What is Precision CNC Milling

Precision CNC milling is a subtractive manufacturing process where computer-controlled machines remove material from a solid block to create detailed parts. Unlike additive methods, CNC milling cuts away excess material using rotating cutting tools, making it ideal for achieving exact shapes and dimensions.

Precision is crucial in CNC milling because it determines how closely the finished part matches the design specifications. Tight tolerances—often down to microns—ensure parts fit perfectly and function reliably in their applications. Without precision, components can fail or cause costly production delays.

Industries that depend heavily on precision CNC milling include aerospace, medical, automotive, and electronics. These sectors require high-precision machining parts that deliver consistent quality for critical applications like turbine blades, surgical instruments, engine components, and connector housings. Precision CNC milling makes it possible to meet these demanding standards efficiently.

Core Components of a CNC Milling Machine

At the center of every precision CNC milling machine is the spindle. It spins the cutting tools at high speeds, making sure the material is cut smoothly and accurately. Without a reliable spindle, achieving tight tolerances is tough.

Next up is the tool changer. This part keeps things moving by automatically switching tools during multi-step jobs. It saves time and keeps your project on track without manual intervention.

The worktable and fixtures play a crucial role by holding your workpiece firmly in place. Stability here is key to maintaining precision and avoiding any unwanted movement while cutting.

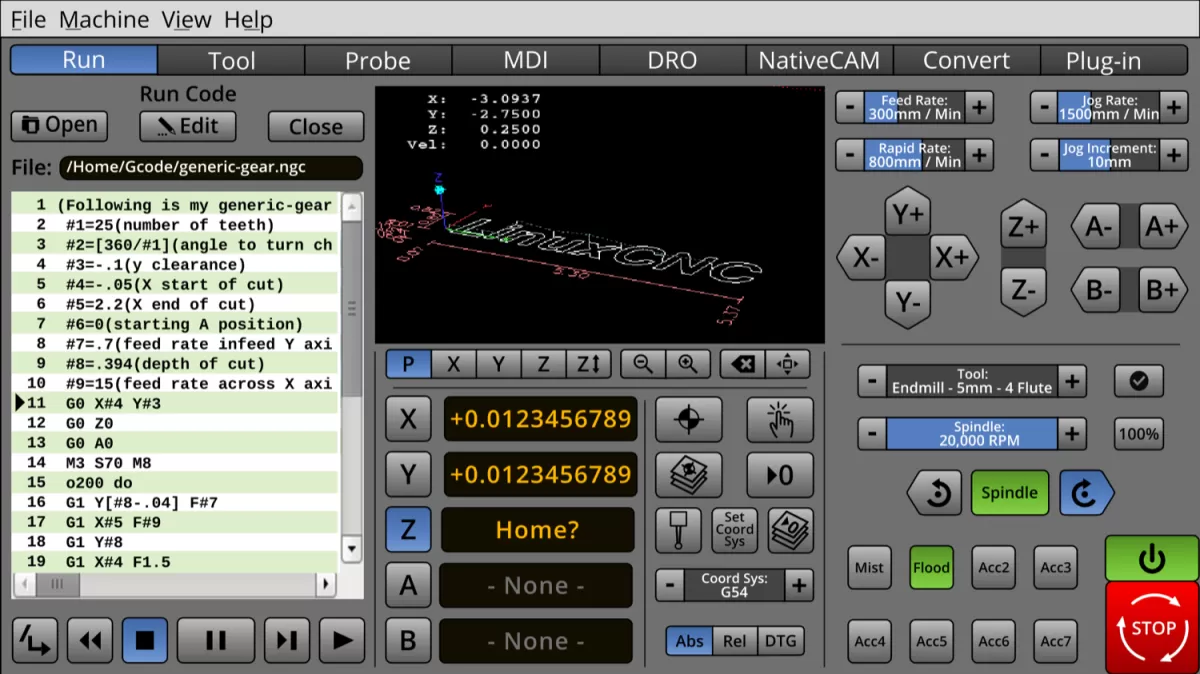

The CNC controller is the brain of the operation. It reads and executes the G-code, controlling the toolpaths with exact detail so every cut is where it’s supposed to be.

Finally, the number of axes your machine has—whether 3, 4, or 5—matters. More axes mean the ability to create complex shapes and detailed components. Multi-axis CNC milling opens doors to intricate designs across various industries.

Together, these components make precision machining parts possible with consistent quality and efficiency.

Types of Cutting Tools in Precision CNC Milling

Precision CNC milling relies heavily on the right cutting tools to deliver tight tolerances and quality finishes. The most common types include end mills, face mills, and drill bits. End mills are versatile and used for detailed features, slotting, and contouring. Face mills handle larger surface areas, making them ideal for smoothing and flattening. Drill bits are essential for creating holes with precision accuracy.

Choosing the right tool material and coatings is just as important. Tools made from carbide, HSS (High-Speed Steel), or coated with TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) offer longer life and better wear resistance. These materials maintain sharpness and improve cutting performance, which is key for precision machining parts.

Tool selection should also match the material you’re working with—whether it’s aluminum, stainless steel, titanium, or plastics. The right tool keeps wear low and ensures you hit those tight tolerances every time. Proper tool choice helps prevent defects and maintains consistency across parts, which is critical in industries demanding high precision CNC milling.

Programming for Precision CNC Milling

Programming plays a crucial role in precision CNC milling. CAD/CAM software is where it all starts—designers create detailed digital models and generate exact toolpaths. These toolpaths guide the cutting tools along precise routes, helping achieve tight tolerances and complex shapes.

Once the paths are set, the program converts to G-code or NC code, which tells the CNC milling machine how to move, at what speed, and when to cut. This code ensures every motion happens exactly as planned, reducing human error.

To get the best results, optimizing programming is key. This means carefully planning toolpaths to avoid collisions, reduce machining time, and keep the process consistent. Testing and refining programs help maintain repeatability, so each part matches the last with high precision.

For more on designing parts that work well with CNC milling, check out our guide on CNC milling part design.

Materials Used in Precision CNC Milling

When it comes to precision CNC milling, the choice of materials plays a big role in the final outcome. Common materials include aluminum, stainless steel, titanium, and various plastics. Each material brings its own challenges and benefits.

- Aluminum is lightweight and easy to machine, making it popular for high precision parts with tight tolerances.

- Stainless steel offers strength and corrosion resistance but can cause more tool wear.

- Titanium is strong and lightweight but requires careful handling due to its toughness.

- Plastics are used when weight and insulation matter, but surface finish needs extra attention.

The material you pick affects everything—from how long your cutting tools last, to the precision you can achieve, and the smoothness of the surface finish. Over the years, we’ve built strong expertise working with a wide range of materials across industries like aerospace, medical, and automotive to deliver consistent, high-quality results.

Achieving Tight Tolerances and High Quality Finishes

In precision CNC milling, tight tolerances mean the final parts meet exact size and shape requirements with minimal variation. This accuracy is crucial for parts that need to fit perfectly or perform reliably in demanding environments. Even a slight deviation can cause issues in assembly or function, so controlling tolerances is non-negotiable.

To reach these tight tolerances and superior surface finishes, techniques like micro-milling come into play. Micro-milling uses extremely small cutting tools to produce sub-micron surface finishes, giving parts a smooth and precise texture that traditional methods can’t match.

Consistency is just as important as precision. That’s where process control methods like Statistical Process Control (SPC) and Internet of Things (IoT) monitoring help. These systems track the milling process in real time, catching any variations early and ensuring each part meets quality standards. By combining advanced techniques and smart monitoring, high precision CNC milling delivers parts that meet the tightest specs and highest finish quality demanded by industries today.

Applications of Precision CNC Milling Components

Precision CNC milling components play a vital role across several major industries in the U.S., where accuracy and reliability are critical.

-

Aerospace: Components like turbine blades and structural brackets demand tight tolerances and durable materials. Precision machining ensures these parts perform safely at high speeds and temperatures.

-

Medical: Surgical tools and implants require biocompatible finishes and exact dimensions. CNC milling provides the high precision needed for reliable, safe medical devices.

-

Automotive: Engine parts and transmission components rely on CNC machining for consistent quality. This helps improve performance and extend the life of vehicles.

-

Electronics: Connector housings and PCB components require fine details and smooth finishes. Precision CNC milling meets these needs, supporting the manufacture of reliable electronic devices.

By focusing on precision and quality, CNC milling components help U.S. manufacturers deliver parts that meet strict industry standards and customer expectations.

Benefits of Partnering with HYCNC for CNC Milling Services

When you choose HYCNC for your precision CNC milling needs, you get access to advanced 3, 4, and 5-axis machining capabilities. This means we can handle complex geometries and tight tolerances with ease, delivering parts that meet your exact specifications every time.

We’re proud to hold ISO 9001:2015 certification, which guarantees a consistent level of quality assurance. This certification reflects our commitment to producing reliable, high precision CNC milling components that you can trust in critical applications.

Whether you need prototypes or mass production runs, HYCNC offers custom solutions tailored to your project’s scale and requirements. We understand each job is unique and adapt our processes to ensure efficiency and accuracy.

Plus, we know timing matters. That’s why we provide fast quotes and reliable global delivery, helping you keep your production schedules on track without sacrificing quality.

Partnering with HYCNC means working with a CNC service provider focused on precision manufacturing techniques and customer satisfaction. Learn more about our precision machining services to see how we can support your next project.

Tips for Optimizing Your CNC Milling Projects

To get the most out of your precision CNC milling projects, focus on a few key areas:

-

Material Selection: Choose the right material for your part’s function. Consider factors like strength, machinability, and surface finish. Picking the right material upfront helps keep tight tolerances and reduces tool wear.

-

Toolpath Planning: Use CAD CAM programming to create efficient, accurate toolpaths. Good planning minimizes unnecessary tool movements and avoids collisions, which improves surface quality and cuts cycle time.

-

Regular Calibration and Maintenance: Keep your CNC milling machine parts in top shape. Regularly calibrate spindles, axes, and tool changers. Routine maintenance avoids unexpected downtime and maintains precision over time.

-

Work With Experienced CNC Service Providers: Partnering with trusted CNC machining professionals like HYCNC helps ensure your designs translate perfectly into high-quality parts. They bring expertise, advanced multi axis CNC milling, and quality control to your projects.

Following these tips helps you save time, lower costs, and achieve the high precision CNC milling results your projects demand.

The Future of Precision CNC Milling

The future of precision CNC milling is shaping up fast with smart tech leading the way. AI-driven analytics are helping operators spot patterns and fix issues before they become problems. IoT integration means machines stay connected, giving real-time data on performance and maintenance needs. These advances tie right into Industry 4.0, where automation and data exchange make manufacturing smoother and more efficient.

At HYCNC, we’re all in on these innovations. We invest heavily in ongoing research and development to bring the latest tech to our CNC machining services. Whether it’s upgrading to smarter multi-axis CNC milling machines or using advanced CAD CAM programming tools, our focus remains on delivering precision machining parts that meet the evolving needs of U.S. manufacturers. This commitment helps us offer fast, reliable, and high-quality solutions for all your CNC milling components.