead to poor contact or even damage the fastener.

In your design files, always specify the correct hole diameter—this means setting the inner circumference size precisely. This ensures the countersink matches the fastener head perfectly and avoids gaps or uneven surfaces.

You also want to keep a good distance between countersinks. Minimum spacing prevents stress buildup or distortion in the material, which can weaken the part or cause warping after laser cutting.

Finally, think about material thickness and post-processing steps like deburring or finishing. Thicker materials may need deeper countersinks, and some finishing methods can affect tight tolerances, so factor those into your design for smooth, reliable results.

Best Practices for Tapping and Countersinking

When it comes to tapping laser-cut holes, using the right tools and techniques makes all the difference. Start with quality taps designed for your material, paired with good lubricants to reduce friction and prevent tap breakage. Always undersize your holes slightly when laser cutting, then drill to the final tapping size. This helps ensure clean threads and reduces the risk of stripping.

For countersinking, aim for a clean, flush finish by using zero-flute countersinks. These minimize burrs and keep the edges smooth, which is especially important to avoid stress points or material distortion. Managing the heat-affected zone (HAZ) caused by laser cutting is key—proper countersink tools and methods reduce warping and improve final fit.

At HYCNC, our precision CNC machining processes blend expert tapping and countersinking techniques with tight laser-cut hole tolerances, delivering consistent, reliable outcomes. Our automated workflows keep quality high and turnaround times fast, giving you confidence in every part.

Common Mistakes and How to Avoid Them

When designing for tapping laser cut holes and countersinking, some mistakes can cost you time and money. Here are the usual slip-ups and how to dodge them:

Incorrect Hole Sizing

- If holes are too small, taps can break or threads strip.

- Oversized holes mean weak threads and poor fastener grip.

- Always follow CNC tapping guidelines for the material you’re using.

Overlapping Countersink Diameters

- Countersinks that are too close can weaken the part.

- Keep enough spacing to prevent cracks or distortion around the hole.

- Stick to countersink angle standards and minimum spacing requirements.

Ignoring Material Properties After Laser Cutting

- Laser cutting changes metal hardness and can create heat-affected zones.

- Harder or brittle edges increase tap breakage risk.

- Adjust your hole sizes or choose proper taps to match the processed material.

Preparing Design Files for HYCNC Services

- Specify exact hole diameters (only the inner circumference for countersinks).

- Indicate if holes require tapping or countersinking and mention angles.

- Use consistent units and label materials clearly to avoid confusion.

- Upload files in formats supported by HYCNC for faster quotes and processing.

Avoiding these common mistakes ensures your tapped and countersunk laser cut holes deliver strong threads and clean finishes every time.

Why Choose HYCNC for Tapping and Countersinking

When it comes to tapping laser cut holes and designing for countersinking, HYCNC stands out with advanced CNC laser cutting and machining capabilities. Our automated processes ensure every hole is sized and finished precisely for consistent, high-quality results. This means less rework and stronger, cleaner threads or flush fastener surfaces every time.

We also offer great support for custom designs, letting you tailor hole sizes, tap specifications, and countersink angles to match your specific needs. Plus, our fast turnaround times keep your projects on schedule, which is critical in the US manufacturing market.

Ready to get started? Upload your design files easily through our online platform for a quick, no-hassle quote. With HYCNC, you get precision CNC machining that meets today’s standards for laser cutting hole design and tapping stainless steel holes, aluminum, and more. Reach out today to see how we can help with your next project.