What Are Jigs

Jigs are specialized tools used in manufacturing to guide and control the location and movement of a cutting tool during machining. Their main purpose is to ensure accuracy and repeatability when drilling, boring, or shaping parts. By holding the workpiece steady and directing the tool, jigs simplify complex operations and reduce human error.

Common Types of Jigs

- Drill Jigs: Most common, used to guide drill bits for precise holes.

- Template Jigs: Use a shaped template to control the tool path.

- Swivel Jigs: Allow angular adjustments for drilling at different angles.

- Channel Jigs: Clamp the workpiece and guide the tool through a channel.

Applications in CNC Machining

In CNC machining, jigs are crucial for:

- Ensuring consistent hole placement and alignment.

- Reducing setup time between batches.

- Enhancing precision in repetitive drilling tasks.

- Minimizing machine downtime by streamlining workflow.

Many CNC operations now integrate jigs to complement automated processes, especially when handling small production runs or custom parts.

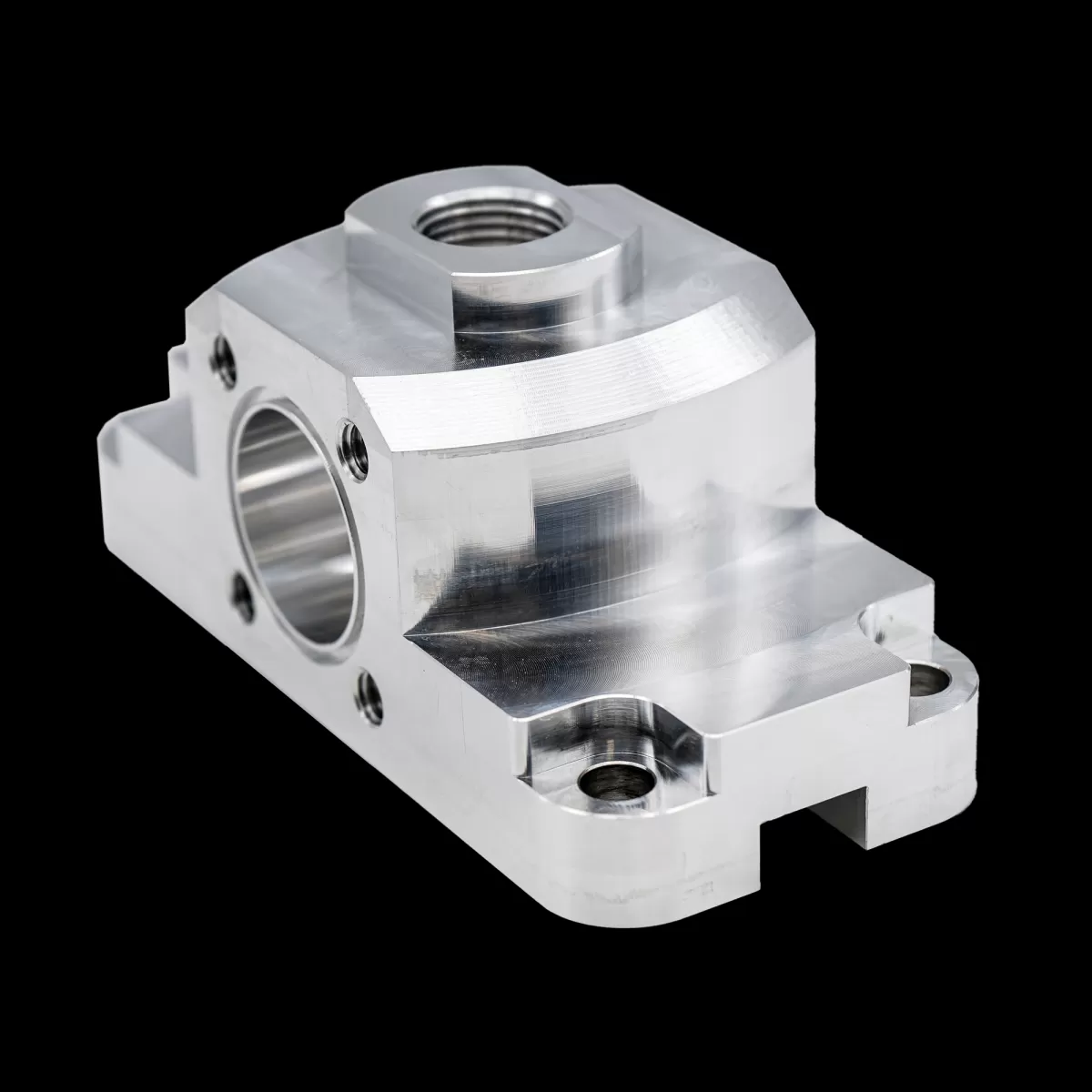

HYCNC Custom Drill Jigs Example

At HYCNC, we design and manufacture custom drill jigs tailored to your specific project needs. Our drill jigs help:

- Achieve high precision in hole positioning.

- Adapt to various workpiece sizes.

- Improve efficiency by reducing manual measurement errors.

Using advanced CAD software and CNC machining, HYCNC delivers jigs that fit your production requirements perfectly, enhancing both quality and speed.

What Are Fixtures

Fixtures are tools that hold and support a workpiece firmly during CNC machining. Unlike jigs, which guide the cutting tool, fixtures keep the part steady so the machine can work accurately. They’re essential for repeatable and stable machining processes, especially when working with complex or delicate parts.

Common Types of Fixtures

- Milling fixtures: Hold parts steady in milling machines.

- Drilling fixtures: Secure workpieces for precise hole drilling.

- Grinding fixtures: Keep the item stable during surface finishing.

- Indexing fixtures: Allow the part to be rotated or positioned precisely for multiple machining steps.

Fixtures in CNC Machining

In CNC machining, fixtures ensure consistent positioning of parts for every run. This stability helps reduce errors, improves machining quality, and speeds up production by minimizing manual adjustments. They are especially useful when handling large volumes or intricate components needing exact alignment.

HYCNC Fixtures for Stable Workpiece Alignment

At HYCNC, we specialize in custom fixtures designed to fit your exact workpiece needs. Our fixtures provide unmatched stability and precision, helping you get reliable results every time. Whether it’s for automotive parts or aerospace components, our fixtures help maintain perfect alignment and reduce cycle times, improving overall CNC machining efficiency.

Jigs vs Fixtures Key Differences

When choosing between jigs and fixtures for CNC machining, it helps to understand their main differences. Here’s a simple comparison to make it clear:

| Feature | Jigs | Fixtures |

|---|---|---|

| Function | Guides cutting tools for drilling or machining | Holds and supports the workpiece securely |

| Complexity | Generally more complex due to guiding parts | Simpler design focused on clamping |

| Weight | Usually lighter | Typically heavier for stability |

| Machine Attachment | Often attached or mounted to the machine tool | Usually fixed to the machine table or base |

| Applications | Drilling, boring, reaming with precise tool guidance | Milling, grinding, turning, and assembly tasks |

| Workpiece Contact | Direct contact with the moving tool | Holds workpiece firmly without guiding the tool |

| Common Materials | Aluminum, steel, sometimes plastic for light-duty jigs | Steel or cast iron for strength and durability |

Understanding these differences helps decide the right tool for your CNC setup. Jigs are ideal when you need exact tool guidance, while fixtures provide steady part holding during cutting or assembly. At HYCNC, we design both with an eye on efficiency and precision to fit your specific needs.

Benefits of Using Jigs and Fixtures in CNC Machining

Using CNC jigs and fixtures brings major advantages for any manufacturing setup. Here’s why they’re a game-changer:

Improved Precision and Repeatability

Jigs and fixtures ensure your workpieces are held in the exact same position every time. This means tighter tolerances and consistent quality across batches. For CNC machining, that repeatability is key to reducing errors and rework.

Increased Productivity and Reduced Setup Time

With a well-designed jig or fixture, you don’t spend long aligning or clamping parts manually. This speeds up your setup process and lets machines run jobs faster. You get more parts done in less time without sacrificing precision.

Cost Savings and Safety

By cutting down on mistakes and speeding up production, jigs and fixtures lower overall manufacturing costs. Plus, they help secure the workpiece, reducing the risk of accidents during machining—keeping your team and equipment safer.

HYCNC Case Study on Production Time Reduction

At HYCNC, we helped a US-based manufacturer reduce their drilling operation time by 30% using custom CNC drill jigs. By optimizing the jig design for easy part loading and precise positioning, the production line became both faster and more reliable. This saved them thousands of dollars annually and boosted on-time delivery rates.

In short, investing in custom jigs and fixtures is a smart move for any U.S. business looking to improve CNC machining efficiency and quality. At HYCNC, we tailor solutions that meet those needs perfectly.

Design Considerations for Jigs and Fixtures

When designing jigs and fixtures, several key factors come into play to ensure they perform well and last long.

Material Selection

Choosing the right material is crucial. Most CNC jigs and fixtures are made from steel, aluminum, or composites depending on the strength, weight, and durability needed. For lighter, less demanding jobs, aluminum works great. Steel is better when you need toughness and wear resistance.

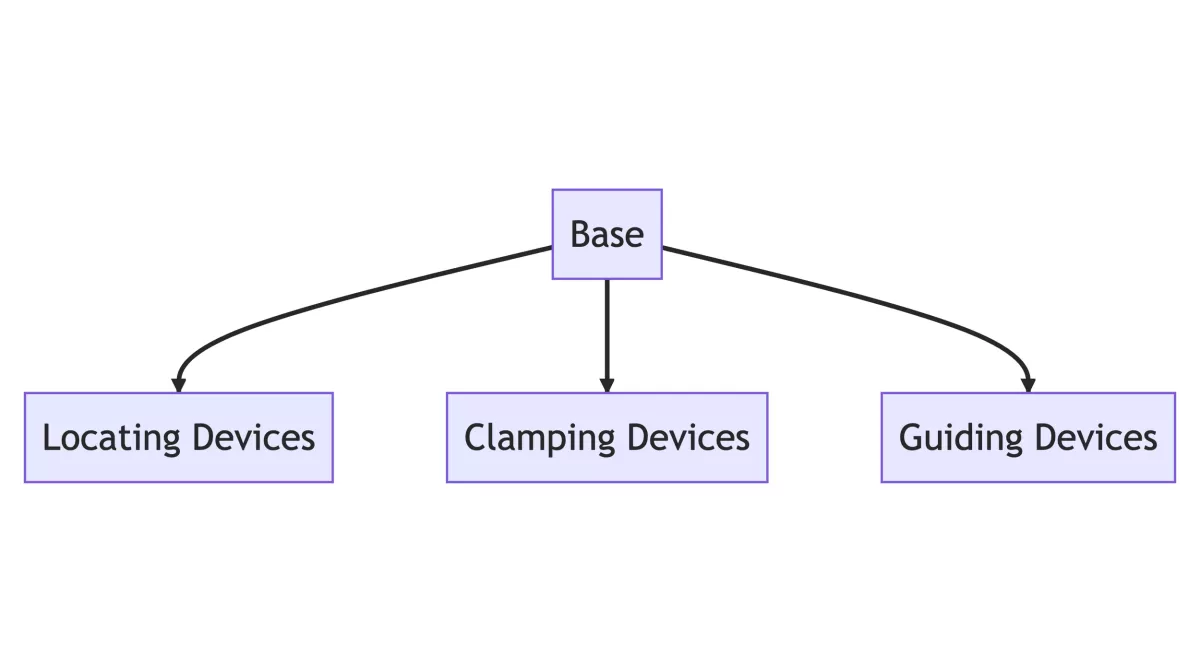

Clamping and Locating Principles

Good jigs and fixtures must hold the workpiece securely in one exact position. Proper locating points and clamps prevent any shifting during machining. The design needs to make loading and unloading quick and easy while keeping the part stable.

Force Analysis

Understanding the forces during machining helps design supports that withstand cutting pressure without moving or deforming. This keeps tolerances tight and improves the finished part’s precision.

Customization

Every job is different. Effective jig and fixture design means tailoring the tooling for the specific workpiece shape, machining operations, and production volume. Custom solutions avoid unnecessary complexity and cost.

HYCNC’s Design Approach with CAD and FEA

At HYCNC, we use advanced CAD software to create precise digital models of jigs and fixtures. Then we run FEA (Finite Element Analysis) to simulate forces and stress points before building anything. This approach cuts trial-and-error time, boosts accuracy, and delivers reliable custom tooling ready for your CNC machining needs.

Manufacturing Jigs and Fixtures

When it comes to making jigs and fixtures, there are a couple of common approaches. Traditionally, CNC machining has been the go-to method. It ensures precision and durability, especially for metal tools that need to handle tough shop conditions. Machining offers tight tolerances and reliable finishes, which are crucial for accurate workpiece holding in CNC machining.

On the modern side, 3D printing is changing the game. It allows for faster prototyping and can produce complex shapes that might be difficult or costly with traditional machining. With 3D printed jigs, you can quickly test designs and make adjustments before committing to full production. This method also helps reduce lead times and costs for custom tools.

At HYCNC, we combine both methods to deliver the best results. Our rapid prototyping lets us quickly create and refine custom CNC jigs and fixtures tailored to your needs. Plus, once designs are finalized, we shift to precision CNC machining for durable, high-quality production tools that stand up to daily shop use.

Whether you need a quick prototype or a long-lasting production fixture, HYCNC’s manufacturing capabilities have you covered.

Applications Across Industries

Jigs and fixtures play a crucial role across many industries where precision and efficiency matter. In the automotive sector, assembly line fixtures help hold parts securely, speeding up production while maintaining quality. Aerospace relies heavily on precision drilling jigs to ensure exact hole placement for critical components. Medical manufacturing uses custom fixtures for implants and surgical tools, where accuracy is non-negotiable.

At HYCNC, we support a broad range of industries by providing custom CNC jigs and fixtures designed to meet specific needs. Whether it’s creating durable fixtures for automotive parts or intricate drilling jigs for aerospace applications, our solutions help you achieve higher precision and faster turnaround. We’re committed to helping U.S. manufacturers improve their processes with reliable, tailor-made workholding tools.

Why Choose HYCNC for Custom Jigs and Fixtures

At HYCNC, we bring expert CNC machining and prototyping skills to every custom jig and fixture project. We understand how important precision and reliability are for your manufacturing process, so we tailor solutions that fit your exact needs.

Here’s why you should choose us:

-

Expertise in CNC machining and prototyping

We have years of hands-on experience making complex jigs and fixtures for different industries. Our team knows how to fine-tune designs for the best fit and function.

-

Custom solutions

No cookie-cutter parts here. We work closely with you to create jigs and fixtures that match your unique workpieces and production requirements, ensuring maximum efficiency and accuracy.

-

Fast turnaround and cost-effectiveness

Time is money. That’s why we prioritize quick delivery without compromising quality. Plus, our competitive pricing helps keep your project within budget.

Ready to boost your CNC machining with reliable, custom jigs and fixtures? Contact HYCNC today for a quote and see how we can optimize your production process.