Key Design Considerations for Small Parts

Designing small parts for laser cutting requires careful attention to several critical factors to ensure precision and durability. Here’s what you need to keep in mind:

Material Selection

Choosing the right material is essential. For small parts, consider strength, durability, and thermal properties:

- Metals like stainless steel and aluminum offer strength and heat resistance.

- Plastics such as polycarbonate provide precision but need heat sensitivity consideration.

- Wood and foam are suitable for lightweight or decorative parts but require low laser power to avoid burning.

Minimum Feature Size

To prevent distortion and maintain part integrity, design holes, slots, and cutouts to be at least 50% of the material thickness. Features smaller than this often warp or fail during cutting.

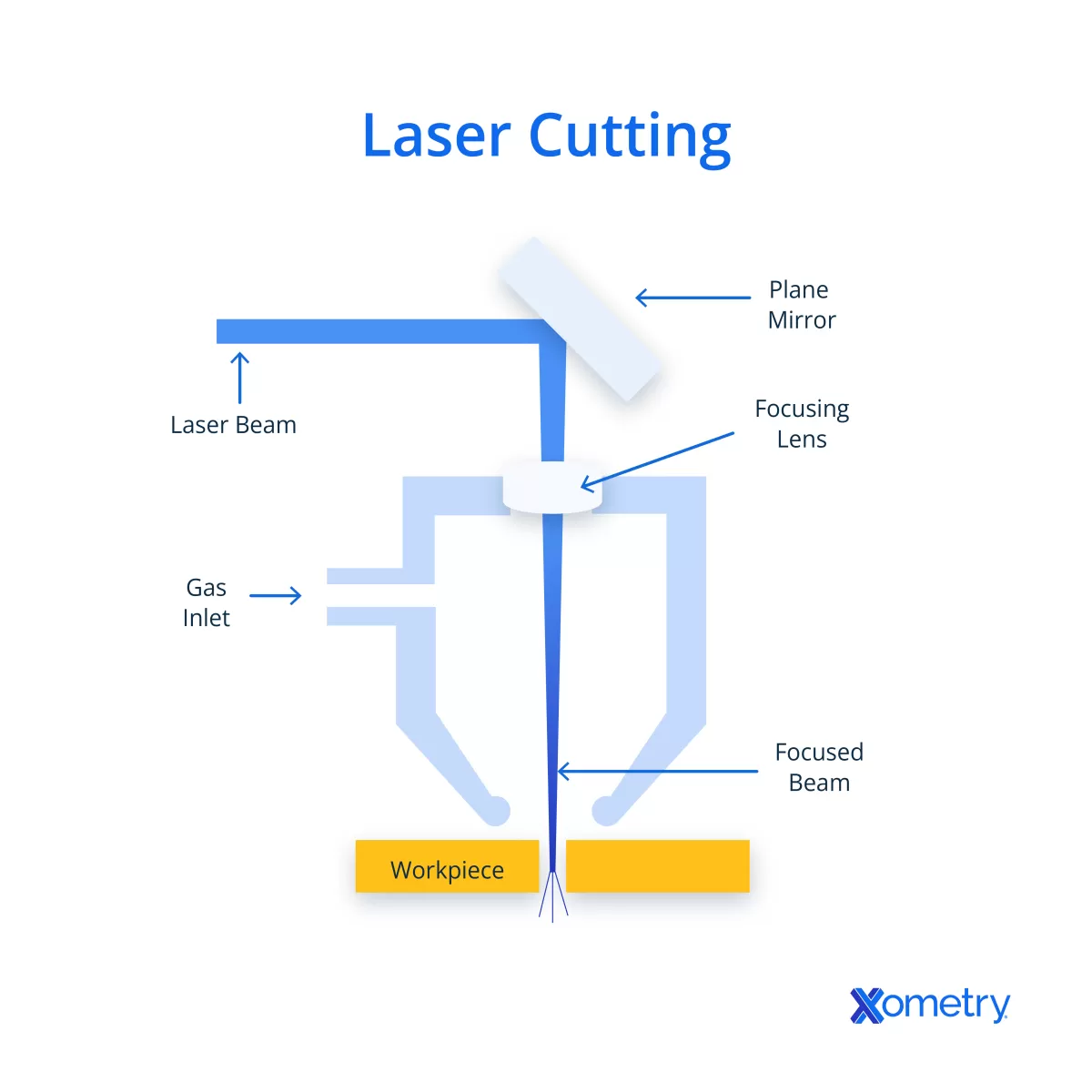

Kerf Compensation

The laser beam has a measurable width called kerf. Ignoring this can cause dimensional inaccuracies, especially in parts designed for tight assemblies. Adjust your design dimensions by accounting for kerf width to maintain precise fits.

Avoiding Overly Complex Designs

Complex geometries increase cutting time and risk damage to material edges. Simplify your design whenever possible:

- Remove unnecessary small details.

- Use clean, straightforward shapes.

- Limit intricate internal cutouts.

Focusing on these design principles helps you produce reliable, high-quality small parts every time. For more detailed design advice on small-scale applications, you can also explore HYCNC’s expert tips here.

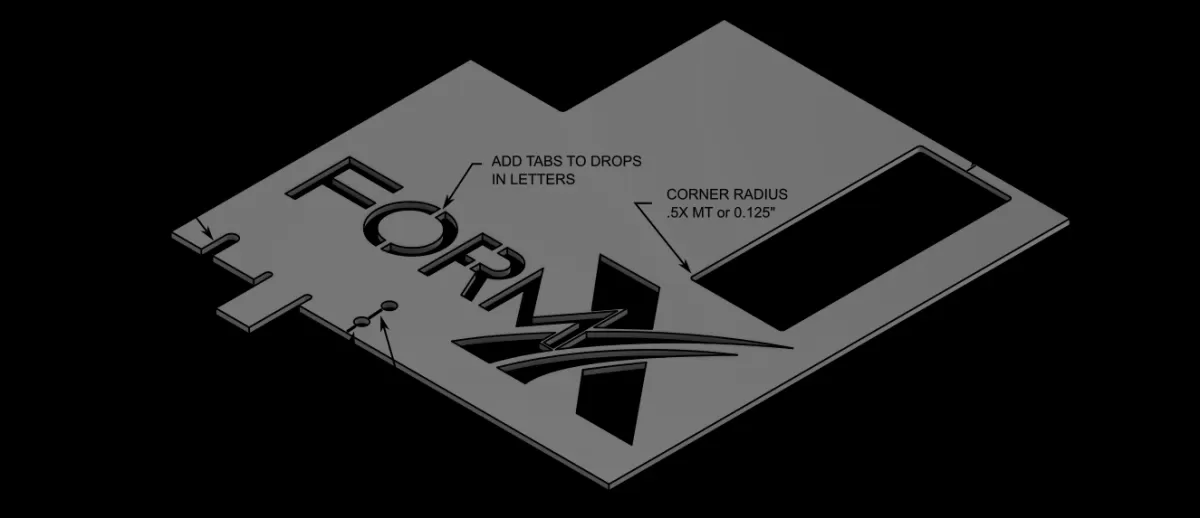

Best Practices for Preparing Design Files

Preparing your design files right is key for smooth laser cutting of small parts. Here’s what I suggest:

-

Use Vector Files: Stick to formats like DXF, AI, or EPS. These work best with laser cutting machines and keep your designs crisp and accurate.

-

Convert Text to Outlines: Always turn any fonts into shapes before sending your file. This prevents issues where the laser cutter can’t read the text properly.

-

Check for Closed Loops: Make sure every shape is fully connected without gaps. Open paths can cause incomplete cuts or scratches on your parts.

-

Design at 1 to 1 Scale: Create your design at the exact size you want the final part to be. This avoids guesswork and keeps dimensions spot-on.

Following these steps helps avoid common digital issues and ensures your laser cutting small parts come out exactly as planned.

Optimizing Laser Cutting for Small Parts

To get the best results when laser cutting small parts, a few key practices can make a big difference:

-

Spacing Between Cut Lines

Keep at least twice the material thickness between cuts. This spacing helps prevent melting, warping, or even fire hazards during the laser process.

-

Pierce Point Placement

Position pierce points in less critical areas of your design. This minimizes splatter and heat-affected zones, which can otherwise damage delicate features.

-

Bridging for Stability

Add small bridges or tabs to hold tiny parts in place while cutting. This stops them from moving or falling out before the job is done, keeping your cut clean and precise.

-

Test Cuts

Always run small-scale test cuts first. This helps you verify how your design interacts with the material and laser settings, saving time and avoiding costly mistakes.

These optimized steps ensure your small part designs come out accurate, clean, and ready for use. For more tips on precision laser cutting and kerf compensation, check out our design tips for CNC milled low volume parts.

Material Specific Tips for Laser Cutting

When working with small parts, choosing the right material makes a big difference in your laser cutting results. Here’s a quick guide for common materials:

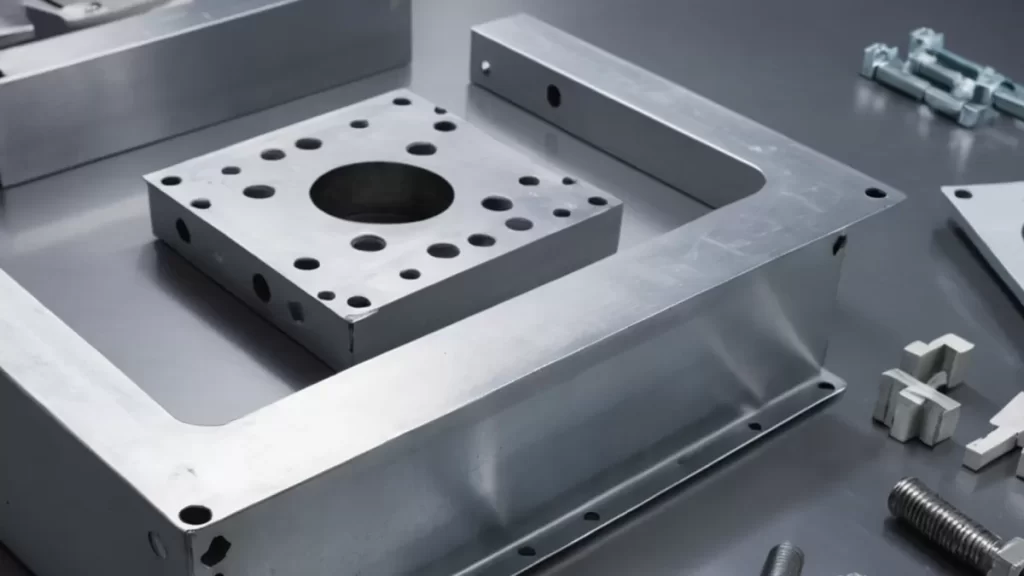

Metals

- Use stainless steel or aluminum for strong, durable parts.

- Avoid high heat settings to prevent warping and distortion.

- Aluminum is great for lightweight parts, offering good precision without sacrificing strength.

- For more on laser cutting aluminum, check out laser cut aluminum options.

Plastics

- POM (acetal) and polycarbonate work well for precise, small features.

- Be mindful of their heat sensitivity; use moderate laser power to avoid melting or charring.

- These plastics offer good durability and detail when cut properly.

Wood and Foam

- Ideal for decorative or lightweight parts where strength is less critical.

- Use lower laser power settings to avoid burning or scorching the edges.

- Great for prototypes or parts that don’t require mechanical strength.

Matching your material choice and laser settings ensures clean cuts, less waste, and better overall quality for your small parts.

Common Mistakes to Avoid

When designing small parts for laser cutting, steering clear of these common mistakes will save time and material:

-

Overlapping or intersecting lines

These cause unwanted cuts and can ruin your part. Make sure all lines are clean and don’t cross unnecessarily.

-

Ignoring kerf

The laser beam removes a small amount of material called kerf. Forgetting to factor this in leads to parts that don’t fit right. Always include kerf compensation in your design.

-

Designing features smaller than material thickness

Features smaller than about 50% of the thickness risk breaking or warping. Keep holes, slots, and cutouts large enough to maintain strength.

-

Failing to specify tolerances

For parts that need tight fits, not defining tolerances can cause assembly issues. Clear tolerances ensure everything fits just right.

Avoid these pitfalls to get precise, reliable parts every time when laser cutting small geometry.

How HYCNC Enhances Your Laser Cutting Projects

At HYCNC, we use advanced CNC laser cutting technology that delivers precise cuts quickly, helping you get accurate small parts without delays. Our team provides expert support to guide you through file preparation and material selection, ensuring your designs work perfectly with our machines.

We offer fast prototyping and production backed by ISO-certified services, so you can trust the quality and consistency every time. Plus, with our easy-to-use platform, you can upload your design files, get instant quotes, and streamline your entire order process, making your laser cutting projects smoother and hassle-free.