What is Vacuum Casting

Vacuum casting is a manufacturing process used to create high-quality plastic parts in small to medium volumes. It involves making a silicone mold from a master model, then using a vacuum to fill that mold with liquid resin. This method ensures precise detail and excellent surface finish on the final parts.

Key Stages of Vacuum Casting

- Master Model Creation: The process begins with designing and producing a detailed master model, often made using CNC machining or 3D printing.

- Silicone Mold Making: The master model is used to create a flexible silicone mold, which can be reused several times.

- Resin Mixing and Pouring: Liquid polyurethane resin is mixed and poured into the mold inside a vacuum chamber.

- Vacuum Application: The vacuum removes air bubbles, ensuring a smooth and bubble-free casting.

- Curing and Demolding: After the resin cures, parts are carefully removed from the mold.

Advantages of Vacuum Casting

- High Detail Accuracy: The vacuum process captures intricate designs with fine detail.

- Cost-Effective for Low Volume: Ideal for prototypes and small batch production without expensive tooling.

- Fast Turnaround: The process is quicker than traditional injection molding.

- Material Versatility: Supports a wide range of polyurethane resins that mimic various production plastics.

- Reusable Molds: Silicone molds can be reused multiple times, reducing costs over several production runs.

Typical Applications

Vacuum casting is widely used in industries that require quick, accurate prototypes or short production runs. Common applications include:

- Functional prototypes for testing

- Small batch production parts

- Customized components for electronics, automotive, and medical devices

- Silicone mold prototyping and urethane casting parts where precision and material properties matter

If you need reliable low-volume production with excellent surface quality, vacuum casting is often the perfect solution.

Why Design Matters in Vacuum Casting

Good design is the backbone of successful vacuum casting. When you get the design right, you reduce manufacturing errors, improve part quality, and keep costs low. Poor design often leads to issues like thin walls, warping, or parts that don’t fit together well.

Using CAD software is a game changer here. It lets you visualize the part, spot potential problems early, and make adjustments before production starts. This cuts down on wasted time and material.

At HYCNC, our advanced CNC machining capabilities ensure your designs are precisely translated into master models for vacuum casting. We work closely with you to refine designs, helping optimize draft angles, wall thicknesses, and other critical factors for smooth casting. In short, combining smart design with our CNC expertise sets the stage for quality parts every time.

Key Design Considerations for Vacuum Casting

Getting the design right is crucial for a smooth vacuum casting process and top-quality parts. Here are the main points to keep in mind:

Wall Thickness Recommendations

- Aim for consistent wall thickness to avoid defects.

- Typical thickness ranges between 1.5mm to 4mm, depending on the part size.

- Avoid very thin walls; they can cause warping or incomplete filling.

Draft Angles Guidelines

- Use draft angles of at least 1.5° to 3° on vertical faces.

- Draft helps in easy part removal from the silicone mold without damage.

- Larger draft angles might be needed for deeper molds or complex profiles.

Undercuts and Overhangs

- Minimize undercuts or design them to be removable with flexible silicone molds.

- Avoid complicated overhangs that can trap air or cause incomplete resin flow.

- When necessary, design living hinges or slide mechanisms to handle tricky geometry.

Ribs and Bosses Design Tips

- Add ribs to improve stiffness but keep them thin (about 40% of wall thickness) to prevent sink marks.

- Bosses for screw inserts should have at least 1.8mm wall thickness and proper draft.

- Avoid sharp corners on ribs and bosses to reduce stress and increase mold life.

Text and Logos Specifications

- Keep raised texts or logos shallow (around 0.5mm high) for better detail replication.

- Use sans-serif fonts to improve legibility and reduce molding issues.

- Avoid very fine or slender text that may not fill properly during casting.

Tolerances Standards

- Typical tolerances for vacuum casting range from ±0.1mm to ±0.3mm depending on complexity.

- Tight tolerances increase cost and should be specified only where critical.

- Discuss your tolerance needs upfront for better results.

Shrinkage Allowance

- Account for material shrinkage, usually around 0.5% to 1.5% depending on resin type.

- Adjust the CAD model dimensions based on specific resin properties to ensure final part accuracy.

By following these guidelines, you can avoid common vacuum casting pitfalls and make sure your parts come out just right. For more on design optimization and CNC machining tips, check out our design optimization in CAD article.

Material Selection for Vacuum Casting

Choosing the right material is a big part of successful vacuum casting. The most common materials used include polyurethane resins, silicone, and various elastomers. These materials offer a good balance of strength, flexibility, and detail that work well for prototypes and small batch production.

Material properties directly impact the final part’s durability, finish, and performance. For example:

- Rigid polyurethane is great for tough, load-bearing parts.

- Flexible polyurethane works well for elastic or rubber-like components.

- Clear resins are perfect if you need transparency.

- Heat-resistant resins help in applications that require thermal stability.

At HYCNC, we bring deep material knowledge to help you pick the right resin based on your project needs and industry standards. We combine this expertise with our CNC machining and vacuum casting capabilities to ensure you get parts that fit your performance and appearance requirements perfectly.

Common Design Pitfalls and How to Avoid Them

When designing for vacuum casting, some mistakes can cause delays, extra cost, or poor-quality parts. Knowing these pitfalls helps you avoid headaches and get better results.

Typical Issues to Watch For

- Uneven wall thickness causing weak spots or warping

- Insufficient draft angles making it hard to remove parts from molds

- Complex undercuts and overhangs that complicate mold design

- Overly tight tolerances which are tough to meet in vacuum casting

- Ignoring shrinkage allowance, leading to parts that don’t fit right

- Poor rib and boss placement that can cause stress points or mold damage

- Low-quality text and logo details that may not reproduce cleanly

How to Fix These Problems

- Keep walls uniform and follow recommended thickness guidelines

- Add proper draft angles (usually 1 to 3 degrees) for smooth part release

- Minimize undercuts; when necessary, design side pulls or inserts

- Set realistic tolerances, remembering vacuum casting is precise but not injection molding level

- Factor in shrinkage rates depending on the material used

- Place ribs and bosses thoughtfully to support parts without causing flaws

- Use simple, bold fonts and raised or recessed features for text and logos

HYCNC’s Quality Control Support

At HYCNC, we back up your design with thorough quality checks. Our experts review your CAD files early to flag potential issues and suggest fixes. During production, we use precision CNC machining to create master models and apply strict inspection standards on cast parts. This keeps your projects on track and parts top-notch.

By avoiding these design pitfalls and relying on HYCNC’s experience, you get parts that perform well and look great—every time.

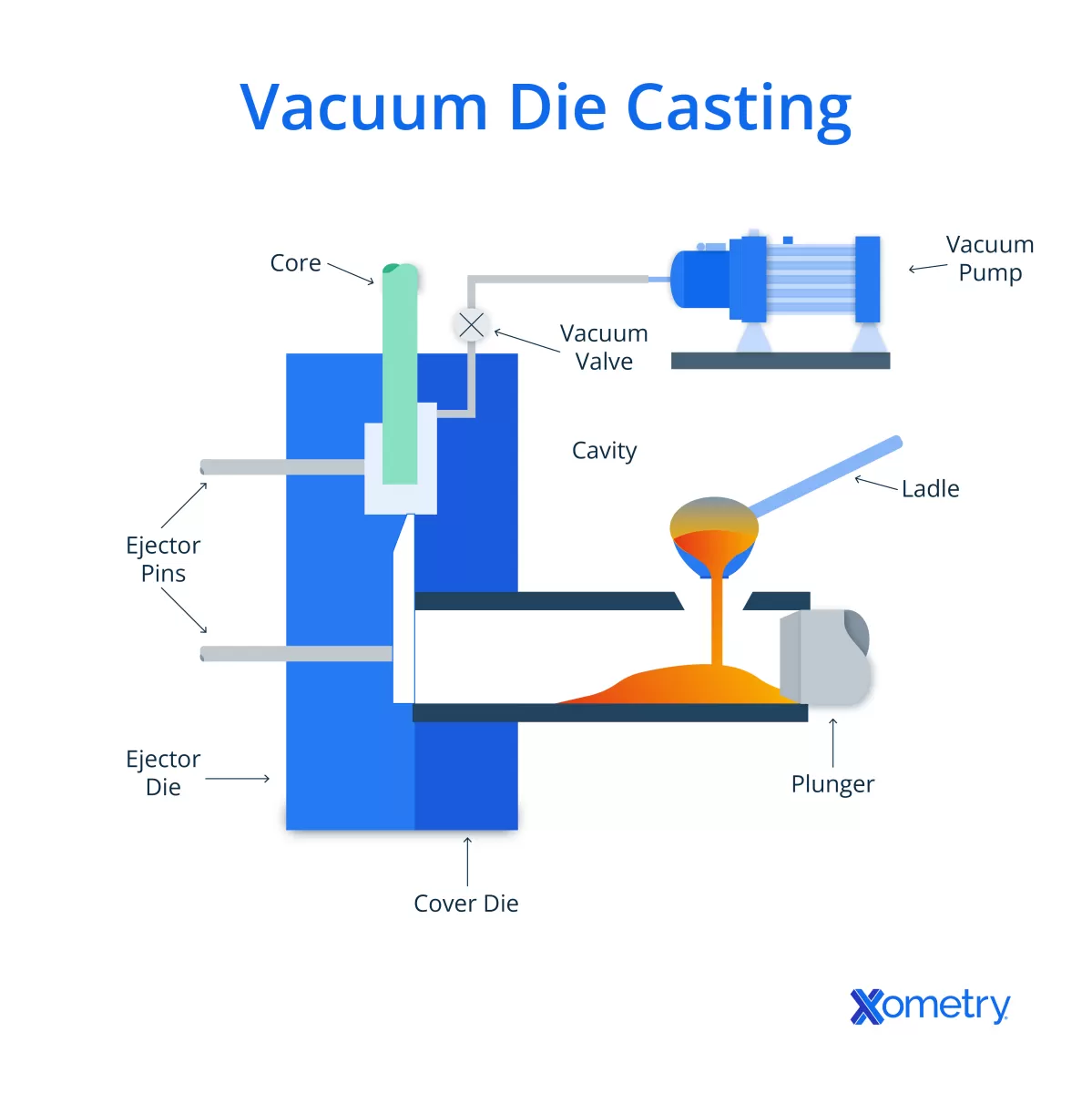

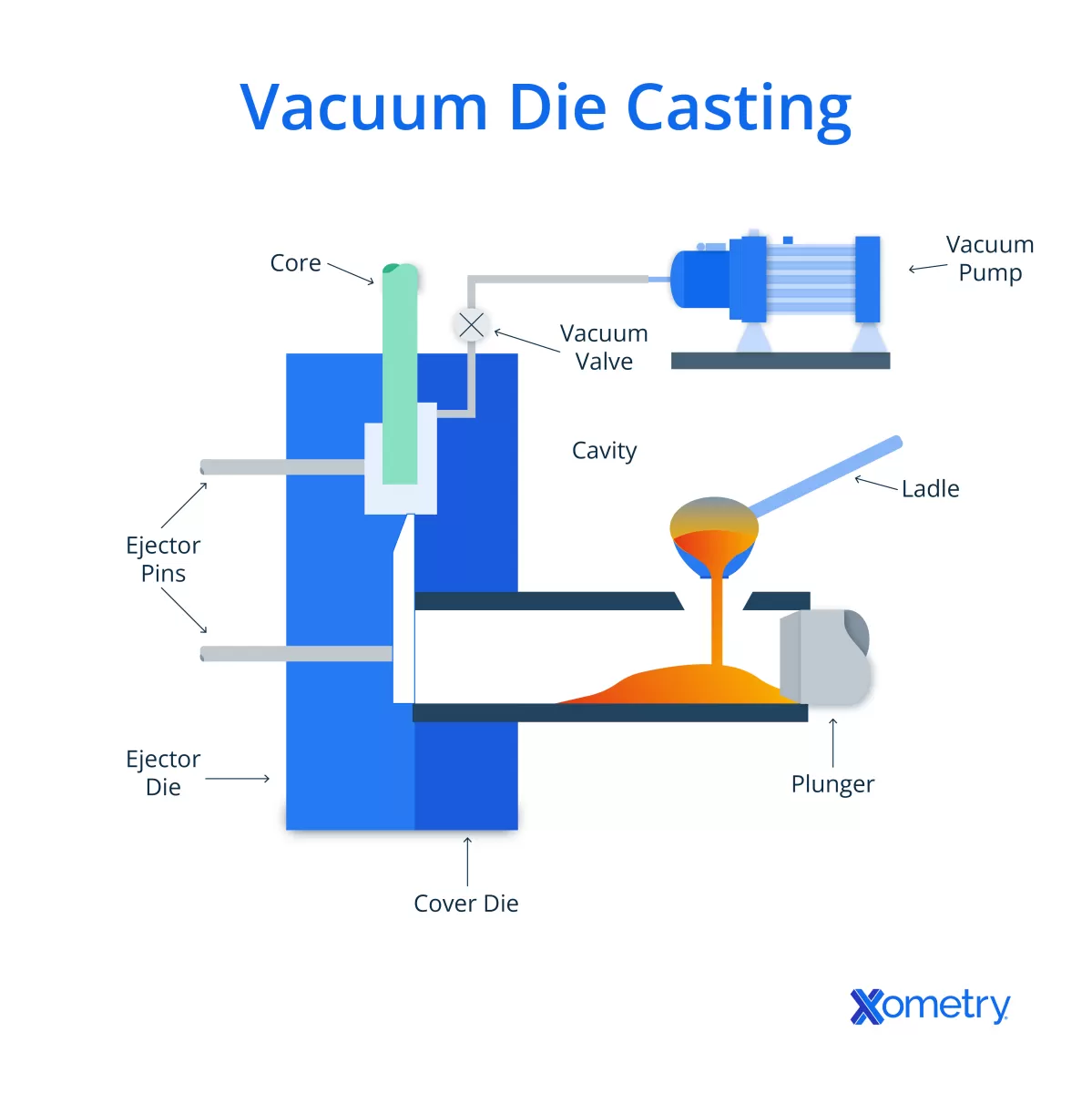

Step-by-Step Vacuum Casting Process

Vacuum casting starts with creating a precise 3D model, usually designed with CAD software. This digital design ensures accuracy before moving forward.

Next is master model production. Using CNC machining, HYCNC manufactures a high-quality master model, which serves as the basis for creating the silicone mold. Precision here is key to a successful final part.

Once the master model is ready, silicone mold casting is done by pouring silicone rubber around the master model. After curing, this mold captures every detail of the master.

After the mold is set, resin pouring takes place under vacuum conditions. This step removes air bubbles for smooth and detailed parts. Once poured, the resin cures, hardening into the final shape.

Part removal is then carefully done. The silicone mold can be reused multiple times, which makes vacuum casting ideal for small-batch or prototype production.

HYCNC offers integrated services that cover everything from 3D modeling and CNC machining to silicone mold making and vacuum casting. This seamless process saves time and ensures quality throughout.

For more insights on related CNC machining techniques, check out the guide on design tips for CNC milled low volume parts.

Applications of Vacuum Casting in Modern Industries

Vacuum casting is widely used across many industries because of its accuracy and cost efficiency for low-volume production. It’s perfect for prototyping and small batch runs where you want parts that look and function like final products without a big upfront investment.

Industries benefiting from vacuum casting

- Automotive: Interior components, small functional parts, and trim pieces

- Consumer electronics: Housings, buttons, and connectors

- Medical devices: Prototypes for devices, enclosures, and non-sterile parts

- Industrial equipment: Functional prototypes and custom tooling parts

- Aerospace: Lightweight parts for testing and prototypes

HYCNC project example

At HYCNC, we helped a client in the consumer electronics field create detailed prototype housings using our vacuum casting process. The parts matched the design exactly — both in texture and structural integrity — enabling fast market testing. Our CNC machining supported the creation of high-precision master models that resulted in flawless silicone molds. This case shows how vacuum casting effectively bridges the gap between prototype and production.

Why vacuum casting works for prototyping and small batches

- Produces high-fidelity parts that closely resemble injection molded quality

- Allows quick turnaround from 3D CAD models to finished parts

- Supports a broad range of polyurethane casting materials tailored for strength or flexibility

- Enables easy mold reuse for up to 20-25 parts per mold, ideal for testing or limited runs

For manufacturers and designers focused on rapid prototyping and small-scale production, vacuum casting offers the flexibility and precision needed without the hefty costs of tooling for full-scale manufacturing. HYCNC’s combined CNC and vacuum casting abilities ensure a smooth path from design to functional part ready for evaluation or market launch.

Learn more about how design influences manufacturing efficiency with our design optimization in CAD guide.

Why Choose HYCNC for Vacuum Casting

When it comes to vacuum casting, HYCNC stands out for its proven expertise and strong track record. We hold key industry certifications that guarantee quality and reliability on every project. Our skilled team combines advanced CNC machining with vacuum casting to deliver precise, high-quality prototypes and small batch parts every time.

One of the biggest advantages of working with HYCNC is our fast turnaround. We understand tight deadlines and keep your project moving without sacrificing attention to detail. Plus, we offer cost-efficient solutions tailored to your production needs, making vacuum casting accessible without breaking the bank.

Ready to get started? Contact us today for a quote and experience why HYCNC is the trusted choice for vacuum casting services in the US. Let us help bring your designs to life with precision and speed.