Sheet Metal Dimple Forming: Your Guide to Stronger, Lighter Parts with HYCNC

Struggling to create lightweight, durable sheet metal parts that stand out? Sheet metal dimple forming is the secret to boosting strength, cutting weight, and adding a sleek look to your projects. As a fabrication expert, I’ve seen how the right dimpling process can transform components for industries like automotive, aerospace, and electronics.

In this guide, you’ll discover proven techniques, essential design guidelines, and how HYCNC’s CNC dimple forming delivers precision results every time. Ready to elevate your fabrication game? Let’s dive in!

What is Sheet Metal Dimple Forming

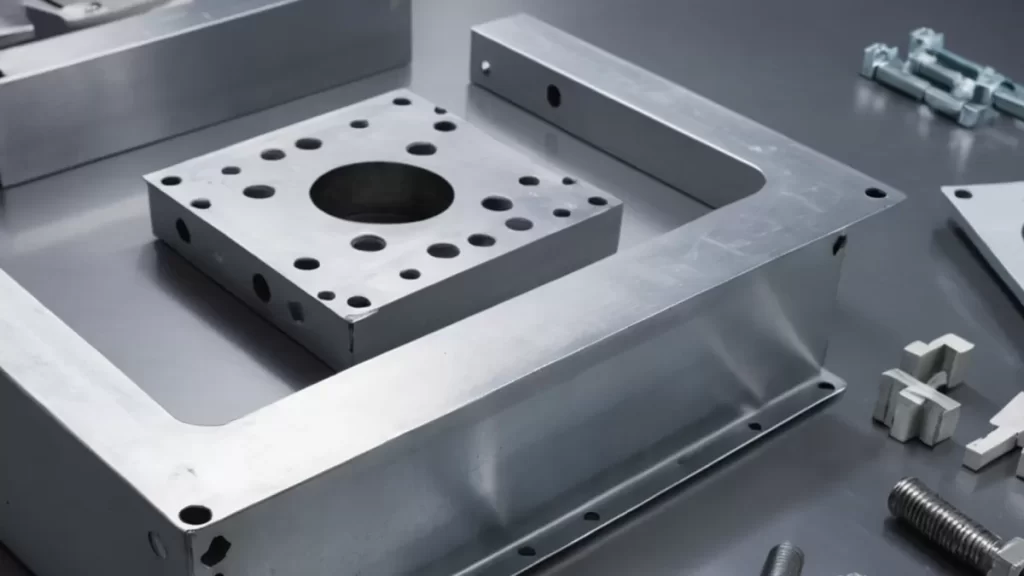

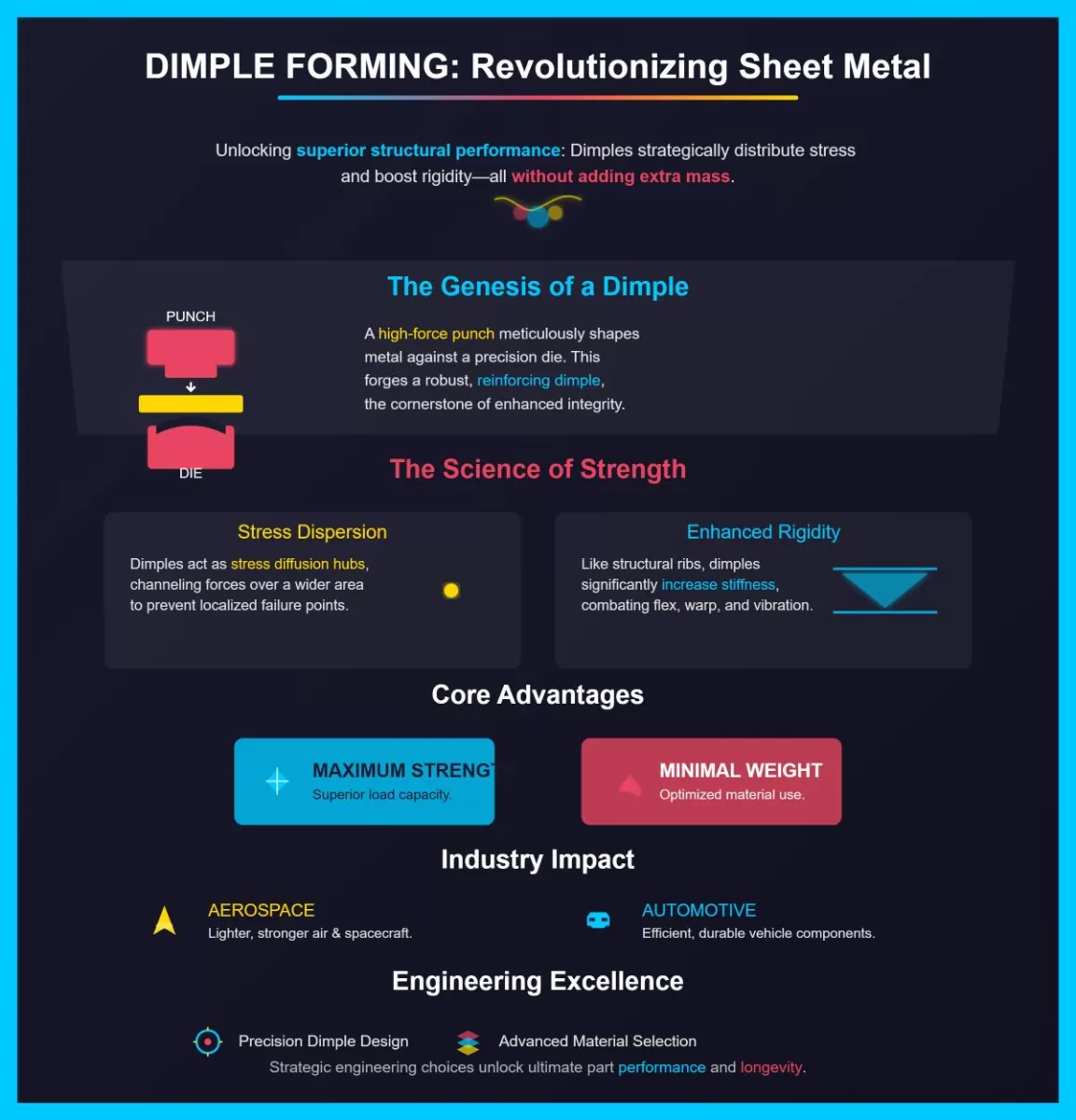

Sheet metal dimple forming is a manufacturing process that creates small, shallow indentations or dimples on flat metal sheets. These dimples add strength and rigidity to the sheet without adding extra weight, making the metal more durable and structurally sound. The process works by pressing the sheet metal into a die that shapes the dimples through controlled deformation.

Common materials used in dimple forming include aluminum, stainless steel, and mild steel. These metals are chosen for their balance of strength, formability, and weight. Aluminum is popular in aerospace and automotive for its lightweight properties, while stainless steel offers corrosion resistance and durability.

The origins of dimple forming stem from early metal strengthening techniques that aimed at improving structural performance without thickening sheets. Over time, the method has evolved, especially with the rise of CNC machining technology, allowing more precise and consistent dimples for complex designs.

Dimple forming is now a key process in precision sheet metal fabrication, widely used across industries seeking strong yet lightweight components.

Benefits of Dimple Forming in Sheet Metal Fabrication

Dimple forming offers several advantages that make it popular in sheet metal fabrication. Here’s why it’s a go-to technique:

Improved strength-to-weight ratio

Dimples create small indentations that increase the metal’s stiffness without adding extra material. This means you get stronger parts without the added weight, which is crucial for applications where every pound counts.

Increased rigidity

By introducing controlled shapes into the sheet metal, dimple forming reduces flex and bending. This added rigidity helps parts maintain their shape under stress, improving overall durability.

Aesthetic enhancements

Dimples add a textured pattern that can improve the look of sheet metal parts. Whether for industrial equipment or consumer products, this subtle detail enhances visual appeal while serving a functional purpose.

Weight savings

Because dimpling strengthens metal without thickening it, manufacturers can use thinner sheets and still meet strength requirements. This saves material costs and reduces the overall weight of the finished product.

Versatility across industries

You’ll find dimpled sheet metal in everything from automotive panels and aerospace components to electronics enclosures and medical devices. Its ability to boost strength without bulk makes it valuable in many sectors.

By combining these benefits, dimple forming remains a smart, efficient option for precision sheet metal forming that meets modern design and manufacturing demands. For those looking to explore more about sheet metal fabrication techniques, check out our guide on sheet metal manufacturing.

Dimple Forming Techniques and Tools

Dimple forming in sheet metal usually follows a simple process: drill, align, and press. First, a hole or pilot mark is drilled where the dimple will go. Then, the sheet metal is aligned with the dimple die, and pressure is applied to form the dimple shape without cutting through the material.

There are several types of dimple dies to choose from depending on your design needs:

- Circular – the most common shape, offering uniform strength

- Oval – used when elongated strength or aesthetic is needed

- Square – adds rigidity with its angular shape

- Triangular – less common but good for specific strength patterns

The tools for dimple forming include dimple die sets, punch and flare tools, and CNC machines. Manual methods rely on hand presses with die sets or punch and flare tools, which work well for smaller jobs or prototypes. Automated approaches use CNC dimple forming for precise, repeatable results on larger production runs.

Manual vs Automated Methods

| Aspect | Manual | Automated (CNC) |

|---|---|---|

| Precision | Moderate, depends on operator skill | High precision and repeatability |

| Production Speed | Slower, better for low volume | Faster, ideal for high volume |

| Cost Efficiency | Lower upfront cost, higher per part | Higher upfront investment, lowers cost per unit |

| Complexity | Limited by manual setup | Capable of complex patterns and tight tolerances |

Using CNC dimple forming tools not only improves accuracy but also reduces the chance of tooling marks and material defects, especially on lightweight metal components where consistency matters a lot.

For more details about sheet metal fabrication and design tips, check out our guide on sheet metal fabrication process materials applications and explore our dimple forming services to see what we offer.

Design Guidelines for Effective Dimple Forming

When it comes to sheet metal dimple forming, good design is key to getting strong, precise results without costly mistakes. Here are some straightforward guidelines that work well, especially if you’re aiming for high-quality parts like those made with HYCNC’s CNC precision technology.

Material Selection Recommendations

- Choose materials that respond well to dimple forming like aluminum, stainless steel, or mild steel. These metals have the right ductility to form clean dimples without cracking.

- Thicker sheets hold dimples better but may require more force. Thin sheets need careful handling to avoid deformation.

Dimple Placement to Avoid Stress Concentration

- Space dimples evenly and keep them away from sharp corners or holes, which are natural stress points.

- Avoid placing dimples too close to edges or each other to prevent weakening the metal or causing cracks under pressure.

Methods to Prevent Bowing

- Add bent flanges or stiffening ribs around the dimpled area. This helps keep the metal flat and controls any distortion caused by forming.

- Proper clamping and support during forming also reduce the chance of bowing.

Use of CAD and Simulation Software

- Use CAD and simulation tools to model your design before production. These tools predict metal flow and stress points, helping optimize dimple size, shape, and placement.

- Simulation helps avoid trial-and-error on the shop floor, saving time and materials.

HYCNC’s CNC Precision Approach

- At HYCNC, we use CNC machines that provide exact control over dimple forming, ensuring consistent depth, shape, and location across parts.

- CNC allows for complex patterns and tight tolerances, which manual methods can’t reliably deliver.

- This precision supports both prototype and large-volume runs while keeping quality high and turnaround quick.

For more on precision sheet metal forming and related services, visit our sheet metal fabrication page.

Applications of Dimple Forming Across Industries

Dimple forming is widely used across industries where strength, weight savings, and durability matter. In automotive manufacturing, it helps create lightweight panels and mounts that improve fuel efficiency without sacrificing strength. Aerospace relies on dimpled sheet metal for components that need to be strong yet aerodynamic, reducing drag while maintaining rigidity.

In electronics, dimple forming improves the strength and looks of enclosures, protecting sensitive parts with a sleek finish. Medical devices benefit from dimpling too, as it makes components more durable and easier to handle, adding portability without extra bulk.

A great example of HYCNC’s expertise is our involvement in a robotics competition. We delivered precision dimpled parts that boosted the robot’s structure and helped the team achieve top performance. This shows how effective CNC dimple forming can be in high-stakes, cutting-edge projects.

Why Choose HYCNC for Sheet Metal Dimple Forming

At HYCNC, we use precision CNC technology to deliver consistent, high-quality sheet metal dimple forming every time. Our CNC machines ensure tight tolerances and clean dimples that strengthen your parts without adding extra weight.

We offer transparent pricing with no minimum order requirements, making it easy for local businesses and prototyping projects to get exactly what they need without extra costs. Plus, our fast turnaround times and reliable shipping keep your projects on schedule.

HYCNC works with all common file formats, so your designs integrate smoothly with our CNC system—no headaches, just quick setups. And our customer support team is ready to help you optimize your dimple forming design for the best strength and appearance, making sure your parts perform exactly as planned.

Choose HYCNC for sheet metal dimple forming you can trust from start to finish.

Common Challenges and Solutions in Dimple Forming

Dimple forming in sheet metal can bring some challenges, but knowing how to handle them makes a big difference.

Material Bowing and Stress Issues

- Bowing happens when the metal bends or warps during forming.

- To prevent this, we recommend adding bent flanges or supports around the dimple areas.

- Using the right material thickness and proper dimple placement also cuts down on stress.

Deformation of Nearby Holes or Features

- Sometimes dimpling can distort holes or other nearby parts.

- To avoid this, keep enough distance between dimples and holes—usually at least two times the dimple diameter.

- Precision CNC dimple forming helps maintain tight tolerances and avoids unwanted deformation.

Tooling Marks on Parts and Finishing

- Tool marks from dimple die tools or punch and flare tools are common but can affect appearance.

- Using high-quality dies and controlling press force reduces marks.

- Finishing processes like light sanding or polishing clean up tooling marks for a smooth, professional look.

By addressing these issues with proper design and quality tools, we ensure your sheet metal parts are strong, accurate, and visually appealing.