You might be wondering how 3D printing for automotive applications can transform your manufacturing process…

But what exactly does it offer, and how can it drive innovation?

As experts in precision manufacturing, we at HYCNC have seen additive manufacturing revolutionize the automotive industry, from rapid prototyping to lightweight car parts. In this guide, we’ll uncover the power of 3D printing, explore its game-changing applications, and show how HYCNC’s expertise in CNC and 3D printing delivers unmatched results.

Ready to accelerate your production? Let’s dive in!

What is 3D Printing in Automotive Applications

3D printing in automotive applications refers to the use of additive manufacturing technologies to create car parts, prototypes, and tooling by building layers of material based on digital designs. Unlike traditional subtractive methods like CNC machining, 3D printing adds material only where needed, enabling more complex shapes and faster production times.

Key 3D printing technologies used in the automotive sector include:

- Selective Laser Melting (SLM): This method fuses metal powders layer by layer with a laser, ideal for strong, lightweight metal parts.

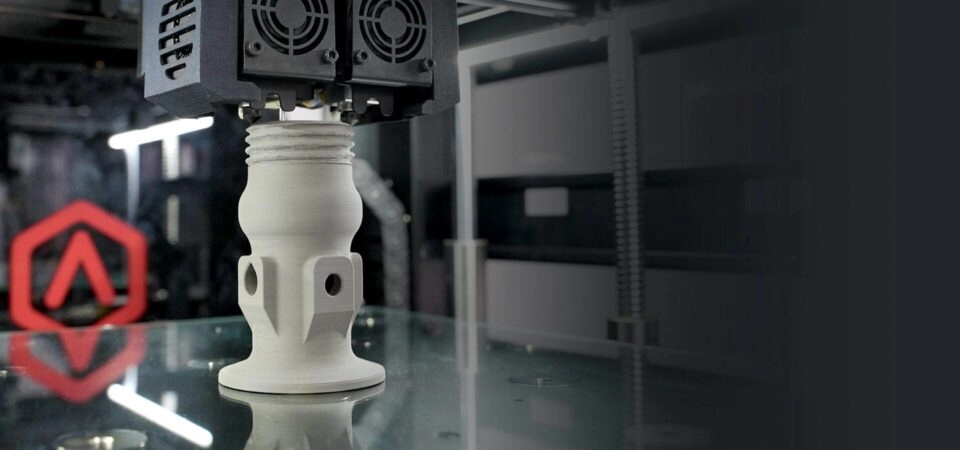

- Fused Deposition Modeling (FDM): FDM extrudes thermoplastic filaments to build parts, commonly used for rapid prototyping and functional plastic components.

- PolyJet: This technology jets layers of photopolymer resin to produce detailed multi-material and multi-color parts, perfect for realistic prototypes.

Compared to traditional CNC machining, 3D printing offers:

- Greater design flexibility to create intricate geometries that are difficult or impossible to machine.

- Reduced material waste since it deposits material precisely rather than cutting away excess.

- Faster iteration cycles for prototyping, allowing automotive engineers to test and refine designs quickly.

However, CNC machining still excels in producing parts with tight tolerances and finishes on large production runs. Combining both technologies often delivers the best balance of speed, cost, and quality for automotive manufacturing.

For a deeper look at CNC versus 3D printing in automotive prototyping and small-batch production, explore our detailed comparison here.

Key Applications of 3D Printing in Automotive

3D printing is making a real impact in several key areas of the automotive industry. Here’s where it shines:

-

Prototyping Complex Multi-Material Parts

Rapid prototyping lets engineers test designs that combine different materials in ways traditional methods struggle with. It speeds up product development and cuts costs by creating accurate models fast.

-

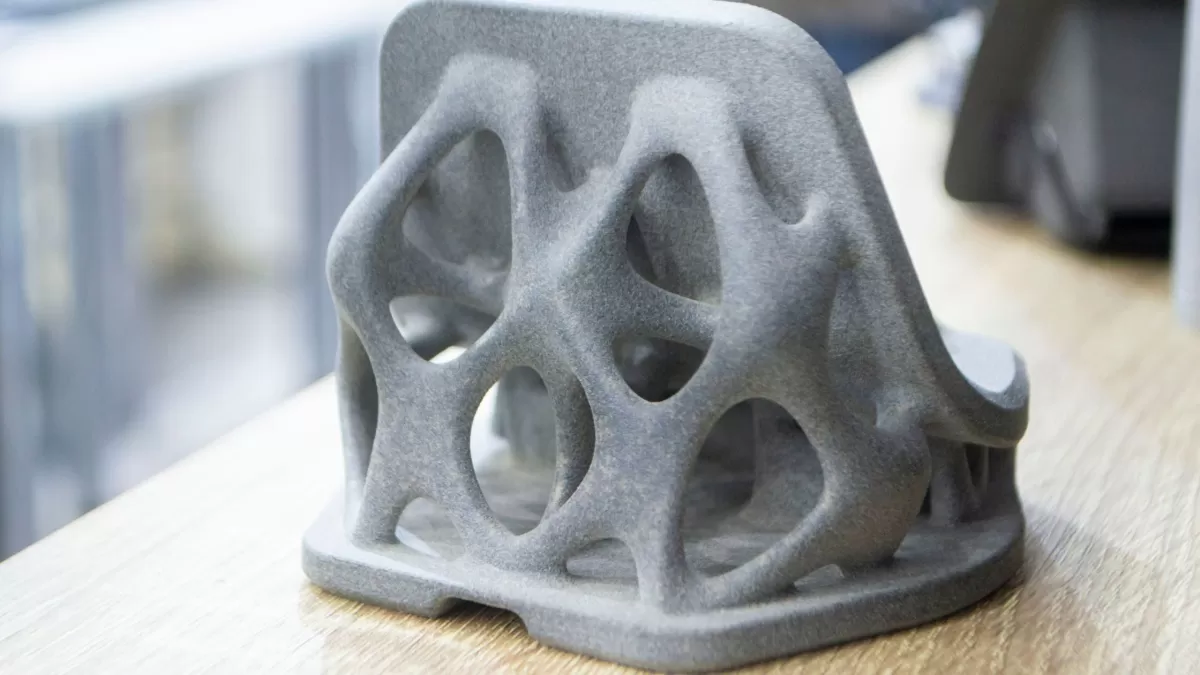

Lightweight Durable Components for Fuel Efficiency

Using 3D printing, manufacturers produce lightweight parts without sacrificing strength. This helps improve fuel efficiency, a big deal in today’s market where every pound matters.

-

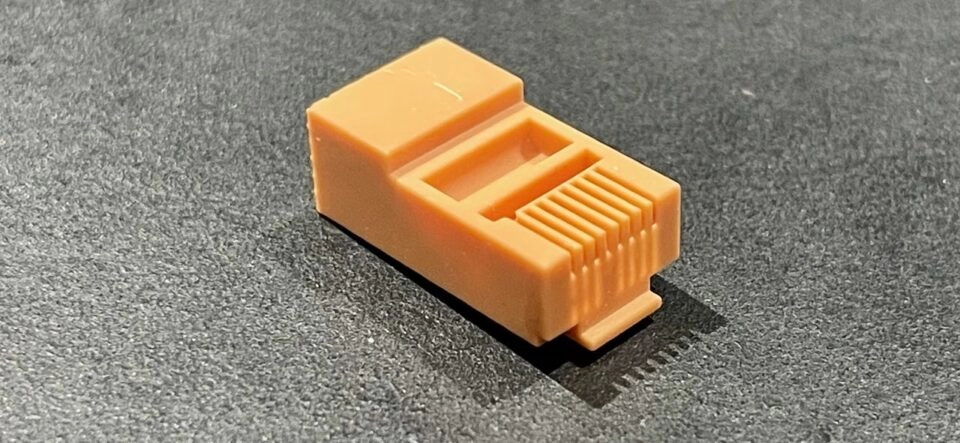

Custom Parts and Personalization

From unique interior trims to specialized aftermarket parts, 3D printing lets you tailor components to specific needs. This level of customization supports both small-batch production and one-off orders.

-

Tooling and Molds with 3D-Printed Metal

3D printed metal tools and molds speed up production cycles and reduce lead times. They’re more cost-effective for low to medium volume runs compared to traditional tooling methods.

These applications highlight how automotive additive manufacturing is transforming everything from design to production. For a closer look at how 3D printing blends with CNC machining in automotive parts, check out CNC prototyping vs 3D printing.

Materials Used in Automotive 3D Printing

When it comes to materials in automotive additive manufacturing, there’s a mix of thermoplastics, metals, and ceramics, each serving different needs.

Thermoplastics like ABS, PLA, and nylon are common for prototyping and some lightweight parts. They’re easy to print and pretty durable. Nylon and glass-filled composites stand out because they offer extra strength and heat resistance, making them great for under-the-hood parts and custom components.

Metals such as aluminum, stainless steel, and titanium are popular for making strong, lightweight, and heat-resistant parts, especially when using Selective Laser Melting (SLM). These metals can handle high stress and are perfect for tooling, molds, and some structural parts.

Ceramics are less common but useful for applications needing high heat resistance and electrical insulation.

One thing we always focus on is material quality and compatibility. Using the right materials means parts perform well and last longer. We ensure all materials meet automotive standards, which helps with safety and durability. Plus, verifying compatibility with specific 3D printing technologies avoids print failures and keeps production smooth.

Whether you need lightweight composites or tough metals, choosing the right material is key for performance and reliability in automotive 3D printed parts.

Benefits of 3D Printing for Automotive Manufacturing

3D printing offers clear benefits for automotive manufacturing here in the U.S. First off, it helps cut costs by reducing material waste. Unlike traditional methods like CNC machining, additive manufacturing builds parts layer by layer, using only what’s needed. This means less scrap and lower material expenses.

Design flexibility is another big plus. Complex shapes and internal structures that are tough or impossible to machine can be produced easily with 3D printing. This gives engineers more freedom to create lightweight, durable parts that boost vehicle performance and fuel efficiency.

Speed is also a game-changer. Rapid prototyping lets teams test and tweak designs fast, slashing development times and getting vehicles on the road quicker. Shorter lead times mean quicker adjustments during production, helping avoid costly delays.

Sustainability matters more than ever, and 3D printing supports this by enabling lighter components that improve fuel economy and reduce emissions. This aligns well with stricter environmental standards in the automotive industry.

A solid example comes from HYCNC, a trusted CNC and 3D printing service provider in the U.S. They’ve delivered cost-effective solutions by combining advanced 3D printing tech with their CNC expertise, optimizing both production speed and part quality. This hybrid approach offers manufacturers practical ways to get high-quality custom parts while controlling costs.

Challenges and Solutions in Automotive 3D Printing

While 3D printing offers huge benefits for automotive manufacturing, it’s not without its challenges. One common issue is material limitations—not all 3D printing materials meet the strength or durability needed for certain car parts. That’s why selecting the right material, like high-grade metals or glass-filled composites, is critical to get lasting results.

Another challenge comes from patent considerations. The automotive industry has many patented designs, so ensuring your 3D printed parts don’t infringe on patents takes careful planning and creativity.

Post-processing challenges also play a big role. After printing, parts often need finishing like polishing, heat treatment, or machining, which can add time and cost if not managed efficiently.

At HYCNC, we’ve tackled these hurdles by combining advanced CNC machining with 3D printing. This integration lets us enhance printed parts with precise machining for perfect fits and finishes, overcoming material and post-processing limits.

Looking ahead, the future of automotive 3D printing points to durable alloys and large composite parts. These materials will expand what’s possible, making lightweight, strong components faster and more cost-effective. With HYCNC’s expertise, we’re ready to help your automotive projects keep pace with these innovations.

Why Choose HYCNC for Automotive 3D Printing

At HYCNC, we bring together the best of CNC machining and 3D printing to offer unbeatable solutions for automotive applications. Our deep expertise means you get precise, reliable results whether you need rapid prototyping or production-grade tooling.

We tailor our services to fit your project perfectly—whether it’s custom car parts, lightweight components, or specialized molds. This approach helps you reduce lead times and costs without sacrificing quality.

Quality and precision are at the heart of everything we do. We use advanced technology and strict quality control to ensure your parts meet industry standards and perform as expected.

Ready to bring your automotive 3D printing projects to life with a trusted partner? Contact HYCNC today for a consultation and see how we can help speed up your production with top-notch additive manufacturing solutions.