What is a CNC Machine Shop

A CNC machine shop specializes in precision CNC machining, using computer numerical control (CNC) technology to produce custom parts with high accuracy and consistency. CNC machining involves automated milling, turning, drilling, and cutting processes controlled by computer programs, allowing for the creation of complex geometries and tight tolerances.

These shops serve a wide range of industries, including aerospace, automotive, medical, electronics, and industrial manufacturing. Each sector relies on CNC machining for durable, precise components tailored to their specific needs.

At HYCNC, we pride ourselves on delivering custom CNC parts through expert craftsmanship and advanced technology. Our team works closely with clients to provide tailored solutions, whether you need rapid prototyping, small batch production, or high-volume CNC machining. This personalized approach ensures your project meets exact specifications and industry standards.

HYCNC’s CNC Machining Capabilities

At HYCNC, we specialize in precision CNC machining that meets tight tolerances and handles complex geometries with ease. Whether your project requires intricate details or large, precise components, our advanced CNC milling and turning services deliver consistent, high-quality results.

We work with a broad range of materials, including various metals like aluminum, steel, and titanium, as well as engineering-grade plastics. This versatility lets us serve diverse industries with custom CNC parts tailored to exact specifications.

Our shop is equipped with the latest CNC machines, operated by certified professionals. We hold certifications that ensure quality and reliability, giving you confidence in every part we produce.

Whether you need rapid prototyping, small batches, or high-volume CNC production, HYCNC has the experience and resources to handle your order efficiently and on time.

Benefits of Choosing HYCNC CNC Machine Shop

When you choose HYCNC for your CNC machining needs, you get fast turnaround times and quick delivery across the US. We know speed matters, so we keep production efficient without cutting corners.

Our instant online quoting system lets you upload your CAD files and get a precise quote right away—plus, you get design for manufacturing (DFM) feedback to help improve your parts before production starts.

Quality is at the core of everything we do. We follow strict quality control procedures and use certified materials, so you can trust the consistency and reliability of your custom CNC parts.

On top of great quality and speed, we offer competitive pricing and free shipping across the United States to help keep your project on budget.

Whether you need local support or global service, HYCNC is set up to assist you wherever you are—making us a top choice for precision CNC machining in your area.

How to Choose the Right CNC Machine Shop

Picking the right CNC machine shop can make a big difference in your project’s success. Here’s what you should focus on:

-

Precision and Tolerances

Look for shops known for tight tolerances and consistent, high-quality work. Precision CNC machining ensures your parts fit right and work as expected.

-

Certifications Matter

Choose an ISO-certified CNC shop or one with relevant industry certifications, especially if you’re in aerospace, medical, or automotive fields. Certifications mean they follow strict quality standards.

-

Material Options

A good shop offers a wide range of materials—from metals like aluminum, steel, and titanium to various plastics. This flexibility is key for finding the right match for your parts.

-

Lead Times and Turnaround

Fast turnaround can be critical. Local CNC machine shops often offer quicker communication and faster shipping, reducing project delays.

Local shops matter because being nearby means easier phone calls, quicker responses, and easier visits if needed. That’s where HYCNC shines—we combine advanced CNC equipment with a team that understands local customer needs, making communication smooth and lead times short.

Tips for Design Submission

To get the best results from your CNC machine shop, keep these in mind when submitting designs:

- Provide clean CAD files in common formats like STEP or DXF.

- Specify tolerances clearly—tight or loose—so the shop knows your precision needs.

- Include material specs and any finishing requirements up front.

- Ask for design for manufacturability (DFM) feedback to catch potential issues early.

At HYCNC, we make it easy to upload your design online and get instant feedback, helping you avoid costly mistakes and speed up production.

Industries We Serve

At HYCNC, we work with a wide range of industries, tailoring custom CNC parts to meet their unique needs.

Aerospace

We deliver high precision CNC machining with tight tolerances essential for aerospace components. Our ISO-certified processes ensure parts meet strict industry standards, ideal for both prototyping and final production.

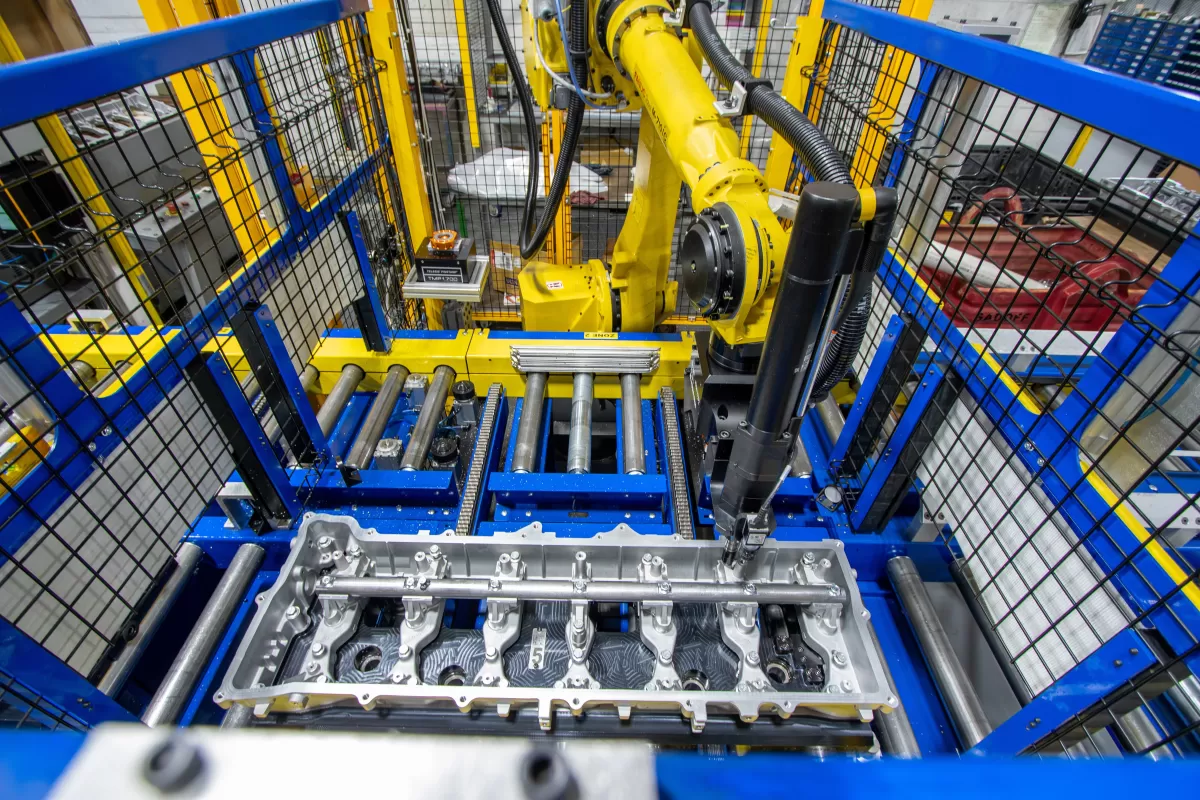

Automotive

From rapid prototyping CNC parts to high-volume CNC production, we help automotive clients create durable custom parts. Whether you need complex geometries or fast turnaround, we support your design and production needs.

Medical

We machine biocompatible materials suited for medical devices and implants. Our quality control and certifications guarantee the safety and precision required for healthcare applications.

Electronics

Precision CNC milling services and CNC turning services produce small, intricate parts used in electronics manufacturing. We handle a variety of materials and tight tolerances to fit your electronic components perfectly.

Examples and Case Studies

Our work spans from custom aerospace brackets to medical-grade implant prototypes. We’re proud to deliver reliable results that help businesses across the US innovate and scale efficiently.

Looking for a CNC machine shop near me? HYCNC’s expertise and local service make us the trusted partner for your industry’s machining needs.

The HYCNC Process from Quote to Delivery

Getting your custom parts started with HYCNC is simple and fast. Just upload your CAD files on our website to receive an instant CNC quote. Along with the quote, we provide helpful DFM (design for manufacturability) feedback to make sure your design is optimized for precision CNC machining.

Next, you’ll select the right materials and finishes from our wide range of metals and plastics, tailored to your project needs.

Once everything is set, our advanced CNC machines take over. We carefully follow every step of the precision CNC machining process to create parts that meet tight tolerances and complex geometries.

Before your parts leave our shop, they go through thorough quality assurance and inspection to guarantee accuracy and surface finish. This attention to detail helps us maintain our reputation as a reliable, ISO-certified CNC shop.

Finally, we offer fast and reliable shipping options—often with free shipping in the US—so you get your parts when you need them.

If you want to learn more about achieving the best surface quality for your CNC parts, check out our guide on good surface finish for CNC machined parts.

Why Local CNC Machine Shops Matter

Choosing a local CNC machine shop comes with clear benefits. You get faster turnaround times because shipping is quicker and easier. When you need changes or updates, communicating with a nearby CNC shop means less waiting and clearer collaboration. This helps keep your projects on track and reduces costly delays.

At HYCNC, we understand the value of personalized local support. We’re committed to being responsive and accessible, so you always have a real person ready to help. Whether you’re in aerospace, automotive, or medical industries, our local presence means we know your needs and work closely with you.

Looking for a reliable CNC machine shop near me? HYCNC is proud to serve multiple areas across the U.S. Be sure to search for “CNC machine shop near me” along with your city or region to find our services close to you. Local access means better service and quicker delivery times every time.

Get Started with HYCNC Today

When you choose HYCNC, you get precision, speed, and reliable CNC machining all in one place. Whether you need custom CNC parts, rapid prototyping CNC services, or high-volume CNC production, we deliver quality you can trust with quick turnaround times.

Ready to start? Simply upload your CAD file for an instant CNC quote and get design feedback to optimize your part. If you have questions or need help with your project, our expert team is just a call or message away.

Visit our website at www.hycncservice.com to upload your design or contact us directly for personalized support. Don’t forget to check out our case studies and customer testimonials to see how we’ve helped businesses like yours.

Let’s bring your project to life with precision CNC machining you can rely on.

FAQs About CNC Machine Shops

What materials can HYCNC machine?

We work with a wide range of materials, including aluminum, stainless steel, brass, titanium, plastics like ABS and Delrin, and more. Whether you need metals or plastics, we’ve got the right tools and experience to deliver quality parts.

What are typical turnaround times?

Our turnaround depends on the project size and complexity, but we pride ourselves on fast delivery. Prototypes or small batch jobs often ship within a few days, while larger high-volume orders have competitive lead times. We always keep you updated.

What tolerances can HYCNC achieve?

We specialize in precision CNC machining, maintaining tight tolerances often down to ±0.001 inch. This precision fits industries like aerospace and medical where every fraction counts.

Do you offer design support and DFM feedback?

Yes, we provide instant online quoting with design for manufacturability (DFM) feedback to help optimize your parts for production. Our team works with you from the start to avoid costly mistakes and improve part performance.

Are you certified for aerospace and medical machining?

Absolutely. HYCNC holds necessary certifications including ISO and industry-specific ones required for aerospace and medical components. Quality control and material certifications back every job to meet strict standards.