Understanding Tab and Slot Designs

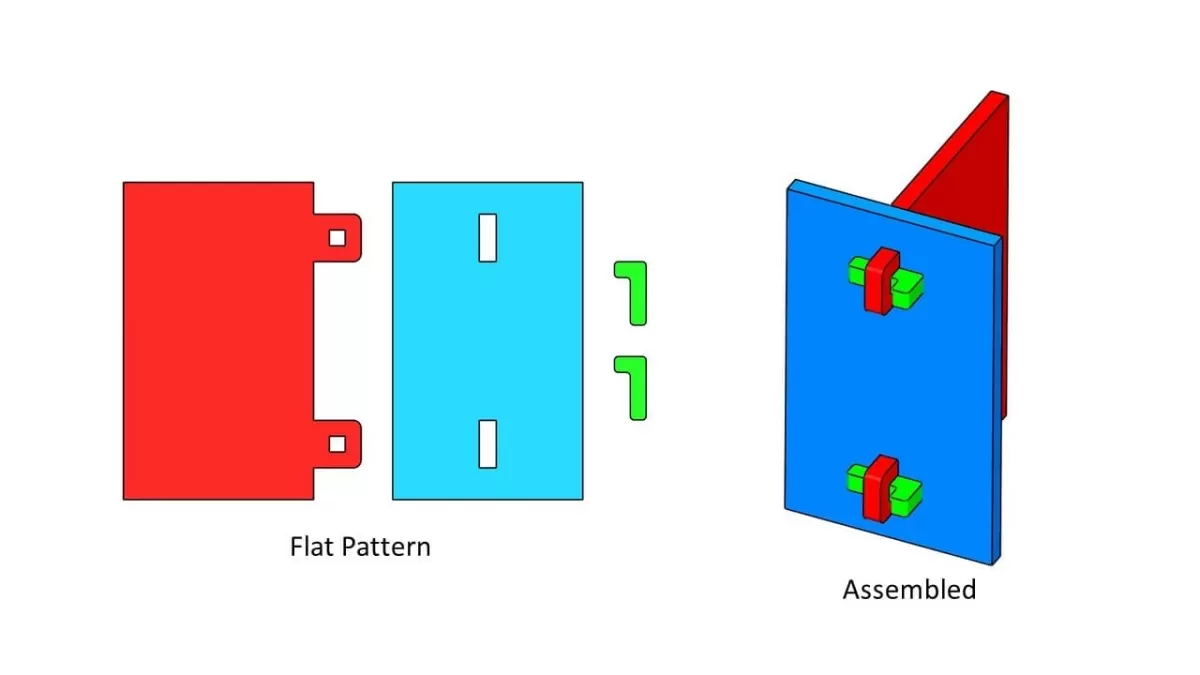

What Are Tab and Slot Designs

Ever tried fitting puzzle pieces together? That’s basically what tab and slot designs are all about. They’re a smart way to connect parts by using tabs (protruding pieces) that slide perfectly into slots (matching cutouts). This method keeps parts aligned, stable, and easy to assemble—no screws or glue needed.

Benefits

Why choose tab and slot designs? Here are some clear benefits:

- Easy assembly – Parts snap or slide together quickly.

- Strong joints – Tabs and slots lock tightly for durability.

- Cost-effective – Reduces hardware and labor costs.

- Precise alignment – Keeps components perfectly positioned.

- Reusable fits – Great for prototypes and multiple assemblies.

- Clean look – No visible fasteners for sleek surfaces.

Common Applications

You’ll find tab and slot designs everywhere:

- Furniture assembly

- Signage and displays

- Enclosures and boxes

- Sheet metal frameworks

- Toys and models

- Architectural panels

Industries

Lots of industries rely on tab and slot parts, like:

- Manufacturing

- Architecture and construction

- Automotive

- Aerospace

- Consumer products

- Electronics

Why Laser Cutting

Laser cutting takes tab and slot designs up a notch. It offers:

- Extreme precision for tight-fitting tabs and slots

- Clean edges with minimal finish work

- Ability to cut complex shapes like dogbone slots for flawless fits

- Fast turnaround on small or large production runs

- Wide material compatibility from wood and plastics to metals

Whether you’re making laser cut interlocking parts for prototypes or production, laser cutting brings unbeatable accuracy that helps your parts snap together right every time.

Key Principles for Designing Tab and Slot Parts

When designing laser cut tab and slot parts, getting the basics right is crucial to ensure your project fits together perfectly and functions as intended.

Material Thickness and Tolerances

Start by measuring your material thickness precisely. Since laser cutting slightly burns away material, known as the laser kerf, you need to factor in this small cut width when designing slots and tabs. Always leave a bit of clearance to accommodate CNC laser cutting tolerances. This helps avoid parts that are too tight or loose.

Slot Design Variations

Slots can be straight, dogbone-shaped, or have rounded corners depending on the material and assembly needs. Dogbone slots are popular because they allow square corners on tabs to fit snugly while compensating for the laser’s round cut edges.

Tab Design Considerations

Tabs should be strong enough to hold parts securely but flexible enough to assemble without breaking. Consider the length, width, and thickness of tabs based on your material and how often you expect to assemble and disassemble the parts. Interlocking laser cut parts also help add stability during assembly.

Poka Yoke Mistake Proofing

Include simple error-proofing features in your design, like asymmetric tabs or keyed slots. These poka yoke elements make sure parts only fit the right way, reducing assembly time and avoiding costly mistakes.

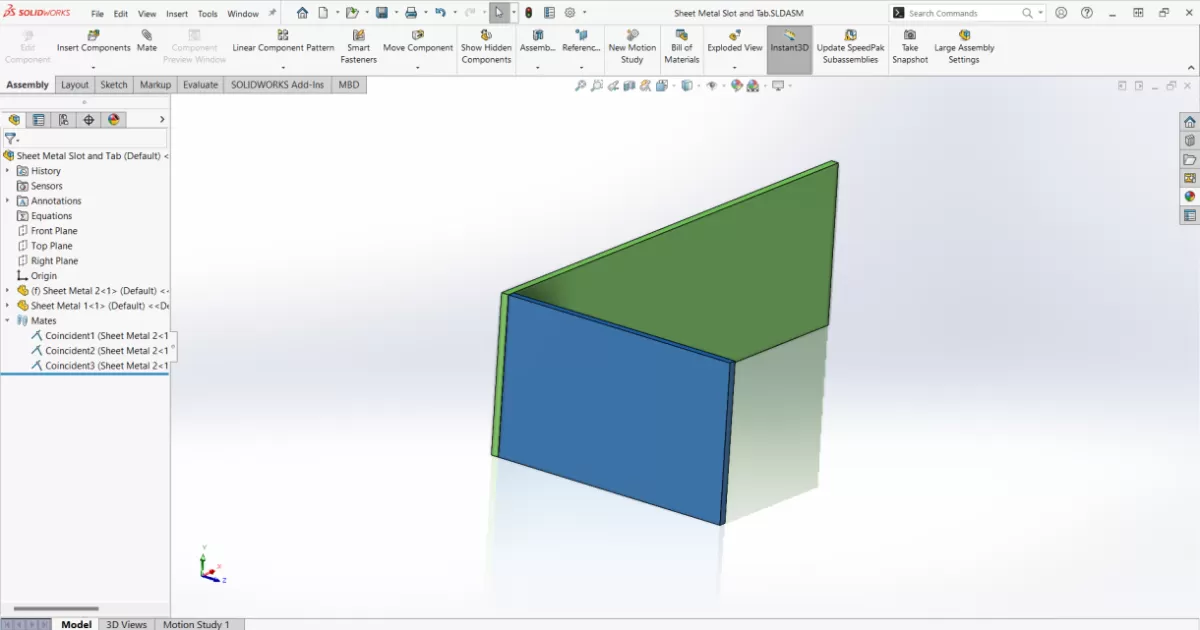

Software Tools for Design

Use CAD software with laser cut tab and slot design capabilities. Many programs have features to automatically add kerf compensation and suggest tab and slot sizes based on your material. Look for software that supports self-fixturing laser cut parts and integrates well with CNC machining workflows.

Keeping these principles in mind helps create precise, efficient tab and slot designs ready for quality laser cutting.

Best Practices for Laser Cut Tab and Slot Parts

When designing laser cut tab and slot parts, following some best practices can save you time and ensure a better final product.

Account for Material Properties

Every material reacts differently to laser cutting. Factor in thickness, flexibility, and hardness. For example, metals may expand or char, while wood or acrylic could burn or warp. Knowing this helps you adjust tab sizes and slot fits for a solid connection without forcing parts.

Optimize for Assembly

Design tabs and slots so parts slide easily but fit snugly. Use laser kerf compensation to adjust for the material lost during cutting. This ensures clean, precise joints and speeds up assembly—no hammering or extra tools needed. Consider self-fixturing laser cut parts that hold themselves in place right after cutting.

Minimize Stress Concentrations

Sharp corners in slots and tabs can create weak points that quickly wear or crack. Include slight fillets or use dogbone slot design to spread stress evenly. This reduces breakage, especially in load-bearing or moving parts.

Test and Iterate

Don’t assume your first design will be perfect. Run small tests to check fit, durability, and assembly ease. Adjust tab thickness, slot size, or corner shapes based on real-world results. Continuous iteration helps you deliver parts that work flawlessly every time.

Following these steps ensures your laser cutting tab and slot design is reliable, precise, and ready for smooth assembly in industries serving the US market.

Common Mistakes to Avoid

When working on laser cutting tab and slot designs, there are a few common pitfalls that can cause headaches down the line. Here’s what to watch out for:

Ignoring Kerf and Tolerances

Laser kerf—the width of material the laser burns away—affects how tight your tabs and slots fit. Not accounting for this can make parts too loose or too tight, messing up assembly. Always build in kerf compensation and consider CNC laser cutting tolerances for your specific material.

Overcomplicating Designs

Complex tab and slot designs might look cool but often add unnecessary difficulty and cost. Keep designs simple and functional to ensure ease of assembly and reliable part fit. Overly detailed tabs also increase the chance of errors during cutting.

Neglecting Material Finish

Different materials react differently to laser cutting. Ignoring how the edges finish can lead to rough slots or weak tabs, which affects the strength and look of your parts. Think about post-cut finishes and how material properties will influence your design.

Poor Corner Design

Sharp internal corners, sometimes common in tabs and slots, can cause stress concentrations, leading to cracks or breaks. Using dogbone slot design or rounded corners helps prevent this issue and makes parts easier to fit together without damaging edges.

Avoiding these mistakes ensures your laser cut interlocking parts work smoothly, saving time and money during manufacturing and assembly.

How HYCNC Enhances Your Tab and Slot Designs

When it comes to laser cutting tab and slot designs, HYCNC stands out with its precision and reliability. Here’s how we make your projects easier and better.

Precision Laser Cutting Services

We use advanced CNC laser cutting machines that deliver tight tolerances and clean cuts every time. This means your tabs and slots fit perfectly, reducing assembly hassles and improving the overall strength of your parts.

Material Expertise

We work with a wide range of materials—from sheet metal to plastics—and know how each one reacts to laser cutting. This experience helps us advise you on the best material choices and adjust designs to suit the material properties, making your parts last longer and perform better.

Instant Quoting and Fast Turnaround

Need quick answers? Our online quoting system gives you instant prices based on your design files. Plus, we understand the importance of deadline-driven projects, so we offer some of the fastest turnaround times in the industry without compromising quality.

Support for Prototyping

Got a new tab and slot design you want to test? We support prototyping so you can validate your parts before full production. This hands-on approach lets you fine-tune your design early, saving time and cost down the line.

If you’re ready to take your laser cut tab and slot parts to the next level, reach out to HYCNC today. Our team is here to help you design smarter, build faster, and bring your ideas to life with precision.

FAQs

What is a tab and slot design in laser cutting?

Tab and slot design is a way to create interlocking parts where tabs fit into matching slots, allowing easy assembly without extra fasteners. This is popular in laser cut interlocking parts.

Why is laser cutting ideal for tab and slot parts?

Laser cutting offers high precision and clean edges, which are crucial for tight fits and reliable assembly. It also handles complex designs and varying material thicknesses well.

How do I account for laser kerf in tab and slot designs?

Laser kerf is the material the laser removes during cutting. It’s important to compensate for kerf by adjusting slot widths to ensure a snug fit, especially when working with metals or acrylics.

What materials work best for laser cut tab and slot parts?

Common materials include steel, aluminum, and various sheet metals. Each material behaves differently, so understanding its thickness, flexibility, and finish helps optimize your design. See our laser cut steel and laser cut aluminum pages for more info.

Can I design tabs and slots for self-fixturing parts?

Yes, tab and slot designs often serve as self-fixturing features that hold parts in place during assembly, reducing the need for additional clamps or fasteners.

What software tools help with tab and slot CAD design?

Popular CAD software like SolidWorks, AutoCAD, and Fusion 360 have features or plug-ins specifically made for designing tabs and slots and managing CNC laser cutting tolerances.

How do I avoid common design mistakes like overcomplicating or ignoring tolerances?

Keep designs simple and test prototypes to check fits. Always factor in laser kerf and material tolerances. Using poka yoke mistake proofing techniques can help avoid assembly errors.

How quickly can I get laser cut tab and slot parts with HYCNC?

We offer instant quoting and fast turnaround services, ideal for prototyping and production runs alike. Reach out to see how we can support your project from design to delivery.