Understanding CNC Cutting Technologies

What is CNC Cutting

CNC cutting refers to the use of computer numerical control (CNC) machines to precisely cut, shape, or engrave materials. These machines follow programmed instructions to automate cutting tasks, increasing accuracy and efficiency. CNC cutting is widely used across industries like manufacturing, aerospace, automotive, and construction for its repeatability and precision.

Overview of EDM Laser Waterjet and Plasma

There are several popular CNC cutting methods, each with different strengths:

-

Electrical Discharge Machining (EDM) uses electrical sparks to erode material, making it ideal for tight, complex cuts in hard metals.

-

Laser Cutting employs a focused light beam to melt, burn, or vaporize material. It offers high precision and clean edges, suitable for thin metals and detailed patterns.

-

Waterjet Cutting uses a high-pressure stream of water, sometimes mixed with abrasives, to cut through a wide variety of materials without heat, preventing warping or structural damage.

-

Plasma Cutting generates an ionized gas jet that cuts through electrically conductive materials fast and cost-effectively, especially for thick metals.

Each of these CNC cutting technologies suits different materials, thicknesses, and project requirements. Understanding their basic principles helps you choose the right method for your needs. For a deeper dive into these methods and their advantages, check out this detailed EDM vs Laser vs Waterjet vs Plasma CNC Cutting Comparison.

In-Depth Comparison of CNC Cutting Methods

Let’s break down the main CNC cutting methods: EDM, Laser, Waterjet, and Plasma. Understanding each will help you figure out which one fits your project best.

EDM Electrical Discharge Machining

EDM uses electrical sparks to cut through metal. It’s perfect for super precise cuts, especially on hard materials like hardened steel or titanium. The process is slow but offers excellent accuracy and smooth finishes. It’s great for small, detailed parts where tight tolerances matter most.

Laser Cutting

Laser cutting shines in precision and speed. It focuses a high-powered laser beam to melt or vaporize material, usually metals and some plastics. Laser cutting delivers clean edges with minimal waste, and it’s highly efficient for thin to medium-thick materials. Plus, it handles tight, complex shapes well, making it a popular all-around choice. You can learn more about laser cutting advantages here.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to slice through materials. It’s versatile because it can cut virtually any material—metal, stone, glass, and even composites—without heat, which means no heat-affected zones. It’s slower than laser but excellent for thicker materials and maintaining the integrity of heat-sensitive substrates.

Plasma Cutting

Plasma cutting blasts an ionized gas at extremely high temperatures to melt through electrically conductive materials, mostly steel and aluminum. It’s fast and cost-effective for thick metals but doesn’t match the fine precision of laser or EDM. Plasma is great when you need quick, rough cuts in heavy steel fabrication at a lower price point.

Each method has its niche, whether precision, speed, or material flexibility, so choosing comes down to what your project priorities are. For a detailed contrast, check out this CNC machining comparison.

Key Factors to Consider When Choosing a CNC Cutting Method

Picking the right CNC cutting method depends on a few important factors. Here’s what you need to keep in mind before deciding between EDM, laser, waterjet, or plasma cutting.

Material Compatibility

Not every cutting tech works with every material.

- EDM is best for hard metals like steel and titanium but only cuts electrically conductive materials.

- Laser cutting handles metals and non-metals well but struggles with reflective materials like brass.

- Waterjet is versatile for almost any material—metal, stone, glass, or composites—because it uses high-pressure water and abrasive.

- Plasma cutting mainly works with electrically conductive metals like steel and aluminum but struggles with thin or non-conductive materials.

Precision and Tolerance

How precise your cuts need to be makes a big difference.

- EDM offers ultra-high precision, ideal for complex, intricate parts.

- Laser cutting delivers clean, precise cuts with tight tolerances suitable for detailed work.

- Waterjet gives good precision but not as fine as EDM or laser.

- Plasma has lower precision, suited for rough cuts or thicker metals.

Speed and Efficiency

Your project timeline will impact the choice too.

- Plasma cutting is fast, great for large sheets of thick metal.

- Laser cutting is also quick but best with thinner materials.

- Waterjet is slower because of the abrasive process but offers versatility.

- EDM is the slowest due to the spark erosion process but necessary for precise tasks.

Cost Considerations

Budget matters, especially for large or ongoing projects.

- Plasma cutting is generally the most affordable.

- Waterjet and laser cutting have higher operational costs due to equipment and maintenance.

- EDM tends to be the most expensive because of its precision and slower process.

Material Thickness

Thickness of your workpiece can make or break which method to choose.

- Plasma and waterjet can handle thick materials (up to several inches).

- Laser works best on thin to medium thickness metals.

- EDM is typically used for thin to medium parts, mostly detailed inside cuts.

Edge Quality and Finishing

The finish on your cut edges affects whether you need extra processing.

- Laser cutting produces smooth edges with minimal burrs.

- Waterjet can cut without heat, so edges stay clean and cool—great if heat distortion is an issue.

- EDM gives smooth, burr-free edges but may require post-processing in some cases.

- Plasma edges might be rougher and require grinding or sanding.

Choosing the right CNC cutting method means balancing these factors based on your project’s needs. For detailed comparisons of different metals and cutting costs, check out this guide on sheet metal cutting cost and learn more about cutting technologies in our Laser vs Waterjet vs Plasma CNC Cutting contrast article.

Comparison Table

| CNC Cutting Method | Material Compatibility | Precision and Tolerance | Speed and Efficiency | Cost Considerations | Material Thickness Range | Edge Quality and Finishing |

|---|---|---|---|---|---|---|

| EDM | Best for hard metals and complex shapes | Extremely high precision | Slow | Higher due to specialized setup | Thin to medium thickness | Smooth edges, minimal distortion |

| Laser Cutting | Metals, plastics, wood, fabrics | High precision | Fast | Moderate | Thin to medium thickness | Clean edges, may require finishing |

| Waterjet Cutting | Almost any material, including composites | High precision | Moderate | Moderate to high | Very thin to very thick | Excellent edge finish, no heat affected zone |

| Plasma Cutting | Conductive metals, mostly steel and aluminum | Moderate precision | Very fast | Low to moderate | Medium to thick metals | Rougher edges, may need secondary finishing |

This comparison table gives a quick snapshot of how EDM, Laser, Waterjet, and Plasma CNC cutting methods stack up on key factors like material compatibility, cutting precision, speed, cost, thickness range, and edge quality. Use this to quickly spot what fits your project needs best.

How to Choose the Right CNC Cutting Method for Your Project

Picking the best CNC cutting method depends on a few key things about your project. Here’s a simple way to figure it out:

-

Know Your Material

Different materials need different methods. For example, EDM is great for hard metals, waterjet works well for stone or composites, laser is perfect for thin metals and plastics, and plasma is your go-to for thicker steel.

-

Think About Precision

If your project needs super tight tolerances and fine details, EDM and laser cutting stand out. Waterjet is also precise but better for slightly thicker materials. Plasma is less accurate but faster for rough cuts.

-

Consider Thickness

Waterjet and plasma handle thick materials better — up to several inches. Laser works best on thinner sheets, and EDM is for smaller, intricate parts.

-

Budget Matters

Plasma typically costs less and cuts fast, making it good for big jobs with less strict tolerance. EDM and laser usually cost more but deliver higher precision.

-

Speed and Volume

Need quick, high-volume production? Plasma or laser cutting can speed things up. For slower, more detailed work, EDM or waterjet might be better.

-

Finish Quality

If you want a clean edge without much finishing, laser and waterjet are excellent choices. Plasma may require extra cleanup.

By weighing these factors—material, precision, thickness, budget, speed, and finish—you’ll be able to pick the best CNC cutting method for your project. If you’re ever unsure, consulting with a trusted CNC cutting service in the US can help tailor the choice to your needs.

Real-World Applications and Case Studies

When it comes to choosing between EDM, laser, waterjet, and plasma CNC cutting methods, real-world applications help highlight their strengths.

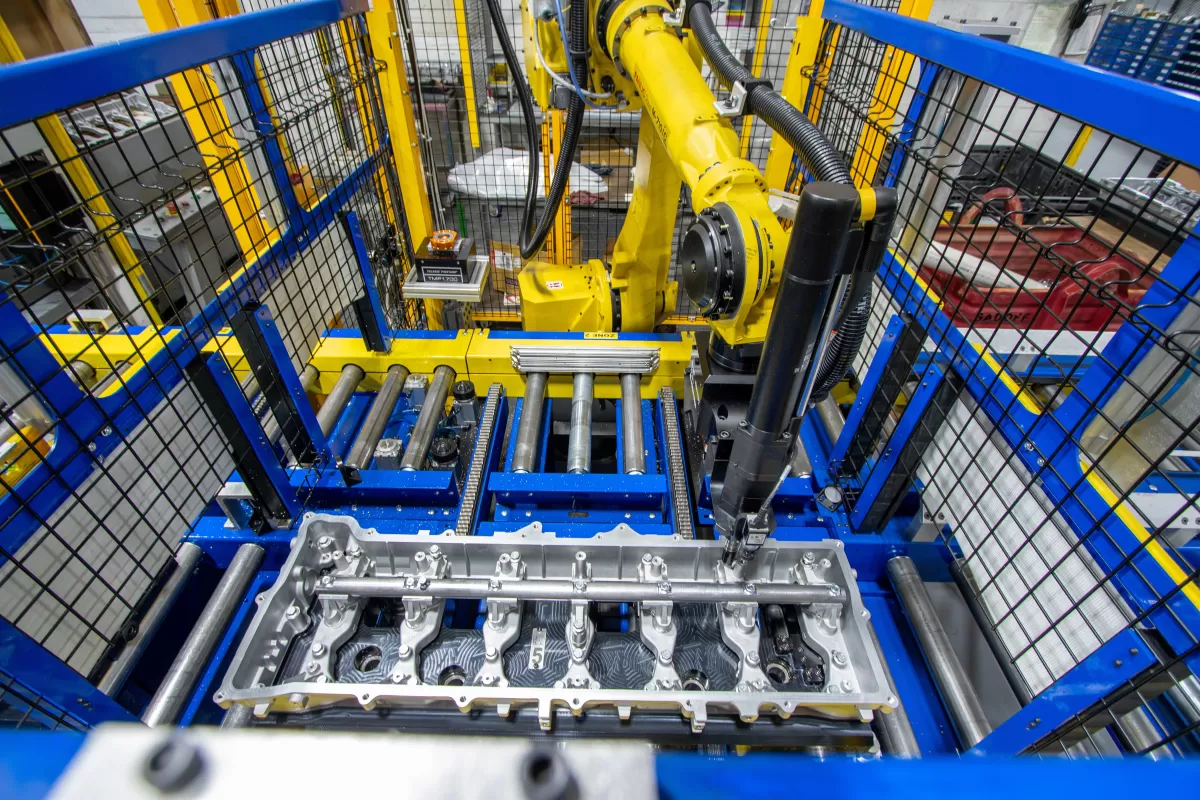

EDM Cutting Precision is ideal for tooling and mold-making, especially when working with hard metals like titanium or hardened steel. For example, aerospace parts requiring intricate internal shapes often rely on EDM’s accuracy.

Laser Cutting Advantages shine in industries like automotive and electronics, where clean cuts and detailed patterns on thin metals and plastics are essential. Companies making custom enclosures or decorative metalwork often choose laser cutting for its speed and precision.

Waterjet Cutting Versatility makes it the go-to choice in construction and heavy machinery sectors. It handles thick materials—like stone, glass, and composites—without heat distortion. For instance, manufacturing contractors use waterjet for cutting large steel plates to build heavy equipment frames.

Plasma Cutting Cost benefits are clear in fabrication shops working with thicker, conductive metals like mild steel and aluminum. It’s fast and affordable for projects like metal signage, HVAC components, and structural steel cutting.

Here’s a quick look at typical projects where these CNC cutting methods excel:

- EDM: Precision molds, aerospace parts, medical tools

- Laser: Electronics enclosures, automotive panels, architectural models

- Waterjet: Heavy machinery parts, glass cutting, composite materials

- Plasma: Structural steel cutting, HVAC ductwork, metal art

For local businesses in the U.S., understanding these applications can help match the CNC cutting service to your project needs efficiently. Check out detailed insights comparing methods like laser vs. waterjet vs. plasma CNC cutting on this blog for more examples and real case studies.