What Are Welding Defects

Welding defects are imperfections in welds that compromise the strength, appearance, or functionality of a welded joint. These flaws can range from small surface issues to serious structural problems that weaken the overall weld. Whether visible or hidden inside the weld, defects reduce reliability and can lead to failures under stress.

Welding defects impact many industries, including automotive, aerospace, and construction. In these fields, even minor weld imperfections can cause costly downtime, safety risks, or part replacements. For example, weld cracking in aerospace components or porosity in automotive frames can lead to dangerous failures or expensive recalls.

Addressing welding defects is especially important in CNC welding processes where precision and consistency are critical. Properly managing defects improves safety, extends the life of welded structures, and ensures high-quality results in demanding manufacturing environments. At HYCNC, we focus on eliminating weld imperfections to deliver durable, defect-free products that meet industry standards.

Common Types of Welding Defects

Welding defects come in several common forms that can affect the strength and appearance of your welds. Here’s a quick rundown:

- Porosity: These are tiny gas pockets trapped inside the weld. They weaken the weld and can cause it to fail under pressure.

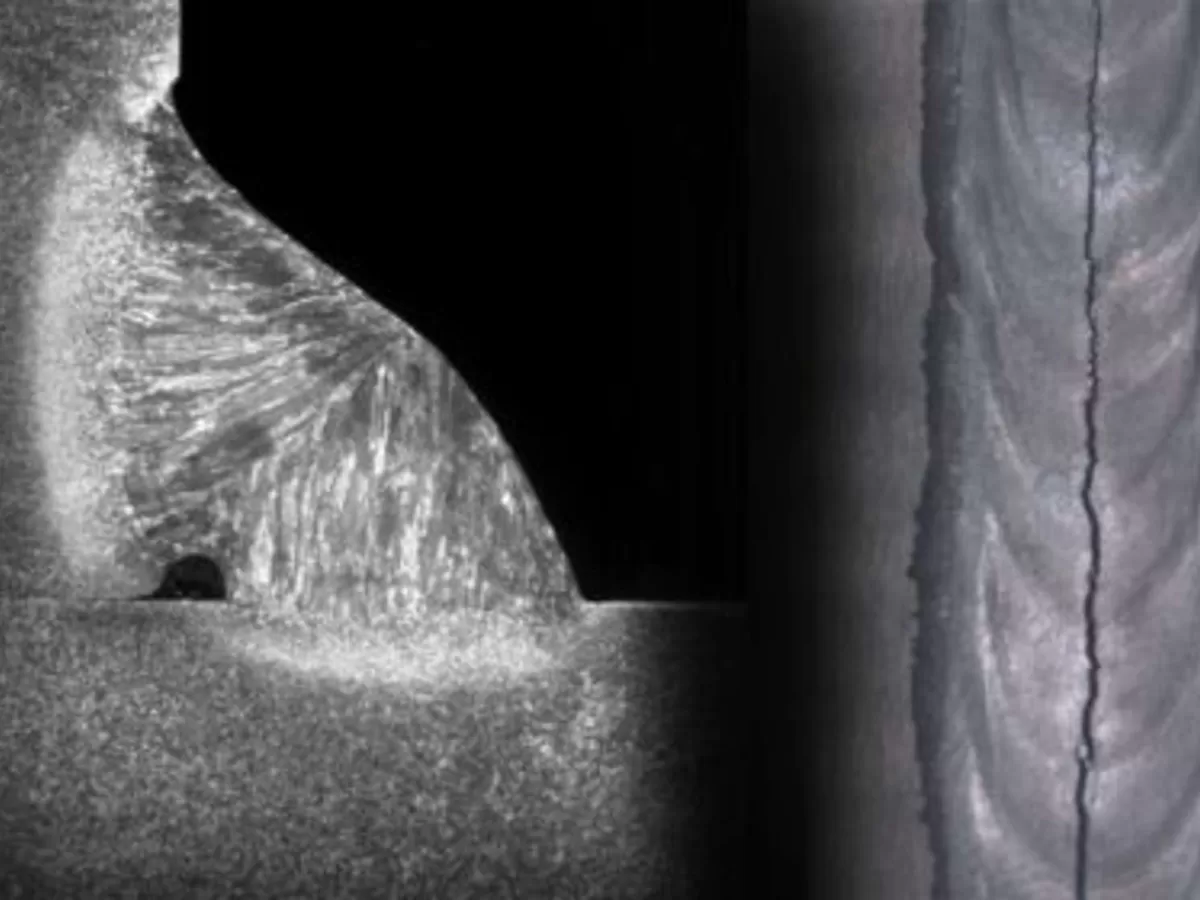

- Cracks: Cracks happen when stress or improper cooling messes up the weld. They include:

- Hot cracks that appear while the metal is still hot.

- Cold cracks that form after the weld has cooled down.

- Incomplete Fusion: This defect means the weld metal didn’t properly bond with the base material, leaving a weak joint.

- Spatter: These are unwanted droplets of molten metal scattered around the weld area. Spatter affects both the look and quality of the weld.

- Undercut: This is a groove that forms at the weld toe, reducing the structural integrity of the joint.

- Slag Inclusions: Non-metallic materials like flux get trapped inside the weld, weakening it from within.

Understanding these common welding defects is key to spotting problems early and making sure your welds hold up in the long run.

Causes of Welding Defects

Welding defects happen for a few key reasons, and understanding these causes helps avoid weak or flawed welds.

-

Human Error

Improper welding technique or lack of training often leads to defects. Even with CNC systems, skilled operators are needed to set up and supervise the process.

-

Equipment Issues

Faulty CNC welding machines or wrong settings can cause inconsistent weld quality. Poor equipment maintenance or calibration issues often lead to problems like porosity or cracks.

-

Material Factors

Using low-quality materials or welding on dirty or contaminated surfaces introduces defects. Oils, rust, or dirt interfere with proper bonding during welding.

-

Environmental Factors

Conditions like high humidity, extreme temperatures, or insufficient shielding gas cause weld imperfections. For example, moisture can create porosity, while inadequate gas coverage leads to oxidation.

At HYCNC, our advanced CNC systems are built to minimize these risks. We use precise controls and consistent settings for every weld, reducing human error and equipment problems. Plus, we focus on material prep and maintain ideal environmental controls to keep welds strong and defect-free.

Preventing Welding Defects in Manufacturing

Stopping welding defects before they happen is key to making strong, reliable products. Here’s how we do it at HYCNC to help you get it right every time.

Proper Training

Skilled welders make all the difference. We ensure everyone working with CNC welding machines understands the precise techniques needed to avoid common weld imperfections like porosity or incomplete fusion.

Equipment Calibration

Using HYCNC’s precision CNC machines means your equipment is always set up correctly. Regular calibration keeps welding parameters consistent, reducing issues like spatter and undercut that come from faulty settings.

Material Preparation

Starting with clean, high-quality materials is a must. Removing contaminants and selecting the right metals prevents problems such as slag inclusions and weak bonding in the welds.

Process Optimization

Adjusting welding speed, heat input, and other parameters is essential. We fine-tune these settings to match your specific CNC welding needs, cutting down on cracks and other weld quality issues.

Quality Control

Thorough inspections like ultrasonic testing and X-rays catch defects early. This helps maintain high standards and ensures any weld imperfections are fixed before moving forward.

Role of Automation

HYCNC leverages advanced automation to minimize human error, ensuring each weld meets strict quality standards. Automation keeps processes consistent, reducing the chances of weld defects across production runs.

By focusing on these prevention steps with the right tools and expertise, HYCNC helps keep your manufacturing process smooth and your welds durable.

How HYCNC Addresses Welding Defects

At HYCNC, we specialize in CNC machining and welding services designed to minimize welding defects and boost overall weld quality. Our advanced CNC technology allows for precise control over welding parameters, ensuring consistent, defect-free welds every time. By integrating cutting-edge equipment with skilled operators, we deliver superior results that meet the strict demands of industries like automotive, aerospace, and construction.

For example, a recent client in the automotive sector struggled with frequent weld porosity and incomplete fusion issues. After switching to our CNC welding solutions, they saw a significant drop in defects, improving their product durability and reducing costly rework.

If you’re dealing with weld imperfections or looking to improve your manufacturing process, contact HYCNC for customized CNC solutions tailored to your needs. We’re here to help you achieve stronger, cleaner welds with reliable performance.