What Is Controlled Rust in Manufacturing

Controlled rust refers to the intentional management of oxidation on metal surfaces during manufacturing. Instead of letting rust develop uncontrollably and cause damage, controlled rust is about either preventing harmful corrosion or applying specific oxidation to create a desired effect. This can mean slowing down rust formation to protect the part or encouraging a controlled layer of rust for aesthetic or functional reasons.

The key difference between uncontrolled rust corrosion and controlled rust is that uncontrolled rust happens unexpectedly and damages the metal, weakening its structure. Controlled rust processes, on the other hand, involve deliberate techniques to manage oxidation in a way that either preserves the integrity of the part or enhances its appearance.

In CNC machining, controlled rust plays a significant role. It helps protect machined components from corrosion, extends their life, and can also create attractive finishes like patinas that industrial or decorative projects require. This makes controlled rust a valuable tool for manufacturers wanting both durability and style.

Metals commonly involved include steel, iron, and their alloys—materials that naturally oxidize but can benefit from expert rust management. Understanding how to handle rust in these metals is essential for ensuring top-quality CNC machined parts.

Techniques for Controlling Rust in CNC Machining

Controlling rust in CNC machining involves several key techniques to keep metal parts protected and looking great.

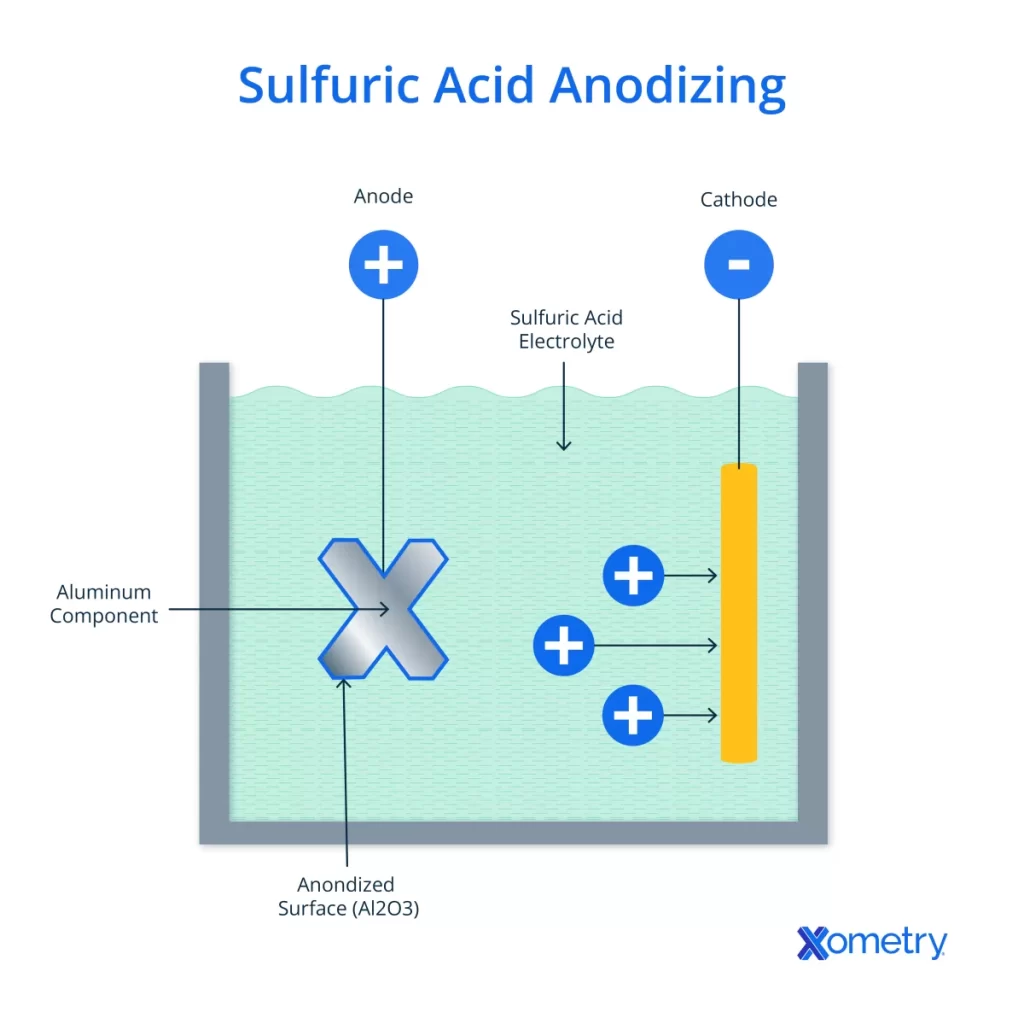

Passivation is one common method. It creates a thin, protective oxide layer on metals like stainless steel, which helps slow down corrosion and rust formation.

Coatings and sealants play a big role too. Applying anti-corrosion coatings such as zinc or epoxy shields the metal from moisture and air, cutting down the chance of rust. These CNC rust-resistant coatings are essential for parts that face tough conditions.

Patina finishing uses controlled oxidation to give metal a unique, often aged look. This technique is popular when you want an aesthetic rust finish rather than simply avoiding rust altogether.

Precision cleaning is critical. Before and after machining, removing dirt, oils, and other contaminants reduces areas where rust can start.

Environmental control helps by managing humidity levels and exposure during the machining process and storage. Keeping metals dry and in a stable environment makes rust less likely.

Finally, the precision of CNC machining itself supports consistent rust control. Accurate, repeatable processes ensure coatings and treatments apply evenly, providing reliable protection every time.

Benefits of Controlled Rust Processes

Controlled rust processes offer several clear advantages in manufacturing. First, they enhance the durability and longevity of machined parts by preventing uncontrolled corrosion that can weaken metal over time. This means parts last longer and perform better, especially in demanding environments.

Next, controlled rust improves the aesthetic appeal of metal components. Whether for decorative architectural pieces or industrial applications, a carefully managed patina or finish can add value and distinctiveness to the product.

Cost savings are another big benefit. By reducing material waste and cutting down on costly rework due to rust damage, manufacturers save money and increase efficiency. Preventing uncontrolled rust right from the start means fewer rejected parts and less downtime.

Compliance with industry standards like ISO and ASTM is easier with controlled rust methods. These standards often require strict corrosion control, and using proven rust management techniques helps meet those guidelines quickly and reliably.

Finally, there are environmental benefits. Controlled rust processes reduce the need for harsh chemicals and excessive waste, promoting more sustainable rust management. This not only helps manufacturers meet environmental regulations but also supports greener production practices overall.

To learn more about rust prevention in CNC machining, check out this guide on rust prevention.

Applications of Controlled Rust in CNC Machining

Controlled rust plays a crucial role in several industries, helping to protect and enhance metal parts while meeting specific functional or aesthetic needs.

-

Automotive Industry

Rust-resistant components are essential for vehicles exposed to moisture, road salts, and varying weather. Controlled rust methods improve durability and reduce corrosion on steel and iron parts, extending vehicle life.

-

Aerospace

In aerospace, parts must withstand extreme environments without failing. Controlled rust processes protect critical components, ensuring safety and performance under harsh conditions while maintaining precision.

-

Architectural and Decorative Uses

Controlled oxidation is popular for patina finishes on metal structures. This gives buildings and decorative pieces a unique, aged look while keeping the metal protected from further uncontrolled corrosion.

-

Industrial Equipment

Machinery in factories faces constant exposure to wear and moisture. Controlled rust techniques help create corrosion-resistant surfaces on equipment, reducing downtime and maintenance costs.

HYCNC Case Study

At HYCNC, we successfully applied controlled rust solutions for a client needing both protection and a distinct aesthetic on steel parts. Using precise CNC machining combined with patina finishing, we delivered components that met their durability requirements and design vision. This project highlights how tailored rust control methods can provide real value, balancing function and style.

For more on rust prevention in CNC machining, check out our detailed guide on preventing rust.

How HYCNC Excels in Controlled Rust Solutions

At HYCNC, we bring top-tier CNC machining capabilities tailored to meet the exact needs of our clients. Our state-of-the-art equipment lets us achieve high precision on every metal part, which is key when managing controlled rust or applying protective finishes.

We use advanced rust control technologies like passivation, specialized coatings, and patina finishing techniques to deliver both protective and aesthetic results. Whether you need durable rust-resistant parts or a unique aged metal look, we customize our approach to match your project requirements.

Choosing HYCNC means working with a team focused on quality and consistency. Our expertise ensures tight tolerances and reliable rust management that meets industry standards. With us, you get precision, trustworthiness, and finishing options that enhance both the performance and appearance of your metal components.

Best Practices for Manufacturers

Choosing the right controlled rust method starts with understanding your project’s goals. Whether you need rust prevention in CNC machining for durability or controlled oxidation for a specific look, pick a technique that fits your metal type and end-use.

Partnering with a trusted CNC provider like HYCNC makes a big difference. We customize rust-resistant coatings, patina finishes, and other corrosion control measures to match your exact needs. Our precision machining ensures consistent, reliable results every time.

Don’t overlook regular maintenance and inspection. Even with top rust management in industrial manufacturing, checking parts periodically helps catch problems early, extending the life of your components.

Finally, keep up with the latest rust control innovations in manufacturing. New coatings, environmental controls, and surface treatments come out regularly, helping you stay ahead in quality and cost efficiency. Working with HYCNC means you have a partner who’s on top of these trends and ready to apply them to your projects.