Why Deburring Affects Sheet Metal Appearance

Burrs and sharp edges leftover from cutting or punching sheet metal can seriously affect how a part looks. These small imperfections catch light unevenly, creating rough or jagged surfaces that make the metal appear unfinished or low quality. Beyond looks, burrs can interfere with paint, powder coating, or plating by preventing smooth adhesion, which leads to peeling or uneven finishes.

Removing burrs improves safety by eliminating sharp edges that can cause injury during handling or assembly. Clean, deburred surfaces also help coatings stick better, extending the life of protective finishes. This is critical in industries like aerospace, automotive, and electronics, where both appearance and performance matter.

In these fields, a smooth, uniform finish isn’t just about looks — it reflects quality, precision, and reliability. Deburring ensures sheet metal parts meet both aesthetic standards and functional requirements, making them safer and more durable in demanding environments.

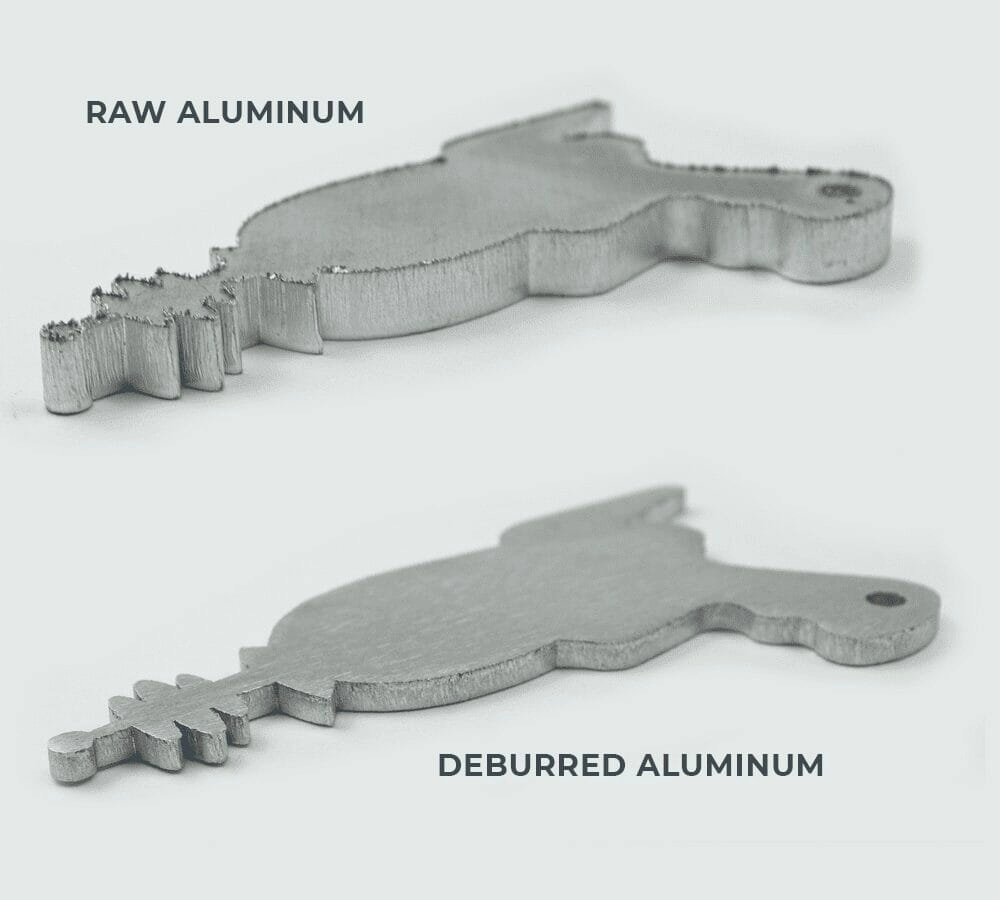

Comparing Deburred vs Unfinished Sheet Metal Parts

Aluminum

Unfinished aluminum often shows rough edges, sharp burrs, and uneven surfaces that dull its natural shine. These imperfections can cause scratches or injuries and reduce the effectiveness of any coatings applied later. On the other hand, deburred aluminum has smooth edges and a clean finish that improves both safety and appearance. This makes it ideal for applications in automotive parts, consumer electronics, and lightweight aerospace components where look and function matter.

Stainless Steel

Unfinished stainless steel parts typically display visible burrs, rough spots, and often laser burn marks from cutting processes. These flaws not only undermine the metal’s sleek look but can also trap dirt and cause corrosion over time. When deburred, stainless steel gains a polished, consistent surface that enhances both its corrosion resistance and visual appeal. Deburred stainless steel is widely used in medical equipment, kitchen appliances, and architectural projects where a clean, professional finish is critical.

Brass and Copper

Brass and copper parts left unfinished tend to develop tarnish, oxidation, and discoloration quickly. Sharp edges are common, which can be unsafe and affect metal surface finishing quality. Deburring these metals removes burrs and smooths the surface, making them ready for protective coatings that prevent oxidation. This gives brass and copper components a brighter, more uniform appearance suitable for decorative hardware, musical instruments, and electrical connectors.

Titanium

Unfinished titanium parts often look dull with noticeable burn marks from machining, which masks the metal’s natural strength and beauty. After deburring, titanium features a sleek brushed look with clean edges that highlight its premium quality. This refined finish is preferred in high-end industries like aerospace, medical implants, and luxury sports equipment, where both aesthetics and durability matter.

Deburring Methods and Their Impact on Appearance

Manual Deburring

Using handheld tools like files and scrapers gives you precise control, especially for complex or detailed sheet metal parts. This method is great for small runs or delicate jobs but can leave slight inconsistencies in the surface finish. It’s less ideal for high-volume work since it’s time-consuming and depends heavily on the operator’s skill.

Mechanical Deburring Linear

Mechanical methods like belt sanders and Timesavers machines work well on flat sheet metal surfaces. They deliver a consistent, smooth, and brushed finish, making them perfect for larger production runs. This method speeds up the process and ensures uniform appearance across many parts, which helps maintain quality standards in industries demanding repeatability.

Tumbling

Vibratory or centrifugal tumbling is used mostly for small parts with lots of edges. It rounds out burrs and smooths corners but tends to give a duller finish compared to linear methods. This process is ideal when a less shiny, safer edge is preferred, though it may not meet high aesthetic demands on its own.

Wet vs Dry Deburring

- Wet Deburring uses liquids to clean and cool the parts during the process, cutting down on corrosion and helping achieve a cleaner finish. It’s best for metals prone to rust or discoloration.

- Dry Deburring is faster and often more cost-effective since there’s no liquid handling or drying time involved. However, it carries a higher risk of surface oxidation and may require extra finishing steps depending on the material.

Choosing between wet and dry deburring depends on your priorities—whether you want speed and savings or cleaner, corrosion-resistant surfaces.

Choosing the Right Deburring Process for Your Project

Picking the best sheet metal deburring process depends on a few key factors:

- Material type: Different metals like aluminum, stainless steel, or titanium respond better to certain deburring methods. For example, softer metals may work well with tumbling, while harder metals might need mechanical or CNC deburring.

- Part size and shape: Small, complex parts often require precise manual or CNC deburring for tight tolerances. Larger, flat pieces can be handled efficiently with linear mechanical methods like belt sanding.

- Production volume: High-volume runs benefit from automated options like tumbling or mechanical deburring, while prototyping or low-volume orders usually rely on manual or CNC deburring for better control.

To get the right balance between how your parts look and how they function:

- Customize your deburring process based on the final use. If aesthetics are crucial, choose methods that provide a smooth, consistent finish.

- For parts needing better coating adhesion or tighter tolerances, opt for deburring that reduces surface flaws without adding roughness.

When specifying deburring in your design files, keep these tips in mind:

- Clearly mark edges that need deburring.

- Define the desired finish level or surface roughness.

- Include notes on whether sharp edges must be fully removed or softened.

- Communicate any special requirements for coating compatibility or safety standards.

This approach helps ensure you get sheet metal parts that not only look great but also perform reliably in your applications.

Visual and Functional Benefits of Deburring with HYCNC

At HYCNC, we understand how important a clean, smooth finish is for your sheet metal parts. Our deburring process enhances the overall look, giving parts a polished, professional appearance that meets high aesthetic standards.

Beyond looks, deburring with HYCNC improves part functionality. Removing burrs makes coatings stick better and helps achieve tighter tolerances, which means parts fit and perform as designed without unexpected issues. This also boosts durability and resistance against corrosion.

Safety is another big factor. Sharp edges and leftover burrs can cause injuries during handling or assembly. Our precision CNC deburring eliminates these hazards, creating safer working conditions and reducing risks.

For example, we worked with an automotive client who needed deburred metal components for engine assemblies. Our process not only delivered the smooth finish and exact dimensions required but also improved coating adhesion, extending the part’s lifespan and reliability under tough conditions.

Choosing HYCNC for deburring means getting top-quality metal surface finishing that balances aesthetics, function, and safety. It’s a smart step for any project focused on precision and dependable results.

Common Applications of Deburred Sheet Metal Parts

Deburred sheet metal parts play an important role across many industries. Here’s where you’ll often find the best results from precise sheet metal deburring:

-

Aerospace: Safety and reliability are critical here. Clean, burr-free finishes prevent issues like part failure and help ensure smooth assembly. The smooth surface also supports better coating adhesion and inspection.

-

Automotive: Deburred metal components offer durability and an attractive look. Removing sharp edges improves safety, while a smoother surface helps with paint and finish quality on visible parts.

-

Electronics: Smooth, burr-free enclosures and connectors are essential for protecting sensitive components and providing a clean, professional appearance. It also reduces wear and potential short circuits caused by sharp burrs.

-

Medical: Devices and instruments need to be hygienic and safe. Burr removal helps eliminate places where bacteria can hide and reduces the risk of injury during use or handling. A clean, smooth finish is vital for medical applications.

In all these industries, deburring boosts both the appearance and function of sheet metal parts, making it a standard step in quality metal surface finishing.

How HYCNC Ensures Superior Deburring Results

At HYCNC, we use advanced CNC deburring technology to deliver clean, precise sheet metal deburring every time. Our state-of-the-art machines remove burrs efficiently while maintaining tight tolerances and consistent surface finishes, improving both the appearance and function of your parts.

We’re focused on quality and precision. Every project undergoes thorough inspection to make sure it meets your exact specifications. Our team works closely with you to ensure customer satisfaction, whether you’re in aerospace, automotive, electronics, or any other industry needing reliable metal surface finishing.

Ready to improve your sheet metal part quality? Contact HYCNC today for a quote or consultation. We’re here to help you get the best deburring results that match your project’s needs and budget.