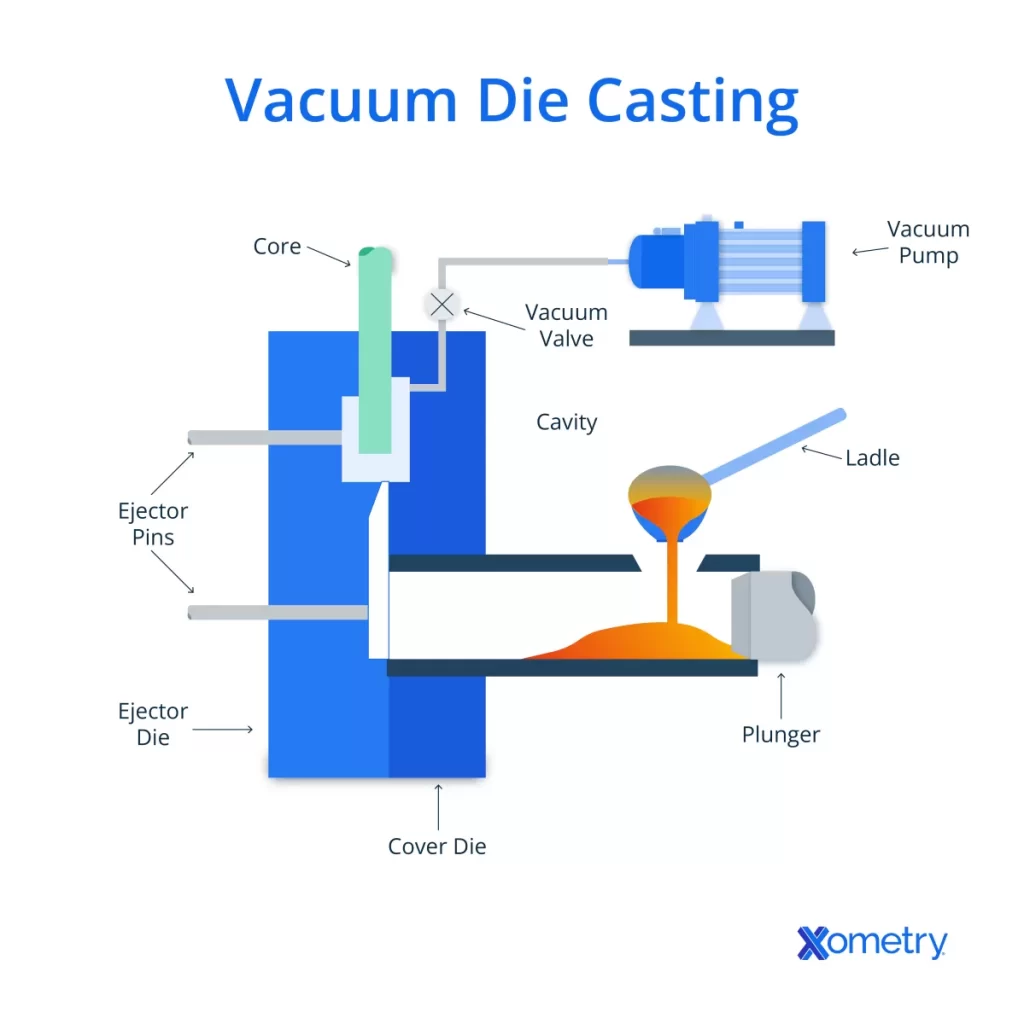

Understanding Vacuum Casting and Material Needs

Vacuum casting is a manufacturing process that uses silicone molds to produce high-quality urethane or polyurethane parts. This technique involves pouring liquid resin into a mold under a vacuum, removing air bubbles and ensuring precise detail and surface finish. It’s especially popular for prototyping and small-batch production because it offers quick turnaround times and cost-effective flexibility.

This process serves critical industries such as automotive, medical, consumer electronics, and aerospace, where part performance and accuracy are vital. Each application demands specific material properties—like high tensile strength for durability, flexibility for complex shapes, thermal stability to withstand heat, and attractive aesthetics for visual appeal.

Choosing the right vacuum casting material directly affects the mold’s lifespan, production costs, and the final part’s quality. Materials that are incompatible with the mold or application conditions can shorten mold life and increase expenses. Meanwhile, selecting a resin that matches your project’s mechanical and environmental needs ensures consistent production performance and superior parts.

Key Factors in Vacuum Casting Material Selection

When picking the right material for vacuum casting, a few important factors come into play. First, consider your application requirements. You want materials that can handle the environment they’ll be used in—like UV resistance for outdoor uses or biocompatibility for medical parts.

Next, look at the mechanical properties. Think about tensile strength, impact resistance, flexibility, and hardness depending on how the part will perform. For example, a durable automotive prototype needs different strength compared to a flexible consumer product.

Aesthetic and finish needs are also key. Your material should support the right surface quality, whether you want clear transparency or a surface that holds paint well.

Cost considerations cannot be ignored. It’s about finding the right balance between material cost, performance, and how many parts you plan to produce. Low-volume runs might allow for pricier options, while bigger batches need cost efficiency.

Don’t forget about regulatory compliance too. Certain projects require food-grade, flame-retardant, or medical-grade materials to meet safety standards.

Finally, match the material to your production volume and lead time. Some materials are better suited for fast prototyping, while others shine in small-batch production runs. Picking the right one helps keep your project on schedule and on budget.

Common Vacuum Casting Materials and Their Applications

Choosing the right vacuum casting material depends on your part’s needs. Here’s a quick look at popular options and where they shine:

-

ABS-like Resins

Known for high strength and dimensional stability, ABS-like resins are perfect for prototypes and consumer goods. They offer a solid balance of toughness and detail, making them a go-to choice for testing form and function.

-

PC-like Resins

These resins deliver excellent impact resistance and optical clarity. They’re commonly used in lenses, medical devices, and any parts that need transparency along with strength.

-

PP-like Resins

Flexible and tough, PP-like resins are ideal for snap-fit parts and packaging components. Their elasticity helps in applications requiring bending or repeated use.

-

PMMA Acrylic

If transparency and UV resistance matter, PMMA is your best bet. It’s widely used in lighting enclosures where clarity and durability under sunlight exposure are important.

-

Silicone Rubbers

Silicone offers unmatched flexibility and biocompatibility. This makes it popular in medical devices and food-grade applications where safety and softness are a priority.

-

Polyurethane Elastomers

When abrasion resistance is key, polyurethane elastomers are the material of choice. They serve well in industrial components, seals, and gaskets where wear and tear are frequent.

| Material | Key Properties | Typical Applications | Cost Level |

|---|---|---|---|

| ABS-like Resin | High strength, stable | Prototypes, consumer goods | Moderate |

| PC-like Resin | Impact resistant, clear | Lenses, medical devices | Higher |

| PP-like Resin | Flexible, tough | Snap-fits, packaging | Low to Moderate |

| PMMA Acrylic | Transparent, UV resistant | Lighting enclosures | Moderate |

| Silicone Rubber | Flexible, biocompatible | Medical, food-grade parts | Higher |

| Polyurethane Elastomer | Abrasion resistant | Industrial parts, gaskets | Moderate |

Selecting the right material impacts your part’s performance, look, and cost. For more on choosing materials suited for vacuum casting and rapid prototyping, check out our vacuum casting design guide.

How to Optimize Material Selection for Your Project

Choosing the right material for vacuum casting can make or break your project. Here’s how to get it right:

-

Work with HYCNC engineers on DFM analysis

Design for Manufacturability (DFM) helps spot potential issues early. Our experts review your design to ensure it fits vacuum casting processes and the material chosen.

-

Think about mold lifespan

Silicone molds usually last between 10 to 30 runs. Picking materials that don’t wear down the mold quickly saves money and keeps production smooth.

-

Evaluate environmental factors

Consider where your part will be used — temperature swings, chemical exposure, UV light — and choose materials that can handle those conditions without losing quality.

-

Balance cost and quality

For prototyping and small-batch runs, it’s tempting to pick the cheapest option, but don’t sacrifice key properties like strength or flexibility. We’ll help find a material that fits your budget and meets performance needs.

Using these steps ensures your vacuum casting parts are made with the best materials for your project’s demands while keeping production efficient and cost-effective.

Common Mistakes to Avoid in Material Selection

When picking vacuum casting materials, there are a few common missteps that can cause big issues down the line. Here’s what to watch out for:

-

Ignoring application-specific needs

Don’t just grab a material because it’s popular or cheap. Make sure it fits the part’s real-world use, like temperature exposure, flexibility, or strength.

-

Overlooking mold compatibility and curing times

Some materials don’t work well with certain silicone molds or need longer curing. This can ruin parts or shorten mold life if not planned.

-

Skipping regulatory and environmental checks

If your product needs to meet FDA, food-grade, or flame-retardant standards, double-check material certifications before choosing.

-

Putting cost ahead of performance on key parts

Saving money on materials might backfire, especially for parts under stress or safety-critical roles. Balance price with what the part requires.

Avoid these mistakes, and you’ll get better quality parts while saving time and money on your vacuum casting projects.

Why Choose HYCNC for Vacuum Casting Material Selection

At HYCNC, we bring deep expertise in CNC machining and vacuum casting to deliver precise, high-quality parts every time. Our team understands how critical the right material is for your project’s success, which is why we provide thorough material selection support tailored to your specific needs.

We don’t just make parts; we help you choose the best vacuum casting resins by analyzing your design through Design for Manufacturability (DFM). This ensures your parts meet performance and durability goals without breaking your budget.

Plus, our fast turnaround times mean you get prototypes and small batches quickly, keeping your project on schedule. For example, we recently helped a client select an ABS-like resin for a durable automotive prototype, balancing strength and cost efficiently.

When you work with HYCNC, you get more than just parts — you get a partner focused on smart material choices and quality that matches your U.S. market demands.