What is Vacuum Casting Definition and Process Overview Why It’s Ideal for Medical Devices

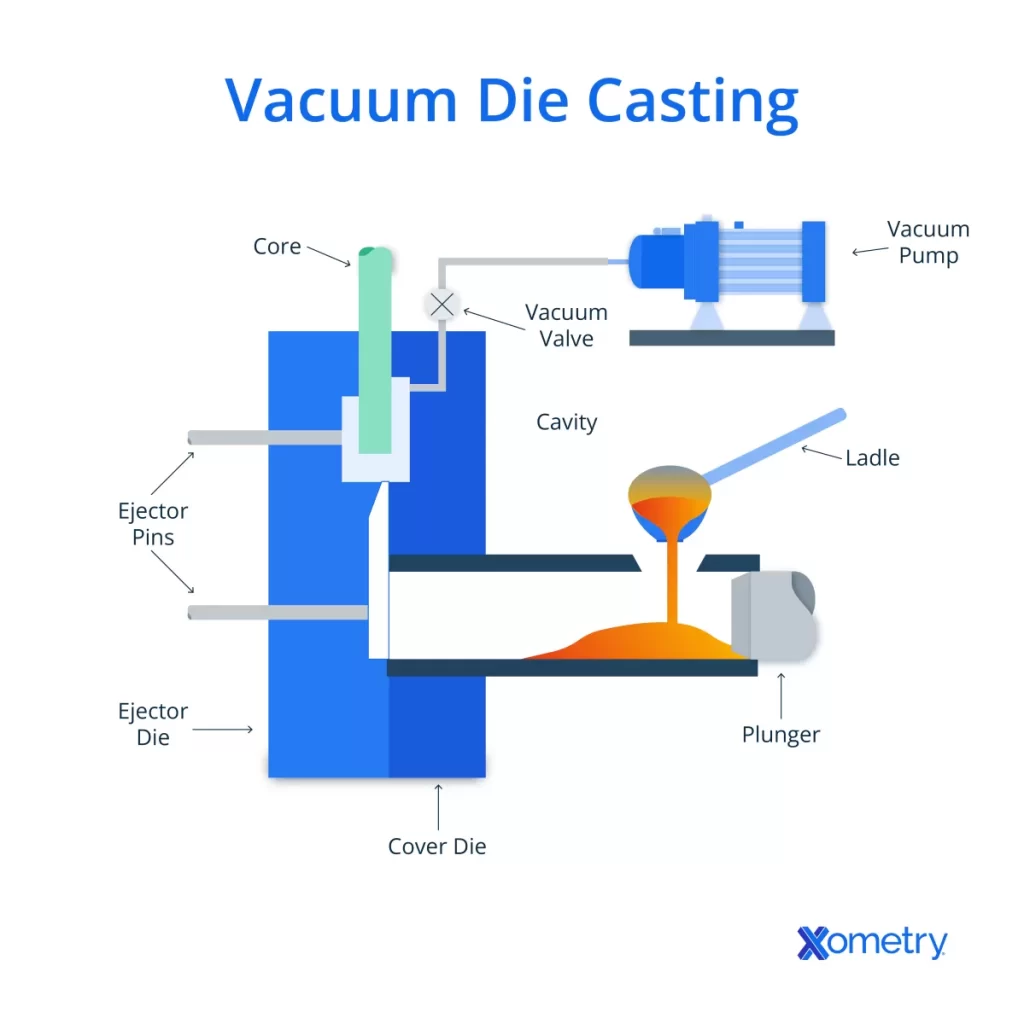

Vacuum casting is a manufacturing process that produces high-quality plastic parts by pouring liquid resin into a silicone mold under a vacuum. This technique removes air bubbles and ensures the resin fills all mold details, resulting in precise, defect-free components.

Here’s how it works:

- A master model, often made with CNC machining, is used to create a flexible silicone mold.

- Liquid resin, commonly polyurethane or biocompatible resins, is mixed and poured into the mold inside a vacuum chamber.

- The vacuum eliminates trapped air and improves resin flow.

- Once cured, the molded part is removed and finished as needed.

Vacuum casting stands out in medical device manufacturing because it delivers high precision and smooth surface finish essential for medical-grade components. It supports biocompatible materials that comply with strict health standards. This process is especially useful for medical device prototyping, rapid prototyping medical devices, and low-volume medical device production.

In , vacuum casting combines accuracy, flexibility, and material options to meet the demanding requirements of the medical industry, making it a go-to method for creating precision medical components reliably and efficiently. For a deeper dive into vacuum casting, you can explore our detailed guide on What is Vacuum Casting.

Benefits of Vacuum Casting for Medical Device Manufacturing

Vacuum casting offers several advantages that make it a top choice for medical device manufacturing, especially in the U.S. market where quality and speed matter.

Cost Effectiveness

Vacuum casting is budget-friendly for low-volume medical device production. Unlike large-scale methods like injection molding, it requires less upfront investment, which means lower tooling costs. This helps startups and mid-sized companies develop precise prototypes or small batch runs without breaking the bank.

High Precision and Quality

This process delivers highly detailed and accurate parts, crucial for precision medical components. The vacuum environment minimizes air bubbles and defects, producing smooth surfaces and tight tolerances. This level of quality is essential for devices that must meet strict regulatory standards and ensure patient safety.

Material Versatility

Vacuum casting supports a wide range of materials, including biocompatible resins like polyurethane and silicone. This versatility allows manufacturers to mimic the look and feel of final parts, making it ideal for functional prototypes, prosthetics, and other medical applications.

Speed and Efficiency

Compared to traditional manufacturing, vacuum casting is fast. Molds can be made quickly from master models, often produced through CNC machining, speeding up the prototyping phase and reducing the time to market. This rapid turnaround is a big plus for medical device companies navigating tight development schedules.

Design Flexibility

Vacuum casting works well for complex geometries and detailed designs. It supports custom, precise iterations without the limitations of mass production. This flexibility lets designers tweak and optimize devices early on, ensuring better performance and compliance down the line.

These benefits make vacuum casting a practical and reliable choice for medical device prototyping and low-volume production, meeting both quality demands and budget realities. For more detailed insights on vacuum casting, check out our vacuum casting design guide.

Applications of Vacuum Casting in Medical Devices

Vacuum casting plays a key role in medical device prototyping, especially when getting regulatory approval. It allows manufacturers to produce accurate prototypes quickly, helping to test design, function, and safety before full-scale production. This speeds up the approval process while reducing costs.

Some common medical devices made using vacuum casting include:

- Prosthetics and orthotic components

- Surgical instruments and handles

- Diagnostic device parts

- Custom-fit wearable devices

Vacuum casting also works great for small batch production. When you don’t need thousands of units, this method delivers high-quality parts with consistent precision—without the high tooling costs tied to injection molding. That makes it ideal for limited runs, special projects, or when trying out new designs with minimal risk.

By using materials like biocompatible resins through silicone mold casting, medical manufacturers ensure their parts meet strict health and safety standards, which is crucial for any device coming into contact with patients.

Why Choose Vacuum Casting Over Other Methods

When it comes to medical device manufacturing, vacuum casting stands out compared to injection molding, 3D printing, and CNC machining. Here’s why:

Comparison with Injection Molding

- Lower tooling costs: Vacuum casting uses silicone mold casting, which is far cheaper to set up than the steel molds required in injection molding.

- Better for low-volume runs: Injection molding is great for mass production, but vacuum casting shines when you need small batch production or prototypes.

- Faster turnaround: The mold preparation for vacuum casting takes less time, speeding up your project without the heavy upfront investment.

Comparison with 3D Printing

- Superior surface finish: Vacuum casting produces parts with smoother surfaces and fewer post-processing steps than many 3D printed parts.

- Material options: You can use biocompatible resins and flexible polyurethane casting materials not always available in 3D printing.

- Stronger final parts: Vacuum cast parts often have better mechanical properties, making them ideal for precision medical components.

Comparison with CNC Machining

- Cost efficiency: Machining each part from a solid block can get expensive, especially for complex shapes or multiple pieces. Vacuum casting offers a more affordable way to replicate parts repeatedly.

- More design flexibility: Vacuum molding is less limited by geometry; intricate designs and undercuts work better with silicone molds than milling.

- Speed for prototypes and small runs: CNC machining is slower when you need many copies. Vacuum casting produces consistent results quickly without sacrificing detail.

Overall, vacuum casting hits a sweet spot for rapid prototyping medical devices, low-volume medical device production, and creating precision medical components—all with cost-effective, high-quality results.

How HYCNC Enhances Vacuum Casting for Medical Devices

When it comes to vacuum casting for medical devices, HYCNC brings real value with their deep expertise and tailored approach.

Expertise in CNC-Driven Master Models

HYCNC specializes in CNC machining to create precise master molds. These master models set the foundation for high-quality silicone mold casting, ensuring every part meets strict medical standards. Their CNC service guarantees tight tolerances needed for complex medical device prototyping and precision medical components.

Quality Assurance

Medical device manufacturing demands consistent quality. HYCNC follows rigorous quality assurance processes throughout their vacuum molding and casting steps. This means you get biocompatible resins cast with accuracy, meeting regulatory and safety requirements every time.

Customized Solutions

Every medical device project is unique. HYCNC offers customized vacuum casting solutions tailored to your specific needs—whether you’re working on rapid prototyping medical devices, low-volume medical device production, or parts requiring special materials like polyurethane casting. They adapt to your design and material needs for the best outcome.

End to End Service

From CNC machining your master molds to vacuum casting the final prototypes or small batches, HYCNC handles the full process. This comprehensive service reduces delays, cuts costs, and simplifies project management for medical device manufacturers looking for reliable, local support.

By combining advanced CNC machining with expert vacuum casting, HYCNC helps U.S. medical device makers build accurate, high-quality components faster and more efficiently.

Local Search Habits and Considerations

When looking for vacuum casting services for medical devices, U.S. manufacturers often focus on local providers. Choosing nearby companies can reduce shipping times, lower costs, and make communication smoother—important when working on precision medical components.

Here are some key points about local search habits and what matters for medical device makers:

Targeting Regional Manufacturers

- Local suppliers understand U.S. industry standards and regulations better.

- They can offer faster turnaround times for prototypes and small batch production.

- Being nearby means easier onsite visits to review CNC machining for master molds or vacuum mold setups.

Addressing Industry Pain Points

- Medical device manufacturing needs strict quality control and material traceability.

- Quick adjustments and customized solutions often come up during prototyping.

- Local casting services that prioritize communication help resolve issues faster.

Mobile Friendly and Technical Content

- Medical engineers and buyers frequently search on mobile devices while on the go.

- Clear, accessible websites with detailed technical content help them make decisions quickly.

- Providing easy-to-understand info about vacuum casting, polyurethane casting, and biocompatible resins improves buyer confidence.

Focusing on these local and practical needs helps manufacturers in the U.S. find the right vacuum casting partner for medical devices.

FAQs

What is vacuum casting for medical devices?

Vacuum casting is a process where liquid materials like polyurethane are poured into silicone molds a vacuum. This removes air bubbles, producing high-quality, precise medical parts quickly and cost-effectively.

Why is vacuum casting ideal for medical device prototyping?

It offers fast turnaround, excellent detail, and uses biocompatible resins suitable for testing and regulatory approval. Plus, it’s great for low-volume medical device production without the high cost of injection molding.

Can vacuum casting make complex or flexible parts?

Yes, silicone mold casting combined with vacuum casting can create intricate designs, soft-touch components, and even prosthetics with high precision.

How does vacuum casting compare to other methods like 3D printing or CNC machining?

Injection molding is great for large runs but expensive upfront. Vacuum casting is best for low-volume batches.

3D printing is fast for concept models but may lack the surface finish or material properties vacuum casting offers.

CNC machining is precise but slower and costly for complex shapes or small runs.

What materials can be used in vacuum casting for medical devices?

Materials include polyurethane and other biocompatible resins, ideal for precision medical components and different mechanical requirements.

Is vacuum casting suitable for regulatory submissions?

Yes, vacuum casting lets you create accurate prototypes that pass testing and regulatory standards needed for medical device approval.

How does HYCNC support vacuum casting in the U.S. market?

HYCNC provides expert CNC machining of master molds, quality control, and tailored solutions with fast local service, making vacuum casting straightforward for U.S. medical device manufacturers.