Are you looking to boost precision and efficiency in your CNC machining projects? Mastering jigs and fixtures can transform your workflow, saving time and ensuring flawless results. As a CNC expert, I’ve seen firsthand how the right workholding solutions elevate quality and productivity. In this guide, you’ll uncover the essentials of jigs and fixtures in CNC machining, from their types and benefits to expert design tips. With HYCNC’s custom solutions, you’re just steps away from optimizing your operations. Let’s get started!

Understanding Jigs and Fixtures

When working with CNC machining, you might wonder, what exactly are jigs and fixtures, and why are they so important? Simply put, jigs and fixtures are essential CNC workholding solutions that help improve precision, speed, and safety during machining.

Definition of Jigs

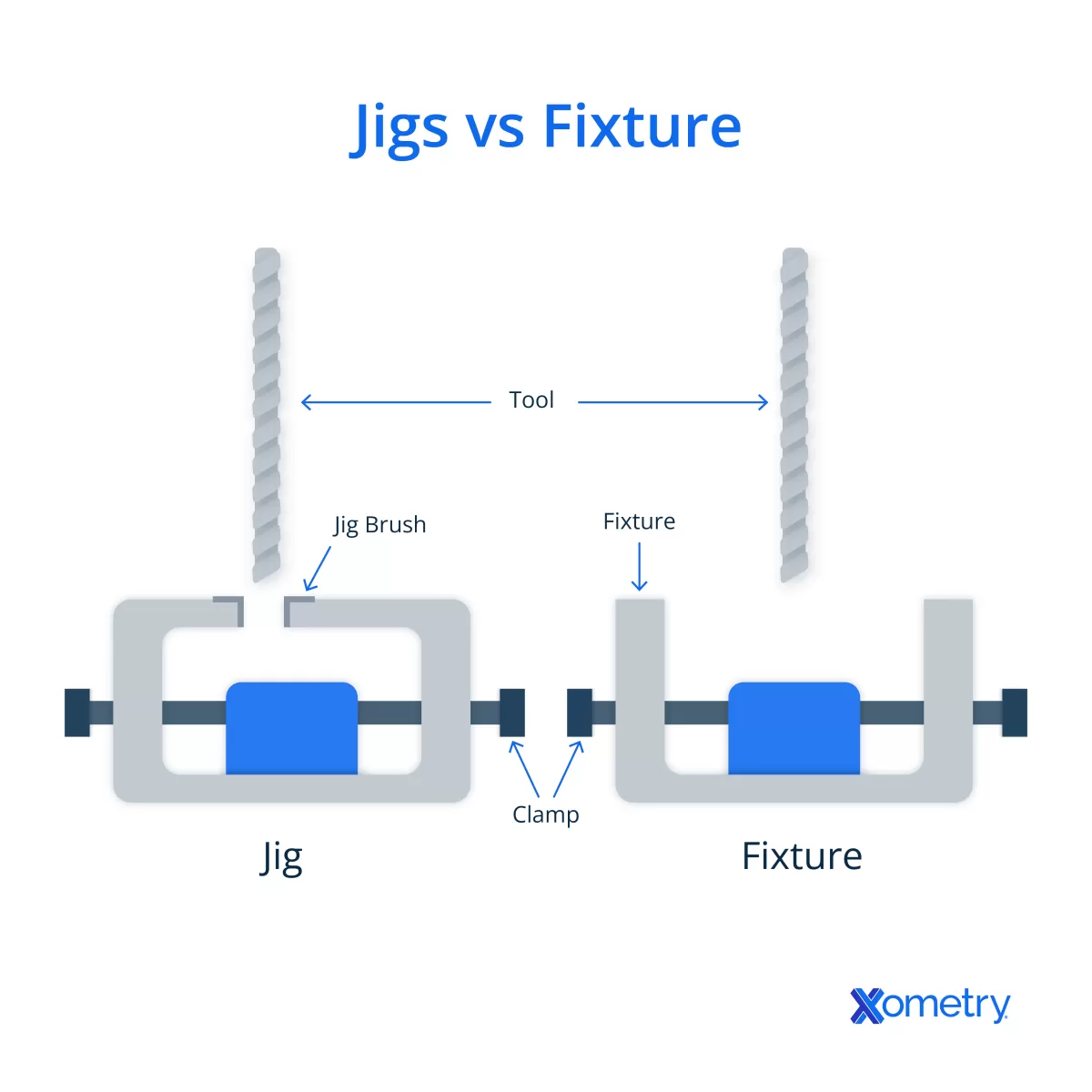

A jig is a special tool that both guides the cutting tool and holds the workpiece in place. It ensures that the tool moves accurately according to the required operation, like drilling or cutting, which enhances repeatability across multiple parts. Jigs are often designed to move with the tool.

Definition of Fixtures

A fixture, on the other hand, exclusively secures the workpiece firmly so it remains stable throughout the machining process. Unlike jigs, fixtures don’t guide the tool but provide a solid, consistent hold to prevent any movement, which is critical for precision machining.

Key Differences Between Jigs and Fixtures

- Function: Jigs guide both the tool and hold the part; fixtures only hold the part.

- Mobility: Jigs are usually designed to move with the tool, while fixtures stay fixed on the machine.

- Complexity: Jigs tend to be more complex due to the guiding function; fixtures focus on strong, stable positioning.

Understanding these differences helps you choose the right CNC workholding solution to enhance your machining efficiency and product quality. If you want a deep dive into how jigs and fixtures compare, check out our detailed guide on jigs vs fixtures.

Types of Jigs and Fixtures in CNC Machining

When it comes to CNC machining, having the right jig or fixture can make all the difference in efficiency and accuracy. Here’s a quick look at the common types you’ll find in the shop.

Common Types of Jigs

-

Drill Jigs

These guide the drill bit exactly where it needs to go, ensuring holes are placed perfectly every time. They’re a staple for hole patterns and repetitive drilling tasks.

-

Template Jigs

These act like stencils, helping operators follow a set path for cutting or shaping parts. They’re simple but effective for consistent shapes.

-

Indexing Jigs

Used when a workpiece needs to be rotated to specific positions. They’re great for machining multiple faces and complex geometries without removing the part.

Common Types of Fixtures

-

CNC Vises

Probably the most familiar fixture. They clamp the workpiece tightly in place on the CNC table. Vises come in many styles, including precision and multi-axis varieties.

-

Angle Fixtures

Designed to hold parts at precise angles for machining surfaces that aren’t flat or straight on. These fixtures unlock more complex part designs.

-

Vacuum Fixtures

These use suction to hold thin or delicate workpieces without damaging them. Vacuum fixtures are handy in industries like electronics where fragile parts need stability.

Specialized Fixtures and Jigs

Beyond the usual types, CNC machining often calls for custom or specialized jigs and fixtures tailored to unique project needs. These could be hybrid designs combining features or made from special materials to handle very specific workholding challenges.

Using the right jig and fixture not only improves workpiece stability but also boosts overall CNC machining productivity and precision.

Benefits of Using Jigs and Fixtures in CNC Machining

Using jigs and fixtures in CNC machining brings several clear advantages that boost productivity and quality. Here’s what you can expect:

Enhanced Precision and Repeatability

Jigs and fixtures keep the workpiece perfectly positioned every time. This ensures cuts and drills are made exactly where they should be, reducing variation between parts and improving overall accuracy.

Faster Setup and Reduced Downtime

They simplify the setup process. With the workpiece securely held in place, you spend less time aligning and more time machining. This speeds up production and cuts down on machine idle time.

Improved Safety and Reduced Human Error

By holding the workpiece firmly, jigs and fixtures minimize the risk of slips or movement that could cause damage or injury. They also reduce operator mistakes since the guidance and holding mechanisms take much of the guesswork out of positioning.

Cost Savings Through Efficiency and Less Waste

Better precision keeps scrap rates low. Faster setups and fewer mistakes mean less downtime, which saves money. Over time, this efficiency translates into significant cost reductions for your CNC projects.

Enabling Complex Part Machining

Jigs and fixtures make it easier to handle complicated shapes or multi-axis operations. They provide stability and positioning options that let you machine complex parts accurately without constant adjustments.

Using the right CNC workholding solutions like custom jigs and fixtures enhances your machining performance and helps you deliver high-quality parts faster and more reliably.

Design Considerations for Effective Jigs and Fixtures

Creating jigs and fixtures that boost CNC machining efficiency starts with the right design choices. Here are some key points to keep in mind:

Material Selection

- Steel offers strength and durability for heavy-duty jobs.

- Aluminum is lighter and easier to machine, making it good for quick setups.

- Sometimes, composite materials or plastics work for specific applications.

Workpiece Positioning

- Make sure the jig or fixture holds the workpiece so the cutting tool can reach all necessary areas without obstruction.

- Proper alignment ensures consistent precision and reduces rework.

Force and Stability Analysis

- The design should handle cutting forces without flexing. Stability means better accuracy and less vibration during CNC operations.

- Think about how clamps and supports distribute pressure evenly.

Simplicity and Ease of Use

- Complex setups slow down production. Keep it straightforward for faster loading and unloading.

- Quick adjustments help when switching parts or working on multi-piece runs.

Adaptability for Multi-Axis Machining

- With 3-axis or 5-axis CNC machines, your jig or fixture needs to support angles and rotations while keeping the workpiece secure.

- Versatile designs save time and reduce the need for multiple fixtures.

By focusing on these factors, you’ll design jigs and fixtures that make CNC machining smoother, faster, and more reliable for your shop. For more on CNC workholding solutions and precision machining, check out our precision machining services.

Manufacturing Jigs and Fixtures

When it comes to making jigs and fixtures, precision and reliability are a must. That’s why CNC machining is the go-to method. It lets us create highly accurate components that fit perfectly and perform consistently every time. Whether it’s simple or complex designs, CNC machining delivers top-notch quality and durability.

3D printing also plays a role, especially when speed and complex shapes matter. It allows quick prototyping and production of intricate parts that might be tough or costly to machine. Combining both CNC machining and 3D printing means we can offer flexible, efficient manufacturing options tailored to your needs.

At HYCNC, we specialize in custom jigs and fixtures designed specifically for your CNC machining projects. Our team has deep expertise in CNC processing, ensuring each tool fits your exact specifications. We provide tailored solutions that improve your machining efficiency and part quality.

Plus, we understand the importance of fast turnaround times and reliable quality controls. When you work with HYCNC, you get prompt service without sacrificing precision or durability, helping you keep your production on track.

Applications of Jigs and Fixtures in CNC Machining

Jigs and fixtures play a vital role across many CNC machining operations. In CNC milling and turning, they ensure the workpiece stays perfectly in place, allowing for precise cuts and consistent part quality. When it comes to drilling and boring, drill jigs guide the tool exactly where it needs to go, reducing errors and speeding up the process.

Beyond machining, jigs and fixtures support welding and assembly tasks by holding parts securely for accurate joining. They also improve quality control and inspection by keeping components steady during measurement, helping catch defects early.

Using the right CNC workholding solutions like custom jigs and fixtures not only boosts efficiency but also guarantees repeatability and accuracy throughout your project.

How HYCNC Can Help

At HYCNC, we specialize in custom design and fabrication of jigs and fixtures that fit your exact CNC machining needs. Whether you’re in automotive, aerospace, or another industry, we tailor every solution to improve your setup and boost productivity.

We offer free DFM (Design for Manufacturing) analysis and quick quoting to make sure your project is efficient and cost-effective from the start. Our expertise in CNC workholding solutions means you get reliable, precision results every time.

Ready to improve your CNC machining process? Get started with HYCNC today and experience faster turnaround, better quality, and expert support tailored for U.S.-based manufacturers.