Defining Kerf in Laser Cutting What is Kerf Why Kerf Matters

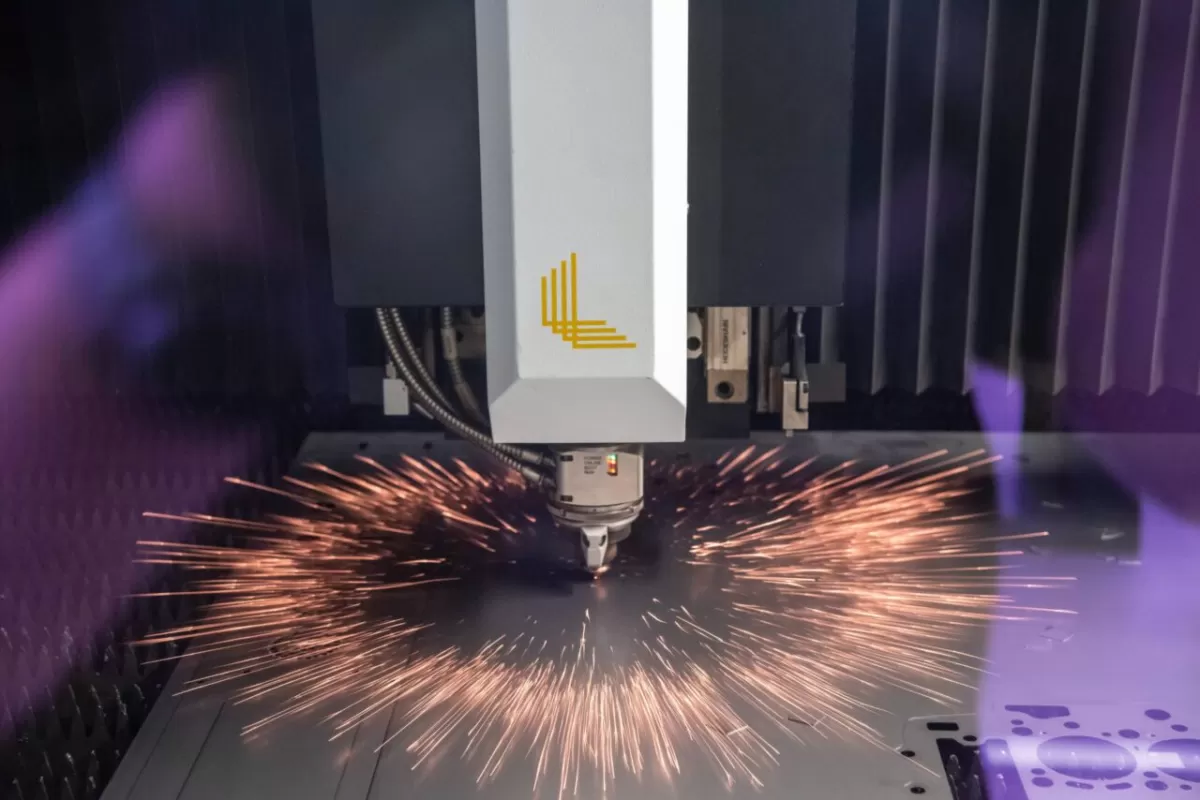

If you’ve ever wondered why your laser-cut pieces don’t fit perfectly or why there’s always a tiny gap after cutting, the answer often lies in something called kerf. In laser cutting, kerf is the width of material removed by the laser beam as it slices through your workpiece. Think of it as the thickness of the cut line.

Understanding kerf is essential because it directly affects the precision of your designs. Whether you’re working with wood, acrylic, metal, or other materials, the laser beam doesn’t just cut on a zero-width path—it actually vaporizes or melts a narrow strip of material. This width, or kerf, changes based on several factors, but ignoring it can lead to parts that don’t fit well or extra material waste.

Simply put, kerf matters because it influences how accurately your CNC laser cutting projects come out. It’s a key detail that separates good laser cutting precision from sloppy results. Getting a handle on kerf helps you create sharper designs, reduce fitting headaches, and optimize material use, saving you time and money in the process.

Factors Influencing Kerf Width

Kerf width in laser cutting isn’t a fixed number—it changes based on a few key factors.

Laser Beam Characteristics

The laser beam’s size and quality play a big role. A narrower beam means a thinner kerf and better laser cutting precision. Different types of lasers, like fiber laser vs CO2 laser, also create different kerf widths because of how their beams focus and interact with materials.

Material Type and Thickness

Not all materials cut the same. Thicker or denser materials tend to have wider kerf widths. Some materials melt or burn differently, affecting how much material the laser removes during cutting.

Cutting Parameters

Settings like laser power, speed, and focus impact kerf width too. Higher power or slower speeds can increase kerf size by burning more material. Adjusting these parameters helps fine-tune the cut for exact tolerances.

Machine Calibration

Finally, how well the CNC laser cutting machine is maintained and calibrated matters. A well-calibrated machine keeps kerf width consistent, which is key for precision manufacturing and ensuring your parts fit perfectly.

Keeping these factors in mind helps manage kerf and reduce material waste in laser cutting projects.

How Kerf Affects Your Laser Cutting Projects

Kerf plays a big role in how your laser cutting projects turn out. It’s the width of the material that the laser removes while cutting. If you don’t account for kerf, your design might not fit together right or could waste more material than necessary.

Design Considerations

When planning your cuts, keep kerf in mind. If your parts need to fit tightly—like puzzle pieces or metal brackets—kerf can change the size slightly. Ignoring kerf means gaps may appear, or parts might be too tight and hard to assemble.

Fit and Assembly

Kerf impacts the precision of joins and assembled parts. For example, if you want a tab to fit into a slot, the kerf width determines how snug or loose this fit will be. Proper kerf compensation ensures a smooth assembly process without having to force pieces together or deal with wobbly fits.

Material Waste and Cost

Every cut removes a bit of material equal to the kerf width. Over many parts, this adds up. Larger kerf widths mean more material lost, increasing costs—especially when working with expensive metals or hardwoods. Managing kerf precisely can help reduce waste and save money in the long run.

In laser cutting, understanding kerf’s impact on fit, design, and material use is essential. It helps make your projects cleaner, more precise, and cost-effective.

How to Account for Kerf in Your Designs

When working on laser cutting projects, accounting for kerf is crucial to get precise results. Here’s how you can handle it effectively.

Measure and Test

Start by measuring the kerf width for the specific laser and material you’re using. The kerf can vary based on factors like laser type, material thickness, and settings, so always run a few test cuts. This helps you understand the exact amount of material the laser removes, giving you a baseline for adjustments.

Kerf Compensation Techniques

To compensate for the kerf in your design:

- Adjust your vector paths: Shrink or expand your cut lines by half the kerf width to ensure final parts fit as intended.

- Use software tools: Many CNC laser cutting software programs have built-in kerf compensation features to automate this process.

- Tighten tolerances carefully: Be mindful when setting tight fits. Accounting for kerf prevents parts from being too loose or too tight at assembly.

HYCNC’s Approach

At HYCNC, we take kerf into account right from the start. Our experienced team measures and tests kerf on each material and laser type we use. We apply precise kerf compensation tailored to your design, ensuring clean cuts and perfect fit. This approach helps minimize material waste and saves you time and money on post-processing.

By measuring kerf, adjusting your designs accordingly, and partnering with a reliable CNC service like HYCNC, you can achieve top-notch precision in your laser cutting projects every time.

Practical Tips for Minimizing Kerf Related Issues

Managing kerf is essential to keep your laser cutting projects precise and cost-effective. Here are some practical tips to help you minimize kerf-related challenges:

-

Measure Your Kerf Consistently

Always test cut a small sample of your material to measure the exact kerf width before full production. Kerf can vary depending on the batch, so stay updated.

-

Use Kerf Compensation in Your Design

Adjust your CAD files to include kerf compensation, especially for tight fits. This prevents parts from being too loose or too tight and improves assembly accuracy.

-

Optimize Cutting Parameters

Fine-tune your laser’s power, speed, and focus to reduce excessive kerf width. Lower power or faster speeds can minimize the heat-affected zone and narrow the cut.

-

Choose the Right Laser Type

Depending on your material, using a fiber laser or CO2 laser can impact kerf width. For example, fiber lasers tend to have a narrower kerf on metals, improving precision.

-

Maintain Your Machine Regularly

Proper machine calibration and clean optics ensure the laser beam stays focused and consistent, which keeps the kerf predictable.

-

Plan for Material Waste

Account for kerf in your nesting layout to reduce scrap, saving on costly materials and improving overall efficiency.

Implementing these strategies will help you achieve better laser cutting tolerances, lower material waste, and more precise CNC laser cutting results. For deeper insights on laser cutting design, check out our best practices for designing and laser cutting small parts.

Why Choose HYCNC for Your Laser Cutting Needs

When it comes to laser cutting, precision matters—and that’s exactly what you get with HYCNC. We specialize in CNC laser cutting services that focus on accuracy, quality, and efficiency. Whether you’re working with thick metals or delicate materials, our expert team knows how to manage kerf width and ensure your designs come out just right.

Here’s why HYCNC stands out:

- Advanced Equipment: We use state-of-the-art fiber and CO2 laser machines for sharp, clean cuts with minimal kerf width, perfect for tight tolerances and precision manufacturing.

- Kerf Compensation Expertise: Our pros understand how to measure and adjust kerf in your projects, reducing material waste and avoiding costly mistakes.

- Custom Solutions: We tailor cutting parameters based on your material and design needs, so every piece fits perfectly without guesswork.

- Local Service: Based in the U.S., we offer fast turnaround times and clear communication to keep your projects on schedule.

- Cost-Effective: With efficient processes and skillful kerf management, we help lower your overall costs while maintaining top-tier quality.

Choosing HYCNC means choosing reliability for your CNC laser cutting needs. We’re here to take the hassle out of laser cutting so you get precise parts, every time.