Understanding Waterjet and Laser Cutting

When it comes to precision cutting methods, waterjet cutting and laser cutting are two of the most popular choices in the CNC machining world. Each offers unique benefits depending on the material and project requirements. But what exactly are these cutting technologies, and how do they work?

What is Waterjet Cutting

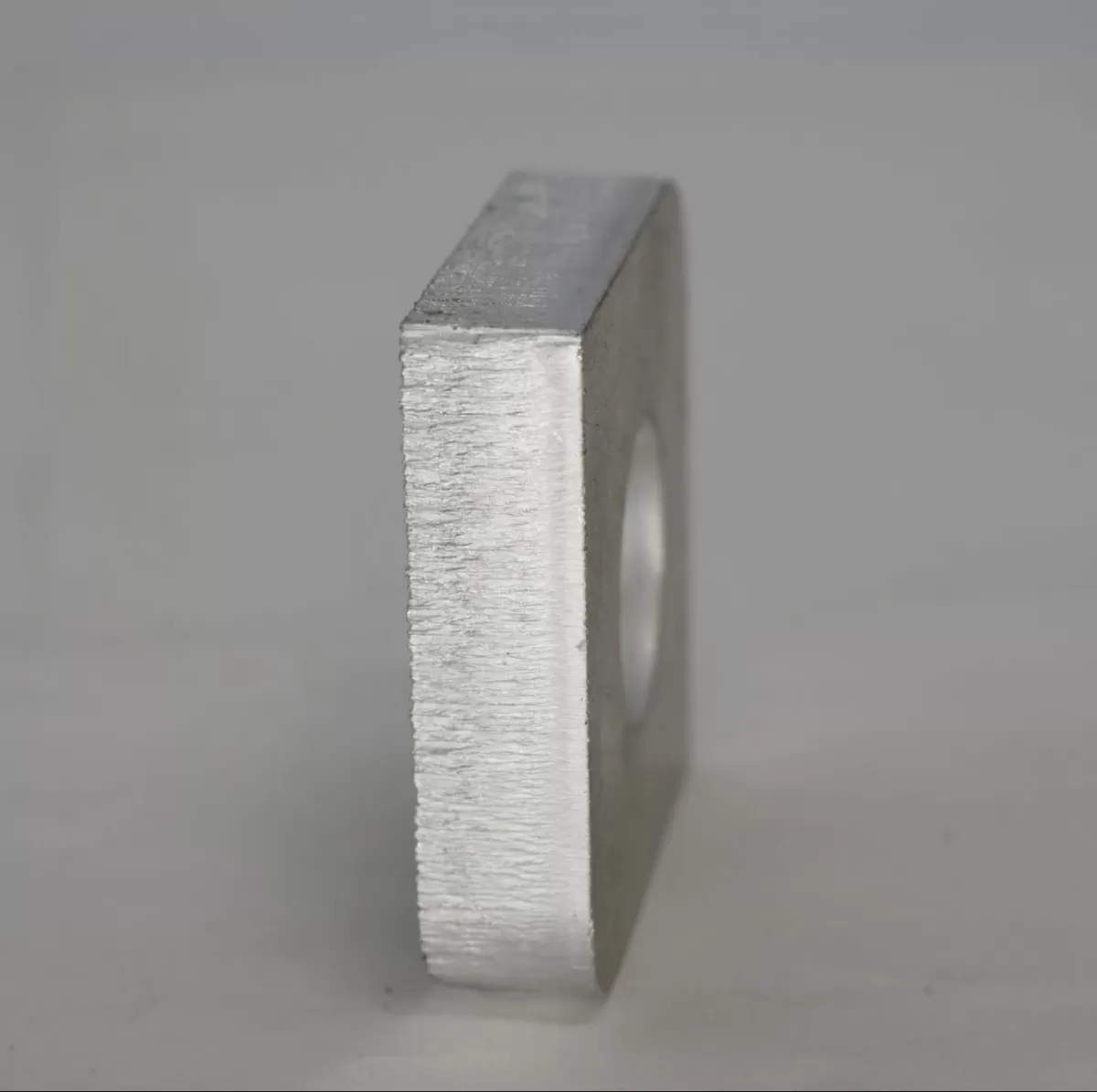

Waterjet cutting uses a powerful stream of high-pressure water mixed with abrasive particles to cut through materials. This method doesn’t generate heat, making it ideal for cutting heat-sensitive materials without warping or damaging them. Waterjet cutting versatility is impressive—it can handle metals, stone, glass, plastics, and composites with clean, smooth edges. Because it uses physical erosion rather than heat, it’s perfect for thick material cutting where precision and material integrity are critical.

What is Laser Cutting

Laser cutting uses a focused beam of light to melt, burn, or vaporize material along a defined path. Laser cutting precision is excellent on thin to medium-thickness materials, especially sheet metal fabrication, offering sharp, detailed cuts and clean edges. This method is faster than waterjet for thinner materials and works best with metals, wood, plastics, and some composites. It’s widely used when speed, accuracy, and intricate designs are needed.

Understanding these basics helps when choosing between waterjet and laser cutting services, as each excels in different applications depending on your material and project needs. For more on how precision cutting impacts metal fabrication, check out our article on sheet metal fabrication tips.

Key Differences Between Waterjet and Laser Cutting

When comparing waterjet cutting vs laser cutting service, several key factors come into play to help decide which method fits your needs best.

Material Compatibility

- Waterjet Cutting works well with a wide range of materials including metals, stone, glass, plastics, and composites. It’s great for materials that can warp or melt with heat.

- Laser Cutting shines with metals, thin sheets, and plastics but struggles with reflective or very thick materials. It’s not ideal for materials sensitive to heat.

Precision and Edge Quality

- Laser Cutting Precision is very high with clean, sharp edges, especially on thin materials. It’s perfect for designs requiring tight tolerances.

- Waterjet Cutting delivers smooth edges too but can leave a slight roughness, suitable for most industrial applications where ultra-fine detail isn’t critical.

Thickness Capabilities

- Waterjet Cutting cuts thick materials effortlessly, often over several inches, without loss of quality due to its cold cutting method.

- Laser Cutting has limits on thickness, generally best for thinner materials (up to about half an inch thick depending on the laser power).

Speed and Efficiency

- Laser Cutting usually operates faster on thin materials, making it cost-effective and efficient for high-volume sheet metal fabrication.

- Waterjet Cutting is slower, especially on thick or hard materials, but its versatility, especially on tough materials, often outweighs speed in certain projects.

Cost Considerations

- Waterjet Cutting tends to be more expensive due to higher operating costs like abrasive materials and slower cutting speeds.

- Laser Cutting often provides lower CNC machining costs for thin materials with faster turnaround times, ideal for many fabrication needs.

Knowing these differences helps to pick the right precision cutting method for your project whether it’s thick material cutting or laser cutting precision that matters most.

Pros and Cons of Each Method

Advantages of Waterjet Cutting

- Versatile on materials: Works well on metals, stone, glass, and even composites.

- No heat affected zone: Cuts without heat, so no warping or material distortion.

- Thick material cutting: Can handle much thicker materials than laser cutting.

- Smooth edges: Leaves clean edges that often need little to no finishing.

- Environmentally friendly: Uses water and abrasive, avoiding harmful fumes.

Disadvantages of Waterjet Cutting

- Slower cutting speed compared to laser, especially on thinner materials.

- Higher operating costs due to water, abrasive materials, and maintenance.

- Less precision on very fine or intricate cuts compared to laser.

- Water management: Requires proper disposal and recycling of used water and abrasives.

Advantages of Laser Cutting

- High precision and detail: Ideal for intricate designs, sharp corners, and fine cuts.

- Fast cutting speed on thin and medium thickness materials.

- Clean cuts with minimal finishing needed for some metals and plastics.

- Low operational waste: No water or abrasive material needed.

- Great for sheet metal fabrication where speed and accuracy are critical.

Disadvantages of Laser Cutting

- Limited thickness capacity: Not the best choice for very thick materials.

- Heat affected zone can cause warping or discoloration, especially on heat-sensitive materials.

- Material limitations: Some materials like reflective metals or certain plastics don’t cut well with laser.

- Higher initial equipment costs can reflect in service pricing.

Choosing between waterjet cutting vs laser cutting service means weighing your project needs—whether that’s thick material cutting, precision, or cost-effectiveness.

When to Choose Waterjet vs Laser Cutting

Choosing between waterjet cutting and laser cutting depends largely on your project needs, material type, and desired finish. Here’s a quick guide on when to go for each method.

Best Use Cases for Waterjet Cutting

- Thick Materials: Waterjet cutting is ideal for thick metals, stone, glass, and composites. It can easily handle materials that are tough for lasers.

- Heat-Sensitive Materials: Since waterjet cutting doesn’t generate heat, it’s perfect for materials that could warp, melt, or get damaged by high temperatures.

- Versatile Material Cutting: Great for cutting metals, ceramics, rubber, plastics, and food products without affecting the material’s structure.

- Complex Shapes: Waterjets provide smooth edges and allow intricate designs, especially when edge quality matters.

- Low Waste Production: Waterjet is efficient for materials you want to conserve, keeping waste minimal.

Best Use Cases for Laser Cutting

- Thin to Medium Sheet Metal: Laser cutting excels at precision cuts on thin metals like mild steel, aluminum, and stainless steel with clean edges.

- High Precision and Detail: When you need extremely fine cuts or small features, laser cutting offers unbeatable accuracy.

- Speed for Production Runs: Laser cutting is faster for thinner materials and repetitive jobs, making it suitable for quick turnaround in sheet metal fabrication.

- Smooth Finishes: Cuts come out with clean, burr-free finishes, often reducing or eliminating the need for secondary trimming or sanding.

- Cost Efficiency for Thin Materials: When working with mild steel or aluminum sheets, laser cutting often delivers faster results at a lower CNC machining cost.

Understanding these use cases will help you pick the best precision cutting method for your project, balancing cost, speed, and material needs effectively.

For more on materials we work with, check out our laser-cut aluminum options or explore our broader CNC machining services.

Why Choose HYCNC for Your Cutting Needs

When it comes to CNC cutting services in the U.S., HYCNC stands out for a few solid reasons. First, we offer both waterjet cutting and laser cutting options, so you get the right precision cutting method based on your material and project needs. Whether you’re working with sheet metal fabrication, thick materials, or delicate parts, HYCNC has the expertise and technology to handle it.

Our team focuses on delivering clean cuts, quick turnaround times, and competitive CNC machining costs. We understand the local market demands and offer tailored solutions that fit your budget without sacrificing quality. Plus, we use the latest industrial cutting solutions that keep your projects efficient and precise.

Choosing HYCNC means working with a reliable partner that values clear communication, accuracy, and consistency. We’re here to help you pick the best material cutting technology—waterjet or laser—so your project finishes strong every time. If you want top-notch results with a local touch, HYCNC is the smart choice for your cutting needs.

Local Considerations for CNC Cutting Services

When choosing between waterjet cutting vs laser cutting service in your area, local factors can make a big difference. Here are some things to keep in mind:

-

Availability of Technology

Not all CNC cutting services offer both waterjet and laser cutting. Confirm what options your local providers have so you get the best fit for your project.

-

Material Expertise

Some local shops specialize in certain materials like sheet metal fabrication or thick material cutting. Picking a service familiar with your material ensures better results.

-

Turnaround Time and Capacity

Depending on demand, local shops might have varying lead times. If you need quick delivery, check how fast they can handle your job, especially with more complex cutting methods.

-

Cost and Pricing Structure

Regional cost differences can affect CNC machining costs. Ask for detailed quotes and compare services for the most cost-effective solution without compromising quality.

-

Support and Communication

Working with local CNC services means easier communication and onsite support, which can help troubleshoot issues and speed up adjustments during production.

At HYCNC, we balance the latest material cutting technologies with local customer needs, offering both waterjet cutting versatility and laser cutting precision. We’re here to guide you on the best method for your project while providing top-notch CNC machining and precision cutting services you can rely on.

Explore our precision machining services to learn how we support your manufacturing needs with local expertise.