What Are Stress Concentrations and Why Do They Matter in CNC Machining

If you’ve ever wondered why some machined parts fail unexpectedly, stress concentrations are often the hidden culprit. Simply put, stress concentrations happen where stress gathers in a small area, usually around sharp corners, holes, or abrupt shape changes. These spots create stress risers that can lead to cracks, fatigue, and ultimately part failure.

Understanding stress concentrations is crucial when designing CNC-machined parts because they directly impact durability and reliability. Ignoring them can lead to parts that break prematurely, causing costly downtime or safety issues, especially in demanding industries like aerospace and automotive.

At HYCNC, we specialize in precision CNC machining that minimizes these risks. Through careful design optimization and advanced machining techniques, we reduce sharp transitions and ensure smooth, accurate geometries. This approach helps prevent stress concentrations from becoming failure points, delivering parts you can trust to perform longer and stronger.

Causes of Stress Concentrations in Machined Parts

Stress concentrations mainly happen because of geometric discontinuities—these are sharp corners, notches, holes, or sudden changes in shape where stress tends to pile up. When a part has an abrupt edge or a tight radius, it creates a stress riser, making those spots more prone to failure.

Material properties also play a big role. Some materials handle stress better than others. For example, brittle materials might crack more easily under high stress concentrations, while ductile materials can absorb and distribute the load more evenly. Choosing the right material helps reduce the chance of stress-related failures.

Manufacturing processes can worsen stress concentrations if not done carefully. Machining errors like chatter marks, tool deflection, or improper toolpaths can introduce tiny flaws or rough edges that become hotspots for stress. This is why precise CNC machining and optimized toolpaths matter so much.

Here are some real-world examples where stress concentrations show up in CNC-machined parts:

- Keyways: Sharp edges in the slot can cause localized stress.

- Fillets: Properly sized fillets reduce stress, but too small or missed fillets worsen it.

- Threads: The root of a thread is a common stress riser if not cut cleanly.

Understanding what causes these stress risers helps us design and machine parts that last longer and perform better.

Effects of Stress Concentrations on Part Performance

Stress concentrations can seriously impact how well a machined part performs over time. When stress builds up around sharp corners, notches, or holes, it creates weak points that often lead to material failure. This usually shows up as fatigue cracking, where tiny cracks form and spread under repeated loads, eventually causing the part to break unexpectedly.

Because of these weak spots, the lifespan of a product can be much shorter than expected. Parts fail prematurely, resulting in costly repairs or replacements—and that can hurt your bottom line. This is especially critical in industries like aerospace and automotive, where safety is non-negotiable. A single failure caused by stress concentrations could lead to dangerous situations, making it essential to control these stress risers from the start.

For example, one aerospace component with sharp internal corners experienced frequent fatigue cracks during testing. By redesigning those corners with smooth fillets and running a finite element analysis, engineers reduced the stress concentration factor significantly. That small design change improved the part’s durability and reliability, preventing costly failures down the road.

At HYCNC, we focus on identifying and addressing these stress points through precise design and machining, helping you avoid issues that compromise part performance and safety.

How to Identify Stress Concentrations in Design

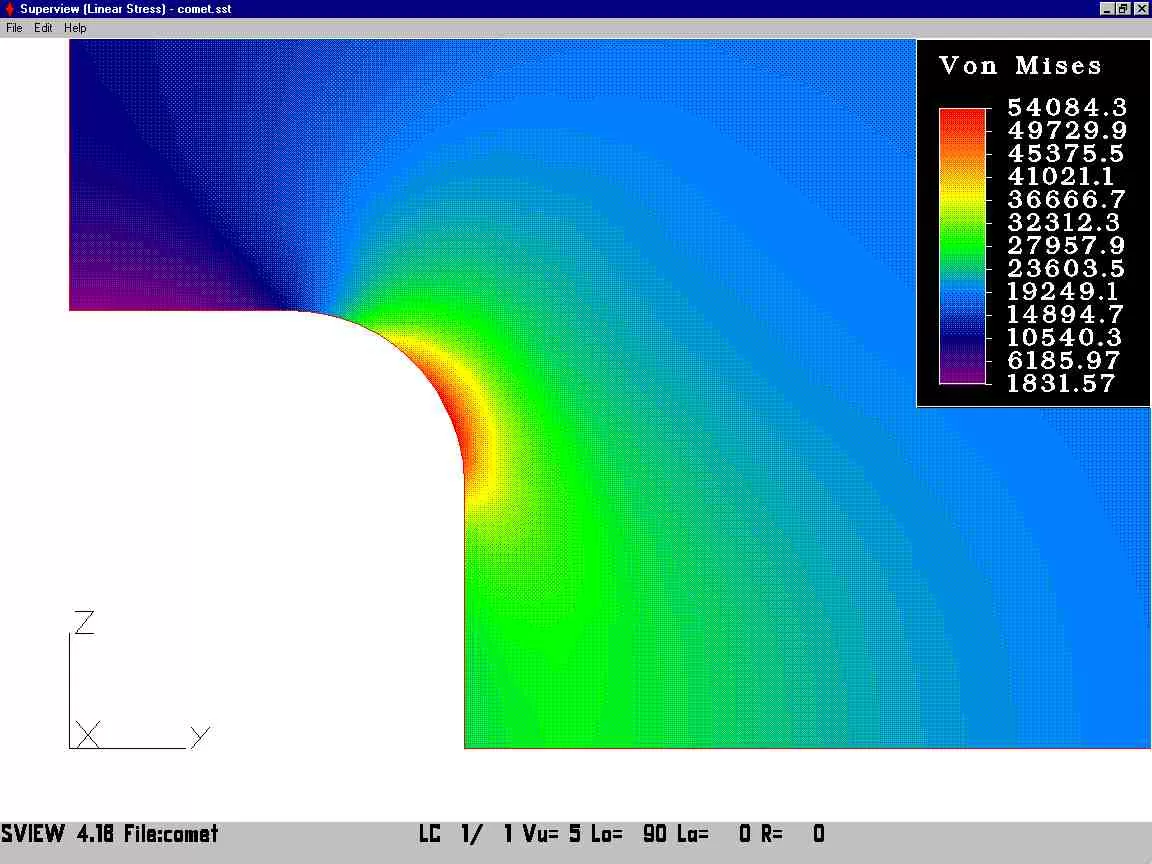

Spotting stress concentrations early is key to avoiding part failure. One of the best tools we use is Finite Element Analysis (FEA). FEA simulates how stress spreads across a part, showing exactly where high-stress areas or stress risers form. This helps us adjust designs before any machining starts.

Besides simulations, we rely on visual inspections and testing to catch potential issues. Non-destructive methods like X-ray and ultrasonic testing allow us to examine parts for internal flaws or cracks without damaging them. This step is crucial for quality control, especially in critical industries like aerospace and automotive.

At HYCNC, we combine advanced FEA tools with thorough inspection techniques to make sure every component meets exact stress and durability standards. This layered approach ensures parts don’t just look good but perform reliably under real-world conditions.

Strategies to Reduce Stress Concentrations in CNC Machining

Reducing stress concentrations in your parts starts with smart design and careful machining. Here’s how we at HYCNC approach it to deliver durable, reliable components:

Design Optimization

- Use fillets and rounded edges to smooth out sharp corners and transitions. This helps spread the stress more evenly and avoids stress risers.

- Avoid abrupt geometric changes like sudden step downs or tight notches that can create weak spots.

- Optimize load distribution so the forces are better balanced across the part, reducing areas of concentrated stress.

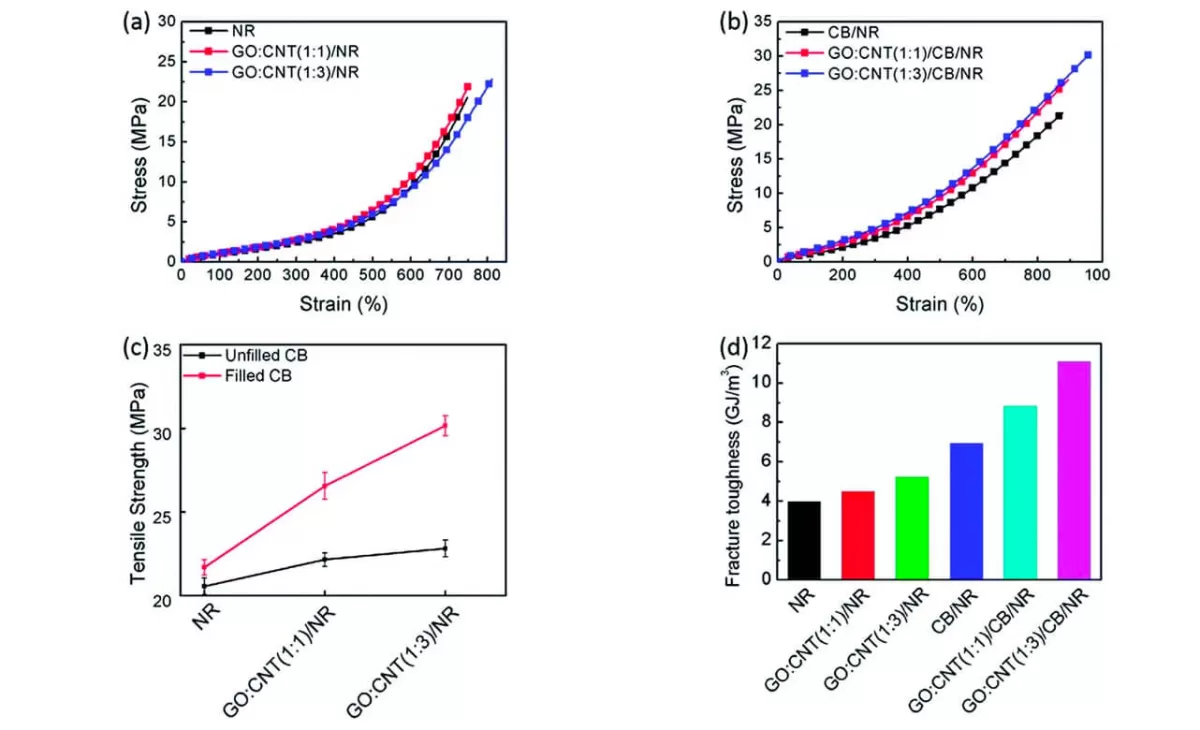

Material Selection

- Pick materials known for higher fatigue resistance. Certain alloys and composites handle repetitive stress better, improving overall part lifespan.

Precision Machining Techniques

- Our CNC machines create smooth surfaces and exact geometries to prevent small imperfections that can turn into stress concentration points.

- We pay special attention to toolpath optimization to avoid unnecessary tool marks or sharp edges that could act as stress risers.

Post-Processing

- Techniques like polishing, heat treatment, or shot peening help reduce residual stresses inside the material. These steps strengthen the part and cut down the risk of early failure.

By combining these strategies, HYCNC ensures that your parts handle stress better and last longer in their real-world applications.

Why Choose HYCNC for Stress-Free CNC Machining

At HYCNC, we understand how crucial it is to control stress concentrations for parts that last and perform reliably. With years of experience crafting precision components for industries like aerospace, automotive, and medical, we have the know-how to handle the toughest challenges.

We use advanced CNC machines combined with cutting-edge finite element analysis (FEA) tools. This lets us accurately predict and reduce stress risers before production even starts, helping prevent mechanical failure and fatigue issues. Our technology ensures smooth surfaces, precise geometries, and optimized toolpaths that lower residual stress in every part.

Quality assurance is a top priority at HYCNC. We run thorough inspections through non-destructive testing and dimensional checks to confirm your parts meet the highest standards. This dedication to detail means you get reliable parts ready for demanding applications.

If you’re looking to minimize stress concentrations and boost your product’s durability, reach out to HYCNC. We’d be happy to review your designs and share how our expertise and technology can improve your next CNC machining project.

Frequently Asked Questions About Stress Concentrations

What is a stress concentration factor Kt

The stress concentration factor (Kt) measures how much stress increases around a geometric change like a notch or hole. It shows how much higher the stress is compared to the normal stress on a part. Knowing Kt helps predict where parts might fail.

How do stress concentrations affect fatigue life

Stress concentrations create weak spots where cracks can start. These areas take more repeated stress, which leads to fatigue failure sooner. This shortens the part’s lifespan and can cause unexpected breakdowns.

Can CNC machining eliminate stress concentrations entirely

No machining process can remove stress concentrations completely, but good CNC machining can greatly reduce them. Precision cutting, smooth finishes, and proper toolpaths help lower stress risers and minimize risks.

How does HYCNC ensure low stress concentrations in machined parts

At HYCNC, we use advanced CNC technology combined with finite element analysis (FEA) to design and machine parts with minimal stress concentration. We optimize toolpaths and apply post-processing like polishing or heat treatment to reduce residual stresses, ensuring stronger, longer-lasting parts.