Are you wondering whether CNC milling or CNC turning is the right choice for your next machining project? Choosing between these two processes can be tricky, but it’s a decision that can make or break your project’s success. At HYCNC, we’ve seen firsthand how the right machining method can boost efficiency, cut costs, and deliver precision parts that meet your exact needs. With years of expertise in CNC machining, we’re here to break down the differences between CNC mill and CNC turn in a way that’s clear and actionable. In this guide, you’ll uncover the key distinctions, practical applications, and

What Is CNC Milling

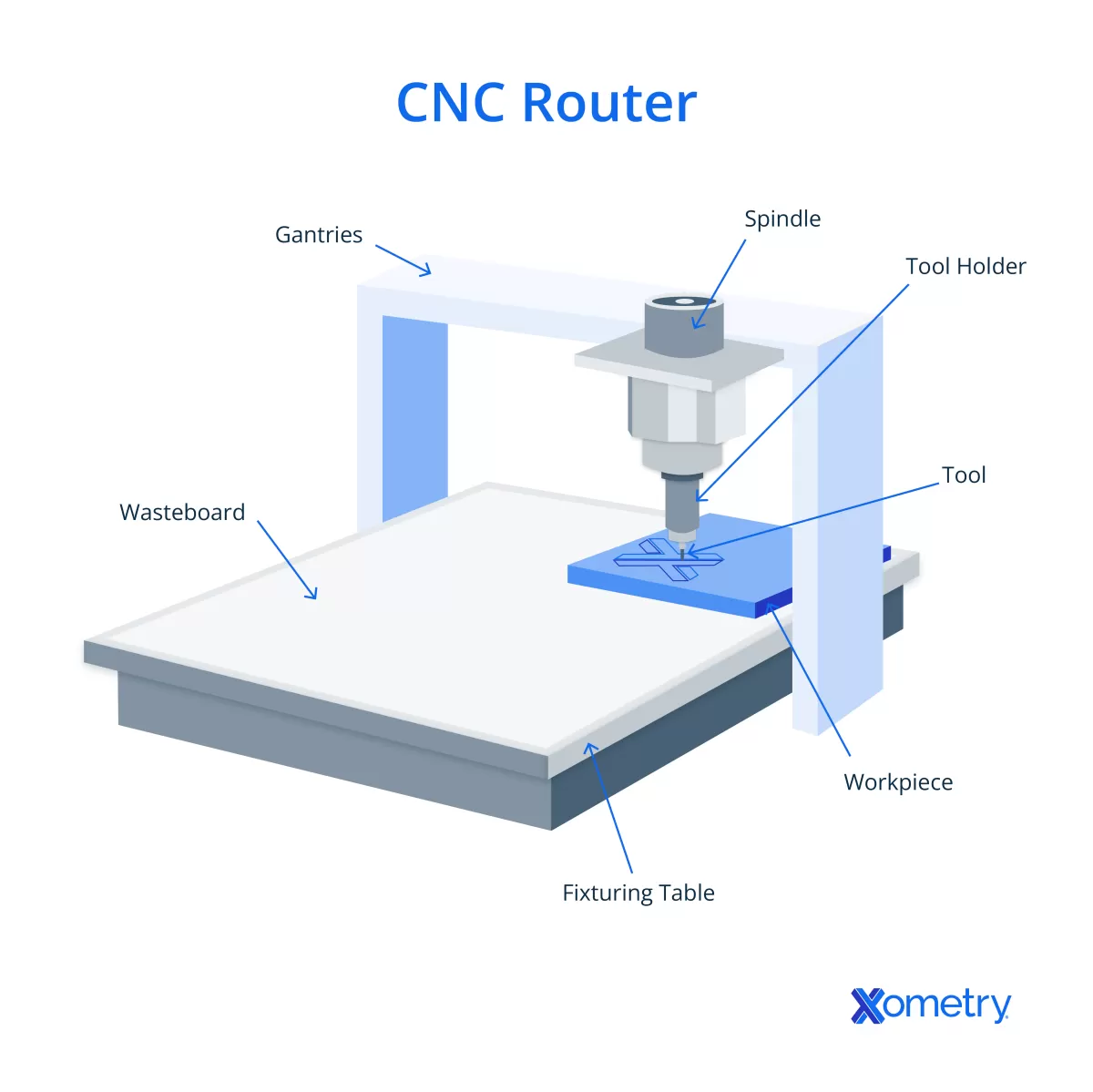

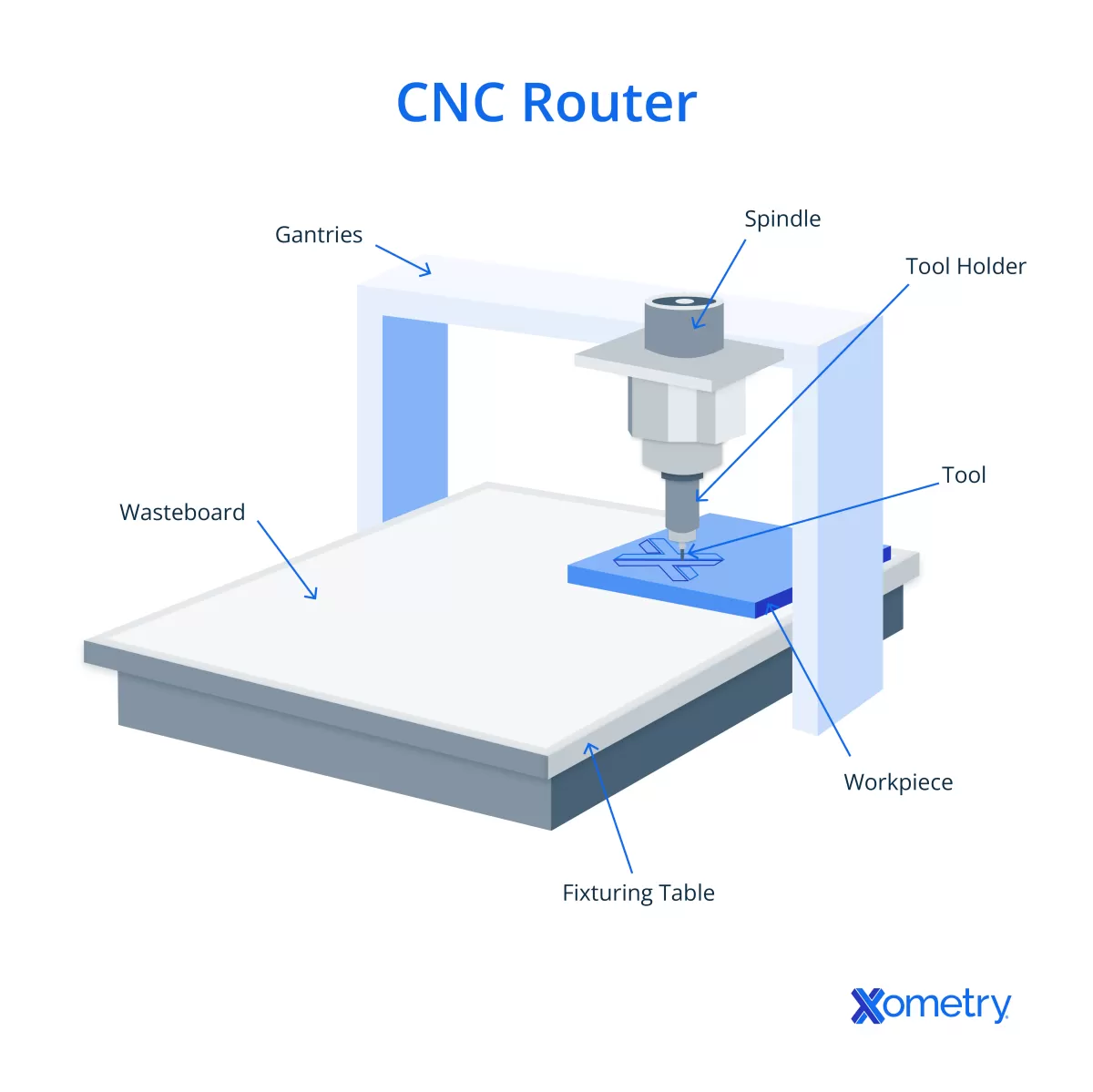

CNC milling is a subtractive manufacturing process where a rotating cutting tool removes material from a workpiece to create the desired shape. This process uses computer numerical control (CNC) to guide the machine with precision, allowing complex and detailed parts to be produced consistently.

Milling machines operate by moving the cutting tool along multiple axes (usually three to five), which lets them carve out intricate features such as slots, holes, and contours. The workpiece is typically held stationary on a table or fixture while the milling cutter spins at high speeds to cut away material.

Key features of CNC milling include:

- Precision machining with tight tolerances

- Ability to handle complex geometries

- Use of various cutting tools to shape parts

- Multi-axis movement for flexible designs

Common applications for CNC milling span across industries such as aerospace, automotive, medical devices, and custom manufacturing, where parts often require detailed surface finishes and complex shapes.

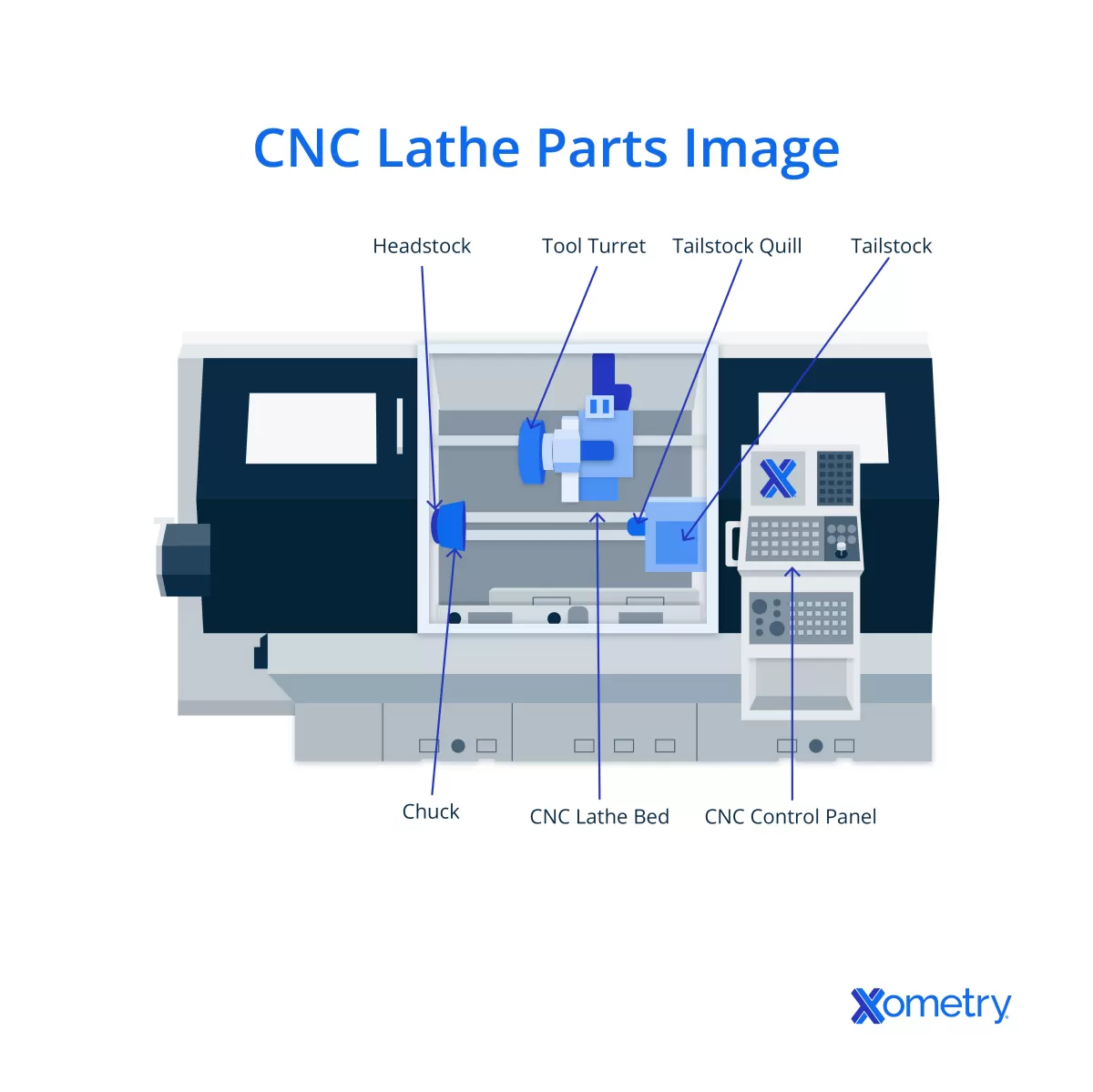

What Is CNC Turning

CNC turning is a subtractive manufacturing process where a cutting tool removes material from a rotating workpiece. Unlike milling, the workpiece spins on a CNC lathe, while the cutting tool moves along different axes to shape the part. This method is ideal for creating round or cylindrical shapes, like shafts, bushings, and pulleys.

Turning is known for its efficiency—once set up, it can produce consistent, high-quality parts quickly. It’s commonly used in industries like automotive, aerospace, and manufacturing for parts that require smooth finishes and tight tolerances. Whether you need small batches or large volumes, CNC turning offers a reliable solution for precision machining of cylindrical parts.

Key Differences Between CNC Milling and CNC Turning

Here’s a quick look at how CNC milling and CNC turning differ across key factors:

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Motion | Tool moves around a stationary part | Part rotates while the tool stays still |

| Geometry | Best for flat, complex shapes | Ideal for round, cylindrical parts |

| Tooling | Multiple cutting tools for various operations | Mainly uses cutting tools on a lathe |

| Applications | Complex components like gears, molds | Shafts, pins, bushings, and rods |

| Axes | Usually 3 to 5 axes for multi-directional cuts | Typically 2 to 3 axes moving around the axis of rotation |

| Materials | Handles metals, plastics, composites | Mostly metals but some plastics too |

| Speed | Slower due to complex tool paths | Faster for simple, repetitive cylindrical parts |

| Cost | Higher setup and operating costs | Generally lower due to simplicity and speed |

What This Means for Your Project

- If you need complex shapes with detailed features, CNC milling is usually the way to go.

- For cylindrical parts or pieces with a consistent circular shape, CNC turning is more efficient and cost-effective.

- Choosing the right process depends on part complexity, production volume, material, and budget.

Understanding these differences helps you pick the best CNC machining method for your manufacturing needs.

Advantages and Limitations of CNC Milling

CNC milling stands out for its precision and versatility. It’s great for creating complex designs with tight tolerances, thanks to its ability to operate on multiple axes. This makes it ideal for parts that require detailed cuts, pockets, or 3D shapes. Whether you’re working with metals, plastics, or composites, CNC milling handles a wide range of materials effectively.

However, there are some limitations. Milling can be slower compared to other CNC processes, especially for large-volume runs or simple shapes. The setup costs can also be higher because of tooling changes and programming complexity. This means it might not be the most cost-effective option for basic parts or very high volumes.

Example: A local automotive shop used CNC milling to produce custom engine components with complex cavities and fine features. The precision milling process ensured each part met exact specs but required careful programming and setup, which increased upfront costs. Despite that, the quality and versatility made it worth the investment for their specialized needs.

Advantages and Limitations of CNC Turning

CNC turning offers several strong advantages that make it a favorite for many precision machining projects:

Advantages

Efficiency: Turning is fast when working on cylindrical parts since the workpiece spins while the cutting tool moves, speeding up production.

Surface Finish: It provides excellent surface finishes, especially on round shapes, reducing the need for extra polishing.

Cost-Effectiveness: Lower tooling costs and quicker setups typically mean CNC turning is more budget-friendly for high-volume runs of simple shapes.

Limitations

Shape Restrictions: Turning mainly works on round or tubular parts, so it struggles with flat surfaces or complex geometries that milling can handle easily.

Limited Versatility: For parts needing intricate features or multi-directional cuts, turning alone often won’t cut it.

Real-World Example

A great example is the production of automotive shafts. CNC turning machines efficiently shape the shaft’s cylindrical form with tight tolerances and smooth finishes, keeping costs low and output high. However, if the shaft requires flat sections or complex pockets, that’s when milling or a hybrid process usually steps in.

When to Choose CNC Milling vs CNC Turning

Choosing between CNC milling and CNC turning mostly depends on the part you need and your project requirements. Here’s a quick guide:

Best use cases for CNC milling

- Complex parts with detailed shapes and multiple features

- Components requiring flat surfaces, slots, or holes at various angles

- Prototypes or low to medium production volumes needing versatility

Best use cases for CNC turning

- Cylindrical parts like shafts, pins, or bushings

- High-volume production where speed and surface finish matter

- Simple round shapes with fewer complex contours

Mill-turn hybrid machines combine both milling and turning in one setup. These are great if your part needs both round features and complex details, cutting down on handling time and improving precision.

Decision factors to consider

- Part geometry: Is it round or complex?

- Material type: Harder materials can affect machine choice and tooling

- Production volume: Higher volumes might favor turning for efficiency

- Budget: Milling setups can be pricier upfront but offer more flexibility

- Tolerances: Tight tolerances sometimes require more precise milling or hybrid processes

By figuring out what your part looks like and what you need, you can pick the right CNC machining process to get the job done efficiently and within budget.

How HYCNC Can Help with Your CNC Machining Needs

At HYCNC, we bring years of expertise in precision CNC machining to help you get the job done right. Whether you need CNC milling, CNC turning, or a combination of both, our advanced equipment handles everything from simple parts to complex geometries with high accuracy.

We work with a wide range of materials including metals, plastics, and composites, offering versatile manufacturing solutions customized to your project’s requirements. Our team focuses on delivering fast turnaround times without sacrificing quality, making us a reliable partner for both low and high-volume production.

If you’re looking for expert advice or a custom machining solution, get in touch with us today. Request a quote or consultation and see how HYCNC can streamline your manufacturing process with the right CNC services tailored for the US market.

FAQs about CNC Mill vs CNC Turn

What’s the difference between CNC milling and CNC turning?

CNC milling uses rotating cutting tools to remove material from a stationary workpiece, good for complex shapes and multi-axis machining. CNC turning spins the workpiece on a lathe, cutting away material to create cylindrical parts. Milling handles more complex geometries, while turning is faster for round parts.

Which process is faster for cylindrical parts?

CNC turning is generally faster for cylindrical parts because the workpiece spins on the lathe, allowing quick, efficient cutting. Milling can do cylinders but usually takes more time and effort.

Can milling and turning be combined?

Yes, some jobs require both. Mill-turn machines combine the two processes into one setup, saving time and improving precision for complicated parts with both cylindrical and flat features.

What materials are suitable for CNC milling and turning?

Both processes work well with metals like aluminum, steel, brass, and plastics. Choosing milling or turning depends more on part shape and tolerances than material alone.

How do I know which CNC process to choose?

Consider your part’s shape, volume, budget, and precision needs. Choose milling for complex, detailed parts and turning for simple round shapes or high-volume cylindrical parts. If unsure, experts like HYCNC can help you pick the best option.

Why choose HYCNC for CNC machining services?

At HYCNC, we offer expert CNC milling and turning services using advanced multi-axis machines. We work with a wide range of materials, delivering custom solutions tailored to your needs, whether it’s precision, cost-efficiency, or speed. Contact us for a quote or consultation to see how we can bring your projects to life.