What is 3D Prototyping

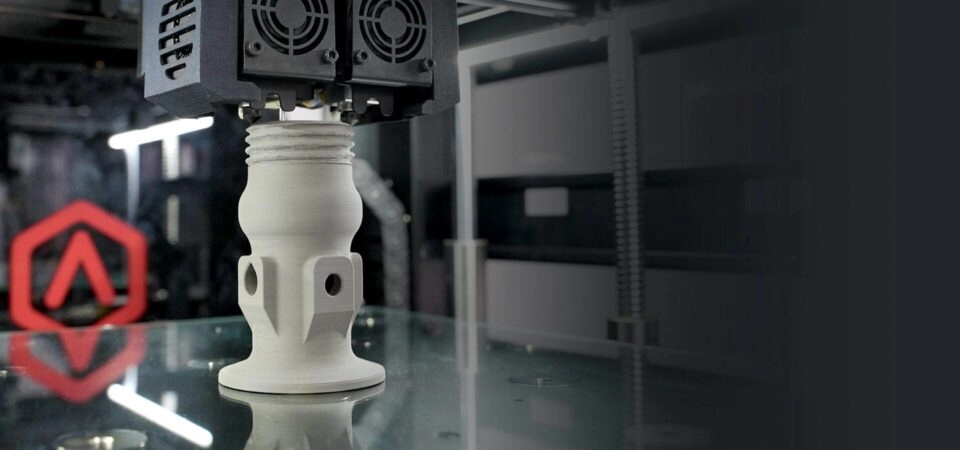

If you’ve ever wondered how new products go from concept to reality so quickly, 3D prototyping is a big part of the story. Simply put, 3D prototyping is a way to create physical models of parts or products directly from digital designs using additive manufacturing. Instead of carving or cutting material away like traditional methods, additive manufacturing builds objects layer by layer, saving time and allowing for complex shapes that were once impossible.

Here are the key technologies used in 3D prototyping:

- Fused Deposition Modeling (FDM): This is the most common form of 3D printing, where melted thermoplastic is deposited layer by layer to build a part. It’s affordable and great for quick functional prototypes.

- Stereolithography (SLA): High-resolution printing using a laser to cure liquid resin layer by layer. SLA provides smooth surfaces and is perfect for detailed, precise prototypes.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material like nylon or metal, producing durable and complex parts ready for functional testing.

Compared to traditional prototyping — like CNC machining or injection molding — 3D prototyping offers faster turnaround and more freedom for design iteration without costly tooling. CNC machining usually involves cutting parts from solid blocks, which can be slower and limited in complexity.

At HYCNC, we combine the best of both worlds. Our experts integrate CNC machining with 3D prototyping so you get both precision cutting and the design flexibility of additive manufacturing. This hybrid approach means you get prototypes faster, with superior quality and ready for real-world testing.

Benefits of 3D Prototyping for Product Development

3D prototyping speeds up product development by allowing rapid iterations. You can test designs quickly, make changes, and get to market faster than with traditional methods. This rapid turnaround helps keep projects on schedule and responsive to feedback.

Cost efficiency is another big advantage. Compared to traditional processes like injection molding, 3D prototyping requires less upfront investment, especially for small batches or one-off designs. This makes it a budget-friendly choice for startups and established companies alike.

Customization is easy with 3D prototyping. It lets you create complex shapes and tailor products to exact specifications without extra tooling costs. This flexibility supports innovative designs and multiple versions without breaking the bank.

When it comes to quality and precision, 3D prototyping delivers high-fidelity models that are great for functional testing. You get detailed, accurate prototypes that closely match the final product, helping catch issues early.

Real-world examples highlight this too—medical devices and automotive parts often rely on 3D prototyping for development. These sectors benefit from the ability to test precise, custom parts swiftly, ensuring safety, performance, and compliance before full-scale production.

How HYCNCs 3D Prototyping Services Stand Out

At HYCNC, we combine advanced CNC machining with state-of-the-art 3D printing to deliver top-notch prototyping solutions. Whether you need precise CNC prototypes or complex 3D printed parts, our capabilities cover it all. We work with a wide range of materials including ABS, PLA, and various metal alloys, so you get the right fit for your project.

We understand speed matters. That’s why we offer fast turnaround times and scalable services that support everyone—from startups launching their first product to large enterprises managing multiple projects.

One of our recent clients cut prototyping costs by 30% using our combined CNC and 3D printing approach, speeding up their product development without sacrificing quality.

We also integrate seamlessly with your CAD software, making it easy to upload designs and get expert design consultation to optimize your prototypes for manufacturing. You can learn more about the differences and benefits of our CNC prototyping vs 3D printing services on our CNC prototyping vs 3D printing page.

For quick project starts and reliable 3D prototyping options, explore our full rapid prototyping services.

Choosing the Right 3D Prototyping Solution

Picking the right 3D prototyping method depends on a few key factors: material complexity, budget, and timeline. If your prototype needs intricate details or complex shapes, 3D printing is often the best choice. It handles geometry that’s tough or impossible for traditional machining. However, if you need stronger materials or tight tolerances, CNC machining might be the way to go.

Here’s when to lean on each option:

-

3D Printing

- Best for quick, detailed parts

- Ideal for complex shapes and rapid iteration

- Good for small to medium runs with lower upfront costs

-

CNC Machining

- Great for durable, high-strength parts

- Offers excellent surface finish and precision

- Better suited for larger production runs or metal components

At HYCNC, we know no two projects are the same. That’s why we tailor our approach to your industry needs—whether you’re in aerospace, medical, or consumer goods. We combine our CNC expertise with 3D prototyping to deliver the best solution that fits your material requirements, budget, and schedule.

To get the most out of your prototype, keep these design tips in mind for manufacturability:

- Design with clear, consistent wall thickness to avoid weak spots

- Simplify overly complex geometries where possible to reduce print or machining time

- Add draft angles and fillets to help with material flow or machining

- Choose materials compatible with your prototyping method and final product use

Following these helps ensure your prototype not only looks good but functions well and is ready to move through product development smoothly.

The Future of 3D Prototyping

3D prototyping is changing fast, and some big trends are shaping what’s next. AI-driven design tools are making prototypes smarter, helping us cut design time and improve accuracy. Virtual prototyping is also gaining steam—letting teams test and tweak products digitally before even printing a physical model. Plus, there’s a growing focus on sustainable materials to reduce waste and environmental impact.

At HYCNC, we stay ahead by investing in the latest 3D printing and CNC machining tech. This means faster turnaround, higher precision, and access to new, eco-friendly materials that meet the needs of U.S. businesses.

Looking toward 2026 and beyond, 3D prototyping will be more integrated with artificial intelligence and automation. We expect quicker design cycles, smoother production handoffs, and even greater customization options. These advances will help American companies bring innovative products to market faster and with less cost, keeping them competitive in a global market.

Getting Started with HYCNCs 3D Prototyping Services

Starting your 3D prototyping project with HYCNC is straightforward and hassle-free. Here’s how to get going:

-

Request a Quote

Visit our website and fill out a quick form with your project details. Be sure to include your 3D CAD files for an accurate quote. Our team reviews your files and sends a customized estimate fast, so you can plan your next steps without delay.

-

Upload Your 3D CAD Files

We accept common CAD formats to keep things simple. Upload your design directly through our secure portal. This helps us understand your specs and pick the best prototyping method, whether it’s CNC machining, 3D printing, or a combo.

-

Design Consultation

If you want, our experts provide advice on design for manufacturability, materials, and cost-saving options. This makes sure your prototype won’t just look good—it will perform well under real-world conditions.

-

Local Service Benefits

Based in the U.S., HYCNC offers fast turnaround times and responsive customer service tailored to local businesses across industries like aerospace, medical, and consumer goods. You get quality results without long waits or communication barriers.

For direct support or to kick off your project, contact us at [contact info] or visit our website. We’re ready to help you bring your ideas to life quickly and affordably.

Start your 3D prototyping journey with HYCNC today and experience the difference of integrated CNC and additive manufacturing.

For more on rapid prototyping options, check out our Rapid Prototyping services. If you’re torn between CNC and 3D printing, this comparison guide can help you decide.